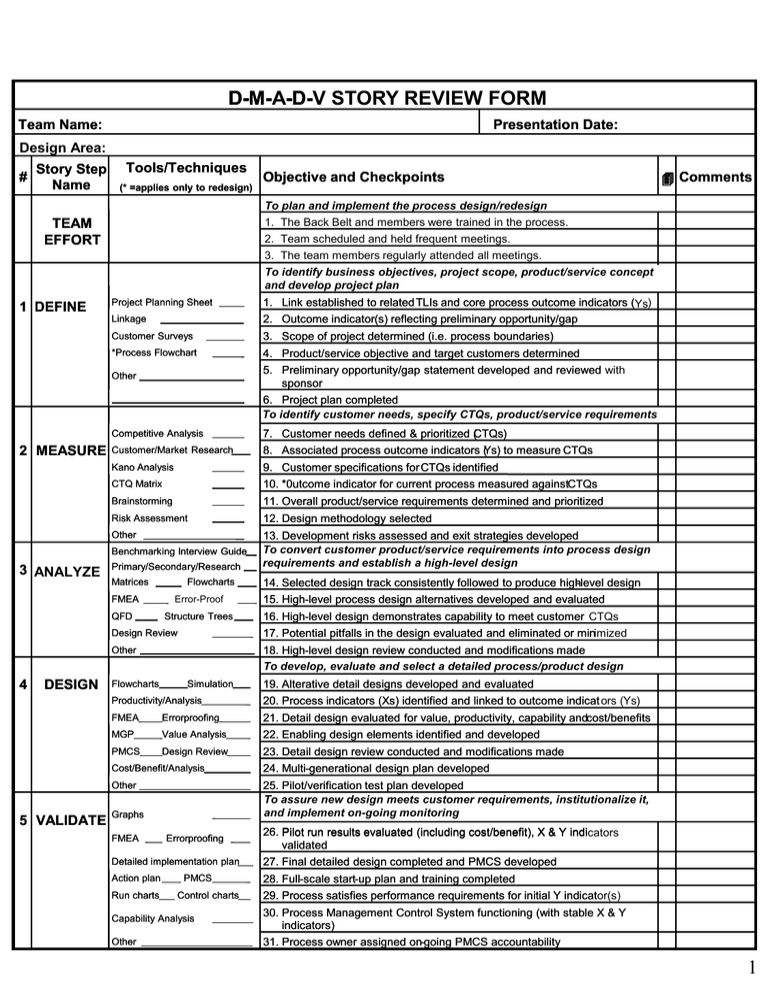

DMADV Checklist Template

advertisement

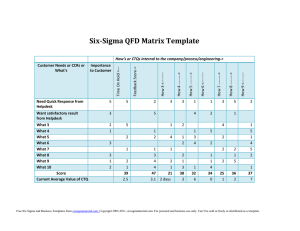

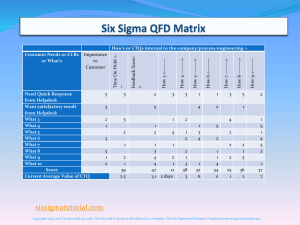

D-M-A-DD-M-D-V STORY REVIEW FORM Team Name: Presentation Date: Design Area: # Story Step Name Tools/Techniques (* =applies only to redesign) Objective and Checkpoints 4 Comments To plan and implement the process design/redesign 1. The Back Belt and members were trained in the process. 2. Team scheduled and held frequent meetings. 3. The team members regularly attended all meetings. TEAM EFFORT To identify business objectives, project scope, product/service concept and develop project plan 1 DEFINE Project Planning Sheet 1. Link established to related TLIs and core process outcome indicators (Ys) Linkage 2. Outcome indicator(s) reflecting preliminary opportunity/gap Customer Surveys 3. Scope of project determined (i.e. process boundaries) *Process Flowchart 4. Product/service objective and target customers determined Other 5. Preliminary opportunity/gap statement developed and reviewed with sponsor 6. Project plan completed To identify customer needs, specify CTQs, product/service requirements 2 MEASURE Competitive Analysis 7. Customer needs defined & prioritized (CTQs) Customer/Market Research 8. Associated process outcome indicators (Ys) to measure CTQs Kano Analysis 9. Customer specifications for CTQs identified CTQ Matrix 10. *0utcome indicator for current process measured againstCTQs Brainstorming 11. Overall product/service requirements determined and prioritized Risk Assessment 12. Design methodology selected Other Primary/Secondary/Research 13. Development risks assessed and exit strategies developed To convert customer product/service requirements into process design requirements and establish a high-level design Matrices 14. Selected design track consistently followed to produce high-level design Benchmarking Interview Guide 3 ANALYZE FMEA QFD 4 DESIGN 5 VALIDATE Flowcharts Error-Proof Structure Trees 15. High-level process design alternatives developed and evaluated 16. High-level design demonstrates capability to meet customer CTQs Design Review 17. Potential pitfalls in the design evaluated and eliminated or min minimized Other 18. High-level design review conducted and modifications made To develop, evaluate and select a detailed process/product design Flowcharts Simulation 19. Alterative detail designs developed and evaluated Productivity/Analysis 20. Process indicators (Xs) identified and linked to outcome indicat ors (Ys) FMEA Errorproofing 21. Detail design evaluated for value, productivity, capability andcost/benefits MGP Value Analysis 22. Enabling design elements identified and developed PMCS Design Review 23. Detail design review conducted and modifications made Cost/Benefit/Analysis 24. Multi-generational design plan developed Other 25. Pilot/verification test plan developed To assure new design meets customer requirements, institutionalize it, and implement on-going monitoring Graphs FMEA Errorproofing 26. Pilot run results evaluated (including cost/benefit), X & Y indicators indi validated Detailed implementation plan 27. Final detailed design completed and PMCS developed Action plan 28. Full-scale start-up plan and training completed Run charts PMCS Control charts 29. Process satisfies performance requirements for initial Y indicator(s) indicat Capability Analysis 30. Process Management Control System functioning (with stable X & Y indicators) Other 31. Process owner assigned on-going PMCS accountability 1