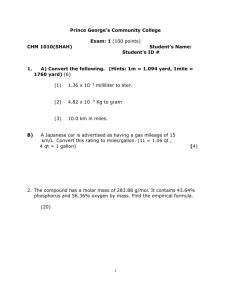

PowerPoint-Präsentation

advertisement

Methods of phase equilibrium study in ceramic materials Control of oxygen partial pressure Examples of using phase diagram for ceramic materials Al2O3-GdAlO3 DSE Al2O3-YAG-ZrO2 DSE Al2O3-YAG DSE Al2O3-GdAlO3-ZrO2 DSE Experimental methods to construct phase diagrams for ceramics Sample preparation Solid state reactions Starting materials are oxide mixtures and/or oxy-salts (e.g. carbonates). When heated oxy-salts decompose forming oxides and gas products released from sample. The starting powders are mixed together by grinding in agate mortar with small amount of acetone or alcohol. Automated milling can be also used. Co-precipitation (for slow-reacting oxide system) Starting materials are salts (e.g. nitrates , dissolved in water or mineral acids). Elemental analysis should be done to control composition (ICP-OES). NH4OH is used for precipitation of hydroxides. After drying to remove most of the water, the samples are calcined to form oxide mixture. Other sol-gel methods including organic substances. Pyrolysis is necessary to destroy organic materials. The mixed powders are pressed into pellets and heat treated at desired temperatures. Pt-crucibles or foil packets are recommended. Sample characterisation: XRD, SEM/EDX, EPMA Experimental methods to construct phase diagrams for ceramics Furnaces: Ni-Cr heating elements up to 1200°C, SiC – up to 1600°C, MoSi2 – up to 1800, ZrO2 – up to 2050°C in air C (graphite) heating elements in vacuum or inert atmosphere - up to 3000°C. Temperature control – Pt/Pt-Rh thermocouple, pyrometer at high temperature > 1700°C Scheme of vertical quench furnace Modification of quench furnace to control atmosphere Experimental methods to construct phase diagrams for ceramics Oxygen partial pressure control When heated under isothermal condition M/MOx mixture will exchange oxygen with the carrier gas until equilibrium pO2 is established according to the following reaction Scheme of using metal/metal-oxide buffers to control oxygen partial pressure Buffer gas mixtures pO2 depends on CO/CO2 ratio and temperature Phase and compositional analysis Visual inspection can provide information if the sample was melted or partially melted, if there was reaction with crucibles. Cracking or crumbling may signify unquenchable transition. Optical microscopy in polarized light can be helpful in identification small amounts of second phase. It can be confirmed if equilibrium conditions were achieved. (1) immersion method (powdered sample is immersed in the liquid with known refractive index ; crystal optical properties and refractive indices can be determined); (2) thin section method (morphological structure, melting and crystallisation behaviour); (3) polished section method in reflecting light microscope. X-ray diffraction is the most common method to determine phase assemblage of ceramic system. Phase fractions, lattice parameters and grain sizes can be determined by Rietveld analysis. The corresponding software generate theoretical diffraction pattern based on atom positions and site occupancies. This way X-ray pattern of the solid solutions can be fitted. Every peak should be assigned to a phase and indexed. Electron microscopy SEM/EDX and EPMA play important role in construction of phase diagrams in combination with XRD. Microstructure investigation can identify if sample was equilibrated, partially melted. Phase compositions can be determined by EDX or EPMA. Quantitative analysis requires relatively large grains, larger than sampling volume of electron beam. EPMA require to use standards, which are the best if they are similar to the system under study. Example: Ga2O3-In2O3-SnO2 system XRD can be used to determine phase compositions: XRD for single phase samples to plot unit cell volume vs. composition b. (Ga1-xInx)2O3 c. (Ga1-xInx)4Sn2O10 Graphs are used to determine phase composition for two phase sample (p) and threephase sample (q) Lattice parameters can be calculated using Rietveld analysis Identification of a new phase Compositional analysis using EPMA is necessary to prepare phase pure sample. Single –crystal X-ray diffraction is preferred method for