PDF instructions for Universal Kit p/n 12V12B2138UNRT

advertisement

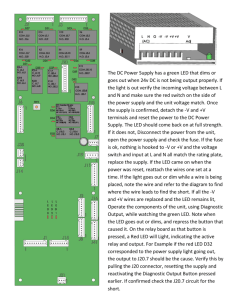

INSTALLATION INSTRUCTIONS for the Airlutions AIR-Rat Table of Contents INSTALLATION ............................................................................................................................................... 3 Before you begin ....................................................................................................................................... 3 Recommended tools ................................................................................................................................. 3 LET’S BEGIN ................................................................................................................................................... 5 SENSOR WIRE ................................................................................................................................................ 6 PCV Filter ....................................................................................................................................................... 8 ADD-A-FUSE INSTALLATION .......................................................................................................................... 9 FUSE AND RELAY INSTALLATION ................................................................................................................. 11 INDICATOR LIGHT INSTALLATION ............................................................................................................... 12 FINAL INSTALLATION AND TUNING ............................................................................................................ 13 TUNING the AIR-Rat .................................................................................................................................... 14 FINE TUNING the AIR-Rat ........................................................................................................................ 15 CARE AND FEEDING OF THE AIR-Rat ........................................................................................................... 15 DO’S AND DON’TS ................................................................................................................................... 15 INSTALLATION Before you begin Only a qualified mechanic should install the AIR-Rat. Those with limited automotive knowledge or experience are not advised to install without supervision of qualified automotive technician. Keep all work areas clean and always be diligent to insure that no debris enters the vehicle’s air intake system. Before you begin installation, you should decide if you are going to use the stock airbox, a modified air-box or an aftermarket cold air intake system. This will determine how and where the AIR-Rat is installed and may require major modification to the cold air intake system you use. The soldering of wire connections is critical. Any loose connections can cause a checkengine light and or force the vehicle into “limp mode” and damage the AIR-Rat. This instruction manual describes the installation of the Universal AIR-Rat. Your kit may appear different or have other modifications specific to your vehicle. If you have any questions, please feel free to contact Dan at 801-835-9087 or email support@airlutions.com. Keep all intake tubing, intake housings, diffusers, etc. clear of dust, dirt or metal filings. Failing to do so could potentially damage your engine and or AIR-Rat and require major repairs. Recommended tools Soldering Iron Electrical Tape Wire cutters/strippers/crimper Volt/ohmmeter suitable for automotive testing Various sockets and wrenches Heat gun to shrink heat shrink Drill and bits, suitable to pierce fire wall and install indicator light Figure 1 - AJ's at Teraflex, 2007 Jeep Rubicon with 3.6-liter engine with AIR-Rat installed. LET’S BEGIN Figure 2 - AIR-Rat 2.5-liter Jeep custom install using DIY Kit Install the AIR-Rat and air intake system in a way that it is clear of belt, hoses and wires. Some installs can use the existing OEM air box, but it is recommended that you use the 4” plastic DIY kit when possible. NOTE: It is critical that the MAF air sensor be located behind the AIR-Rat and before the throttle body. If it is not possible to use the OEM housing for the MAF, there are kits readily available. NEXT PERFORM THE FOLLOWING: 1. Attach the AIR-Rat’s large red wire to battery positive source. 2. Attach the AIR-Rat’s large black wire to ground source. 3. Attach the AIR-Rat’s yellow wire to a KEY-ON power source. 4. Solder the AIR-Rat’s white wire to the variable volt wire on the TPS or MAP sensor (see below). SENSOR WIRE Figure 3 - Checking for variable voltage wire on MAP. Locate and identify the variable voltage signal wire from the Throttle Position Sensor (TPS) wire harness. This is the preferred method for obtaining the variable signal. There are three wires on a typical TPS or MAP sensor (a drive-by-wire system will have more on the TPS). To check for the proper wire, with the key in the run position, one of the three wires is constant reference +5 volts and one is -ground. The CORRECT wire is the variable throttle signal wire the computer uses for its reference. Verify the correct wire by the voltage increase and decreasing with the throttle movement. If using the MAP sensor, the vehicle must be running to determine the correct wire. Warning: Use extreme caution when working in any engine compartment when