EPOSCHIELD/C - Index S.p.A.

advertisement

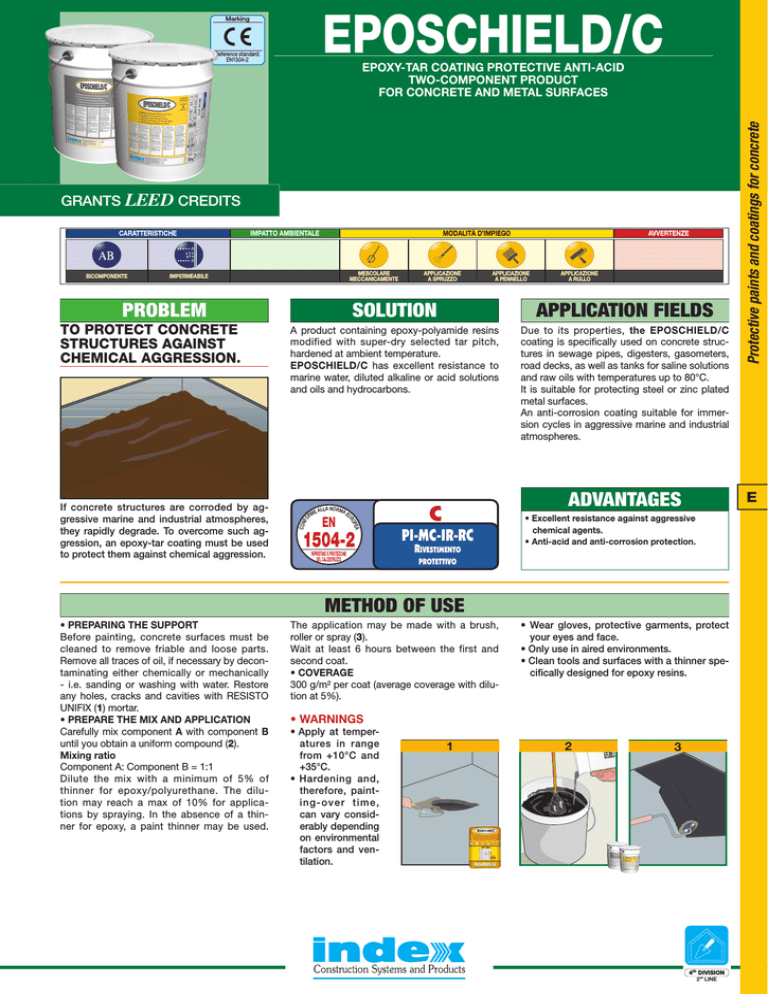

1 C Partita VEICOLO ACQUA MESCOLARE MECCANICAMENTE TO BE MEHANICALLY MIXED d’Azzano - Verona MIN. TEMPERATURA DI APPLICAZIONE + 5°C APPLICATION MINIMUM TEMPERATURE 37060 Castel CON APPLICARE RULLO ALL’ACQUA A - ITALY - kg • FOR PROFESSIONALE USE ONLY e in concrete. walls made parts. Weak foundations detaching to improve • APPLICATIONS.to waterproof and with no is recommended spread dry, clean new material. In order has to be to previously with • DIRECTIONS. replaced with to be treated before use The surfaceto be eliminated anddry surfaces, it is recommended to be mixedor spraying devices. parts have onto porous and water-diluted . has rollers the adhesiveconsisting in a 30% be made with brushes, a first layerdrills. Application can mechanic • CONSUMPTION. metre/year. 0.5 kg/square in concrete. walls made parts. Weak foundations detaching to improve • APPLICATIONS.to waterproof and with no is recommended spread dry, clean new material. In order has to be to previously with • DIRECTIONS. replaced with to be treated before use The surfaceto be eliminated anddry surfaces, it is recommended to be mixedor spraying devices. parts have onto porous and water-diluted . has rollers the adhesiveconsisting in a 30% be made with brushes, a first layerdrills. Application can mechanic • CONSUMPTION. NL metre/year. 0.5 kg/square in concrete. walls made parts. Weak foundations detaching to improve • APPLICATIONS.to waterproof and with no is recommended spread dry, clean new material. In order has to be to previously with • DIRECTIONS. replaced with to be treated before use The surfaceto be eliminated anddry surfaces, it is recommended to be mixedor spraying devices. parts have onto porous and water-diluted . has rollers the adhesiveconsisting in a 30% be made with brushes, a first layerdrills. Application can mechanic F • CONSUMPTION. metre/year. 0.5 kg/square in concrete. walls made parts. Weak foundations detaching to improve • APPLICATIONS.to waterproof and with no is recommended spread dry, clean new material. In order has to be to previously with • DIRECTIONS. replaced with to be treated before use The surfaceto be eliminated anddry surfaces, it is recommended to be mixedor spraying devices. parts have onto porous and water-diluted . has rollers the adhesiveconsisting in a 30% be made with brushes, a first layerdrills. Application can mechanic D • CONSUMPTION. metre/year. 0.5 kg/square in calcestruzzo. muri di fondazione Le D’IMPIEGO.impermeabilizzare parti di distacco.e • CAMPI per e priva di porose è consigliatoD’IMPIEGO. essere asciutta, pulita sulle superfici va • MODALITÁ da trattare deve ricostruite. Per l’adesivitàal 30% con acqua. nel consumo di diluita La superficievanno eliminate e una manodi prodotto. Non eccedere applicato. prodotto parti friabili consigliabile la stesura trapani mmani contenuta nel secche, è prima dell’uso con dell’acqua mescolato per non l’evaporazione per mano GB • CONSUMI.2 per mano. 0,500 kg/m DISPOSITIVI INDIVIDUALI UTILIZZARE DI PROTEZIONE USE SUITABLE PROTECTION CON APPLICARE FRATTAZZO PLASTERING tel. 045.512233 STOCCAGGIO: GELO TEME IL KEEP AWAY FROM FROST APPLICARE SPRUZZO SPRAY APPLICATION USO PROFESSIONALE 2 TO BE APPLIED BY ROLLER The application may be made with a brush, roller or spray (3). Wait at least 6 hours between the first and second coat. • COVERAGE 300 g/m² per coat (average coverage with dilution at 5%). WATER BASED RIVESTIMENTO COATING ELASTOMOERO-BITUMINOSO RIVESTIMENTO ALL’ACQUA ELASTOMER/BITUMINOUS WATER-BASED COATING ELASTOMOERO-BITUMINOSO RIVESTIMENTO ELASTOMER/BITUMINOUS COATING WATER-BASED ELASTOMER/BITUMINOUS BY WATER-BASED TO BE APPLIED TROWEL I • Apply at temperatures in range from +10°C and +35°C. • Hardening and, therefore, painting-over time, can vary considerably depending on environmental factors and ventilation. PI-MC-IR-RC F A RIPRISTINO E PROTEZIONE DEL CALCESTRUZZO NL 1504-2 C D LA NORMA E AL E EN O PE UR • PREPARING THE SUPPORT Before painting, concrete surfaces must be cleaned to remove friable and loose parts. Remove all traces of oil, if necessary by decontaminating either chemically or mechanically - i.e. sanding or washing with water. Restore any holes, cracks and cavities with RESISTO UNIFIX (1) mortar. • PREPARE THE MIX AND APPLICATION Carefully mix component A with component B until you obtain a uniform compound (2). Mixing ratio Component A: Component B = 1:1 Dilute the mix with a minimum of 5% of thinner for epoxy/polyurethane. The dilution may reach a max of 10% for applications by spraying. In the absence of a thinner for epoxy, a paint thinner may be used. RM I If concrete structures are corroded by aggressive marine and industrial atmospheres, they rapidly degrade. To overcome such aggression, an epoxy-tar coating must be used to protect them against chemical aggression. APPLICAZIONE A PENNELLO GB PROBLEM APPLICAZIONE A SPRUZZO CON APPLICARE PENNELLO TO PROTECT CONCRETE STRUCTURES AGAINST CHEMICAL AGGRESSION. MESCOLARE MECCANICAMENTE EPOSCHIELD/ IMPERMEABILE TO BE APPLIED BY BRUSH IMPATTO AMBIENTALE MONOCOMPONENTE GRANTS LEED CREDITS MODALITÀ D’IMPIEGO AVVERTENZE APPLICAZIONE A RULLO SOLUTION APPLICATION FIELDS A product containing epoxy-polyamide resins modified with super-dry selected tar pitch, hardened at ambient temperature. EPOSCHIELD/C has excellent resistance to marine water, diluted alkaline or acid solutions and oils and hydrocarbons. Due to its properties, the EPOSCHIELD/C coating is specifically used on concrete structures in sewage pipes, digesters, gasometers, road decks, as well as tanks for saline solutions and raw oils with temperatures up to 80°C. It is suitable for protecting steel or zinc plated metal surfaces. An anti-corrosion coating suitable for immersion cycles in aggressive marine and industrial atmospheres. ADVANTAGES • Excellent resistance against aggressive chemical agents. • Anti-acid and anti-corrosion protection. PROTETTIVO METHOD OF USE • Wear gloves, protective garments, protect your eyes and face. • Only use in aired environments. • Clean tools and surfaces with a thinner specifically designed for epoxy resins. • WARNINGS 3 4th DIVISION 2nd LINE Protective paints and coatings for concrete Reference standard: EN1504-2 ONE-COMPONENT BICOMPONENTE O CARATTERISTICHE CON F Marking EPOSCHIELD/C EPOXY-TAR COATING PROTECTIVE ANTI-ACID TWO-COMPONENT PRODUCT FOR CONCRETE AND METAL SURFACES E TECHNICAL CHARACTERISTICS EPOSCHIELD/C Standard EN 2811-1 COMPONENT A Thick liquid Grey 1.70 ± 0.10 kg/ 80 ± 2% 22,000 ± 2,000 cps 10 12 months COMPONENT B Liquid Black 1.60 ± 0.10 kg/ 80 ± 2% 7,000 ± 1,000 cps 10 12 months 1.65 ± 0.05 kg/ approx. 