structure determination, but Rietveld analysis using XRD powder diffraction or neutron powder diffraction data are increasingly applied for structure determination especially if single crystals are not available. Single crystals for XRD should be ~0.2-0.5 mm. Such crystals can not grown by solid state reactions; growing from the melt is necessary. If the liquidus temperature is too high then suitable flux can be used (flux is a substance which form homogeneous flux from which desired phase can grow). Flux-grown crystals should be chemically analysed to identify possible contamination. Rietveld analysis requires a starting model that include lattice parameters, correct space group and approximate atom positions. Alternatively, unit-cell information can be also obtained using electron diffraction data obtained for polycrystalline samples using a transmission electron microscopy (TEM). Thermal analysis DTA-TGA For ceramic materials DTA is also used to study melting, crystallisation, chemical reactions and polymorphic transformations. Heating rate normally used for ceramic materials is 10 K/min. Lower heating rate can result in broad shallow peak difficult to interpret. Faster heating will result in narrow peaks but may not represent equilibrium temperature of transformation. Pt-crucibles are usually recommended to study ceramic materials up to 1700°C. To study transformations at higher temperatures W-crucibles can be used. Crucibles with lids or sealed crucibles can be used to avoid contamination of sample (e.g. La2O3 by C from the vitreous carbon furnace protection tube) or in case of foam formation to keep liquid inside the crucible (e.g. MgO-Al2O3 system). When sealed crucibles are used, influence of pressure should be considered. In case of ceramics the samples are usually not melted before DTA and do not have fine eutectic microstructure. The heat treated sample of eutectic composition can have large grains of phases. That is why peaks on heating can be not so sharp as expected for eutectic reaction. Eu2O3-Al2O3 system: sample 24%Eu2O3-76%Al2O3 XRD Al2O3+EuAlO3 (EAP) Example: ZrO2-Eu2O3 Sample #2 66.67%ZrO2-33.33%Eu2O3 (Eu2Zr2O7) Tcor=2128 K ( HTXRD (lit.) 1997 or 2273 K) Sample #4 20%ZrO2-80%Eu2O3 Tcor=2155 K XRD 1873 K SEM/EDX heat treatment 1773 K, then 1923 K TGA: thermogravimetric analysis TGA measure mass loss or gain with temperature and/or oxygen partial pressure. TGA can be used to investigate red/ox reactions in M/Oxide system and decomposition reactions accompanied by gas formation (e.g. CaCO3CaO+CO2 (gas)) Calculated phase diagram of the Mn-O system 778°C 3Mn2O3 2aMn3O4+0.5O2 1167°C aMn3O4 bMn3O4 1458°C bMn3O4 3MnO+0.5O2 pO2=10-2 bar Thermogravimetric analysis. Example Fe-O system Calculated potential diagram of the Fe-O system Experiment of Kitayama et al. (2004): Fe2O3 was equilibrated at 1100°C (1373 K) using various gas mixtures CO2/H2 and CO2/O2. WT is total weight gain from reference state (logpO2=-15 pure Fe) to Fe2O3 1 bar of O2. WO2 is weight gain from reference state of pure Fe to present p(O2). XRD is widely used in conjunction with TGA to identify phases before and after mass change. Coulometric titration After heating in vacuum the chamber is sealed and sample is equilibrated. According to Nernst equation: E is measured potential, pO2 is oxygen partial pressure inside the chamber, pO2 ref – outside the chamber. After recording of pO2 oxygen is admitted or removed by driving of current though YSZ (oxygen sensor). The amount of oxygen pumped is recorded (dx) and sample is equilibrated again. This way partial oxygen pressure is recorded as function of oxygen content. Plateaus correspond to decomposition of phase. High-temperature X-ray diffraction and other in-situ methods HT-XRD is very useful tool to identify phases that cannot be retained upon quenching and to study reactions under varying temperature and oxygen partial pressure conditions. The technique is often used in conjunction with DTA, which provide more accurate measurement of the transition temperature. Diffraction data can be collected at temperature below and above transition temperature to provide information about structure of phases. HT-XRD also can be used to determine