ECOVER ANTIPUMPING

advertisement

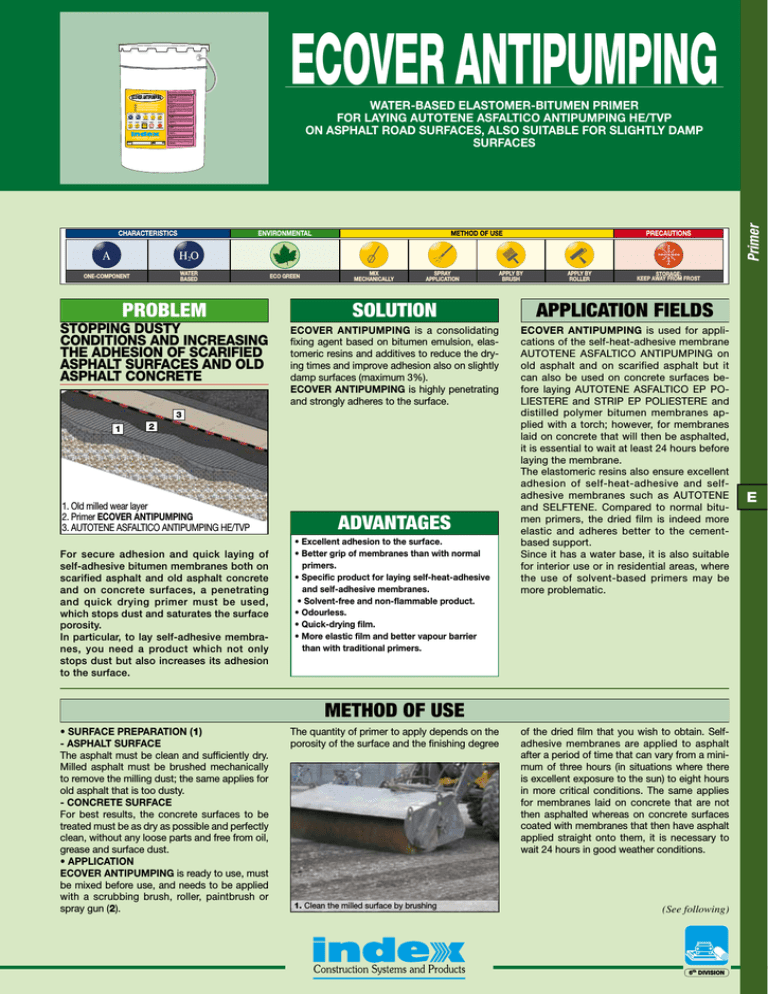

ECOVER ANTIPUMPING USO PROFESSIONALE • FOR PROFESSIONALE USE ONLY ECOVER ANTIPUMPING I GB D F NL ONE-COMPONENT A MONOCOMPONENTE TO BE APPLIED BY BRUSH • CAMPI D’IMPIEGO. è consigliato per impermeabilizzare muri di fondazione in calcestruzzo. • MODALITÁ D’IMPIEGO. La superficie da trattare deve essere asciutta, pulita e priva di parti di distacco. Le parti friabili vanno eliminate e ricostruite. Per l’adesività sulle superfici porose e secche, è consigliabile la stesura una mano di diluita al 30% con acqua. va mescolato prima dell’uso con trapani mmani di prodotto. Non eccedere nel consumo per mano per non l’evaporazione dell’acqua contenuta nel prodotto applicato. • CONSUMI. 0,500 kg/m2 per mano. RIVESTIMENTO ELASTOMOERO-BITUMINOSO ALL’ACQUA WATER-BASED ELASTOMER/BITUMINOUS COATING RIVESTIMENTO ELASTOMOERO-BITUMINOSO ALL’ACQUA WATER-BASED ELASTOMER/BITUMINOUS COATING TO BE MEHANICALLY MIXED SPRAY APPLICATION TO BE APPLIED BY PLASTERING TROWEL APPLICARE A SPRUZZO APPLICARE CON FRATTAZZO APPLICARE CON RULLO • APPLICATIONS. is recommended to waterproof foundations walls made in concrete. • DIRECTIONS. The surface to be treated has to be dry, clean and with no detaching parts. Weak parts have to be eliminated and replaced with new material. In order to improve the adhesive onto porous and dry surfaces, it is recommended to previously spread a first layer consisting in a 30% water-diluted . has to be mixed before use with mechanic drills. Application can be made with brushes, rollers or spraying devices. • CONSUMPTION. 0.5 kg/square metre/year. D H2O MESCOLARE MECCANICAMENTE MINIMUM APPLICATION TEMPERATURE KEEP AWAY FROM FROST • APPLICATIONS. is recommended to waterproof foundations walls made in concrete. • DIRECTIONS. The surface to be treated has to be dry, clean and with no detaching parts. Weak parts have to be eliminated and replaced with new material. In order to improve the adhesive onto porous and dry surfaces, it is recommended to previously spread a first layer consisting in a 30% water-diluted . has to be mixed before use with mechanic drills. Application can be made with brushes, rollers or spraying devices. • CONSUMPTION. 0.5 kg/square metre/year. USE SUITABLE PROTECTION + 5°C APPLICARE CON PENNELLO WATER-BASED ELASTOMER-BITUMEN PRIMER FOR LAYING AUTOTENE ASFALTICO ANTIPUMPING HE/TVP ON ASPHALT ROAD SURFACES, ALSO SUITABLE FOR SLIGHTLY DAMP SURFACES GB WATER-BASED ELASTOMER/BITUMINOUS COATING WATER BASED VEICOLO ACQUA TO BE APPLIED BY ROLLER I TEMPERATURA MIN. DI APPLICAZIONE STOCCAGGIO: TEME IL GELO UTILIZZARE DISPOSITIVI DI PROTEZIONE INDIVIDUALI • APPLICATIONS. is recommended to waterproof foundations walls made in concrete. • DIRECTIONS. The surface to be treated has to be dry, clean and with no detaching parts. Weak parts have to be eliminated and replaced with new material. In order to improve the adhesive onto porous and dry surfaces, it is recommended to previously spread a first layer consisting in a 30% water-diluted . has to be mixed before use with mechanic drills. Application can be made with brushes, rollers or spraying devices. • CONSUMPTION. 