j_ICM2013-07100535_710_140114153230

advertisement

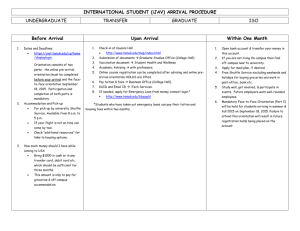

Shipping Service Optimization in Pars Petrochemical Port-Assalouyeh with Using Queuing Theory and Simulation Mohsen Parhizgar (Author) Department of Management Science and research branch, Islamic Azad University Shiraz, Fars, Iran Parhizgar2000@gmail.com Dr. Mohammad Ali Soukhakian Department of Management Science and research branch, Islamic Azad University Shiraz, Fars, Iran Dr. Javad Gerami Department of Management Science and research branch, Islamic Azad University Shiraz, Fars, Iran Abstract Nowadays, integrity of supply chain processes (suppliers, producers, terminals and etc.) is one of the most important ways of improving supply chain processes. Meanwhile petrochemical industry due to production and combination of different materials need a very complex logistics processes. Therefore creating a balance between different production and service units in the process of production, storage and distribution is of high importance. Ports with various capacities and various vessel berthing and un-berthing patterns increase the complexity of petrochemical supply chain and logistics process and subsequently will affect severely the balance of terminals and vessel. In this article, ships long standing time, queuing length, ship and terminal costs have been studied in Pars Petrochemical Terminal which is located in Pars Special Economic Energy Zone. For studying current system and designing new improved system, with regards to logistics container management process compliancy, a simulation program and queuing theory are used for this propose. At the end by designing and implementing of model in ARENA software, the results of implemented simulation by study of alternatives have been analyzed. Finally, current optimization leads to increase efficiency in Pars Petrochemical Port and petrochemical industries supply chain cost in Assalouyeh. Keywords: Queuing theory, Simulation, shipping service, transportation, assalouyeh pars petrochemical port 1. Introduction The organizations must improve the effectiveness of its quality management system continuously, through the use of quality Policy, quality objectives, audit results, data analysis and corrective and preventive actions and also management review [3]. Xu Jing Jing (2012) in his article entitled “Queuing Models to Improve Port Terminal Handling Service” writes: The cost covering handling services is composed by fees covered handling mechanical services and unpaid waiting expenses refer to the board-to-bank loading and unloading [21]. 1.1 Queuing theory: In a simple definition, queuing theory is the science of analysis and management of the waiting lines or the same Queue [13]. Queuing systems are ubiquitous in the real world and can play an important role in the design of the systems, including waiting time and planning for services [7]. 1.2 Simulation: The simulation process is applied to the modeling of a process, a phenomenon, or the actual system [12]. Today, for modeling the production systems, a set of methods have been developed one of which is simulation. The simulation is a method that defines, a case which has the probable condition and loss of confidence in variables and parameters, and then gives a model to determine the characters of the time variable [15]. the simulation discuss about the models of the complicated systems which produce acceptable output and can lead to acceptable solutions [9]. 1.3 The relevant variables: The following variables can be examined, for the measurement and analysis of the port data [13]. 1. Average arrival rate of the ships to the port 2. Average arrival rate of export cargo to the port. 3. Average rate of servicing to the ships. 4. Average of the ships stop in the queue (Lq) 5. Average of the ships stop to receive the services. 6. Average of waiting time in the queue. 7. Average of waiting time to receive services. 