New Projects

advertisement

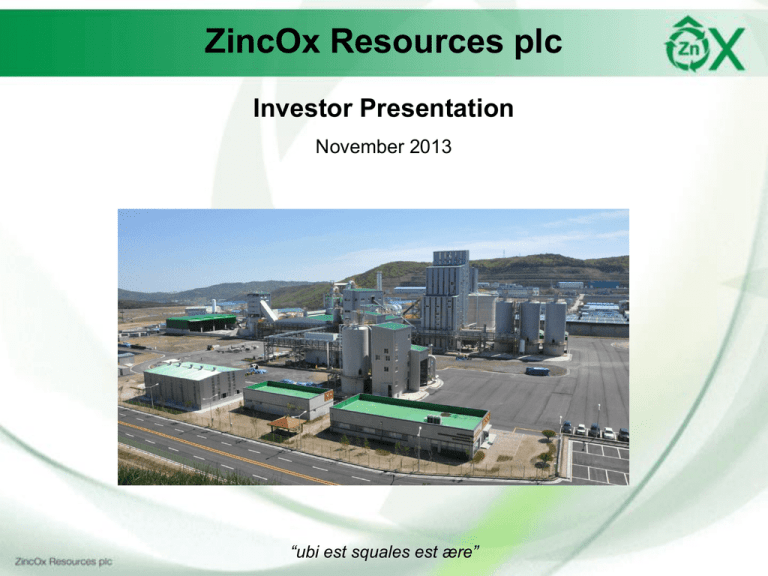

ZincOx Resources plc Investor Presentation November 2013 “ubi est squales est ære” Disclaimer This document is for informational purposes only and must not be used or relied upon for the purposes of making any investment decision or engaging in any investment activity. No reliance may be placed for any purpose whatsoever on the information contained in this Presentation, nor on assumptions made as to its completeness. No representation or warranty, express or implied, is given by ZincOx Resources plc or any of its advisers, directors, officers, employees or agents, as to the accuracy, fairness or completeness of the information or opinions contained in this Presentation and no liability is accepted for any such information or opinions (which should not be relied upon) or for any loss howsoever arising, directly or indirectly, from any use of this document or its contents or information expressed in the Presentation. The information contained in this Presentation is subject to amendment, revision and updating in any way without any notice or liability to any party. Certain statements in this document relate to the future, including forward looking statements including but not limited to those with respect to the financial position and strategy of the Company, the price of zinc, the estimation of mineral resources and reserves, the realisation of mineral reserve estimates, the timing and amount of estimated future production, costs of production, capital expenditures, costs and timing of development of new deposits, success of exploration activities, permitting time lines, currency fluctuations, requirements for additional capital, government regulation of mining operations, environmental risks, unanticipated reclamation expenses, title disputes or claims and limitations on insurance coverage and the timing and possible outcome of pending litigation. These forward looking statements involve known and unknown risks, uncertainties, assumptions and other important factors that could cause the actual results, performance or achievements to be materially different from future results, performance or achievements expressed or implied by such statements. Such risks, uncertainties, assumptions and other important factors include, among other things, general economic conditions, exchange rates, interest rates, the regulatory environment, structural changes in the industries in which the Company operates, competitive pressures, selling price and market demand. The forward looking statements in this document reflect views held only as of the date of this document and the Company expressly disclaims any intention or obligation to update or revise any forward looking statements, whether as a result of new information, future events or otherwise, except in accordance with applicable securities laws. Contents Part 1 General Risk Factors Corporate Overview Part 2 Korean Recycling Plant Ramp-Up Revised Economics Part 3 Growth New projects Added Value Part 4 Fund raising Appendices: Zinc price, stock, share price 3 Risk Factors Financial Fall in zinc price Adverse exchange rate movement Korean Recycling Plant Delay in reaching full capacity Equipment failure and cost of replacement Ramp-up may create further complications including known issues and unforeseen ones Inability to realize value of iron product Future Projects Inability to enter into EAFD supply contracts Development of a more economically attractive technology by competitors 4 Introduction • British zinc recycling company • Taking hazardous waste generated by the recycling of steel scrap • Operating zinc recycling plant – South Korea • Cleaner more efficient technology • Producing zinc