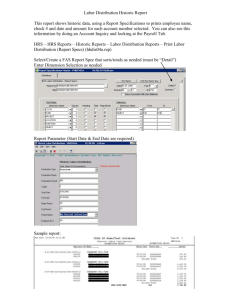

PRS-EE SPECIFICATIONS-Final2013R1

advertisement