5679531d0e783

advertisement

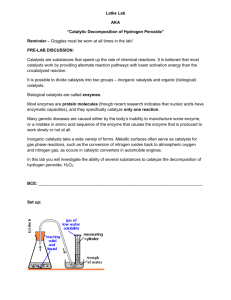

Write-up for Techinnovation 1) Title of Tech offer New Catalysts for Sustainable Liquid Biofuels 2) Abstract (Summary of Tech offer) Novel Fischer Tropsch (FT) capsule catalysts with dual functionalities that enable both FT condensation and catalytic cracking to occur have been successfully created by Republic Polytechnic. These catalysts with an average particle size of 700-1000 nm were formulated and developed by encapsulating core FT catalytically-active species into a selective penetrable shell of zeolite materials. Using these catalysts, direct conversion of syngas to liquid fuels with high octane number with the use of a single-step reactor instead of the existing two-step reactor for the FT process can now be achieved. This reduces the overall operational cost of the gas-to-liquid process. To date, the team has achieved about 99% of encapsulation efficiency with defect-free, smooth surface and uniform capsule shapes. 3) Technology Overview (A brief summary or description of the invention - What is the problem solved by this technology? Who is going to buy this technology? How is this IP addressing a need/problem in the marketplace?) Though biofuels produced from renewable sources e.g. biomass can be used as a substitute, transforming syngas into a high-value fuel equivalent to gasoline requires a costly two-step process. The current technology has to be carried out in two process steps using two different reactors and catalytic materials, and this would increase the energy consumption and the overall cost of the syngas-to-gasoline process. Through this project, Republic Polytechnic has successfully invented new enhanced catalysts in the form of capsules by encapsulating syngas-to-liquid catalytically-active species into a selective penetrable shell of zeolite materials. To date, we have achieved about 99% of encapsulation efficiency with defectfree, smooth surface and uniform capsule shapes. These capsule catalysts are expected to possess dual functionalities, i.e. the inner surface is capable of bringing about syngas-to-liquid reactions, while the surface pores of the zeolite shell will enable catalytic cracking and isomerisation to occur, thus achieving a one-step process. 4) Technology Features and Specifications (What does the technology comprise of? E.g. Video camera, software algorithm) The technology offers well-characterised prototype capsule catalysts that are capable of converting syngas from wood chips to high value-added liquid fuels with high octane number. The technologies for both catalyst production and conversion of syngas to liquid transport fuels are highly scalable. 5) Potential Applications (In which industry can this technology be employed? What are the products that can be marketed based on this technology?) These catalysts can be used for gas-to-liquid (GTL) conversion of syngas (e.g. from wood waste) to light-chain liquid hydrocarbons for liquid fuels. Singapore can therefore diversify its energy sources and keep development sustainable. Biomass has been identified as one of the sustainable and economically viable solutions for Singapore because cellulosic feedstock can be obtained from waste agricultural and horticultural industries, either locally or from neighbouring regions. 6) Market Trends and Opportunities (What is the approximate market size for this technology? What makes this IP attractive to the market?) New capsule catalysts have good potential for scaling up and commercialisation because the global projection for such catalysts is valued to be US$1.3 billion due to the greater investment in gas-to-liquid technology. Therefore, this project has the potential to disrupt the existing market for catalytic materials in the gasto-liquid processes. The success of the technology will drive down biofuel production costs. 7) Customer Benefits (How is this an improvement over the "State of the Art?" What is the Value Proposition?) Produce higher value-added products using this technology as compared to the conventional gas-to-liquid process Reduce overall cost of the process as only one reactor is required with these novel catalysts as compared to two reactors using the existing technology