A private sector case study from Thailand

advertisement

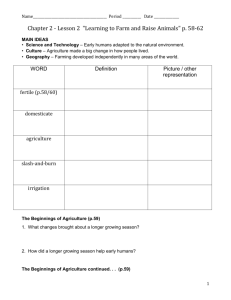

CASE STUDY Response by a company in THAILAND CASE STUDY KAMPHAENG – SAEN COMMERCIAL CO., LTD. • Established in 1993 as a packing house in Central Thailand, selling produce through exporter • Upgraded in 1999/2000 • Ships green asparagus, baby corn, and a range of other tropical fruits and vegetables by air to the UK, the Netherlands, France and Japan • Specialized in packed vegetables and fruits, including ready - to eat packages; direct sale to high-end retailers • Recently also sale to same retailers in Thailand • Most products sold under own brand name KC FRESH CASE STUDY Challenges and Response (1) Challenge • In late 1990s, with the emergency of BRC and EUROGAP, buyers in UK voiced that upgrading standards would become necessary Response: proactive and offensive strategy • Acquired land for establishing Good Agricultural Practice (GAP) • Upgraded all facilities, introduced HACCP, ISO 9001 • Extensive training of staff CASE STUDY Challenges and Response (2) Response: (continued) • Shortened supply chain and started direct export • BRC accredited in 2003 • After EUROPGAP was established, expansion of sales through contract farming • Sales increased from US$ 3.3 million in 1999 to US$ 8.5 million in 2003 • Expect 2004 US$ 11.5 million CASE STUDY System of Contract Farming • Supplier organizes farmers in groups, provides technology (GAP), provides input in kind, ensures compliance • All input use is registered daily • Farmers group has a small collection place, organizes collection, initial sorting, grading and coding • Rules of compliance strict with self-control by farmers groups and supervision by supplier ( Internal Audit) • End of 2003, 900 small farmers involved in contracts • Loyalty farmers assured by 25% higher price than local market price CASE STUDY Some characteristics of Asparagus production • Labor intensive crop, attractive for families with many family workers • 0.2 ha per family worker • Income per family US$ 5,000-10,000 for 0.2-0.4 ha • Compares to US$3/day CASE STUDY Own production base and contract farming • Cost of production on own production base 30% higher than in contract farming • Yet a stable 35% of sales comes from own production base; 65% from contract farming • Importance own production base: – basic security for meeting contracts – room for experimentation, benchmark information and demonstration CASE STUDY Some factors for commercial success • Daily or twice daily shipment by air to provide fresh product from farm to shop within 48 hours to Asia and 60 hours to Europe • Regular shipment allows for low negotiated freight rates • Relatively weak points in supply chain are: – Timely issuance of phyto certificates at export – Non-privatized cold chains at airport • Other companies experimented with somewhat different models, that also proved successful • After private sector proved success of contract farming model government became interested in supporting its expansion through a training program CASE STUDY WESTERN CLUSTER GAP • All small farmers under Western Cluster GAP will be accredited to the EUROGAP standard • Either by direct accreditation • PMO (Producer marketing organization) • Certification by a national scheme benchmarked to EUROGAP CASE STUDY The EUREPGAP policy covers the following issues : • • • • • • • • Traceability Record Keeping Varieties and Rootstocks Site History and Management Soil and Substrate Management Fertilizer use Irrigation Crop Protection • • • • • • • Harvesting Post harvest Treatments Waste and Pollution Management, Recycling and Reuse Worker Health and Safety and Welfare Environmental Enhancement Complaint Form Internal Audits