0.5 kg/square metre/year. F NL 37060 Castel d’Azzano - Verona - ITALY Partita kg e • APPLICATIONS. is recommended to waterproof foundations walls made in concrete. • DIRECTIONS. The surface to be treated has to be dry, clean and with no detaching parts. Weak parts have to be eliminated and replaced with new material. In order to improve the adhesive onto porous and dry surfaces, it is recommended to previously spread a first layer consisting in a 30% water-diluted . has to be mixed before use with mechanic drills. Application can be made with brushes, rollers or spraying devices. • CONSUMPTION. 0.5 kg/square metre/year. CHARACTERISTICS ENVIRONMENTAL + 5°C METHOD OF USE PRECAUTIONS TEMPERATURA MIN. DI APPLICAZIONE WATER BASED ONE-COMPONENT PROBLEM STOPPING DUSTY CONDITIONS AND INCREASING THE ADHESION OF SCARIFIED ASPHALT SURFACES AND OLD ASPHALT CONCRETE ECO GREEN MIX MECHANICALLY SPRAY APPLICATION For secure adhesion and quick laying of self-adhesive bitumen membranes both on scarified asphalt and old asphalt concrete and on concrete surfaces, a penetrating and quick drying primer must be used, which stops dust and saturates the surface porosity. In particular, to lay self-adhesive membranes, you need a product which not only stops dust but also increases its adhesion to the surface. STORAGE: KEEP AWAY FROM FROST SOLUTION APPLICATION FIELDS ECOVER ANTIPUMPING is used for applications of the self-heat-adhesive membrane AUTOTENE ASFALTICO ANTIPUMPING on old asphalt and on scarified asphalt but it can also be used on concrete surfaces before laying AUTOTENE ASFALTICO EP POLIESTERE and STRIP EP POLIESTERE and distilled polymer bitumen membranes applied with a torch; however, for membranes laid on concrete that will then be asphalted, it is essential to wait at least 24 hours before laying the membrane. The elastomeric resins also ensure excellent adhesion of self-heat-adhesive and selfadhesive membranes such as AUTOTENE and SELFTENE. Compared to normal bitumen primers, the dried film is indeed more elastic and adheres better to the cementbased support. Since it has a water base, it is also suitable for interior use or in residential areas, where the use of solvent-based primers may be more problematic. 2 1. Old milled wear layer 2. Primer ECOVER ANTIPUMPING 3. AUTOTENE ASFALTICO ANTIPUMPING HE/TVP APPLY BY ROLLER ECOVER ANTIPUMPING is a consolidating fixing agent based on bitumen emulsion, elastomeric resins and additives to reduce the drying times and improve adhesion also on slightly damp surfaces (maximum 3%). ECOVER ANTIPUMPING is highly penetrating and strongly adheres to the surface. 3 1 APPLY BY BRUSH ADVANTAGES • Excellent adhesion to the surface. • Better grip of membranes than with normal primers. • Specific product for laying self-heat-adhesive and self-adhesive membranes. • Solvent-free and non-flammable product. • Odourless. • Quick-drying film. • More elastic film and better vapour barrier than with traditional primers. METHOD OF USE • SURFACE PREPARATION (1) - ASPHALT SURFACE The asphalt must be clean and sufficiently dry. Milled asphalt must be brushed mechanically to remove the milling dust; the same applies for old asphalt that is too dusty. - CONCRETE SURFACE For best results, the concrete surfaces to be treated must be as dry as possible and perfectly clean, without any loose parts and free from oil, grease and surface dust. • APPLICATION ECOVER ANTIPUMPING is ready to use, must be mixed before use, and needs to be applied with a