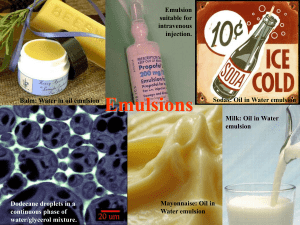

types

advertisement

MULTIPLE EMULSION & SUBMICRON EMULSION Jony Mallik M.Pharm CONTENT 1) Definitio of Emulsion. 2) What is multiple emulsion? 3) What is emulsifing agent? 4) Mechanism of drug release. 5) Equipments used in emulsion preparation. 6) Application 7) What is Microemulsion? 8) Characteristics of microemulsion. 9) Advantage , Disadvantage & Application of microemulsion. EMULSION DEFINATION:”emulsion is a thermodynamically unstable mixture of two immiscible liquids.” TYPES: Micro(transperent) O/W W/0 O/W/O W/O/W =water phase =oil phase Multiple emulsion are complex system which consist of both w/o and o/w at the same time. There are potential matrices for the encapsulation of biactive compounds and for the controlled release compounds w/o/w multiple emulsion are system where small water droplets are entrapped within larger oil droplets and they are disperse continous water phase Because of presense of reseroir phase that can be use to prolong release of active ingredients. Multiple emulsion w/o/w contain two emulsifiers: 1 Low HLB surfactant (Hydrophobic in nature) 2 High HLB surfactant (Hydrophilic in nature) Low HLB surfactant use in disperse phase High HLB surfactant use in continous phase. MULTIPLE EMULSION HYDROPHILIC SURFACTANT HYDROPHOBIC SURFACTANT W/O/W SYSTEM =water phase O/W/O SYSTEM =oil phase surfactants Non ionic Anionic Sodium oleate Pottasium oleate Glyceryl monostearate cationic Benzalkonium chloride span 80 span20 Tween 20 Tween 60 Tween 80 Mechanism of release of drug: Two type inter phase in w/o/w multiple emulsion 1 Primary interface lying between the inner w/o phase contains the low HLB surfactant. 2 Secondary interface lying between droplets and continuous aqueous phase. Low and high HLB surfactant present in it. When hydrophilic surfactant in the continuous aqueous phase exceed its critical micelle concentration the resultant micelles may solubilize the hydrophobic surfactant present in oil phase. Resulting in a decrease in the hydrophobic surfactant concentration and rupture the oil layer and lose of internal aqueous phase. METHOD OF PREPARATION 1) Solvent evaporation method 2) Two step emulsification. 3) Phase inversion technique. SOLVENT EVAPORATION TECHNIQUE EQUIPMENTS To electric motor shaft Impeller/blade Mechanical stirrer MECHANICAL STIRRES •Impellers mounted on a shaft. •Paddles or blade is used. •Degree of agitation is controlled by speed but liquid flow pattern is by type of impellers. inlet Vibrating blade Nozzle jet ultrasonifiers outlet ULTRASONIFIERS •Use ultrasonic enegry for emulsification. HOMOGENIZR outlet (500 to 5000psi) spring Small orifice inlet homogenizer •Forcing liquid mixture through small orifice at very high pressure. •Yiled emulsion of very low particle size(1nm). APPLICATION • In theory, multiple emulsions have significant potential for breakthrough applications in food, agricultural, pharmaceutical, nutraceutical, and cosmetic industries in which they can facilitate the sustained release and transport of active material. • In cosmetics, these systems can prevent degradation of an active ingredient and release it at a controlled rate. • They can also improve dissolutions or solubilization of insoluble materials. • Due to these properties, multiple emulsions find applications related to protecting sensitive and active molecules such as vitamins C and E from the external phase—a process called antioxidation. Microemulsions Microemulsions are thermodynamically stable, optically transparent, isotropic dispersions of aqueous and hydrocarbon liquids stabilized by an interfacial film of surfactant molecules Microemulsions are monodispersed spherical droplets (diameter < 100 nm) of water in oil or oil in water, depending on the nature of the surfactant. Microemulsions and (Macro) emulsions are Different Microemulsion Macroemulsion Thermodynamically Stable Kinetically Stable Droplet size 10 - 100 nm (transparent) 1-10 m (opaque) High surface area: 200 m2/g Low surface area: 15 m2/g Ultra Low O/W IFT (10-2 – 10-3 mN/m) O/W IFT 1-10 mN/m W/O , O/W and Bicontinuous types W/O or O/W types MODERN EQUIPMENTS Bitumen-emulsion system UVB-14 Inline homogenizer Vacuume emulsifier Vacuume emulsifier for Eye ointment and creams. Intake homogenizer