Manufacturing Excellence - Ghatge Patil Industries (GPI)

advertisement

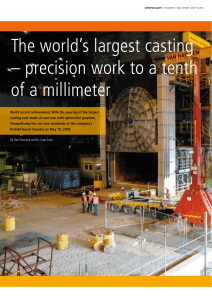

About Us Ghatge Patil Industries Ltd is established in 1960, and is located at Kolhapur, 400 Kilometers South of Mumbai on Mumbai Bangalore National Highway. Nearest international airport is Pune (235 Kilometers), nearest Sea Port is Mumbai. Kolhapur airport will be operational from Dec 12, 2012 and will be connected to MUMBAI Air-Ports 0 Geographical Layout •Total area – 10 hectares. •Covered space – 4.2 hectares Financials Turnover for F.Y. 2011 – 2012 – US$ 87 Million Profit centers Foundry Division Product Division Manufacturing -Foundry • High Pressure Moulding Line from Kunkel Wagner • Box size 1150 X 750 X 400/350 mm • State of the art Sand PLANT 100 TONS PER HOUR • Medium Frequency Induction Furnaces •Auto Press Pour Unit - 4 Tons capacity 4 Manufacturing -Foundry • Nodular Iron with George fisher Converter • Cold box Core Shooters from 6 -100 Liters capacity (14 Nos) • BMD Shot Blasting Machine • State of the art Foundry Engineering supported with the latest 3D Modeling software's (Ideas 12, Pro-E, Wild Fire 5 and Uni Graphics NX5 for Manufacturing) 5 Quality Certification TS Q&A • Spectrometer BELEC 25 Elements Bosh & Lomb 15 Elements • Sand multi controller • 3D Scanner CREAFORM for dimensional measurements • Carl Zeiss Microscope interfaced with Computer • Universal Testing Machine • Hardness Testing Machines 7 Manufacturing Excellence Horizontal Machining Centers (Okuma ) Dedicated for Machining of Castings Grey Iron Castings • Flywheel Housing • Case Transmission • Clutch Housing • Crank Case • 1 /2/3/4 /6 Cylinder Blocks • Differential Housing • Gear Box Housing • Engine Bed Frame • Rear Axle Housing • Brake Drums 9 Nodular Iron Castings • • • • • • Front Axle Support Crank Shaft Hubs Bogie Anchorage King Post Housings ( Safety critical item) 10 Machined Castings CARRARO HOUSING LOMBARDINI BLOCK DANFOSS GEAR BOX JOHN DEERE DIFFERENTIAL Customers World wide CLAAS - FRANCE CAMERON- ROMANIA ARROW ENGINES IVECO, MONTANARI, TRANSFUILD - ITALY CAMERON KNORR BREMSE, DANFOSS - GERMANY EATON KNORR BREMSE JOHN DEERE PNE YANMAR - JAPAN OMNI VALVES, USA TARTAN CANADA •BEML •CARARO •EATON •HMT •JCB •JOHN DEERE •LOMBARDINI •MAN •MHI-VST •OIL INDIA •ONGC INDIA •TATA MOTORS •VST EWM COMMERCIAL, SAUDI ARABIA ARAB PUMP - JORDAN POWER TORQUE – SOUTH AFRICA •CAMERON - SINGAPOREe CENTRAL DIESEL, PT CONDUCTORS – INDONESIA JIS ,Malaysia DRIVETRAIN, AUSTRALIA NEW FOUNDRY • High Pressure Molding Line from SAVELLI s.p.a. 6000 tons per month. • Moulding lines F1 with 120 complete moulds/hr • Mould compaction systems: Formimpress® • Transport system with El-Mec (electro-mechanical devices) • Automatic pattern change stations • Automatic core-setting devices • Auto Pouring systems • Cooling lines in steel jackets NEW -Foundry • Nodular Iron with George fisher Converter – 2MT Capacity • Cold box Core Shooters From 6-100 Liters capacity Total 28 M/C s • Shot Blasting Machine- 4 Nos. • MOUS Fettling M/c – 4 Nos. • Foundry Engineering supported by CAD / CAM Geographical Layout •Total area – 13 hectares. NEW FOUNDRY Q & A • Spectrometer 25 Elements • Inbuilt Sand multi controller • Microscope interfaced with Computer • Universal Testing Machine • Hardness Testing Machines New–Machine shop • Okuma HMC 600H- 40 Nos. • VMC - 04 Nos. Product Division Product Division Valves Power Transmissions OEM Products Automotive Power Take Offs Marine Transmissions Up stream Pipe Line Products . API 6A and 6D Gate Valves Body Forged / Cast Range 1 13/16” to 7 1/16” Pressure rating 2 K to 15 KA complete range from 2” 150 class to 30” 900 class. Parallel Expanding Gate Design Double Block and Bleed Design Hand wheel/Pneumatic Actuation 19 Down Stream Pipe Line Products API 6D Swing Check Valves • Product range 2” 150 Class to 24” 600 Class • Rugged Design • Easy to operate • Provision for Anti Slamming device • Replacable Seats Manufacturing Excellence • Horizontal Machining Centers Okuma ( # 14) • Horizontal Machining Centers Churchill ( # 2 ) • CNC Turning Centres Hitachi Seiki, Churchill, Okuma, WNCL, Beko ( # 6 ) • Vertical Machining Centers, Cooper, Kitamura ( # 6) 21 Manufacturing Excellence Jig Boring Machine SIP 600 ( #1 ) 9 C –30 Turning Centre ( # 3) Turning Centre HMT L 50 ( # 1) General Purpose Machines Turning,Milling,Grinding,Broaching, Gear Profile Generation & Grinding ( # 100 ) In House Heat Treatment shop 22 Q&A • Standards Room • Three Coordinate Measuring Machines( # 3) • Surface Roughness checking Machine • Charpy Impact testing • NDT Testing Q&A • Tensile Testing Machine • Profile Projector • Magnetic Particle Inspection • Ultrasonic Testing (UT) • Hydraulic Testing Rig interfaced with Computer • Gear Testing Quality Certifications API API 6A API 6D Quality Certifications GHATGE PATIL INDUSTRIES LTD Thank You

![5th IFCE Event Report by PFA - Pakistan Foundry Association [PFA]](http://s2.studylib.net/store/data/009963074_1-d84aef6a3e937cf87d85ef1c3cc12137-300x300.png)