I

advertisement

g .*,-.al'r

.

-.- -

ACT

COMMERCIAL

FISHERIES

AND DEVELOPMENT

ACT

AITD

DEVEIOffiET{T

RESEANCE

COMUERCtrAI,

FISHEBIESRESEARCH

REPORT

PROGRESS

REPORT

PROCRESS

I

THFLUEilCEOF

OF

AND THE

TTTEINFLUENCE

CONTROLLED

REARING

CRAB

IARVAE AND

DUNGSNSSS

COITTROLT,ED

REARI}ICOF

CNABLARVAE

OT DUNGENESS

ST'RVIVAL

ENVIRONMENTAL

CONDITIONS

ON

THEIR

SURVIVAL

OH THEIB

ENVIROIiIMENTAL

CONDX,TtrONS

1966

November

16, 1965

1965 to

to June

June 30, 1966

Novober 16,

Prepared

Prepered by:

by:

Bl,oLogdst

H. Reed,

Reed, Aquati,c

Aquatic Biologist

Paul H"

Oregon

Fish

of Oregon

F{sh Coemission

Cosmfseton'of

Approved by:

Approved

byr

Researcb

Jack

H. Van

Marine Research

Vaa Ryning,

Hynlngo Harl,ne

Jsck U,

Supervisor, Fish

of

Ftsb Coeeiission

Sarpervlaoro

Co{,sEton of

Oregon

Oregoa

July 1966

1966

July

Interior

Department of

of Interior

U.S. Dqart8ent

Fish end

and !{{,l.dltfe

Wildlife Service

Segvi,ee

Flsh

Fisherf,ee

Bureau

Bureau of

0cmersial Fisheries

of, Comzercia1

gu$-proJect No.

Sub-project

Ho. l.5.ft-1

1-5-R-1.

Contract No.

No. Ur-17-0007-353

1447.0007-353

Coatract

-

INTRODUCTION

INTRODUCSTON

.

rearing

devel.opuent of

of rearing

Construction of

Construetloo

and development

larvel rearing

rearlng system

syst€D and

of a larval

ftrst

of, the

the first

techniques

were the

eechnl,ques for

the objectives

obJectlves of

for Dungenese

Dtngeness crab

lanrae rer€

erab larvae

progrrn.

year's

vearrs program.

l,lterature

oearchl consultation

coneultetlon

Preliminary work

work involved

a literature

search,

Prellnlnery

lavolved e

ytth biologists

larval culture,

*ad

culture, and

with

blologl.ete involved

cnrstrcesn larval

rlth aolluscan

and crustacean

lnvo!,ved with

@llusean and

norkers"

conteryoraty workers0

of contemporary

the

deslgn of

rearl.og system

the design

of, a rearing

on the

the success

stlcceea of

based on

system based

MATERIALS

ND METHODS

USTEODS

UATERIALSAITD

(Flgures 1I

A

requlred and

csnstaucted (Figures

A semi-closed

wes required

and constructed

rearlng system

sen!,-ctrosed rearing

systcm was

throqgh aa

Ebe system

Sea

water from

Yaquina Bay,

enters the

systm through

Sea water

Bay, Oregon, enters

f,rm Yaqulua

and

2).

and 2).

ulttaan ultrapae-systcm! filter,

passes through

second filter,

flteers an

pre.system

head tank,

tank, aa second

fll,tern passes

througb aa head

velveso

aeedle valves.

violet unit,

vi.olet

untte and

tbro$gh needle

and eaters

enters ten

lucubetors through

tea incubators

Used

Used sea

ees

or discarded.

dlscard€d.

reef.rculated or

water

sater drops

drops into

lnAo aa sunp

and is

la either

elther recirculated

euqr and

S

ugter

The

removes

macroscopic matter

pre-eystem filter

nrtter from

fro the

tbe sea

Eea water

the prs-system

ftltes

rencrves Eactoacoplc

(FlSure 3).

