Safety Matters: Real-life scenarios (Slides from 2006)

advertisement

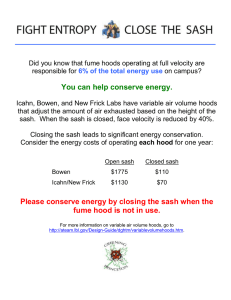

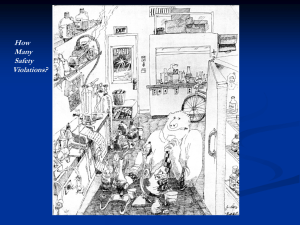

Safety Matters Real – Life Scenarios Accidents Happen April 2006 Safety Workshop TCD Chemical Hygiene: •Skin contact •Accidental stabbing, cuts, other skin breaks, entry into deep tissues, bloodstream •Local Toxicity / effect (dermatitis, cracking of skin) •Penetration through skin - dimethyl sulfoxide, alcohols, benzene, carbon disufide pass through epidermis and act as a “vehicle”. • Inhalation Splash, dust particles, gas, caustic vapours ‘Queen’s University Belfast, Pharmacy Lab – evacuated for 24 hours following Br spill – poisonous, deep oily liquid causing burns’ • Ingestion (object-to-mouth) Contamination, deposition on surfaces, foods, smoking, nail-biting Protective Clothing Hands – cuts, sores forearm – hair folicles eyes - toluene ‘Graduate student severly burnt from waist down – dropped a beaker of ether onto a heated surface which caused a flash explosion beneath a chemical fumehood – hospitalised for 2 weeks’ Chemistry Professor Karen E. Wetterhahn, Dartmouth College Died by poisoning resulting from by a few drops of dimethylmercury. Dimethylmercury, a colourless liquid, was used as a reference standard for NMR experiments. During sample preparation dimethylmercury accidentally penetrated a protective glove. The accident occurred in August of 1996. Six months later symptoms of the mercury poisoning were detected by which time the effects were irreversible. Professor Wetterhahn rapidly went into a coma and died in June 1997. Protective Gloves “During the investigation of this accident, it was learned the MSDS prepared for both the manufacturer and supplier of the dimethylmercury sample in question had erroneous information on the proper gloves to be worn when handling this extremely toxic compound". This is a tragic example of what can happen when MSDS information is incorrect. As a result of her tragedy, safety standards for gloves and other protective equipment were revised, and a movement began to eliminate production and use of dimethylmercury. At the time of her diagnosis and before she lapsed into a vegetative state, Prof. Wetterhahn asked that her case be made known to others in the hope of preventing a similar tragedy. Applied Occupational and Environmental Hygiene Volume 16(2): 233–236, 2001 Laboratory Environment The scene of an accident University of Kentucky 1997 Chemical wastes accidentally mixed resulting in a fire and explosion Choloroform added to the waste bottle resulted in Brown Fumes. The bottle was capped and the student and walked away. A minute or two later it exploded The explosion blew glass shrapnel across the laboratory and was immediately followed by a fire that engulfed the lab giving-off thick black smoke Accident University of Kentucky 1997 The Debri •Burn marks and soot above the hood •Overhead fluorescent lights shattered by flying debris. •Glass fragments from the explosion travelled up to 10 metres •Some embedded up to 20 mm deep in the fumehood insulation Remember: The Fume Hood is not a Storage Area This accident occurred in a hood that contained many stored chemicals as well as waste. Sonicator Causes Explosion Univeristy of Ohio What Happened: A graduate student used a sonicator to agitate a mixture of zinc, ethyl ether, and bromoethylacetate (a lachrymator) in a sealed round-bottom flask. The sonicator caused a rapid rise in temperature which sent the contents of the flask into the fume hood. A graduate, was exposed to the lachrymator vapours, causing intense irritation to the eyes and lungs. What can be done to prevent this from occurring again? Sonicators use sound waves to agitate mixtures...this can cause rapid heating and localized points of increased pressure. They should not be used with sealed flasks or with flammable liquids...especially low-boiling solvents (such as ether). The sonicator was in the fume hood, but it was placed in the front just behind the sash. The equipment should be set as far back as possible...away from the sash. The student was not wearing eye protection. Working In Fume hoods 1. If a hood is being used to store particular chemicals then run the reaction in a different hood. 2. Keep the Sash at the appropriate Level. When not in use, the sash should be closed. When you are using the hood, the sash should be no higher than 14 inches. If higher than, then fumes are escaping into the room and hence into your lungs. 3. Keep all work >15 cm behind sash opening 4. CLEAN UP! Remove all equipment and chemicals that you brought into the hood. Place all reagents back in their proper storage place. Dispose of all waste. Working In Fume hoods 5. Unattended Reactions All unattended reactions must be known about - labelled with a description of the reagents/hazards and contact details In 1997 a fire destroyed a research laboratory at the University of Washington, estimated damage $500,000 and wiping out several research projects. The fire, started by an unattended hotplate, began in a laboratory on the top story of five-story research facility. Fire department officials said the fire was contained largely in one room but was intensely hot. No one was injured. Safe Science May 1997 Specific Procedures Solvent Wastes Storage – chemical turn-around Distillation – destroying the evidence Sodium – in the distillation of solvents Fire at UT Austin Chemistry Laboratory On October 19, 1996, a fire broke out in an organic-synthetic chemistry lab. The fire began when a post-doctoral researcher was disposing of some sodium metal. The researcher was in the process of deactivating the sodium by exposing the metal to alcohol. A small amount of residual metal, came into contact with water as he poured the material down the sink creating a small flame. The fire grew into a blaze when the researcher accidentally broke a container of acetone into the sink in an attempt to remove the container from the sink area where it was being stored. The principal investigator characterized the laboratory as a total loss (0.5 million dollars of damage). Many research records and notes for current projects were destroyed, as well as a lot of archival material going back 10 to 15 years. In addition, two adjacent laboratories were heavily damaged by smoke and water. The Austin Fire Department primarily blamed the incident on poor housekeeping of chemicals. Chemical inventories for the laboratory were kept electronically and the responding fire fighters had no information on what chemicals were involved in the fire. As a result, unlabelled containers and improperly stored flammable chemicals were encountered during the fire fighting effort. Real-life Events have Highlighted : Chemical storage, turn-around - Keeping accurate risk assessment Personnel saftey equipment -Wear appropriate protection Correct fumehood use -Close the sash, keep clear, keep equipment to the back Chemical waste disposal -Do not mix wastes – metal residues, caustic residues, chlorinated solvents