GROUP #10: ME Project - Air Conditioner

advertisement

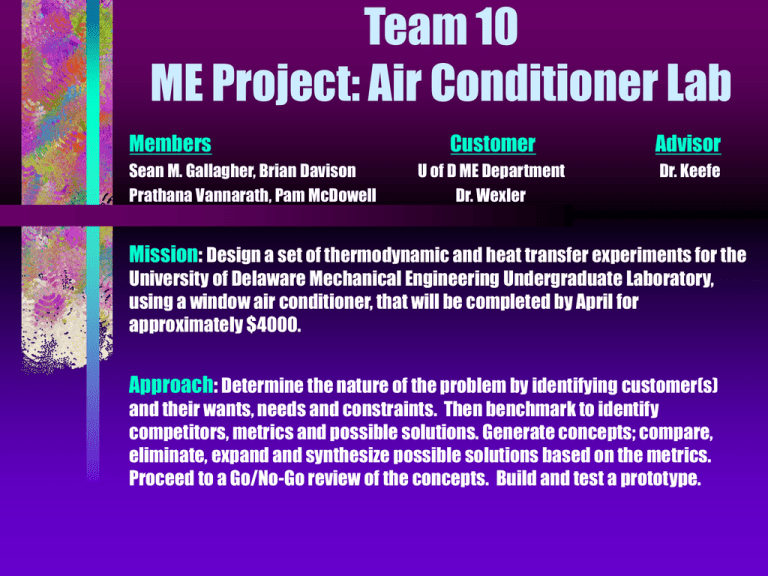

Team 10 ME Project: Air Conditioner Lab Members Sean M. Gallagher, Brian Davison Prathana Vannarath, Pam McDowell Customer Advisor U of D ME Department Dr. Wexler Dr. Keefe Mission: Design a set of thermodynamic and heat transfer experiments for the University of Delaware Mechanical Engineering Undergraduate Laboratory, using a window air conditioner, that will be completed by April for approximately $4000. Approach: Determine the nature of the problem by identifying customer(s) and their wants, needs and constraints. Then benchmark to identify competitors, metrics and possible solutions. Generate concepts; compare, eliminate, expand and synthesize possible solutions based on the metrics. Proceed to a Go/No-Go review of the concepts. Build and test a prototype. Project Background • ME 2000 Curriculum – Joint Laboratory Classes – Combined Thermodynamics II and Heat Transfer Lab • Single lab apparatus for multiple labs • Increased understanding of Thermodynamic and Heat Transfer fundamentals Problem Description • Hardware – Develop a lab apparatus using a window air conditioner and sensors – Develop a Data Acquisition Program • Lab Experiments – Develop a set of experiments that include a variety of Thermodynamic and Heat Transfer Principles Lab Setup Schematic Expansion valve Mass flow fluid T, P T, P X M air T1 P P T2 M air T3 RH T, P T4 Relative Humidity T, P Compressor M water Outside Coil Inside Coil Customers Dr. Wexler Dr. Advani Undergraduate students Graduate students Dr. Sun George Sestak from ASHRAE Manufacturers: Hampden, Armfield Ltd. Other Schools: Georgia Tech, Penn State Wants Effective learning tool Easy to Use Self Evident Easy to set up Cost Effectiveness Easy fabrication LabView compatible data acquisition Forgiving of incompetence Quiet Quick Constraints (Prioritized) • Portable • Schedule dictated by NCDA • Budget set by Sponsor • Dr Keefe set by himself Systems Benchmarking (Competitors) • Hampden Basic Refrigeration Cycle Trainer • Hampden Basic Refrigeration Cycle and Heat Pump Trainer • Hampden Refrigeration Demonstrator • Hampden Heat Pump Trainer • Armfield Heat Exchanger Training Equipment Series • Armfield Heat Transfer Teaching Equipment Series • Armfield Temperature Measurement Bench Metrics Hardware • Cost Effectiveness – – – – Low initial price Low operating cost Durable Parts availability • Easy to Use – Visible Components – Accessible Components Hardware Cont’d • Easy Maintenance – Parts visibility – Parts availability • Easy to set up – Time • Target value 15 minutes – Self Contained • Quiet – Low noise level • Target value of 60 dB Metrics Lab Experiments • Effective Learning Tool • Self Evident – Fun – Number of Fundamentals – Clear Lessons/Objectives – Real World Connection to Students – Keeps Students’ Interests – Hands-on/Interactive – Clear Lessons/Objectives – Logical Procedure Lab Experiments Cont’d • Multiple Purposes – Number of Fundamentals used – Combination of Thermodynamic and Heat Transfer Principles • Quick – Time • Target Value within set lab time (2 hrs) Preliminary Functional Benchmarking Benchma rking: Compa ra tive Performa nce Sca le of (0-5) Effec tive Lea rning Tool Ea sy Set Up Abbrevia ted Ea sy to Use Low Cost List of Wa nts Self Evid ent The Top 10 #REF! #REF! #REF! #REF! #REF! Competitors H-RST-3B H-6710-CDL H-RST-2 H-6830 HT10X HT30X HT2 sc ore 4.0 3.5 3.5 3.0 2.0 2.0 1.0 4.0 4.0 4.0 4.0 3.0 3.0 2.0 3.0 3.0 3.0 3.0 2.0 2.0 3.0 4.0 4.0 4.0 4.0 2.0 2.0 2.0 .0 .0 .0 .0 1.0 1.0 