concentrate and intermediate iron product • Global roll out potential • Slower than expected production ramp-up to full production • Major problems resolved • Ongoing improvements to ramp-up to full production • Production at 65% of full production and rising • Placing of new shares to take company through to sustained cashflow • International Finance Corporation intend to support the placing 5 Vision The technology employed by ZincOx transforms a global hazardous waste problem into a global zinc resource opportunity The key technology is the Rotary Hearth Furnace (RHF) The RHF creates intermediate zinc and iron products and No Waste Considerable additional value would be created by further processing of the intermediate products into industrial raw materials 6 Corporate Overview Experienced team of metallurgists and resources professionals - Andrew Woollett: Executive Chairman (57) Geologist: MSc, ex: Rio Tinto, Cluff Resources. Founder of Reunion Mining plc which designed the Skorpion Mine/smelter taken over by Anglo American. Founded ZincOx in 1999. - Simon Hall: Finance Director (44) Accountant: BSc Eng., ACA. Initially worked with Hanson plc in UK, India and China, before joining British Telecom where he worked in property, BT Openworld, the corporate division and BT Mobile He joined ZincOx in 2006. - Jacques Dewalens: Technical and Production Director (66) Metallurgical engineer: PhD in Sciences. Until joining ZincOx in 2008, he worked for in the zinc industry for Union Miniere in several roles, including General Manager of the Balen smelter and Metallurgical Process Director for Umicore Engineering. ZincOx was originally set up to repeat the success of Skorpion To develop unconventional (“oxide”) zinc resources Mining sold off, entirely focused on recycling AIM quoted, 103 million shares in issue Debt: Corporate - US$6.3 million, KRP – US$52.7 million Head Office in UK, Technical Office in Belgium, Main operation in South Korea 82 employees 7 Background A thin layer of zinc is used to protect (galvanise) steel from corrosion At the end of its life, a steel object is commonly scrapped and recycled 1/3 of steel is produced by recycling in Electric Arc Furnaces (EAF) EAF generates a waste dust, EAFD, which contains the zinc (20%-30%) ZincOx modified the Rotary Hearth Furnace to recover the zinc and an iron rich by-product - so no waste The first plant is the Korean Recycling Plant, KRP First production April 2012 Other potential projects in: Turkey Thailand Russia (51% JV) SEE FILM 8 Korean Recycling Project Development Cost: US$ 134 million (Equity: US$60mil., Inter-company loan; US$21mil., Debt: US$53mil.) Experienced Korean management team Technical support from Belgian office Workforce: 61 Supply contracts: 9 years Sales contracts: Exclusive offtake agreement with Korea Zinc, 9 years Full Capacity tonnes per annum EAFD, tonnes pa 200,000 Zinc in concentrate 48,000 Iron product (ZHBI) 100,000 9 KRP Full Production, Actual and Forecast 10 KRP Production, Actual and Forecast Oct. 2013, 2,963t zinc contained 11 Key Indicators: 1. Availability (running time) 12 Key Indicators: 2. Recovery 13 Key Indicators: 3 Feed Rate 14 Products ZINC CONCENTRATE Approximately 90% of expected total revenue Higher grade than envisaged, >64% zinc (expected 59%) All sold to Korea Zinc 85% paid within 30 days, balance after 40 days Sales price based on LME price in line with standard industry practice IRON PRODUCT Presently lower quality than expected when at full production due to: - less iron in feed, - lower metallisation, more oxide - less removal of volatile elements Quality will improve with full fuming efficiency Investigating overseas and local markets Potential to install melter pig iron and slag for cement