3)"

pree1uding obstruction

€t'lter (Figure

precluding

of the

second filter

obEtructtsa of

tbe second

Sea

water falls

fslle

$ea rater

gravele

cosrsG gravel,

contaln!,ng coarse

into

stages

fllter

stag€s containing

tenk through

three filter

lnto the

the bead

bead tank

tbrougb three

gravel and

gfrcs woos,

reepetlvely.

fine

f,!.ne gravel

woolo respectively.

and glass

cleaning.

eteanlng,

f,or rapid

rapld

Each

rencvable for

ts remcvabie

Each stage

ctege is

per minute.

ga!,lons per

nlnute.

The

capacity

ftlter

ls ten

ten gallons

tle filter

cepaclty is

pertods of

of,

queltty during

durtng periods

A 750-gallon

A

a€,a-Fater quality

75O-gellon head

head tank

tank assures

essur€e sea-water

adverse

conditions and ua!,ntalns

maintains head

head for

for gravi,ty

gravity f,lor

flow to

to otber

other systcs

systm*

advease sea-water

sea-water condltloas

polyctbytreoe sheet.

sheetc

sttb aa polyethylene

components. The

tank is

ts lined

trtned with

comryroBesta.

Xhe tank

Fli,terlte

L 20 uU flt.ter

Most

filter equlpped

equipped

r€ooved by a Filterite

|lleroscople matter

Host microscopic

natter is

ls removed

with

L5 micron

nferou orion

orloa elements.

e!.mentgn

Ettb 55 or

ou 15

bacteri,e

reduee bacteria

A

unit

Ls employed

eryXoyed to

8o reduce

unit is

A Steritronic

ul.tra-vl,olet

Sterltroa{,c SWL-lO

$lfL-LO ultra-violet

levels by 99%.

lene!.a

9!tZ,

ultrathe ultraProtozoans

by the

f,woblllzed

unleel!.uner algae

atrgaa are temobilized

Protogosas and

asd unicellular

violet

v8olee light.

llght.

placed in

bath contain

coa,{tsln

Five-liter

polyethylene incubators

tn aa temperature

polyethylcne

teryet ture bath

tncubators placed

Flvc-lleer

[I:

grayE and

rater

treated sea

eea water

supply of

of, treated

suspended

reeel,ve a continuous

contlnuoua supply

rearlng trays

and receive

auspead.edrearing

I

trQy)

IncuLor net v1ves

a

0,

t:3

\e

l't

oo

.t

u -l-

Iuor

\So

(f)

-!

l-

.t-o

2:

+

{ 'j: )

Nd

as

CUH

\'__

6u,

:

aJ

Iicubtor

l!l

+J

+-

x

Nx

36comartme

I

0,

cGJ

oJ

-.rl l .

2oa

b30 m screee

d

L

-f;r o

--o

3

()

H.

d

)

4

H

o

{J

tt)

L

LTI

--

>r

a

q0

Dust cover

LI

o,

o

H

.d

!)

${

d

-to

G,

o

H

\

f,

U

g

3

a

F

m

Fl

$t

,F{

,E

:)

L)

o

Uflt

+-

.g

+

H

CD

'd

I

r.

v

.L

.tr

1;

.L

ai;

E

)

a

o

A

€

d

+)

o

(t}

b0

E

F{

<

Figure 1.

t-l.

-9

f

d

lr-

d

V

=

Turn VO.ivt.

+'

d

:,1

.r{

t0

to

_9

o

I

.;

fer

vive

I

v

G

s

rt,

/

,o

I

Art

!

.q,

o_ -l-

1

tq,

V /Ultrq-violet

Incubor oQt(et

a

tu

t

.Fl.

Fq

5

qi

.o)

SeQw&i

L)

o

t{

e/i

II

\,

o'6-

I!

(1

71

IL

I

PVC pipe-

/

t'

r{

H

3 Sct9e rrQYstm

t/|

ol

6d

o,

{-5

o

$r

'o

!t)

7=

7

+-

l.a,

.t,

/

z.

