Identification - Khazar University

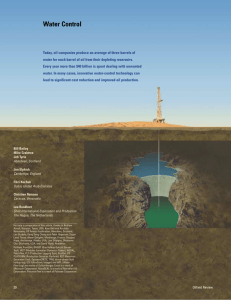

advertisement

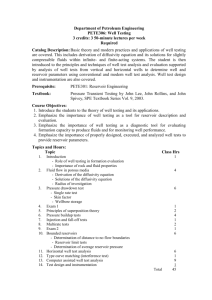

Identification Subject PETE 402: Petroleum Production Engineering Department Program Term Instructor E-mail: Phone: Classroom/hours Prerequisites Language Compulsory/Elective Required textbooks and course materials Petroleum Engineering Undergraduate Spring, 2015 Nazim Nasibov nazim_nasibov@yahoo.com +99455769 7908 11 Mehseti str.(Neftchilar campus), Room 403N, Saturday 18:00-21:00 Office hours Consent of instructor English Required 1.Production Technology. Heriot-Watt University. Institute of Petroleum Engineering. Author: Dr. David Davies. Edinburgh. Available at the department. 2.Applied Petroleum Reservoir Engineering. Authors: B.C. Craft, M.F. Hawkins. Prentice Hall Englewood Cliffs, NJ 07632.ISBN 0-13-039884-5. 3. Reservoir Engineering Handbook. Course website Course outline Course objectives Learning outcomes Teaching methods Evaluation This course is designed for the Petroleum Students and other Technical Specialties. The field of hydrocarbon production is closely related to Petroleum Industry specialists. To support the students academically, to improve their chance of realizing their potential in practice. To encourage students participation and in interaction and fostering and atmosphere of tolerance and respect. To develop on understanding of the theory and practice in Petroleum Production Engineering. To learn engineering methods to evaluate and optimize oil and gas well performance. To build background for the student’s further Petroleum Production Engineering. By the end of the course the students should be able: Planning and designing wells Analytical thinking Critical reasoning Team building Leadership Presentation Other… Lecture Group discussion Experiential exercise Simulation Case analysis Course paper Others Methods Midterm Exam x x x Date/deadlines Percentage (%) 30 Case studies Class Participation We ek Policy Date/Day (tentative) 10 Assignment and quizzes Project 20 Presentation/Group Discussion 40 Final Exam Others 100 Total Preparation for class The structure of this course makes your individual study and preparation outside the class extremely important. The lecture material will focus on the major points introduced in the text. Reading the assigned chapters and having some familiarity with them before class will greatly assist your understanding of the lecture. After the lecture, you should study your notes and work relevant problems and cases from the end of the chapter and sample exam questions. Throughout the semester we will also have anassignment and quizzes. Withdrawal (pass/fail) This course strictly follows grading policy of the School of Engineering and Applied Science. Thus, a student is normally expected to achieve a mark of at least 60% to pass. In case of failure, he/she will be required to repeat the course the following term or year. Cheating/plagiarism Cheating or other plagiarism during the Quizzes, Mid-term and Final Examinations will lead to paper cancellation. In this case, the student will automatically get zero (0), without any considerations. Professional behavior guidelines The students shall behave in the way to create favorable academic and professional environment during the class hours. Unauthorized discussions and unethical behavior are strictly prohibited. Tentative Schedule Topics Textbook/Assignments 1 [1] Ch1 2 Introduction to Petroleum Production Engineeering. The production system and phases. Well productivity, completion, stimulation. Associated production problems. Remedial and Workover Techniques. Artificial lift. Surface Processing. Reservoir Production Concepts Reservoir Depletion Concepts. Reservoir Drive Mechanisms. Solution Gas Drive. Gas-Cap Expansion Drive. Water Drive Reservoir. Gravity Drive. Compaction Drive. Combination Drive. Reservoir Depletion or Material Balance Concepts Application of Material Balance. The Composite Production System. The Producing System. Utilisation of Reservoir p.1-13 [1] Ch 2 p.1-30 Pressure. Supplementing Reservoir Energy. Fluid Injection into the Reservoir. Supplementing the Vertical Lift Process. 