4-6 h approx. 3 h approx. 60-90 minutes approx. 24-36 h approx. 7 days approx. 6 ÷ 24 h +10°C ÷ +35°C 300 µ (per coat) Performance characteristics Regulations Product performance Class and type Permeability to water vapour Adhesion test Water absorption through capillarity Resistance to abrasion Permeability to CO2 Chemical resistance Thermal resistance - Working temperature Reaction to fire Hazardous substances EN 1504-2 EN 7783 EN 1542 EN 1062-3 EN 5470-1 EN 1062-6 EN 13529 C PI-MC-IR-RC 5 m < Sd <50 m - class II ≥3.5 MPa w < 0.01 kg/m²·h0.5 200 mg Sd >50 m No visible defect -40°C ÷ +100°C Euroclass E Complies with note in ZA.1 EN 13501-1 EN 1504-2 Test conditions: temperature 23±2°C, 50±5% R.H. and air velocity in test area <0.2 m/s. The data shown may vary depending on the specific work site conditions: temperature, humidity, ventilation, absorbency of the base coat. (*) The stated times are longer or shorter as the temperature decreases or increases. Pursuant to the general principles defined in EN 1504-2 - Assessment principles for the use of products and systems. PACKAGING S.7/dig. - 1.000 - 9/2014ing.-5/2014ita EPOSCHIELD/C • Component A: 10 kg Pail • Component B: 10 kg Pail • FOR ANY FURTHER INFORMATION OR ADVICE ON PARTICULAR APPLICATIONS, CONTACT OUR TECHNICAL OFFICE • IN ORDER TO CORRECTLY USE OUR PRODUCTS, REFER TO INDEX TECHNICAL SPECIFICATIONS • Internet: www.index-spa.com Informazioni Tecniche Commerciali tecom@indexspa.it Amministrazione e Segreteria index@indexspa.it Via G. Rossini, 22 - 37060 Castel D’Azzano (VR) - Italy - C.P.67 Index Export Dept. T. +39 045 8546201 - F. +39 045 518390 index.export@indexspa.it © INDEX socio del GBC Italia the numerous possible uses and the possible interference of conditions or elements beyond our control, we assume no responsibility regarding the results which are obtained. The purchasers, of their own accord and under their own responsibility, must establish the suitability of the product for the envisaged use. Regulations EN 2811-1 The figures shown are average indicative figures relevant to current production and may be changed or updated by INDEX at any time without previous warning. The advice and technical information provided, is what results from our best knowledge regarding the properties and the use of the product. Considering Component Appearance Colour Apparent density Solid content in weight Brookfield viscosity at 20°C Mix ratio Storage in original packaging in a dry place Product properties and workability Apparent density of the product Workable mix duration - at 20°C (*) Workable mix duration - at 30°C (*) Wait time - for dust-free drying (*) Wait time - for deep drying (*) Wait time - for complete drying (*) Wait time - between the first and second coat (*) Application temperature Average application thickness