H

q,

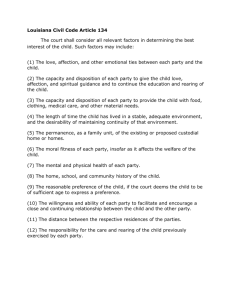

Arrangement and Design *f the Larval Rearing System.

-

INCUBATOR DETAIL

-.o

PAUL H. REED

'TYPE SEMI-CLOSED

CRAB LARVAL REARING SYSTEM,

t""

pT-

lj

3

d

q,

rn

3.

3.

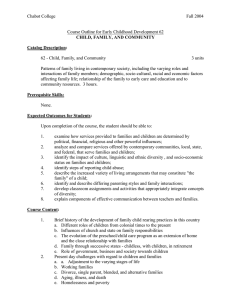

Figure

Flgure 2.

2.

The

The Larval

Reartng System

Syst,emShowing

Showlng the

Pre-system

Larval Rearing

t,he Pre-system

Ftlter,

Filter,

Head

M i c r o n Filter,

Fllter,

Ultra-violet

H e a d Tank,

T a n k , 5 Micron

Ultra-vlolet

Unit,

Sump.

Unlt, Incubating

Incubatlng Enclosure

Enclosure and

and Sump.

F i g u r e 3.

Figure

3.

Pre-system Filter

The

The Pre-system

Showlng the

the

Filter Showing

Stages.

Removable Stages.

Three Removable

4o

(Flgure 4),

(Figure

4).

eecht

25nil

nI capacity

capeclty each,

The

of 25

36 compartments

eomparsm€ntsof

rearlCIg trays,

wtth 36

The rearing

trays, with

(Ftgure 5).

5).

Nltex screen

ltcreen (Figure

bottm with

202 micron

uieron Nitex

are covered

eovered on

on the

wltb 202

the bottom

the system.

syst€n.

in the

are ten

co@partactrt8 in

are

l,ncubators and 360 individual

lndtvtdual compartments

een incubators

There

there

SeaS€3-

clrcul.tes

needle valves

valvee and

and circulates

regulated by needle

water exchange

wat,er

tneubators is

e:lchattge in

ln the

the incubators

ls regulated

eod.

opposLte top

top end.

from the

bottom end

one incubator

f,rom

of ooe

to the

the opposite

the botto

erd of

lucubator to

'lnto

feltre into

aad falls

Sea water

water from

manifold and

Lnto a coomon

conllon rnaulfold

Sea

the incubator

f,lons into

from the

lncubator flows

a 120-gallon

120-gal1on sump.

srryl.

!.e acti

acgl*

During

periods of

floet switch

$ttteh is

recireuLatl,ono a float

Durlng per!,ods

of recirculation,

head tank

tank

vated

prlrtp operation

watea to

to the

the head

returnlag sea

aea water

vaeed and

operat!.on for

for returning

and governs pump

erltch

Duringssrna8,er

see-waterrep!,aeenent

replacementtbc

thefloat

float switch

bypasstng the

bypassing

the pre-systeo

pre-systemf!,lter.

filter. Dur!.ng

overflm

tbrough an overflow

is deactlvated

deactivated and sump

water spilis

the system

systeo through

ts

out of

of the

srry rrater

sptlle out

ptpe,

pipe0

gallon-per.ainute

tmlt

The

pumptgis aa Vauton

CC-T6OA

unit rtsh

with hypalon

hypilon

Veatoa CG-T60A

ten tengallon.per-eiinute

The prry

poLyethylene sea-water

and

and polyethylene

6ca-sat€r components.

coqronents.

,.poXtAll p*pe

pipe end

and val,ves

valves are

are nade

made of

of..poly.

Al.1

(PVC).

vinyl

vlayl chloride

chlor{,de (PVC)0

bl,oeeeayed

uere bioassayed

coostructtron were

Samples

materials used

$anryles of

used in

{,n system

of all

sys8ea construction

a!.1 unaterials

poeslble sources

rl,th

of, toxicity.

torl,c{ty.

with mussel

ellalnate possible

aources of

russel larvae

lervae to

to eliminate

cry.rtnent,

rearl"ag tray

tray compartment.