8. Length of system (Average number of customers in the systems) 9. U: Equipment Efficiency Coefficient (average number of hours for the availability of the equipment) 10. The total cost of the system in this paper consists of four parts, which are: The costs of the port personnel, ship personnel cost, the ship waiting cost and nonworking costs of port equipment. Thesis of Mehrdad Najafi (2010), has predicated the number of jetties and gantry cranes to the reform of the existing container terminal at the port Martyr Rajai for 10 years [14]. Another study performed in 2009, is the thesis of Karim Zandi, entitled “Optimization of how serving the hospital patients, Using queuing theory and simulation” in the Shiraz Martyr Motahari hospital. In this paper, on attempt has been made to use the simulation and its data for the optimization in order to reduce the waiting time [11]. Also, Saeed khanaze dari*; Omid Bagheri ; Ali. Bayat; Mohammad hossein Taban and Babak, Salek Mehdi (2011), in their article, have showed: How the simulation optimizes, the transport way of the dash board to the assembly line by the fork lift and also how much is the amount of the successes as the result of the choosing the proper transport way In Pars – Khodro company [5]. Majid Azadi khah* ; Mehdi Jamalzadeh ; Omid heidary; Hamed Sohrabi and Sajad Shokhouhyar (2011) in their article, have reached the optimal number of paint color buffer in the Pars – Khodro company with using simulation ARENA software [2]. Amir Azaroun, and Farhad kianfar (2001) in their article, have studied using on algorithm to select the shortest path in networks of queue in steady state [1]. A. Nabi. Rahimi Fard, in his master thesis, with using queuing theory, has examined Tehran traffic and has told some suggestions to optimize it [6]. Chen, Laih (2012) in his article, has studied the connection between the pricing of the terminal services and the queue length regarding the queue cost for the ship owners and also for the good owners [16].Senay, Solak; John , paul, B. Clarke, and Ellis L. Johnson (2012) In their paper with the simulation of the entire airport, could increase the airport efficiency and could help the managers to make decisions about the development of old terminal or the construction of the new one [20].David. Lovell, in his article shows a structure to compute continuum approximation of a queuing system, such as airports, high ways and … in a national system [17].Also, Joseph I. Daniel (2008) in his article, using the simulation has studied the delays in the major international airline companies in 27 different airports. He could optimize the selling price regarding the delay, with the help of simulation and its output [18]. 2. Definition of the Case Due to the increasing growth in containerized imports and exports, in the west of asia and Iran, this type of transport is very important after extensive study, a conceptual model of the terminal was built, to make clear the aim and limit of the subject. This model is visible in Figure 1. Figure 1 (conceptual model of the case) According to Figure 1, when the ships arrive in the assalouyeh off shore area, they stop in the dock in coordination with Iranian PMO. Then the jetties become empty and ship is put beside of the berth. After unloading and loading completion, the ship will leave the port. On the other hand, the trucks move empty container to the containerized storage and the full container to the port yard. The process during 24 hours a day, two channels and one step service system, queue as FIFO, none group inputs and infinitely waiting lines are the assumptions. 3. Research methodology To use this model, The information about the arrival and departure of the ships and also other data were collected from the first quarter of the year 2011.then by using data analysis & EXCEL software, The required parameters were estimated by using this information and their distribution function and also with the help of input analyzer software, The required parameters of the queuing theory were studied. After ensuring about the accuracy of the generated model, by the use of Arena simulator software, Various Scenarios were defined and also each of them were studied. 3.1 Types of Scenarios: Scenarios with 2 jetties: 1: The amount of arrival of the trucks and ships in normal condition 2: 4 fold increase in the rate of the trucks arrival and 5 fold increase in the rate of the ships arrival. 3: 2 fold increase in the rate of the trucks arrival and 5 fold increase in the rate of the ships arrival. 4: 5 fold increase in the rate of the trucks arrival and 5 fold increase in the rate of the ships arrival. 5: 7fold increase in the rate of the tucks arrival and 5 fold increase in the rate of the ships arrival. 