industry 15 KRP: Cash Generation At Full Production Assumes availability, recovery and feed rate at target levels 80 70 50 40 30 20 10 3000 2900 2800 2700 2600 2500 2400 2300 2200 2100 2000 1900 1800 1700 1600 0 1500 US$ Million 60 Zinc Price (US$/tonne) Base EBITDA EBITDA (inc ZHBI @ $30/t) KZ Debt Service 16 New Projects – KRP Expansion (KRP2) KRP site laid out to accommodate doubling of capacity Currently, insufficient EAFD generated to fill expanded plant Potential to import EAFD EAFD grade for expansion lower than for existing operation 17 New Projects - Thailand ASEAN regional facility, 200,000 tpa Site near Rayong under negotiation Thai mills generate up to 90,000tpa (zinc grade approx. 27%) Mostly within 80km of site Rayong City Other ASEAN 290,000 tpa Close to port Site well suited to: Melting Zinc concentrate upgrading Proposed site for ZincOx plant 18 New Projects - Turkey Over 350,000 tpa EAFD generated in Turkey Approx. 5 hectare site in the Aliaga Heavy Industrial Zone Within 3 km of over 120,000tpa EAFD Potential for: 200,000 tpa plant 46,000 tpa of zinc in concentrate PLANT SITE 19 New Projects - Russia Joint venture, 51% ZincOx, 49% Ural Recycling LLC (Magnezit subsidiary) Magnezit Group Major magnesite mine, at Satka (since 1901) Largest refractory producer in Russia 1.5 million tonnes per annum 76% to steel industry, of which 24% to Electric Arc Furnaces Joint Venture Magnezit approached ZincOx to form JV Visited KRP in May 2012, CEO plus senior management team Work Programme 2012/14 Project Definition 2014 Feasibility 2015 Construction 2016 Production 20 Value Added Products ZINC CONCENTRATE UPGRADING Exceptional quality Simple washing up-grades to 95% zinc oxide Second proprietary step up-grades to industrial quality (>99% zinc oxide) Not an option for KRP due to long term offtake agreements Industrial quality zinc oxide is an end market of over 1,000,000 tpa Most industrial quality zinc oxide sells at a premium to the zinc it contains ZHBI MELTING KRP originally conceived with ZHBI melter to realize full value Preferred method is Submerged Arc Furnace Testwork and feasibility planned for next year Pig Iron: Scrap substitute for foundries and EAFs Slag: Raw material for the manufacture of cement Potential to double gross revenues 21 International Finance Corporation Private sector arm of the World Bank Mandate to invest in less developed countries Can provide up to 25% of development finance (debt and direct equity) Concerned with: Technology Environmental Corporate governance Global roll-out Discussions with ZincOx over past 18 months Due diligence; financial, technical, governance and environmental Interested in ZincOx’s new projects in Turkey, Thailand and Russia 22 Use of Proceeds Korean Recycling Plant Capital items US$1 mil. New Projects New plant basic engineering (including improvements) Environmental studies Melter testwork and feasibility study US$3 mil. - US$5 mil. Corporate Working Capital US$3 mil. ================= Total US$7.1 mil. – US$9 mil. 23 Structure and Timetable STRUCTURE Placing (inc.IFC subscription) Open Offer to Shareholders US$7.1 mil. up to US$1.9 mil. TIMINGS Placing Roadshow October 29th – November 8th Announcement November 12th Open Offer November 12th to November 22nd General Meeting November 29th Share Admission December 2nd 24 Appendix 1 Zinc: Price and Stocks 5000 4500 LME Zinc stocks - tonnes (right axis) 1400 1200 4000 3500 3000 Thousands LME Zinc price - USD/tonne (left axis) 1000 800 2500 2000 1500 600 400 1000 500 0 200 0 25 Appendix 2. Zinc Price Predictions Lowest Consensus Highest 3000 2500 2250 2000 1750 Source: Metal Bulletin 16Q4 16Q3 16Q2 16Q1 15Q4 15Q3 15Q2 15Q1 14Q4 14Q3 14Q2 14Q1 13Q4 1500 13Q3 Forecast price (USD/tonne) 2750 26