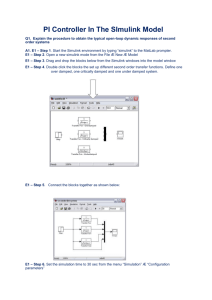

Fig.1 : Flow chart of MOGA-PID Controller

advertisement

Performance Analysis of Multi-objective Genetic Algorithm Tuned PID Controller for Process Control Mohit Jain, Vijander Singh & Asha Rani Division of Instrumentation and Control Engineering, Netaji Subhas Institute of Technology, University of Delhi, New Delhi-110078, India E-mail: nsit.mohit@gmail.com, vijaydee@gmail.com, ashansit@gmail.com Abstract – Proportional-Integral-Derivative (PID) controllers are most widely used in industrial plants due to their ease of implementation and robust performance. This paper presents an effective and fast tuning method using Multi-objective Genetic Algorithm (MOGA) to find the optimized parameters of the PID controller in order to achieve the required performance specifications of the processes under consideration. The improved performance of various plants has been compared with the conventional tuning methods, to observe the effectiveness of proposed method. Keywords – PID controller; Algorithm; Tuning methods; I. Optimization; overshoot is usually not desired at all. This led Tyreus and Luyben (T-L) [3] to recommend another popular conventional tuning approach for more conservative process loops. In [4] Cohen–Coon proposed a different tuning method which was based on process reaction curve. In [5] Kitamori also suggested a new method of PID tuning. There are several more available in literature [6]. These conventional approaches are very popular among control engineers since one can use them especially when no or little information about the plant under control is available. These methods provide stable, robust and quite satisfactory performance but the gains are never guaranteed for being optimal. Also, these conventional tuning methods often fail to achieve satisfactory performance in case of plants having nonlinearity, higher order or time delay. Hence, intelligent approaches have been introduced by the researchers to make the tuning an easier one. In [7] a new scheme of PID tuning is suggested based on Fuzzy gain scheduling technique. A neural networks tuned PID controller by means of fuzzy parameters is presented in [8]. This paper presents a PID tuning method based on Multi-objective Genetic Algorithm (MOGA) and its performance is compared with conventional methods of tuning. The MOGA tuned PID (MOGA-PID) controller is tested on various complex processes often found in control system literatures. So the next section describes about the complex control processes used in this paper for testing the performance of MOGA-PID controller. Genetic INTRODUCTION In the generation of modern and advance controllers, PID controllers are still most widely used (>90%) in process industries like petrochemical, paper, pulp, oil, gas and many more. This is due to the fact of their ease of implementation and robust nature. Moreover they offer very cost effective, efficient and reliable control solution even for very complex control problems. To implement these controllers, three parameters which are the proportional, integral and derivative gains should be tuned properly to provide stable response as well as minimum error while tracking the input. But their appropriate tuning is very difficult since these parameters interact with each other and there is no generalized rule defined for this purpose. However improper PID tuning can produce the oscillatory and unstable system behavior or sometimes causes the system failure [1]. This problem attracted the attention of the researchers to explore the best possible method to tune these three parameters. II. TEST PROBLEMS To demonstrate the effectiveness of the presented method three systems are considered [7]. G1(s) is a time delayed second order system, G2(s) is a third order system and G3(s) is a fourth order system. In process control these systems are most commonly observed, defined as follows: In this scenario one of the most well known methods of PID tuning based on quarter decay ratio was proposed by Ziegler-Nichols (Z-N) [2]. This was too aggressive for most of the plants where oscillations and ISSN (Print) : 2319 – 2526, Volume-2, Issue-5, 2013 33 International Journal on Advanced Computer Theory and Engineering (IJACTE) G1 ( s ) G2 ( s ) G3 ( s ) e 0.5s a) Reproduction (1) ( s 1) 2 4.288 ( s 0.5)( s 1.64 s 8.456 ) 2 27 ( s 1)( s 3) 3 Reproduction or Selection is basically the process of choosing two parents from the population for crossing [11]. A part of the new population can be created by simply copying without any change in selected individuals from the present population. A number of selection methods are defined in the literature [10] and depending upon the problem at hand, one