6: 8 fold increase in the rate of the trucks arrival and 5 fold increase in the rate of the ships arrival. 7: 9fold increase in the rate of the trucks arrival and 5 fold increase in the rate of the ships arrival. 8: 6 fold increase in the rate of the trucks arrival and 5 fold increase in the rate of the ships arrival. 9: 3 fold increase in the rate of the trucks arrival and 5 fold increase in the rate of the ships arrival. 10: 10 fold increase in the rate of the trucks arrival and 5 increase in the rate of the ships arrival. Scenarios with 3 jetties: 11: the amount of arrival of the trucks and the ships in the normal condition. 12: 4 fold increase in the trucks arrival rate and 5 fold increase in the ships arrival rate. 13: 2fold increase in the trucks arrival rate and 5 fold increase in the ships arrival rate. 14: 6fold increase in the trucks arrival rate and 5 fold increase in the ships arrival rate. 15: 3fold increase in the trucks arrival rate and 5 fold increase in the ships arrival rate. 16: 5fold increase in the trucks arrival rate and 5fold increase in the ships arrival rate. 17: 7fold increase in the trucks arrival rate and 5 fold increase in the ships arrival rate. 18: 8fold increase in the trucks arrival rate and 5 fold increase in the ships arrival rate. 19: 9fold increase in the trucks arrival rate and 5 fold increase in the ships arrival rate. 20: 10fold increase in the trucks arrival rate and 5 fold increase in the ships arrival rate. 3.2 Modeling and Simulation in the Arena software In the present case, the entry and output rate at random times, and their impact on the queue length and also the amount of effectiveness and the total cost, make it completely dynamic, so that its effective quantitative analysis only happens with the help of the simulation. For this reason, the creation of a simulation model to evaluate different solutions for optimizing the number of berth and the amount of the entrance and exit, and the analysis of their effects are inevitable. With the purpose of the modeling the case in this paper, the ARENA software has been used. ARENA is one of the software, which is used in the simulation of the discrete systems and uses the SIMAN language [19]. There are the following main sections in the designed model 3.2.1 The section of ships arrival and departure Logic - Arrival of Ships Time and conditions for Entrance A rrival of ships 0 Awaiting a position in the terminal port Organize arriving ships Mark E ntrance Time Go to the pier that is empty 0 N R( Terminal Port) <2 .AN D . ( CalH our( TN OW ) >0 .AN D . CalH our( TN OW ) <24) Figure 2: The designed model In ARENA. 3.2.2 The section determining the way of servicing to the ships Figure 3: the designed model in ARENA Figure 4: the designed model in ARENA 3.2.3 Section of the trucks arrival and departure Logic - Moving Trucks Moving trucks Entry U ploading C ontainer 0 0 Route 2 Departure D ispose 1 0 Figure 5: the designed model in ARENA 3.3 The data collection According to the designed model, the required data were collected from the process of the arrival an exit of the ships and the trucks. These data were collected for a period of 90 days. For each of the required data, the appropriate distribution function is used with input analyzer software– ARENA software. The statistical analysis was performed on data, in the time between the ship arrival and also the trucks. The distribution function chosen for the time between the arrival of the ships into the anchorage area is WEIB (30.9, 1.34) and the distribution of the time of the servicing to the ships is TRIA (0,8.75, 21) and also the distribution function of the total expected time in the system is LOGN (19.7, 28.5) 3.4 Model implementation and results: According to preliminary estimates, the cost is calculated as follows: The cost of a lost opportunity for ships (IRR/hr) A=27000000 (1) The cost of a lost opportunity for B = 63200000 (2) Ship personnel cost (IRR/hr) C = 1750000 (3) Terminal personnel cost (IRR / hr) D=1250000 (4) The total lost opportunity cost for the ship = A * Lq (5) The total lost opportunity cost for the terminal = B * U (6) The lost cost of the system = C + D + (B + U) + (A + Lq) (7) One of the Arena’s simulated model outputs is the coefficient of efficiency and the average waiting time in the queue. Based on the results of the designed model and the results of the implementation of the simulation model, the amount of the total cost different scenarios, is shown in Figure 6. Total Cost (IRR/hr) 700,000,000 600,000,000 500,000,000 400,000,000 300,000,000 200,000,000 100,000,000 18 11 3 1 19 8 10 15 7 14 20 17 16 4 5 12 6 2 9 13 Scenario No. Figure 6 Comparison of the system total cost for different scenarios. The results shown in Figure 6, tell that, the total cost in scenario 18 with 3 jetties has reached the minimum cost, so the total cost has declined 17%. 