Document 11219566

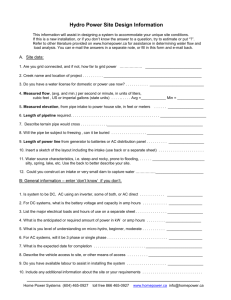

advertisement