®

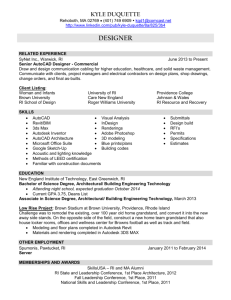

MTConnect :

Shop Floor Interoperability

Paul Warndorf

VP – Manufacturing Technology

AMT – The Association For Manufacturing Technology

© 2012 Autodesk

Class Summary

Current shop floor interoperability is abysmal when compared to where

systems technology is today. Proprietary systems continue to dominate

the landscape, making integration costly. MTConnect, started by AMT The Association For Manufacturing Technology, is a technology initiative

to establish an open architecture mechanism to enable interoperability

between devices on the shop floor. In this class, we will provide

background about MTConnect and as well as some examples of what is

currently possible and what may be available in the future.

© 2012 Autodesk

Learning Objectives

At the end of this class, you will be able to:

Appreciate how limited shop floor interoperability is or was and how the

limitations have hampered advances

Explain the basic concepts behind MTConnect and describe what makes

it different from other "standards" efforts

Describe how MTConnect works and explain how easy it is to implement

List the types of applications that are being developed today using

MTConnect

© 2012 Autodesk

Section Title Goes Here

© 2012 Autodesk

PLANT OPERATIONS

Control: Scheduling, process

sequencing (macro planning),

process variables (microplanning),

CAM programs, facilities, tooling,

quality metrics, rates, cost,

plant wide integration,

asset management…

Information: Utilization, OEE,

verifying simulation with REAL data,

consumable needs, maintenance,

quality/inspection results…

Data: Status, failures/faults,

process/tooling/machine, energy,

sensor data, quality data/inspection…

© 2012 Autodesk

2006 AMT Annual Meeting

David Edstrom

SUN Microsystems

How the Internet’s

Participation Age Will Drive

Dramatic Changes in the

Machine Tool Industry

Dr. David A. Patterson

University of California, Berkeley

Creating a Thriving American

Manufacturing Base

In 21st Century America

© 2012 Autodesk

2006 Challenge

Sensor + Wireless + Services = Solutions

Collect data, send data, leverage data

If CNC embraces inter-operability standards, customer

could monitor all brands of CNC machines

– Live monitoring + historical record

– View over any web browser

Industry could offer customers integrated solutions vs.

incompatible components

© 2012 Autodesk

®

MTConnect.org

© 2012 Autodesk

The MTConnect Myth

What it is NOT:

What it IS:

•

•

•

•

It is a Standard (Open and Royalty Free

to MTConnect Participants and

Implementers)

It is a Communication Protocol for

manufacturing equipment and devices

It is Open Source and Based Upon XML

and HTTP

It is a Data Dictionary that includes

Schema for Components and Data

Items

•

Not an Application

•

Not a Software Package

•

Not a Network

•

Not bidirectional

communications (Read Only)

•

Not for DNC (Direct Numerical

Control)

© 2012 Autodesk

An Integration Nightmare

打開和免版稅將永

遠贏得市場

ومنفتح وحر الملوك الفوز دائما

في السوق

Offene und immer gewinnen

den Marktplatz

Ανοικτή και θα κερδίσει πάντα

την αγορά

Åpen og vil alltid winthe

markedsplass

© 2012 Autodesk

Difference With MTConnect

打開和免版稅將永

遠贏得市場

Defining

of Data

ومنفتح وحر الملوك الفوز دائما

في السوق

Defining

of Data

Offene und immer gewinnen

den Marktplatz

Defining

of Data

Ανοικτή και θα κερδίσει πάντα

την αγορά

Åpen og vil alltid winthe

markedsplass

Native Language

Defining

of Data

Defining

of Data

© 2012 Autodesk

Difference With MTConnect

Define Once – Use Everywhere

打開和免版稅將永

遠贏得市場

Defining

of Data

ومنفتح وحر الملوك الفوز دائما

في السوق

Defining

of Data

Offene und immer gewinnen

den Marktplatz

Defining

of Data

Common Dictionary

Defining

Ανοικτή και θα κερδίσει πάντα

of

Data

την αγορά

Åpen og vil alltid winthe

markedsplass

Defining

of Data

© 2012 Autodesk

Enabling Connectivity

Through Standardization

Offene und immer gewinnen

den Marktplatz

Adapter

Ανοικτή και θα κερδίσει πάντα

την αγορά

Åpen og vil alltid winthe

markedsplass

Common

Interface

Agent

Client

© 2012 Autodesk

MTConnect Standard

© 2012 Autodesk

Devices and Components

© 2012 Autodesk

Version 1.2

Enhancements

Part 1: Overview and Protocol

No significant changes

Part 2: Components and Data Items

Restructured the document

Addition of new Sensor descriptions (data items)