has to decide the best suitable one. All selection methods are based on the same principal, i.e. assigning the fittest chromosomes a larger probability of selection. Four most commonly used methods for selection are given as follows: (2) (3) For time delay definition in process G1(s), a second order (t d ) 2 s 2 6t d s 12 ) is (t d ) 2 s 2 6t d s 12 used. All the three processes show a very complex dynamic behavior and it is a good challenge for any control engineer to design an effective controller to control such processes with required system specification. The next section describes about the overview of Genetic Algorithm. Padé approximation ( e td s 1. Roulette Wheel selection 2. Stochastic Universal sampling 3. Normalized geometric selection 4. Tournament selection b) Crossover III. PRINCIPLES OF GENETIC ALGORITHM Crossover also known as Recombination is basically the process of taking two parent solutions and producing from them a child [11]. The selection process enriches the population with better individuals. Basically selection process makes clones of good strings but it does not create new ones. So crossover operation is applied to the mating pool with the belief that it creates a better offspring. Under this operator, a selected chromosome is splitted into two parts at a selected crossover site and recombines with another selected chromosome which has been splitted at the same crossover site. There are various types of crossover operators like single point crossover, two point crossover, arithmetic crossover and many more [10]. Genetic Algorithm abbreviated as GA, is known as a stochastic global adaptive search optimization technique based on the process of evolution [9]. Evolution is itself an optimization process. It was first proposed by John Holland and his colleagues in 1975. GA has been considered as an adequate and efficient technique for solving complex optimization problems. By carefully avoiding local minima, it converges to global minima. It begins with an initial population having a number of chromosomes where each one corresponds to a solution of the given problem. Then the performance of each individual is evaluated by using a suitable fitness function. Basically, GA consists of three important phases: Selection, Crossover and Mutation. These are also called as GA operators. The application of these three basic operators allows the creation of new children, which may be better than their parents. This algorithm is repeated for many generations and finally stops when meeting offspring that represent the optimum solution to the problem [10]. c) Mutation After crossover operation mutation is applied to the binary strings. Mutation is a process that involves flipping a bit i.e. changing it from 0 to 1 and vice-versa. The mutation operator plays a secondary role in the evolution. It basically prevents the algorithm from trapping into the local minima. It also helps in maintaining the diversity in the population by finding new or restoring lost genetic materials by searching the neighbourhood solution space. Although mutation plays a very important role in a genetic algorithm, it should be noted that it must be introduced with a small probability rate of the entire population [10]. Now the next section describes about the basics of PID controller and its tuning by MOGA. A. Genetic Operators In each generation, the genetic operators are applied to select the best children from the current population in order to create a new population [9]. In most of the cases, the three main genetic operators named as reproduction, crossover and mutation are used. Crossover and mutation operators must be carefully chosen, since their choice greatly affects the performance of the whole genetic algorithm. The three operators are described in brief as follows: ISSN (Print) : 2319 – 2526, Volume-2, Issue-5, 2013 34 International Journal on Advanced Computer Theory and Engineering (IJACTE) IV. MOGA-PID CONTROLLER T ISE e 2 (t )dt A. Basic PID Control Algorithm PID controller consists of three interacting parameters: proportional, integral and derivative gains. Appropriate setting of these parameters can provide good dynamic response of a system with minimized overshoot and steady state error. It can also increase stability of the system under consideration [12]. The transfer function of a PID controller has the following form: Gc ( s) K p Ki / s K d s In fitness function f1 maximum weight is assigned to OS which means minimum overshoot is the main requirement of the system under consideration. Similarly other objective functions can be interpreted. In place of ISE one can use Integral of the time-weighted absolute error (ITAE) and Integral of absolute value of