During

was held

he!.d in

each rearing

ln each

Durlag operation,

opersttona one

lerva raE

oB€ larva

Frlday'

tfednesdayr and

and Friday.

Cleaning

feed!.ng was

wes conducted

every Monday,

Uoaday, Wednesday,

Gleanlng and

and feeding

eondueted every

A

calibrated

pipette was

was trsed

used to

to dlspensc

dispense food

food assuting

assuring aa ual,fom

uniform

callbrated automatic

autmatfc plpette

amount

eaeb larval

Lanral container.

eontatosr.

aaount to

to each

control sas

was aot

not ueed,

used, but

but

A temperature

eeryrereture control,

g€ryeratuf,cg and

nonl,eorlng

by monitoring

reagonsble limits

ti,utts by

temperatures

rlthl,n reasonable

and salinittes

sel!.nltlea were

rere held

held within

tfrcn sea-water

sea-reter

replet ehtng the

systen when

the laboratory

the system

the

leboratotlr sea-water

sea-rater supply

and replenishing

erryply and

quality

was acceptable.

qnratlty ras

acceptsble.

The

were cleaned

cleaned ae

as regltred3

required; af,ter

after

sere

ftltere

The system

systen filters

passed through

750

stem fllter

filter and

and trtca

twice a

a reek

week for

for the

the

gallons passed

pre-systen

750 gallons

the pre-sy

througb the

Pilterite

Fllterite filter,

filter.

nl

rom in

250 ml

A few

conttol room

l,n 250

A

f€nr larvae

uere held

lanrae were

hcld in

*n aa temperature

teryeratuae control

(f,lve per

per flask)

175 nil

Erlenmeyer flasks

nl of,

of aea

sea rater.

water.

f,laelc) containing

flaoks (five

contelntag 175

Erlemeyer

Cleaning

Gleenlag

rear{Bg system

sched$le'

of flasks

Bysten schedule.

fl.asbs and

feedtng larvae

!,anrae followed

f,ol!.owed the

tbe rearing

aad feeding

of

:

5..

5..

/

I

Figure

F i g u r e 4.

4.

Arrangement of

Arrangement

of the

the Incubating

Incubating System

System Inside

Inslde the

the

l^Iaterbath.

Covered

Covered Waterbath.

F i g u r e 5.

Figure

5.

Detail

D e t a l l of

I n c u b a t l n g Tray.

Tray.

o f an

a n Incubating

6"

RESIILTS

SRESULTS

and

tnvestl,gator posltton

of, delayed

delayed filling

of,

the prlnclp€l

Because of

ff[fug

Because

of the

principal investigator

position and

E&oe requ!,red to deaign a,ad coastnrct

trere aval!,ab!,e for eryertmenaatlon

provtded flrst

the systen,

gravld

fc

?bree seParats batches

ef,ter Uarcb 1,, 1966.

zoee crab lanrae f,or !.alttal

rearlng

Dnagelre8s.,€r8b8

hagch oa Harch 9, [966, 288 zoea nene placed {.n the rearing

the ftrst

8rm

atGqtte.

systeor btrt e very

Zoes

htgb bateh{,ag aoorta!.fty was evl.dent befsre the soea were co&lestedo

ppti teaperature

wac not

not con

coat'€!ryterature was

29 to

33 ppt;

ra4gl,ng fron

frena 29

to 33

ranging

were held

hetd at

aE salinities

salla{ttee

above 56 F rere rareo

elalmtngly

aad after

experLnent lndtcated

f{rac

5

belqt

46 F to 58 F, a.lthougb fiuctuatlons

aad ranged frm

trotlsd

Br{ne *hrlry

srese used for food.

eeur deyc less thac f0% rere allve

$urrrlvel

(Flgure

that good eirrr!,vat ras poeatble vlthoue

week of, lncubatton.

f,aceoa,

dcelnatlng factor,

as the

the decinating

Tbereforel

pooE vl,abtlf,ty

50 F and

dro,pped

6-A).