transformations which can not be detected by DTA. High temperature diffractometers with volume heating are now commercially available with heating up to 1200 °C. Custom-built system allow measurements under control atmosphere up to 1600°C. Thermo-microscopy (hot-stage microscopy) can be conducted in dynamic or isothermal modes to monitor a variety of physical changes such as melting, crystallisation, decomposition, oxidation and even crystal transformations. In-situ measurement of electric, dielectric and magnetic properties can be helpful to identify phase transitions which can not be found using DTA. Because the electric properties are highly dependent on microstructure and defect chemistry they are usually used in combination with other in-situ methods. Directionally solidified eutectic ceramic oxides - in situ composites Melt growth composites prepared by unidirectional solidification of oxides have advantages compared with sintered oxides or ceramic matrix composites. Al2O3-based DSE with minimum interphase spacing and free of large defects showed excellent mechanical properties up to temperature close to melting point as well as outstanding microstructural stability and corrosion resistance. DSE ceramic oxides present important advantages for high temperature structural applications. Also DSE present interest for optical, electronic and magnetic applications. The main functional applications are aimed at: The used of DSE oxides is envisaged for a new generation of gas turbines operating with inlet temperatures as high as 1700°C. The applications could be vanes, hollow non-cooled nozzles, eventually turbine blades and in the combustion chamber, liner panels. Oxide eutectic systems Al2O3-based eutectics presents interest because of outstanding creep resistance of sapphire along the c-axis in combination with other oxide properties create new family of ceramic matrix composites with exceptional thermo-mechanical properties. In particular, binary, pseudo-binary and ternary eutectics in the system Al2O3-ZrO2-Y2O3 were explored in detail following phase diagram for this system experimentally studied by Lakiza and Lopato (1997). This includes Al2O3/Y3Al5O12 (YAG) , Al2O3/ZrO2 and Al2O3/ ZrO2(Y2O3) DSE. The addition of Y2O3 to Al2O3/ZrO2 leads to pseudo-binary eutectic in which different ZrO2 polymorphs (monoclinic, tetragonal or cubic zirconia) could be obtained by changing Y2O3 content. Ternary eutectic Al2O3/YAG/YSZ further improve excellent mechanical properties of their binary counterparts. In addition rare-earth aluminate-sapphire Al2O3/RE2O3-Al2O3 are eutectic composites made up by sapphire in combination with perovskite REAlO3 for Sm, Eu, Gd or garnet RE3Al5O12 for Y, Yb, Lu. Al2O3/YAG DSE Al2O3/YAG/ZrO2 DSE Oxide eutectic systems Al2O3/GdAlO3 DSE Al2O3/GdAlO3/ZrO2 s.s. (F) MgAl2O4/MgO – MgO crystalline fibers embedded into spinel matrix, MgAl2O4/Mg2SiO4 MgAl2O4 fibers within Mg2SiO4 matrix ZrO2-based eutectics - NiAl2O4/YSZ is highly ordered colonies of YSZ fibers in hexagonal arrangement embedded in NiAl2O4 single crystal matrix and Ni nano-particles produced by reduction of NiAl2O4. Lamellar NiO/YSZ, CaSZ/CaZrO3 well-aligned lamellae, fibrous MgO/MgSZ is hexagonal array of MgO fibers embedded within a MgSZ single crystal matrix, lamellar NiO/CaO, NiO/Y2O3, NiO/Gd2O3 and fibrous NiO in NiAl2O4. Microstructure and crystallography TE DT T0 Crucial point leading to specific microstructure is coupled growth of two (binary) or three (ternary) phased from the melt. Coupled eutectic growth T avoiding dendrites is complex process implicating numerous phenomena. Lamellar growth is considered for simplicity. Lamellae grow unidirectionally l side by side and perpendicular to the planar growth front (solid/liquid interface). If phases grow separately then long range diffusion is necessary At the point of three phase junction the curvature of solid phases in contact with to insure solute transport in the direction of growth. Solid phase a will liquid (solid/liquid interface) is determined reject in the liquid atoms corresponding to phase b and vice-versa by condition of mechanical equilibrium of (diffusion coupling) thus leading to a diffusion flux parallel to growth