the error (IAE) also. It is the choice of the control engineer that which particular parameter of the control system needs more attention. So as per the requirement a higher weight can be assigned while considering the other necessary specification simultaneously. However the total sum of the weights in an objective function must be equal to one, so that the overall performance of the system should be justified. It shows the flexibility in PID tuning while using MOGA. The Fig. 1 shows the flow chart of MOGA-PID controller. (4) Where Kp, Ki and Kd are known as the proportional, integral and derivative gains, respectively. Another very useful equivalent form of the PID controller is defined as follows: Gc ( s) K p (1 1 /(Ti s) Td s) (11) 0 (5) Where Ti=Kp/Ki and Td=Kd/Kp. Ti and Td are called as the integral and derivative time constants, respectively [7]. The basic block diagram of a plant controlled by PID controller is shown in Fig. 1. Start Generate initial population for Kp, Ti, Td Fig. 1 : A plant controlled by PID controller (7) f 3 0.10 ISE 0.20tr 0.70ts (8) f 4 0.10 ISE 0.80OS 0.10ts (9) f 5 0.10 ISE 0.60tr 0.10OS 0.20ts (10) Check fitness Next generation No Yes Best PID values The fitness function is a very important factor while tuning the PID controller by MOGA. Various multiobjective fitness functions considered in this study are defined as follows: f 2 0.10 ISE 0.70tr 0.20ts Crossover Converged? B. Tuning of PID by MOGA (6) Simulate the Process & evaluate f Mutation Where r(t) is set point, y(t) is the plant output, e(t)=r(t)y(t) is called as error signal and u(t) is the controller output for this particular error signal. f1 0.05 ISE 0.05ts 0.90OS selection Stop Fig.1 : Flow chart of MOGA-PID Controller Performance of the MOGA-PID controller also depends on its convergence rate. The parameters like population size, population type and many more also affect the convergence rate. So in order to avoid premature convergence [13] of GA, it is very important to select the appropriate operators and parameters for it. Table I shows the parameters and operators of GA which are achieved by rigorous experimentation in this work. Where ts is the settling time within 5 percent, tr is rise time, OS is percentage overshoot and ISE is Integral of the square error which can be defined as follows: ISSN (Print) : 2319 – 2526, Volume-2, Issue-5, 2013 35 International Journal on Advanced Computer Theory and Engineering (IJACTE) TABLE I. GENETIC ALGORITHM OPERATORS AND PARAMETERS 1.4 1.2 Value/Method Double vector 20 Feasible population Tournament Mutation Crossover Generations Adaptive feasible Arithmetic 65 1 Output y Parameter Population Type Population Size Creation function Selection method 0.6 0.4 0.2 0 0 10 15 20 Time (Sec) 25 30 35 40 Table II shows the overall performance analysis of the MOGA-PID controller and various conventional PID controllers. In this comparative study the results obtained by Ziegler-Nichols and Kitamori’s PID controller have been referred from [7]. The parameters of Tyreus and Luyben PID controller have been determined by Kp=Ku/2.2, Ti=2.2Pu and Td=Pu/6.3 where Ku is the ultimate gain and Pu is the ultimate period of sustained oscillation [9]. While tuning of PID by MOGA, f1 fitness function is considered which is already explained in section IV. V. SIMULATION RESULTS MOGA based PID tuning have been tested on variety of plants which are commonly found in process control. All these simulations have been performed on a PC having Intel(R) Core(TM) 2Duo processor operating at 2.00 GHz and installed with MATLAB® 7.9.0.529 (R2009b). Fig. 2, Fig. 3 and Fig. 4 show the step response of process G1(s), G2(s) and G3(s) respectively controlled with various conventional and MOGA PID controller. TABLE II. SUMMARY OF COMPARATIVE STUDY Process 1.4 Output y 5 Fig. 4 : Step response of process G3(s) Apart from above two stopping criterion have been used in this paper, the first one is number of generations and the second one is function tolerance which is 1×10 -6. Index Z-N Kitamori T-L MOGA Kp 2.808 2.212 2.1328 2.1245 1.2 Ti 1.64 2.039 7.194 2.3329 1 Td 0.41 0.519 0.519 0.5556 %OS ts (±5%) Kp 32 6.8 0 0 4.16 2.37 16.03 1.57 2.19 - 1.659 2.3505 Ti 1.03 - 4.532 2.6756 Td 0.258 - 0.3269 0.4470 %OS ts (±5%) Kp 17 - 0 0 5.45 - 12.02 4.22 3.072 2.357 2.3272 1.9827 Ti 1.352 1.649 5.9488 1.8419 Td 0.338 0.414 0.4292 %OS 32.8 10.9 0 0.4533 8.8×10- ts (±5%) 3.722 2.3 13.09 G1 MOGA-PID Z-N Kitamori T-L 0.8 0.6 0.4 0.2 0 0 5 10 15 20 Time (Sec) 25 30 35 G2 40 Fig. 2 : Step response of process G1(s) 1.4 1.2 1 Output y MOGA-PID Z-N Kitamori T-L 0.8 G3 0.8 MOGA-PID Z-N T-L 0.6 0.4 0.2 14 1.52 The sign ‘-’ indicates that these values are not provided in the literature 0 0 