scrubbing brush, roller, paintbrush or spray gun (2). The quantity of primer to apply depends on the porosity of the surface and the finishing degree 1. Clean the milled surface by brushing Primer TEMP. MIN. APPLICAZ. of the dried film that you wish to obtain. Selfadhesive membranes are applied to asphalt after a period of time that can vary from a minimum of three hours (in situations where there is excellent exposure to the sun) to eight hours in more critical conditions. The same applies for membranes laid on concrete that are not then asphalted whereas on concrete surfaces coated with membranes that then have asphalt applied straight onto them, it is necessary to wait 24 hours in good weather conditions. (See following) 6th DIVISION E TECHNICAL CHARACTERISTICS ECOVER ANTIPUMPING Standard Appearance Colour Specific weight Solid residue at 130°C Application temperature Viscosity DIN/ 4 cup at 20 °C Waiting time - dry dust free (*) Shelf life in original packaging UNI EN ISO 2811-1 UNI EN ISO 3251 UNI EN ISO 2431 Liquid Brown 0.98 ± 0.10 kg/L 35 ± 3% +5°C ÷ +35°C 20÷30 seconds 30 ÷ 60 minuts 12 months Test conditions: temperature 23±2°C, 50±5% R.H. and air velocity in test area <0.2 m/s. The values may vary according to the specific job site conditions: temperature, ventilation, absorbtion of substrate and applied product. (*) The stated times are longer or shorter as the temperature decreases or increases. (See previous) 2. Laying ECOVER ANTIPUMPING PACKAGING S.7/dig. - 1.000 - 04/2013ing-10/2012ita ECOVER ANTIPUMPING • 200-Liters-Drum. • 20-Liters-Pail. • FOR ANY FURTHER INFORMATION OR ADVICE ON PARTICULAR APPLICATIONS, CONTACT OUR TECHNICAL OFFICE • IN ORDER TO CORRECTLY USE OUR PRODUCTS, REFER TO INDEX TECHNICAL SPECIFICATIONS • Internet: www.index-spa.com Informazioni Tecniche Commerciali tecom@indexspa.it Amministrazione e Segreteria index@indexspa.it Via G. Rossini, 22 - 37060 Castel D’Azzano (VR) - Italy - C.P.67 Index Export Dept. Tel. (+39)045.8546201 - Fax (+39)045.518390 index.export@indexspa.it © INDEX socio del GBC Italia The figures shown are average indicative figures relevant to current production and may be changed or updated by INDEX at any time without previous warning. The advice and technical information provided, is what results from our best knowledge regarding the properties and the use of the product. Considering • Do not apply in the winter or when the surface is at a temperature of less than + 5°C • Keep away from frost. Store at temperatures of above +5°C. • Do not apply the product if rain is expected • Clean the tools with water if the product has not yet dried. Use common diluents (synthetic, white spirit, toluene) if it has dried. Wet the tools frequently during use to prevent the product drying. the numerous possible uses and the possible interference of conditions or elements beyond our control, we assume no responsibility regarding the results which are obtained. The purchasers, of their own accord and under their own responsibility, must establish the suitability of the product for the envisaged use. • APPLICATION WARNINGS • COVERAGE Consumption varies according to the nature of the surface: • On milled asphalt: about 200-250 g/m². • On old asphalt concrete: about 200-250 g/m². • On metal surfaces: about 200-250 g/m². • On concrete surfaces: about 250-400 g/m².