the engine is running. The correct wire signal for the MAP will be approximately >.5 volts at idle and approximately <4.8 volts full throttle. In Figure 3 above, with the engine running and checking the voltage on the MAP, the Volt ohmmeter is showing 1.41 at idle. This voltage will vary when the gas pedal is pressed and released. Do not disconnect the TPS or MAP sensor harness when testing or while the engine is running. Doing so will cause a false reading and an engine code to be set. Figure 4 - Soldering to the signal wire from the Tuner Box to the vehicles MAP sensor variable voltage wire. Once the correct wire has been determined, peel back a small section of the stock wire loom, cut or peel a small section of insulation, around the TPS or MAP signal wire. Cut the AIR-Rat Tuner Box, white sensor wire to length and solder to the MAP variable voltage signal wire. This is the wire that will go to the AIR-Rat tuner box and tells the AIR-Rat how much throttle or load is being used. NOTE: It is recommended the stock wire not be cut through; rather just peel back the insulation. Split the copper strands wide enough to pass the white sensor wire through, twist and solder. Figure 5 - Insulate with electrical tape and re-cover with wire loom. PCV Filter The PCV filter (not Included) can be located inside the air box or near the PCV tubing above the engines intake manifold. Be sure to leave enough room for the air filter or engine cover. Test your location with the air filter or cover installed to ensure there is enough clearance for the PCV filter. If using a system with a MAF, you must use a proper location behind the MAF. The MAF is tuned for this. If not installed correctly behind the MAF, you can throw codes. ADD-A-FUSE INSTALLATION Figure 6 - Typical fuse box Locate a “key-on” empty fuse socket or wire. Install the Add-a-fuse. You can test for power-on-fuse by cycling the key on and off and checking the fuses with a test light. When the key is on, choose a fuse that is on and off when the key is in the off position. It does not matter which fuse you use as long as it is an “ignition-on” fuse. You will be using very low amperages to engage the relay. NOTE: Some vehicles allow some systems to run after the key or engine is turned off and stays on until the door opens. Do not use any of these connections as it can cause undesirable operation of your vehicle or AIR-Rat. Figure 7 - Routing the wire in the fuse box. Route the Add-a-Fuse wire through fuse box. As shown in Figure 7 above, a small “V” is cut in the edge of the Fuse box to allow the wire to exit without it being chafed or pinched. Cut the relay wire to length and crimp it to the Add-a-Fuse wire. FUSE AND RELAY INSTALLATION Figure 8 - Fusible link attached to batter post location in fuse box NOTE: It is recommended that the positive fusible link be attached to the battery stud in the fuse box rather than directly attaching to the battery. Doing so will prevent battery corrosion. Attach the fusible link (large black wire) to the battery cable post in the fuse box stud. Either screw or zip-tie the relay into position. Run the wire for the LED light along the battery tray, across the firewall, over the brake booster through the firewall. Install the ground wires to any good ground strap, just behind the fuse box in the fender or firewall. NOTE: Chevy or GM trucks must be grounded to battery or location nearest the battery. INDICATOR LIGHT INSTALLATION Figure 9 - LED installation in blank switch cover Select a location for the LED indicator Light. Generally a good place is a dummy or blank switch plate, i.e., see an example in Figure 6. Most kits include an “L-bracket” that can be attached to the steering column with double-sided tape (included). Route sensor wires through firewall being careful to ensure that bare wires will never touch. Pull the wires through, then solder, insulate and push indicator light into hole. This LED light, when properly installed, will illuminate when the AIR-Rat is running and, as an indicator, may also be useful for tuning. Because the indicator luminosity is low, it can be installed in the dash cluster gage if you prefer, see Figure 9. NOTE: The wires for the indicator light have no polarity so they may be soldered in either wire. FINAL INSTALLATION AND TUNING Cover wires with wire split loom. Insure that all wires and wire loom are clear of pulleys belts and exhaust manifolds. Also make certain there is no stress or pulling of any of the wires on the installed harness. Zip-tie loose sections of wire loom to prevent chafing. Install the tuner box in the desired location Keep all wires away from exhaust heat and moisture. NOTE: It is recommended that you leave the air filter off for the tuning procedure. With the air filter removed, it easier to see when the fan is running. If you prefer to have it installed during the tuning procedure, you will have to use an observer to view the indicator light during the procedure. WARNING: Keep fingers and any loose materials away from intake of the fan. Wear safety glasses at all times. These fans run at very high rates of speed and can suck loose clothes, papers, tools, etc., into the fan blades. TUNING the AIR-Rat 1. Double-check the wiring, as indicated above. Once the wiring has been verified, installed clear of heat or chafing, install the fuse in the fusible link. If installing via the TPS sensor, turn the key to the run position. Listen to tones that are emitted by the AIR-Rat. You should hear a series of tones, followed by 4-6 longer tones and one long tone. This is normal procedure for the unit to arm and ready to run. This will repeat each time the power is turned off and on. If the AIR-Rat continues to beep quickly or repeatedly, it means the tuner box idle setting (orange dial) is set too sensitive. Turn the left dial (Orange) counter clockwise to reduce sensitivity, slowly, until it arms or quits beeping. NOTE: When using the MAP sensor, the engine must be started and running. You may not be able to hear the tones over the noise of the engine, but you can use the LED indicator light. The LED lights up at the same time the AIR-Rat beeps. 