Part 3: Streams, Events, Samples, and Condition

No significant changes

Part 4: Mobile Assets (New part added)

© 2012 Autodesk

Part 4: Mobile Assets

What are Mobile Assets?

These

are assets that can moved to, or removed from, a

device without detriment to the function of the device,

and can be associated with other devices during their

lifecycle.

The data associated with these assets can be retrieved

from multiple sources that are responsible for providing

their knowledge of the asset.

© 2012 Autodesk

Examples of Mobile Assets

Tooling

Fixturing

Parts

etc....

© 2012 Autodesk

Cutting Tool

Cutting Tool is an assembly of items for removing material from a work-piece through a shearing action

at the defined cutting edge or edges of the Cutting Item.

A Cutting Tool can be a single item or an assembly of one or more Adaptive Items, a Tool Item and

several Cutting Items on a Tool Item.

Used ISO 13399 Cutting Tool Data Representation and Exchange

© 2012 Autodesk

What Does This Mean

To Name a Few

Machine Tool

Tool Management

Systems

Tool Presetter

RFID Identification

© 2012 Autodesk

Proposed Work Activity

for Version 1.3 & 1.4

Accessory Equipment

Metrology

Parts

Enhancement to Alarms and Warnings

Necessary updates as required

© 2012 Autodesk

Accessory Equipment

MACHINE TOOL

BAR FEEDER

READ

ADAPTER

AGENT

CLIENT

PLC

READ

CNC

CLIENT

AGENT

ADAPTER

MTConnect Standard

© 2012 Autodesk

Metrology

DMSC

Probing

CMM

© 2012 Autodesk

Parts

© 2012 Autodesk

An Enabler for Equipment

Data Collection

Asset

management

Shop floor control

OEE - Utilization/Efficiency

Simulation

Verification

Maintenance

More…

Monitoring

software

© 2012 Autodesk

An Example

Athulan Vijayaraghavan, Lucie Huet, and David Dornfeld

Department of Mechanical Engineering

University of California

© 2012 Autodesk

MTConnect Institute

© 2012 Autodesk

History

MTConnect

Institute

Incorporated

First

Demonstration

IMTS 2008

Project

Started

(Feb 2007)

2007

Release

of V1.0

(1 Part)

2008

2009

Second

Demonstration

IMTS 2010

First

Conference

Release

of V1.1

(3 Parts)

Draft

of V1.2

(4 Parts)

2010

2011

Third

Demonstration

IMTS 2012

2012

© 2012 Autodesk

Makeup of the MTConnect Institute:

• 105 – Participants

• 2 – Partners (OPC Foundation, DMSC)

105

100

80

60

40

20

2012

2011

2010

2009

0

2008

# of Participating Organizations

120

© 2012 Autodesk

Technical Advisory Group

© 2012 Autodesk

MTConnect Website

MTConnect.org

© 2012 Autodesk

New MTConnect Forum

MTConnectForum.com

© 2012 Autodesk

•Keynote Speakers - Business Sessions

•Technical (Workshop) Sessions

•Exhibit area

© 2012 Autodesk

Different Devices, Common Connection.

www.MTConnect.org

© 2012 Autodesk

Autodesk, AutoCAD* [*if/when mentioned in the pertinent material, followed by an alphabetical list of all other trademarks mentioned in the material] are registered trademarks or trademarks of Autodesk, Inc., and/or its subsidiaries and/or affiliates in the USA and/or other countries. All other brand names, product names, or trademarks belong to their respective holders. Autodesk reserves the right to alter product and

services offerings, and specifications and pricing at any time without notice, and is not responsible for typographical or graphical errors that may appear in this document. © 2012 Autodesk, Inc. All rights reserved.

© 2012 Autodesk