A lsGer

feedtng durlog the

of Lanvae Bas suepectQd

At 65 days

all tbe

the larnrae

larvae had

had dfed

died and oly

only felr

few

daye aLL

At

soeal stage0

fouEtb sceal

attained

the fourth

atag,€"

attal,ned the

for aa short..term

abott-t€tu

ras used

used for

[966 and

end was

A second

Apu{l 9,

9r 1966

oeeurred on

on April

A

hateh occurred

sacmd hatch

seudy of food auitabtlity"

rnakeabl,fe t€ryeratuae

The aoea were laeubated ln 200 nt gl'ase Jars ln a

bath, but overflotr

to-e e8{rertn€nt prematurely,

of an adJacemt water tsn]

Resulte 8$gg€st lluogenees crab zoea een suw{ve

seven days wtebout, food and that barnaele netpltd

f,ood for

t€talosted

of,fer EubgtanBial pro.iee

as

earty goeal ategeso

144 of

of these

tbeee

20r 1966;

The

on April

Apr!,l 20,

1,966; 144

socs on

grav{,d feuale

fepale produced zoea

flnal gravid

Tbe final

-sere

ln

flaeks in

Erlemeyer flasks

were incubated

rearing aysS€n

system and 30

30 rrere

were set

set ln

in Erlenmeyer

ln the

tbe reerlng

ineubsted in

ro@.

the

control

€otrtrol room,

Bhe tei,erature

tqreratuae

naupll,i.

fed barnacle

barnacle nauplii.

All

were Led

AlL zoea

zoea were

Temperature

Teryercture

pptr

to 33 ppt,

to 58 F and

and 32 to

and salinity

ranges

lrystem were 50 to

for the

raoges for

reardng system

tho rearing

eallolty

ond

reepectl,vety.

respectively.

ln the

c,otrollad

the controlled

!,apae incubated

!,acubated in

The

€or larvae

respect!,ve inforsation

{nforsatlon for

Ete respective

ppt,

34 ppt.

eo 34

and 31 to

temperature

was 60 to

ro@ sag

to 64

64 F and

egryreraturc room

goea inculnsuSurvival of,

of the

the zoea

Sunrlval

but

bated in

rearing syst€s

system rras

was ellght!.y

slightly be8ter

better tban

than the

the first

first att€ry8!

atteit, btrt

the rear!,ag

bated

&n the

4

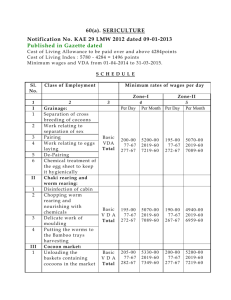

70

TO

.

B

€

fi 100

*

*Bo

,!i

E@

#

F{

g

.

Traneferred

Higher Scqleaturc

Temperature

llhnsfe*zeil to

to E{.eb*

40

r{

H20

tn

$0

ct

B

&

S.

ival Pwtblc

Possible

t&,rd.w tutrlvet

nibe1iea

WttJaoutemlbnf.i@

4'

10

10

Figare

F-tgtro 66"

20

20

30

fr

40

40

50

50

60

50

Age

in Ihya

Iys

Aep f-a

70

80

80

?o

100

90

9o1m

Survival

of Teaious

Variowi lots

Lots of,

of hggucse

Dungeness Csb,

Crab IerlnOr

1rvass

SurtuEl of

iloe, Ratøhed.

288

Msreh 90

9, 3;966

1966 end

end Scasoil

ieared t{ttht

Without

288 Zoem

&t€beil !{a.roh

SourtroLt

Tempirature

Ssfroud;&sa Control;

RGerlgAUt&.nrt

Hatched Aprii

April 20,

Without

2Oo1966

L956 end

snd Reared

zoes,Uotohoti

]-44 Zöem

B.