5 10 15 20 Time (Sec) 25 30 35 It is obvious from the above results that whether it is transient domain specification like percentage overshoot (%OS) or steady state specification like 40 Fig. 3 : Step response of process G2(s) ISSN (Print) : 2319 – 2526, Volume-2, Issue-5, 2013 36 International Journal on Advanced Computer Theory and Engineering (IJACTE) settling time (ts), the performance of MOGA-PID controller is far better than the conventionally tuned PID controller. Fig. 5 shows the comparison of step response of system G1(s) controlled with MOGA-PID controller in which different fitness functions have been used for the purpose of tuning. Process G1 0.8 Output y f2 0.6 f3 0.2 f5 0 0 5 10 15 20 Time (Sec) 25 30 35 40 Best: 1.139 Best fitness Fitness value 3 2.5 2 1.5 1 10 15 20 25 30 Generation 35 40 45 VII. REFERENCES 50 Fig. 6 : Optimization of fitness function f5 by MOGA Fig. 6 shows the minimization process of fitness function f5 by MOGA. Now table III presents a comparative study of MOGA-PID controller used to control process G1(s) by considering various objective functions which are already explained in section IV. [1] K. J. Astrom and T. Hangglund, “Automatic tuning of PID Controllers,” Instrument Society of America, 1988. [2] J. G. Ziegler and N. B. Nichols, “Optimum setting for Automatic Controllers,” ASME Trans., vol. 64, pp. 759-768, 1942. [3] Tyreus, B.D. and W.L. Luyben, “Tuning PI controllers for integrator/dead time processes,” Ind. Eng. Chem. Res. pp. 2628–2631, 1992. [4] G. H. Cohen and G. A. Coon, “Theoretical investigation of retarded control,” ASME Trans., vol. 75, pp. 827-834, 1953. [5] T. Kitamori, “A method of control system design based upon partial knowledge about controlled processes,” Trans. SICE Japan, vol. 15, pp. 549555, 1979. TABLE III. COMPARATIVE STUDY OF MOGA-PID FOR VARIOUS OBJECTIVE FUNCTIONS Process G1 Index Kp Ki Kd %OS ts (±5%) f5 2.1068 0.59 1.1390 In this paper a comparative study has been performed between MOGA-PID controller and conventionally tuned PID controller. Results show that the performance of MOGA based tuning of PID controller is much better in comparison to the conventional tuning approaches. So this can be considered as a powerful tuning scheme for PID controllers. The main advantage of using MOGA is that it is completely independent from the complexity of objective function under consideration. So while tuning a PID controller, the control engineer can consider various objectives rather than restricted to single objective as in the conventional tuning methods. 3.5 5 f4 1.6375 1.38 0.3210 VI. CONCLUSION Fig. 5 : Step response of process G1(s) with MOGA-PID for various objective functions 0 f3 2.2167 0.62 1.0514 A careful observation of the table III clearly shows that MOGA-PID controller gives the freedom to the control engineer to tune it as per the desired requirement. For this purpose, one just requires to create a suitable fitness function in which a suitable weight is assigned to a particular specification. For example in f4 fitness function maximum weight 0.80 is assigned to the percentage overshoot, which is a time domain specification. In this case the target is to reduce the overshoot which is also clear from the table III. 1 f4 f2 2.3348 0.68 0.8159 * Obj is the values of the objective function 1.2 0.4 Index Kp tr Obj* f2 2.3348 1.1161 1.4532 5.23 f3 2.2167 1.3539 1.6870 5.26 f4 1.6375 0.7778 0.7455 0 f5 2.1068 0.8930 1.8782 0.4273 1.30 1.22 2.25 3.32 ISSN (Print) : 2319 – 2526, Volume-2, Issue-5, 2013 37 International Journal on Advanced Computer Theory and Engineering (IJACTE) [6] A. O’Dwyer, Handbook of PI and PID Controller Tuning Rules. Imperial College Press, 2009. [10] [7] Z.-Y. Zhao, M. Tomizuka, and S. Isaka, “Fuzzy gain scheduling of PID controllers,” IEEE Trans. on Systems, Man and Cybernetics, vol. 23, no. 5. pp. 1392–1398, 1993. S. Sumathi, T. Hamsapriya, and P. Surekha, Evolutionary Intelligence. Springer-Verlag Berlin Heidelberg, 2008. [11] S. N. Sivanandam and S. N. Deepa, Introduction to Genetic Algorithms. Springer-Verlag Berlin Heidelberg, 2007. [12] G. Stephanopoulos, Chemical process control: an introduction to theory and practice. Prentice-Hall, 1984. [13] F. Rothlauf, Representations for Genetic And Evolutionary Algorithms. Springer-Verlag Berlin/Heidelberg, 2006. [14] B. W. Bequette, Process Control: Modeling, Design, and Simulation. Prentice Hall PTR, 2003. [8] C. J. Wu, G. Y. Liu, M. Y. Cheng, and T. L. Lee, “A neural network-based method for fuzzy parameter tuning of PID controllers,” J. Chinese Ins. Eng., vol. 25, no. 3, pp. 265-276, 2002. [9] R. L. Haupt, S. E. Haupt, Practical Genetic Algorithms, Wiley, 2004. ISSN (Print) : 2319 – 2526, Volume-2, Issue-5, 2013 38