3 Solutions to Exercises. Performance of Flowing Wells Well Inflow Performance. Darcy’s Linear and Radial Flows in Different States. Non-Darcy Flow. Tubing Performance. Dry Gas Flow. Single Phase Liquid Flow. Gas-Liquid Mixture. Fluid Parameters in Multiphase Flow. Slippage. Flowline Chokes. Completion Flow Performance and Optimization. 4 The assignment for a course project Wireline Services. Surface Equipment for Wireline. Wireline Tool String. Wireline Operating Tools. Tubing Perforator.Consulting on a course project. 6 [1] Ch 4 p.1-39 [1] Ch 5 p.1-21 Completion Equipment. Production Tubing. Specification of Tubing.Wellhead Systems. Xmas tree. Packers. Packer Applications. Wireline Nipple and Mandrel Systems. Subsurface Safety Systems. Tubing - annulus Circulation Equipment. 7 p.1-96 Solutions to Exercises. Wellbore Completion Concepts Bottom Hole Completion Techniques. Selection of Flow Conduit Between Reservoir and Surface Completion String Facilities. Completion String Components. Wellhead Xmas Tree. Production Tubing. Well Completion Designs. Land or Platform Based Completions. Subsea Completions. 5 [1] Ch 3 [1] Ch 6 p 1-61 Solutions to exercises. Multiple Zone Completions. Multiple Zone Depletion Concepts. Multiple Zone Completion Configurations. Dual Zone Completion. Completions for 3 or More Zones.Multiple Completion Equipment. Tubing Hanger Systems. Multiple Tubing Packer Systems.Auxiliary Equipment for Multiple Completions. [1] Ch 7 p.1-14 Multiple Zone Completions. 8 9 Mid-term Exam Perforating Shaped Charge Characteristics and Performance.Principles of Shaped Charges. Assessment of Charge Performance. API RP. 43 Fifth Edition - Standard Tests. Significance and Validity of API RP No 43 Tests. Perforating gun systems. [1] Ch 8 p.1-31 Operational Considerations. Casing Damage. 10 Solutions to exercises. Completion Installation Programming. Practices, Procedures and Operational Constraints and Considerations.Wellbore Preparation. Open Hole Completion.Cased Hole Completion. Completion String Running Procedures. Hydraulic Testing of the Completion. Surface Completion of the Well. Production Initiation. Rreports and Documentation. Consulting on a course project. 11 Well Intervention. General approach to a workover. Types of intervention. Internal Tubing Problems. Tubing Retrieval Problems.Workover Equiptment and Techniques. Selection of a Workover rig. Workover Benefit Analysis.Evaluation Considerations. Economic Benefit.Absolute Measures of Profitability. Measures Which Consider Time Value of Cash Flow. 12 Course project presentation 13 Well Problems. Introduction. the Source of Well Problems.Reservoir Associated Problems.Productivity or Injectivity Problems.Reservoir Management Considerations.Completion Associated Problems. Completions Equipment Malfunctions or Failure. Wellbore Problems. Mechanical Failure. Modification or Redesign. Abandonment. Responses to Well Problems. Reservoir Problems. Productivity/Injectivity Considerations.Reservoir Management Problems. Problems Associated With The Completion. Lift Considerations. Wellbore Problems and Repairs. 14 [1]Ch10 p.1-21 [1] Ch 11 p.1-28 Requirements and Operations for Abandonment. Plug Back Abandonmen. General recommendations for plug back. Seabed Abandonment. Recovery Of Equipment Above Seabed. Recovery Of Equipment To A Specific Point Below The Seabed. Fixed Drilling Locations. Floating Locations. 15 [1] Ch 9 p.1-24 [1] Ch 12 p.1-9 Advanced Wells Horizontal Wells. Extended Reach Wells. Multi-lateral Wells. Intelligent (“Smart”) Wells. Coiled Tubing Drilling. Underbalanced Drilling. Multiple Fractured Horizontal Wells. Multi-lateral Wells. Benefits of Multilateral Wells – Economic & Technical. Extended Reach Wells. Mmultiple [1] Ch 13 p. 1-37 fractured horizontal wells. Uunderbalanced Operations. Smart/Intelligent Wells. Thin Zones. Coiled Tubing Drilling. TBA Final Exam This syllabus is a guide for the course and any modifications to it will be announced in advance.