Be 144

Dayst

25 Duye;

Rlrat 25

Temperature

Cmtrol for

for the

thc First

llle$uleuatareControl

0stnotlcd

Zóa Hatched

eerdt at

et COatrolled

No 1966

1966 end

enil Reared

April 20,

HatobettApril

C0

C " 30

n Zw

Temperature0

Teu;leuraturc"

A.

Ao

So

days

f,{rst ten

ten days

the first

40%survived

About 40%

surv{,ved the

rdas

di,seppotnctng (Figure

6-ts).

sef.[!. disappointing

was still

{Ftgure 6-B)G

bue by 25 days

but

days only

only 3.0%

10% r@al.ned.

reained

tryeratuBes

The zoea

zoea lncubateri

incubatedatathlgher

1igher

teratures

were h!,gh!.y sueeessf,ul--af,Ber a aonth of rearf,og 50% were al{,qta and hee!.th!'y

(F{,gure 6-C),

Ao ln{,tlal

slrry

!,n survl.val was expected due to eryosure to

a uew enwi.rocaeneo ?he s!.i,gtra drop fn surv!,val between 4O and 5O days nay

have been due to metenor?boeis frcm gbe f!,f,th zoea Eo the aegalops.

Af,8er

50 days vtrrtuat!.1r atrI morbelf.ty was due eo eannd.bal{sreen iroa-trart fomed

aoea by aegalops,

Bed eb*s faeeon been e!.i.nlnaued by tsola8{on,

aurvlval

&evels pay hav€ eceeeded 25% through the negal.ops stage (F{,gure 6-er doteed

ltne).

Based os! the above suec€s$p aoea Ssoo abe reer$,ng syetsa were tre$a-

feared eo hlgher rry€raeurea

reduced (Fi,gure 6-9),

sEr Ehe 25th day aad mortal!,ty sae lmedlately

Lerva& Dungeness erab have been sueeeasfuL!,y eultuted

frou ehe egg (Ftgure 7) througb flve

asea1 otages (Ftguse 8), the mega!'ops

shage {Stgure 9}, end fnto the selreneh {nscar or sedmtary

Juvenlt e erab

(F$gure trO),

trecent

by 11nited

!,lnteed success,

succcas, recent

Although

narked by

were marked

rear*ng attempts

acterySa were

AS.choughearly

eartry rearing

stageso

Resulte

veeEuses have resule€d ,,& good survtval

ehlrcugh an1 lawal

are eneouraglag ead s$s8al.a aepfrat*oas

€sr tea8a of, envlromenEaL eff,eeEe

oa !,arva3. grCIEEt! and sucvnva!, attendan8 s{th pero!.ssibl.e nortal!,By rates.

F3.ansare bei.ag foroautated for next season€ crab batetr (Oeeobea;l{arch}.

A&though ref,i.nement of, reari.ag techs,{.ques wtll

be the forsnoeg const'deratlon}

experlmeuts !.mrslvtng the ecrnblaed ef,fects of, SryeraLuae

be*ag desigaed Eo esSf,aage Sotrerasrcetlmfts

&asva3,stage.

and salr,ni,ty are

for theee fac8ors dur{ag eaeh

9.

9.

.

S

F i g u r e 7.

7.

Figure

Eyed Egg

Attachment Stalk,

Egg of

Cancer magister

wlth Attachment

Sta1k,

Eyed

of Cancer

gster with

Two

Two Weeks

Weeks Before

Before Hatching.

Hatching.

,j1

Figure

F

i g u r e 8.

B.

magtster.

C a n c e r magister.

First

Z o e a of

o f Cancer

F t r s t Zoea

10.

10.

S

S

)o

F i g u r e 9.

Figure

9.

F l g u r e 10.

Figure

I0.

Megalops

M e g a l o p s of

maglst er.

o f Cancer

C a n c e r magister.

(flrst

Seventh Instar

magister

a g l s t e r (first

Instar of

of Cancer m

sedentary

s e d e n t a r y stage).

stage).