the interface forces a/b – gab, a/liq – ga front. The eutectic growth is largely governed by diffusive mass b/liq –gb known as capillarity effect. transport. These two phenomena diffusion (through the mean solute undercooling) and capillarity (through the mean curvature undercooling) are the main factors contributing to DT (undercooling ) T0<TE. Another consequence of these two factors is lamellar spacing l varies as a function of growth rate V. Microstructure and crystallography Eutectic behaves like pure chemical substance. Due to latent heat (enthalpy of fusion) phase change from liquid to solid occurs with “thermal arrest” solidification time. High latent heat (e.g. Al2O3) may effect kinetics of undercooling which depends on growth rate V. This is the third contribution to DT0. DT0=TE-T0=DTC+DTs+DTK, where temperature gradient DTC=-miDCC is due to concentration gradient, DTs=2g/(rDSm) is due to interface curvature and DTK is due to kinetics (mi is liquidus slope, DCC concentration gradient dependent on diffusion coefficient D and growth rate V, g- is solid-liquid surface energy, r- radius and DSm melting entropy). Another important factor is materials characteristics, essentially the marked tendency of the two phases to grow under specific crystallographic orientations. Finally, due to effects of the various parameters, such as coefficient of diffusion D of solute in liquid phase, coupled eutectic growth under given growth rate V can be obtained if thermal gradient (GT) in the ceramic ingot attains a sufficient value GT/V> (GT/V) critical Consequently in the Bridgman furnace, where temperature gradient is smaller than in floating-zone method, a lower growth rate leads to coupled eutectic growth. Coupled growth produces regular eutectic growing near extremum conditions . The structure can self-adapt to local growth instability by branching, i.e. mechanism in which lamellae or rod can change growth direction. Two materials characteristics can hinder this adaption: 1) one or both phases grow in preferred directions – this makes change of growth direction difficult and leads to irregular spacing; 2) materials composition departs from eutectic, which leads to producing single phase dendrites or cells. The presence of dendrites or cells depends on growth rate, solidification thermal gradient and concentration gradient: V, GT and DC control planar growth. Microstructure and crystallography The symmetric eutectic coupled zone over phase diagram (n is growth rate) Growth rate dependence Al2O3/YAG a Morphology and microstructure vs. the solidification rate. a. 5 mm/h; b. 20 mm/h; c. 30 mm/h. Change of composition in the range 76.3-86.3% Al2O3 (eutectic 81.3%Al2O3) does not influence microstructure. c b Composition dependence Al2O3/GdAlO3: a. 73%Al2O3; b. 76%Al2O3 (eutectic); c. 77%Al2O3 a Microstructure Homogeneous microstructures are produced in coupled eutectic growth conditions, while uncoupled growth leads to development of colonies or dendrites. Other important aspects are the grain size and shape of eutectic domains and relative crystallographic orientations as well as morphology and nature of eutectic domains. The presence of eutectic grains is a consequence of adaptation of eutectic structure to small instabilities in solidification front and grain size is governed by growth conditions and eutectic ability to accommodate growth fluctuations. The small size of eutectic grains imposes limits in application. Regular structures which consist of non-faceted phases either single crystal rods or lamellae embedded in matrix are found in some DSE. In simplest case of isotropic surface energy rods are predicted when volume fraction of minor phase is less then 28% and lamellar when it is more than 28%. Regular microstructure are rather exception in oxide DSE due to strong tendency of most oxides to grow along certain crystallographic planes. It should be noted that eutectic grains are absent in irregular eutectics. NiO/YSZ DSE Scheme of simplest regular eutectics found in DSE Microstructure The microstructure is irregular when entropy of fusion DS f is high, because growth interface can not easily deviate from certain crystal orientation and faceted phases are