2. With the lid off from the tuner box, locate the two tuning dials. The red dial (High End sensitivity dial) should be set fully counter clockwise position when using the MAP sensor and the orange dial set at about the 6:00 position. With the fuse installed and the key on and engine running, turn the left dial clockwise until the motor inside the AIR-Rat turbine motor begins to run. You can identify this by the indicator light or by observing through the top of the air box. Then turn the orange dial counter clockwise until it quits running. The dials are very sensitive so proceed slowly, with small adjustments, until the proper tune is achieved. This is the preliminary setting for initial start up. 3. Check operation of the AIR-Rat by depressing the throttle pedal or observing the LED indicator light. Since this system runs on engine load, the AIR-Rat may only run briefly while not in gear. FINE TUNING the AIR-Rat 1. With the vehicles engine warmed up, it is a good time to take a quick test drive to check for any problems. There should be no noises coming from the AIR-Rat and verify NO check engine lights have been set inadvertently. The LED indicator light can be used to double check the function of the fan. When the AIR-Rat is running the LED light will illuminate. NOTE: The RAT should never sound like it has a rattle or whining sound. However, there may be some whistling noises at various RPMs. 2. Once the vehicle engine is warm ensure the fan does NOT run at idle when the vehicle is in gear, foot on the brake and no forward or rearward motion. It should be completely off at idle and only start to come on as you slightly depress the throttle. You may need to adjust the orange wheel counter clockwise to adjust the starting point of the unit. Turning counterclockwise decreases the sensitivity of the AIR-Rat of the engine RPMs and determines when the AIR-Rat starts and stops. The speed of the AIR-Rat should speed up as you increase the throttle pressure and be on fully at about ½ to ¾ throttle by adjusting the red dial when using the TPS. NOTE: The red dial is the sensitive dial for the top end performance. It is recommended the red dial be full clockwise for any installation using the MAP sensor. You may tune to your preference. Counterclockwise on the red dial increases the sensitivity to the high-speed performance. CARE AND FEEDING OF THE AIR-Rat DO’S AND DON’TS The AIR-Rat is designed with the highest quality brushless motors available. They require no maintenance and should last the lifetime of the vehicle. Do NOT spray water or cleaners directly on the AIR-Rat tuner box or in the AIR-Rat turbine housing. The AIR-Rat tuner box, electric motor and other electronic is water resistant, but not water proof. Water should not bother the electronics, but care should be taken to keep all electronics dry. The Tuner Box should never be sprayed directly with water or any other liquids. Moisture can cause erratic operation of the AIR-Rat and shorten the life. NEVER put your hands, fingers or other objects in or near the openings in the AIR-Rat while it has power to it. Do NOT run or test AIR-Rat if any of the fan blades are chipped or missing. This fan runs at speeds up to 40,000 RPMs. Any unbalanced vibration could cause severe damage as well as the fan blade discharging from the shaft. NEVER point the AIR-Rat at anyone while it is running or look down the intake. Use the same precautions you would use while handling a firearm ADDITIONIALLY, If you are unsure for any reason or the AIR-Rat is making unusual noise or if there is a problem with your AIR-Rat please pull the 70 amp Maxi fuse immediately and disconnect the blue wire harness from the unit and contact the manufacture or installer. You may continue to drive your vehicle normally until you can get it serviced. The fan is designed so that it will not interfere with normal operation of any vehicle while the AIR-Rat is not running or unplugged. It is highly recommended that you use a suitable cotton high flow air intake filter such as a K&N air filter. This will improve the performance of your AIR-Rat and enhance you gas mileage. Most cold air intakes, performance chips, exhaust will add to the performance of your AIR-Rat. The AIR-Rat can be run day or night and will not damage your charging system, as long as it is in normal working condition. AIR FILTERS To achieve the best performance from your AIR-Rat, it is strongly recommended to choose a good air filter. You should keep it in good maintenance to keep your AIR-Rat in top performance. Since there are many different manufactures and types of air filters, choose one that is suited to your driving conditions. It is the customer’s responsibility to maintain the quality, integrity and care of the intake system. Any air leaks can cause engine damage and/or premature wear on the AIR-Rat.