4. Conclusion In this paper, the process of loading and unloading of the ships, in the South Pars petrochemical terminal has been studied. The aim of this study is to determine the maximum efficiency of terminal equipment’s and also the average of the ships waiting time in scenarios in order to minimized the cost for this purpose, the simulation has been used to study this system regarding the complexities of the terminal processes. Finally, after designing and the implantation in the ARENA, the results of the simulation have been analyzed with the studies of the improve alternatives. Resources: [1] Azarun, amir; kian far, farhad , (1998). Algorithm to select the shortest path in networks of queues in steady state, engineering journal, 2 (35), PP181 – 190. Recovery from “Jahad Daneshgahi scientific information center”. [2]Azadikhah,Majid; Jamalzadeh, Mehdi; Heydary, omid; Sohrabi, hamed; Shokuhyar, Sajjad, (2011). simulation output in order to determine the optimal number of paint color frame buffer by using the ARENA software, “unpublished manuscript”. [3] Jalali, Ali; (translator) (2007). The integrated management system IMS. [27] TEHRAN: D.A.S. IRAN. [4] FARS News Agency. Pars petrochemical capacity of 30 million tons. 15 Jun 2011from http://WWW.farsnews.com/news [5] Khazane dari, Saeed; Bagheri, Omid; Bayat, Ali; TABAN, M.H.; Babak, S. Mahdi; (2011). Picking pride dashboard assembly process simulation software using ARENA, “unpublished manuscript”. [6] Rahimi Fard, A. Nabi; (1975). Application of queuing theory in Tehran traffic. “Master thesis”, institute of statistics, Tehran. [7] Soukhakian, M. Ali; (In press). Queuing theory, Shiraz; Fars science and Research University, school of management. [8] Terminals and tanks petrochemical company (n.d). About us. from http://ttpc.ir/index.aspx?siteid=1&pageid=148. [9] Shokouhyar, Sajad; (2005). Provide a model policy controls the supply chain work in progress (CONWIP). “Unpublished master’s thesis”, Amir Kabir Industrial University, Tehran. [10] Abedi, Sadegh; Hamidi, Naser; Parkhan, Mostafa; (2009). Probabilistic modeling in queuing systems using marcov chain with layout constrain. Quarterly management Journal, 8(22), PP.54-66, Tehran. [11] karim zandi, Masoud; (2009). How to optimize service to hospital patients, using queuing theory and simulations. “Unpublished master’s thesis”, Shiraz University, Shiraz. [12] Kelton, David; Saduski, Randal; stark, David; (2011). Simulation with Arena software (Bagheri Mohsen; Sibouyeh Ali; Hejazi Taha hosein; Trans.), Mashhad; publishing Farazyar (original work published 2006). [13] Modares Yazdi,Mohammad; (1991). Queuing theory, TEHRAN; Daneshgahi center of publishing. [14] Najafi, Mehrdad; (2002). Using queuing theory for estimating No. of containerized jetty in Shahid Rajaee port. “Master thesis”, Tehran Jonoob of Azad University, civil faculty, Tehran. [15] Banks, J., "INTRODUCTION TO SIMULATION", Winter Simulation Conference, 1999, PP 7-13. [16] Chen-Hsiu, Laih; Pey Yuan, Sun; (2012). Effects of the optimal n-step toll scheme on bulk carrier queuing for multiple berth at the busy port. Transport policy. [17] David, J. Lovell; Kleoniki, Vlachou; Tarek, Rabbani; Alexander Bayen; (2012). A diffusion approximation to a single airport queue. Transportation Research Part C. [18] Joseph, I. Daniel; Katherine, Thomas Harback; (2008). (When) Do hub airlines internalize their self-imposed congestion delays?. Journal of urban economics, 63, 583–612. [19] Rathmell, J., Sturrock, D.T., "THE ARENA PRODUCT FAMILY: ENTERPRISE MODELING SOLUTIONS", Winter Simulation Conference, 2002, PP 165-172. [20] Senay, Solak; John-Paul, B. Clarke; Ellis, L. Johnson; (2009). Airport terminal capacity planning. Transportation Research Part B, 43, 659–676. [21] Xu, Jingjing; Liu, Dong; (2012). Queuing model to improve port terminal handling service. Procedia systems engineering, 4, 345-351.