Warm Mix Asphalt

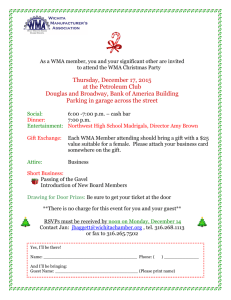

advertisement

Warm Mix Asphalt By: Pam McGowan WMA Goals • HMA quality • Lower temperature • Reduced emissions How WMA Works • Incorporates additives that reduce asphalt viscosity • Reducing viscosity means mixing at lower temperatures Types of Additives • There are currently four types on the market – – – – Aspha-Min WAM-Foam Sasobit Evotherm Aspha-Min WAM-Foam • Product of Germany • Synthetic zeolite crystals • Internally held water creates foam • Uses 2 binders • Soft binder coats aggregate • Water injected to create foam Sasobit Evotherm • Aliphatic hydrocarbon produced from coal gasification (long chain wax) • Reduces rutting • Chemical mixture • Creates emulsion Benefits to WMA Technology • • • • • • Reduction of fuel expenses with lower heat Increase in compaction results Shorter binder curing time Early site opening Reduction in emissions Tested and proven in Europe Concerns with WMA • Shorter aging time of asphalt could increase rutting potential • Plant modifications may be necessary • Additives may increase moisture susceptibility