CHAPTER 4

Strategic

Management of

Costs, Quality, and

Time

PowerPoint Presentation by

LuAnn Bean

Professor of Accounting

Florida Institute of Technology

© 2012 Cengage Learning. All Rights Reserved. May

not be copied, scanned, or duplicated, in whole or in

part, except for use as permitted in a license

distributed with a certain product or service or

otherwise on a password-protected website for

classroom use.

Managerial Accounting 11E

Maher/Stickney/Weil

1

☼

CHAPTER GOAL

☼

This chapter illustrates the significance of

quality.

Prizes recognize improvements in quality.

Japan: Deming Prize

US: Baldrige Quality Award

International standards measure quality

ISO 9000: standards for quality management

ISO 14000: standards for communicating financial

impact of environmental issues

2

LO 1

TRADITIONAL VIEW

The traditional view of quality assumes that

improving quality always requires increasing

costs.

Firms can reduce total costs by

Producing lower-quality goods

Tolerating some level of defective goods

3

LO 1

QUALITY-BASED VIEW

The quality-based view holds that firms should

always attempt to improve quality.

Attempts to improve quality will succeed without

limit

Firms

Should not wait for inspections of finished products to

reveal defects

Must establish quality goals and procedures

Aim for zero defects

High quality pays for itself

4

LO 1

Traditional View

Quality-based View

Quality increases costs

Quality decreases costs

Goods require inspection

Defect-free goods require no

inspection

Workers cause most defects

System causes most defects

Require standards, quotas, goals

Eliminate standards, quotas, goals

Buy from lowest cost supplier

Buy on basis of lowest total cost

Focus on short-run profits

Focus on long-run profits

EXHIBIT 4.1

TRADITIONAL VS. QUALITYBASED VIEW

5

LO 2

QUALITY: Customer View

Three success factors to meet customer

requirements

Service

All the products features, tangible and intangible

Quality

Firm’s ability to deliver its service commitments

Cost

Customers will buy product that provides them with

preferred mix of quality, service, price

6

LO 2

VALUE CHAIN

Prevent quality

problems here

Design

Identify quality

problems here

Production

Marketing

Distribution

Deal with unhappy

customers here

Customer Service

EXHIBIT 4.3

Research and Development

7

LO 3

COSTS OF QUALITY

Prevention

Procurement inspection

Processing control

Design

Quality training

Machine inspection

Appraisal

End-process sampling

Field testing

8

LO 3

COSTS OF FAILING TO

IMPROVE QUALITY

Internal failure costs: detection before delivery

Scrap

Rework

Reinspection/retesting

External failure costs: detection after delivery

Warranty repairs

Product liability

Marketing costs

Lost sales

9

LO 4

EXAMPLE

Steve’s Sushi makes sushi for delivery

only. Steve has concerns about quality

and so he considers various ways he can

ensure/improve quality. He throws away

any prepared sushi that does not meet

strict quality standards. A quality report

follows.

Continued

10

LO 4

COST OF QUALITY REPORT:

Steve’s Sushi

Prevention Costs

Quality training

Materials inspection

Appraisal Costs

End-of-process sampling

10,000

1.00

14,400

1.44

Customer complaints

3,000

0.30

Cost of lost business

17,000

1.70

$ 60,000

6.06%

Internal Failure Costs

Scrap

External Failure Costs

Total costs of quality

EXHIBIT 4.4

Cost Categories

What

actions can

Costs of Quality % of Sales

Steve

forego if he

can’t do

$ 5,800

everything?

10,400

$ 16,200

1.62%

11

LO 4

Generally there is

a long-run decline

in total costs of

quality

EXHIBIT 4.5

12

LO 5

TOOLS

Tools to identify quality problems include

Control charts

Cause-and-effect analysis

Pareto charts

Produce signals about quality control

13

LO 5

SIGNAL: Definition

Is information provided to a decision

maker.

Warning signal indicates something is

wrong

Diagnostic signal suggests cause of

problem and possible solutions

14

LO 5

Control charts

distinguish

between random

variations and

variations to

investigate.

EXHIBIT 4.6

15

LO 5

CAUSE and EFFECT: Definition

Is analysis that first defines the

effect and then identifies the

cause.

16

LO 5

Pareto charts

illustrate

graphically the

problems or

defects.

EXHIBIT 4.7

17

LO 6

JUST-IN-TIME: Definition

Is a philosophy that seeks to

purchase/produce goods and/or

services just when the company

needs them.

18

LO 6

JIT

Factors for success in JIT

Total quality

Smooth production flow

Purchasing quality materials

Well-trained, flexible workforce

Short customer-response times

Backlog of orders

19

LO 7

IMPORTANCE OF TIME

Success in competitive markets demands

shorter new-product development time and

more rapid response to customers.

Customer response time is: (1) newproduct development time and (2)

operational measures of time.

20

LO 7

NEW-PRODUCT DEVELOPMENT

TIME: Definition

Refers to the period between a

firm’s first consideration of a

product and its delivery to the

customer.

21

LO 7

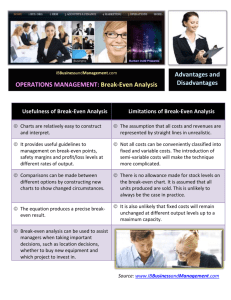

BREAK-EVEN TIME EQUATION

Break-even time =

(Investment ÷ Annual Discounted Cash Flow)

+

Time period from Project approval until Sales begin

22

LO 7

LIMITATIONS: Break-even Time

Break-even time

Ignores cash flows after break-even point

Does not consider strategic, nonfinancial reasons

for new product

Varies from one business to next, depending on

product life cycles and investment requirements.

23

LO 7

OPERATIONAL MEASURES

Indicate

Speed

Reliability

Customer response time

Delivery cycle time

Time from order to delivery

On-time performance

Delivered as scheduled

24

LO 8

BALANCED SCORECARD:

Definition

Reports an integrated group of

financial and nonfinancial

performance measures based on

vision and strategy.

25

LO 8

Balanced

scorecard can

maximize profits

and improve

performance if

used effectively.

EXHIBIT 4.9

26

LO 9

TOTAL QUALITY

MANAGEMENT (TQM)

TQM requires five changes to traditional

managerial accounting systems

System includes information to help solve

problems

Line employees collect information for feedback

Information should be available quickly

Information should be more detailed

Base rewards on quality, customer satisfaction

27

End of CHAPTER 4

28