Effect of reducing variation in a product

more consistency and higher quality

How control charts' upper and lower control limits are determined

by the natural variation in the process

How process capability's upper and lower control limits are determined

by customer specifications

Fact about binding constraints

each has a shadow price

Types of Quality Tools

Fishbone diagrams, flowcharts, histograms, process capability, check sheets, Pareto charts, scatter plots, line charts, control charts, and run charts

Appraisal costs

Costs of activities designed to ensure quality or uncover defects

Prevention costs

All TQ training, TQ planning, customer assessment, process control, and quality improvement costs to prevent defects from occurring

Internal failure costs

Costs incurred to fix problems that are detected before the product/service is delivered to the customer

External failure costs

All costs incurred to fix problems that are detected after the product/service is delivered to the customer

X bar chart

Mean control charts; used to monitor a process' central tendency

R chart

Range control charts; used to monitor the process dispersion

How to Interpret a Range Chart

If the points are all inside the limit, the process is in control.

P chart

Control chart used to monitor the proportion of defectives in a process

C chart

Control chart used to monitor the number of defects per unit

Fact about stable processes

Even if their process control charts say they are in control they can still be incapable.

Quality Assurance Phases

Acceptance Sampling, Process Control, and Continuous Improvement

Acceptance Sampling

Inspection of lots before/after production

Process Control

Inspection and corrective action during production

Continuous Improvement

Quality built into the process

Flowchart process step

Rectangle

Plan-Do-Check-Act Cycle's inventor

W. Edwards Deming

What to do if a process is not capable

Reduce variation

What to do if a process' CP is capable but its CPK isn't

Center the process

Best Process Indicator for capability

CP because it indicates whether the process is capable

Pareto Effect; important few and trivial many concept

Only a critical few inputs have a significant impact on output; concentrate on those; 20-80 effect

Process improvement

A systematic approach to improving a process

Process improvement's goals

increasing customer satisfaction, achieving higher quality, reducing waste, reducing costs, increasing productivity, and reducing processing time

Transportation model assumptions

The items to be shipped are homogeneous, shipping cost per unit is the same regardless of the number of units shipped, and there is only one route or mode of transportation being used between each origin and destination

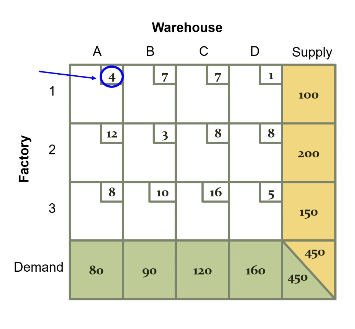

Cost to ship a part from Factory 1 to Customer A

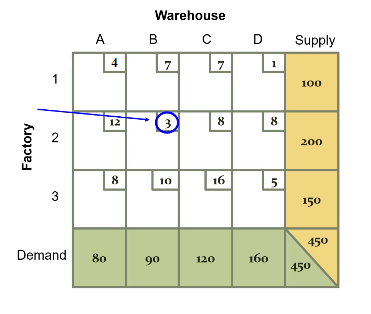

Cost to ship a part from Factory 2 to Customer B

Numbers in the corner boxes in the transportation problem

Costs

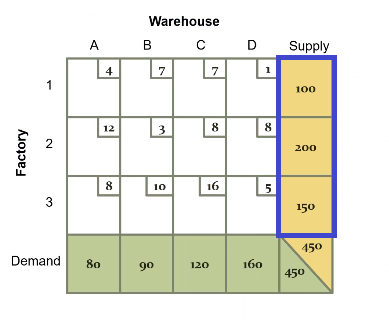

Transportation Problem Supply Constraints

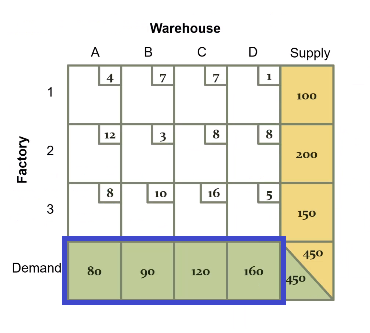

Transportation Problem Demand Constraints

Transportation Problem: type of problem that uses minimization

Cost Problem

Transportation Problem: How to write the objective function for one line

Start by writing "Min." Write the costs in front of the X's, write the factory number as the first digit in the X's subscript, write the warehouse letter as the second digit in the X's subscript, and separate the variables with plus signs.

Transportation Problem: How to write the objective function for the entire grid

Start by writing "Min." Separate each line with a plus sign, either written before or after the line.

Allowable increase

amount to which the objective coefficient in question could increase and the decision variables will still be optimal