1.0 15.25 14.58 14.58 13.90 9.80 9.80 7.90 Lab Experiment Concepts One Experiment using different sensors – Not an effective learning tool – Difficult to set up 5 - 8 Experiments – Easy to set up – More effective learning tool than – Multiple Purposes Lab Experiment Concepts Cont’d 14 Experiments – Easy to set up – More Effective learning tool than – Multiple Purposes Thermodynamic Fundamentals • • • • • • • • Expansion Valve Compressor Condenser Coil Evaporator Coil Phase Changes: Liquid Vapor Coefficient of Performance Diagrams: T-s and P-h Psychrometric Chart Liquid Heat Transfer Fundamentals • Convection • Conduction • Radiation Actual Progress • Wanted to be here: – Generated Concepts – Researching Functional Benchmarking – Researched Effective Learning Tools – Researched Safety Issues – Generating Lab Experiments • We are here: – Generated Preliminary Concepts – Started Functional Benchmarking – Researching Effective learning tools – Researched Safety issues – Beginning Lab Writeups Division Of Labor • Sean • Pam – Heat Transfer Labs • Variables – Knowns – Unknowns • Equations • Possible overlap between labs – Thermodynamics Labs • Variables – Knowns – Unknowns • Equations • Possible overlap between labs Division Of Labor (Cont’d) • Prathana – Ambassador of Educational Prowess • Continue to investigate various methods of teaching • Determine criteria for evaluating educational effectiveness of each lab • Apply criteria to each individual experiment • Brian – Locate and obtain window AC unit from UD housing to be used as a reference – Determine which brands of AC units best fit our wants Detailed 4 Week Outlook • Week of 10/26 – Evaluate variables and equations • conduction • expansion valve • compressor – Research, organize, and classify various methods of teaching – Obtain free or really cheap AC unit from • Week of 11/2 – Evaluate variables and equations • convection • condenser coil • evaporator coil – Determine criteria to evaluate educational effectiveness of each lab – Determine where in AC unit sensors could be placed for labs • conduction • expansion valve • compressor Detailed 4 Week Outlook (Cont’d) • Week of 11/9 – Evaluate variables and equations • Radiation • Phase changes • Coefficient of performance – Where to place sensors • convection • condenser coil • evaporator coil – Educational Effectivness • convection • condenser coil • evaporator coil • Week of 11/16 – Evaluate variables and equations • Diagrams: T-s and P-h • Psychrometric Chart – Where to place sensors • Radiation • Phase changes • Coefficient of performance – Educational effectiveness • radiation • Phase changes • Coefficient of performance Generic Schedule Overview • December – Finish evaluating each of our lab concepts against our metrics • January – Sleep • February – Compare lab concepts against maximum overlap of sensor position optimum set of experiments – Determine AC unit to be used in the experiments • March – Send AC unit away to have sensors installed • April – Finishing touches Preliminary Budget Preliminary Budget: Project 99.10, ME Air Conditioning Experiment Fully Instrumented Version Component Est. Price Quantity Subtotal Total Air Conditioning Unit $ 250.00 1 $ 250.00 Lab Cart $ 100.00 1 $ 100.00 Rel. Humidity/Temp Sensor $ 225.00 4 $ 900.00 Mass Flowmeter $ 1,000.00 1 $ 1,000.00 Thermocouple $ 25.00 4 $ 100.00 Pressure Transducer $ 255.00 10 $ 2,550.00 Air Flowmeter $ 400.00 2 $ 800.00 Assorted Fittings $ 100.00 1 $ 100.00 Wiring, Connectors $ 75.00 1 $ 75.00 Refrigerant Recharge $ 25.00 1 $ 25.00 $ $ Total: $ 5,900.00 Concluding Remarks