produced. A special case of irregular microstructure was found in DSE oxides where the phases are continuously entangled in three-dimensional interpenetrating network (TDI). TDI microstructure is a homogeneous and fine dispersion of phases free of grain boundaries. The absence of grain boundaries together with excellent bonding between phases lead to extraordinary mechanical properties as well as high temperature stability and corrosion resistance. The TDI are found in faceted Al2O3/non-faceted YSZ DSE grown at low growth rate and in faceted Al2O3 / faceted YAG DSE grown in wide range of growth rate . The domains Al2O3/YAG exhibit sharp angle facets (morphology known as Chinese Script). The same morphology of continuous networks of two singlecrystal phases is observed in sections perpendicular to solidification direction and parallel to the growth direction. It should be noted that phases are not elongated in growth directions, but perfectly similar in shape and size in both sections. The phases interpenetrate without grain boundaries, pores or colonies. SEM micrograph showing threedimensional microstructure of the Al2O3-GAP eutectic composite The growth direction is shown by vertical arrow. Microstructures Microstructure of binary DSE Al2O3 and garnet or perovskite are shown. In each case continuous network of single phases are observed Al2O3 (dark) and perovskite or garnet (bright). The domain mean size (length of shortest axis) is similar in Al2O3/EAG(Er3Al5O12) and Al2O3/GAP(GdAlO3), but much larger in Al2O3/YAG. Also Al2O3/EAG and Al2O3/GAP exhibit curved interfaces, while Al2O3-YAG exhibits faceted interfaces. From left to right: Al2O3/YAG, Al2O3/EAG and Al2O3/GAP Typical microstructures of ternary eutectics Al2O3/RE aluminate/YSZ are shown in figure. Morphology of garnet type phase depends of rare earth and ZrO2. The Al2O3/YAG/ZrO2 DSE exhibits fine microstructure with smooth interfaces contrary to coarser microstructure with large planar interfaces and sharp angles in Al2O3/YAG. ZrO2 grows at interfaces between Al2O3 and YAG, while in other cases ZrO2 dispersed grains are observed in Al2O3. From left to right: Al2O3/YAG/ZrO2, Al2O3/EAG /ZrO2 and Al2O3/GAP/ZrO2 Crystallography Aligned eutectic microstructure grow by unidirectional solidification usually consists of single crystal phases grown preferentially along well-defined crystallographic directions. These directions are not necessarily the directions of easy growth of the isolated phases but correspond to minimum of interfacial energy configuration between phases. The perfect crystal lattices of each phase are related by orientation relationships which are unique in most systems and produce well defined interface planes corresponding to dense atomic arrangements in the correspondent phases. Electron diffraction studies performed in TEM on thin plates cut perpendicularly to solidification axis reveal growth directions and corresponding well-defined crystallographic directions. Methods of DSE production Bridgman method – growing bulk samples of large size. Melt is contained in Mo, W or Ir crucibles heated by resistance heater or radio-frequency induction through graphite susceptor. Unidirectional solidification is achieved by slow pulling the crucible off the hot zone. The apparent temperature gradient <100 K/cm, growth rate V should be less 100 mm/h to avoid cellular growth, l > 10mm. Czochralsky method. Contact between crucible and growth material is avoided since the eutectic is pulled out from the melt pool. Thick rods 6 mm diameter can be grown by this method. Melt zone methods: fiber crystal growth from free melt meniscus i.e. melting zone . Floating zone (FZ), pedestal growth (PG) are crucible-less methods in which small sample volume is melted by laser, radio-frequency or lamp mirror furnaces. Temperature gradients are 10000 K/cm. Al2O3/YAG DSE grown by laser-heated floating-zone method presents interface spacing less 1 mm. Other growth-from-meniscus methods are edge-defined film growth (EFG) and micropulling down (m-P) give thermal gradients 1000 K/cm. Solidified sample is pulled out at high growth rate from liquid pool feed by capillaries though the shaping dies. Floating zone method EFG m-P