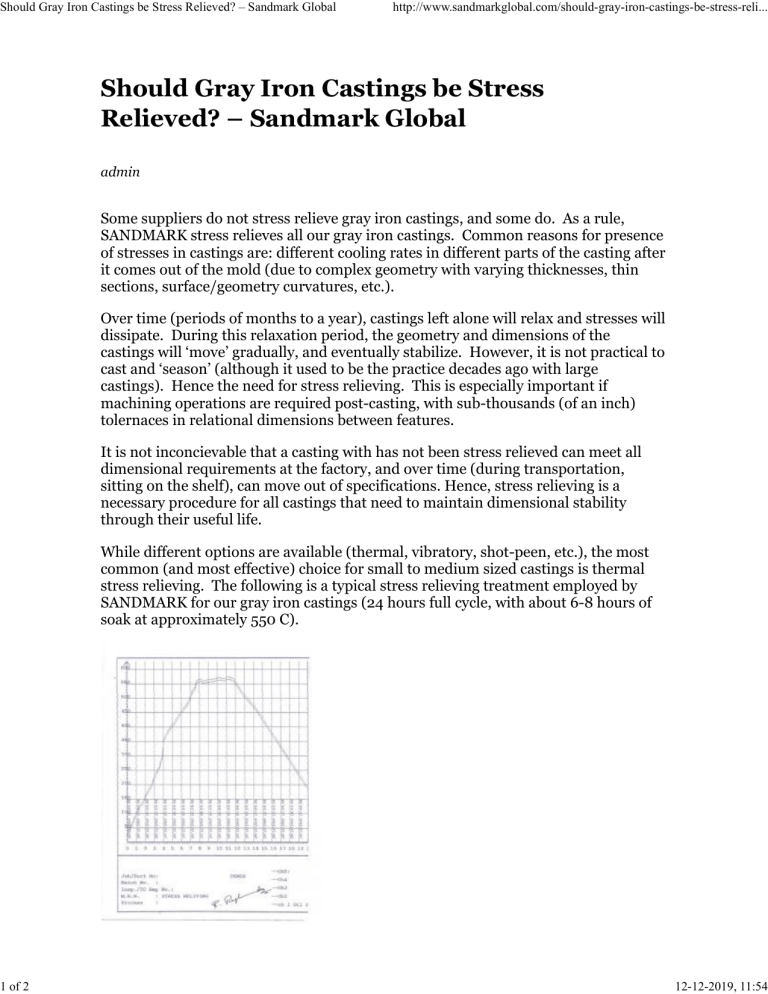

Should Gray Iron Castings be Stress Relieved? – Sandmark Global 1 of 2 http://www.sandmarkglobal.com/should-gray-iron-castings-be-stress-reli... Should Gray Iron Castings be Stress Relieved? – Sandmark Global admin Some suppliers do not stress relieve gray iron castings, and some do. As a rule, SANDMARK stress relieves all our gray iron castings. Common reasons for presence of stresses in castings are: different cooling rates in different parts of the casting after it comes out of the mold (due to complex geometry with varying thicknesses, thin sections, surface/geometry curvatures, etc.). Over time (periods of months to a year), castings left alone will relax and stresses will dissipate. During this relaxation period, the geometry and dimensions of the castings will ‘move’ gradually, and eventually stabilize. However, it is not practical to cast and ‘season’ (although it used to be the practice decades ago with large castings). Hence the need for stress relieving. This is especially important if machining operations are required post-casting, with sub-thousands (of an inch) tolernaces in relational dimensions between features. It is not inconcievable that a casting with has not been stress relieved can meet all dimensional requirements at the factory, and over time (during transportation, sitting on the shelf), can move out of specifications. Hence, stress relieving is a necessary procedure for all castings that need to maintain dimensional stability through their useful life. While different options are available (thermal, vibratory, shot-peen, etc.), the most common (and most effective) choice for small to medium sized castings is thermal stress relieving. The following is a typical stress relieving treatment employed by SANDMARK for our gray iron castings (24 hours full cycle, with about 6-8 hours of soak at approximately 550 C). 12-12-2019, 11:54 Should Gray Iron Castings be Stress Relieved? – Sandmark Global 2 of 2 http://www.sandmarkglobal.com/should-gray-iron-castings-be-stress-reli... Typical Profile for Stress Relieving Certain Gray Iron Castings at SANDMARK When to stress relieve: Typically, it is best to stress relieve after rough machining and just prior to final machining. Because of logistical and other cost considerations, it may be tempting to stress relieve raw castings and then perform machining operations with no further treatment. However, machining operations can also introduce varying degrees of stresses into the part. By stress relieving immediately prior to final machining, both casting stresses and machining stresses can be removed prior to final machining, thereby the best possible outcome can be achieved. For castings with demanding precision requirements, it may be necessary to stress relieve twice, once after the casting comes out of the mold and again after rough machining. Reference: Gray Iron – A Unique Material Stress Relief of Gray Cast Iron, Naval Research Laboratory 12-12-2019, 11:54