Printing in the Darkroom

advertisement

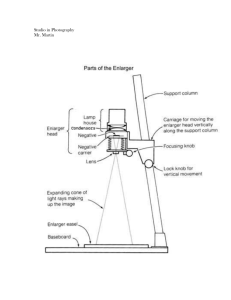

Printing in the Darkroom: Ch. 7 Physical Characteristics of Paper • • • • • • • Texture: The surface pattern of a paper. Ranges from smooth to slightly rough. Some finishes resemble canvas, silk, or other materials. Smoother surfaces reveal finer details in the image and any graininess of the negative more than rougher surfaces do. Gloss: The surface sheen of paper, Ranges from glossy (greatest shine) to luster (medium shine) to matte (dull). The dark areas of glossy papers appear blacker than matte papers. Very high gloss can cause distracting reflections. Paper base tint: The color of paper, pure white and off white tints available (cream, buff, or ivory) Image tone: The color of the silver deposit in the finished print. Ranges from Warm (brownish-black) to cool (blueish-black) Weight: The thickness of the paper Size 8x10 inches is common Resin coating: A water-resistant,plastic-like coating. Absorb little moisture, dry flat. Too much heating during drying can damage surface. Paper • Paper is light sensitive • Orthochromatic:emulsion that is sensitive to only blue and green light, and thus can be processed with a red safelight. • Vary in texture, color, contrast…etc • We will use VARIABLE CONTRAST, RESIN COATED (VC/RC) paper: you change contrast by changing the color of the enlarger light through the use of filters. • You may check out filters to use in class. • Our paper has a GRADE of 2 so any number higher than 2 will create more contrast (more blacks and whites, less grays), and anything less will create more grays. Filters range from 0 to 5+ Paper Texture • Many photographers prefer a glossy surface, smooth textured paper because it has the greatest tonal range and brilliance. • Prints are seen by reflected light, and a matte texture or rough surface scatters light so it decreases the tonal range between the blackest blacks and the whitest highlights • Resin Coated/RC paper requires less washing time than fiber based papers. Fiber based papers have more tonality, surface quality, and archival properties yet they are more difficult to work with as they tend to warp. They are also more expensive than RC papers. Paper Storage • DO NOT OPEN YOUR PAPER OUTSIDE OF THE DARKROOM • KEEP PAPER INSIDE YOUR SAFE BOX UNLESS YOU ARE PRINTING • Most papers last about 2 years without fogging The Darkroom: Dry side • Photographic Paper is used to make a print • Dust and fingerprints are a common problem of the dry side • Enlarger and cutting equiptment The Darkroom: The Wet Side • Contamination of chemicals causes spots, stains, and weakened chemicals • DON’T allow chemicals to dribble onto the floor, clothing, or surrounding counter tops • Always allow chemicals to drip off over the appropriate tray before transferring your print to the next tray Equipment and Supplies • • • • • • • • • • • Enlarger Printing Paper Easel (printing and glass for contact sheets) Focusing magnifier Safelight: A relativly dim amber safe-light allows you to see what you are doing, but not so much that the paper becomes fogged with spots Paper cutter Timer Trays Tongs Squeegee Drying Racks • You MUST be able to locate all of the above in the darkroom Chemicals • Developer: DEKTOL produces a neutral or blueblack tone when used with the correct paper. Converts the crystals in the paper’s emulsion into visible metallic silver • Stop bath: acidic acid halts the action of the developer • Fixer: removes unwanted silver halides from the emulsion • Wash: running H2O removes all chemicals but can warp paper if left too long The Enlarger Lamp Condenser Filters Base Supporting Column Timer Test Strip Contact Sheet Making a contact sheet • • • • • • • • • Prepare the enlarger Identify the emulsion side of the film Identify the emulsion side of the paper Place negatives and test strip under glass Expose the test strip Process the test strip Evaluate a correct time Create a new test strip if necessary Create contact print