to see the whole project as a ppt. presentation

T.1-2 DESCRIPTION OF GENERAL DETAILS

OF THE FIRM AND ORGANIZATION CHART

T. 3 STRATEGY FOLLOWED TO GET A

COMETITIVE ADVANTAGE

T. 4-7 QUALITY FUNCTION DEPLOYMENT

(QFD) AND PROCESS DESIGN

T. 5 DESIGN AND PRODUCTION

T. 6 OPERATIONS TECHNOLOGY

DESCRIPTION OF GENERAL

DETAILS OF THE FIRM AND

ORGANIZATION CHART

• Headquarter: Stuttgart, Germany

• Production:

Argentina, Austria, Bosnia and

Herzegovina, Brazil, Canada, Egypt, Ghana,

Hungary, India, Indonesia, Iran, Malaysia,

Mexico, Nigeria, South Africa, South Korea,

Thailand, Turke, United Kingdom USA

• Products : Passenger cars, Trucks, Buses and vans, Utility vehicles

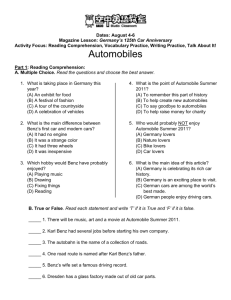

• 1886 the first car was developed

• Foundation: 1887

• Founders: Gottlieb Daimler

Karl Benz

• 1894 first serial production

• Cooperation of: Mercedes (Daimler) and

Benz because of bearing the crisis, until the 1926’s unification.

• 1928 the first formula 1 car(“Silber Pfeil”) was built

• Cars for middle and upper class. They try to offer high quality cars at good relation price-quality. Prices vary depending on the model you are to buy.

• Their cars are always on the edge from a technological point of view since they have been produced with the best technological tools.

COMPETITORS

Their strongest competitors come from the luxurious car’s market.

Mercedes is supposed to be the strongest one in its field.

Main Competitors:

- BMW

- Audi

- VW

other car manufacture companies (Jaguar,

Opel (GM) Porsche...

STRATEGY FOLLOWED TO

GET A COMETITIVE

ADVANTAGE

THE STRATEGY

FOLLOWED BY MERCEDES

BENZ TO BECAME

LEADERS IN THE CAR

MARKET ARE:

THE PORTER’S GENERIC

STRATEGIES:

DIFFERENTIATION

VERSATILITY

BROAD SCOPE

THE DIFFERENTITATION

STRATEGY (horizontal axis)

THE COST LEADERSHIP

STRATEGY (horizontal axis)

STRATEGIC FOCUS AND

SCOPE (vertical axis)

Vertical axis:

F

O

C

U

S

Horizontal axis:

DIFFERENTIATION // COST LEADERSHIP

1. DIFFERENTIATION

INVOLVES MAKING OUR PRODUCT

DIFFERENT AND MORE ATTRACTIVE THAN

THOSE OF OUR COMPETITORS.

FEATURES FUNCTIONALITY DURABILITY

SUPPORT

BRAND IMAGE

THAT OUR

CUSTOMERS

VALUE

1. DIFFERENTIATION

TO MAKE A SUCCESS OF A

GENERIC DIFFERENTIATION

STRATEGY, WE NEED:

1.

Good research, development and innovation.

2.

The ability to deliver high-quality products or services.

3.

Effective sales and marketing

GLOBALIZE DIFFERENTIATION

REASONS :

1. Reduce costs

(labor, taxes, tariffs, etc.)

2. Improve supply chain

3. Provide better goods and services

4. Understand markets

5. Learn to improve operation

6. Attract and retain global talent

DRAWBACK :

HANDICAP

BEING UNIQUE

2. THE COST LEADERSHIP

STRATEGY

REDUCING ITS ECONOMIC

COSTS BELOW ITS

COMPETITORS

THE ABILITY OF A VALUABLE

COST-LEADERSHIP

COMPETITIVE STRATEGY TO

GENERATE A SUSTAINTED

COMPETITIVE ADVANTAGE

DEPENDS ON THAT STRATEGY

BEING RARE AND COSTLY TO

IMITATE.

I

L

S

T

T

V

E

R

Y

3. FOCUS OR STRATEGIC SCOPE

THIS DIMENSION IS NOT A SEPARATE

STRATEGY PER SE, BUT DESCRIBES THE

SCOPE OVER WHICH THE COMPANY SHOULD

COMPETE BASED ON COST LEADERSHIP OR

DIFFERENTIATION.

THE FIRM CAN CHOOSE TO COMPETE IN:

THE MASS MARKET WITH A BROAD SCOPE,

A DEFINED, FOCUSED MARKET SEGMENT WITH A

NARROW SCOPE.

MERCEDES BROAD SCOPE

QUALITY FUNCTION

DEPLOYMENT (QFD)

Customer Room

(What customers want)

This is the “voice of the customer”

Done With focus groups

Must be what customers want and not what builder wants

Engineering Room

This is the HOW room, How can each customer attribute be measured and evaluated by the company.

Integrator room

These are the What's’ in rows and How's in columns

This s the relationship room

Described in 3 ways:

Strong moderate and weak

Competitors room

This room assesses how well we are meeting customers requirements

Tester Room

Technical priorities

Relationship and importance to customer

The Attic

About quality cost analysis

( http://www.kaner.com/qualcost.

htm )

Content

Definition quality cost

Different types of Quality cost analysis

○ Prevention costs

○ Appraisal costs

○ Internal failure costs

○ External failure costs

Benefits by analysis cost of quality

Risks by analysis cost of quality

Definition

• Quality Cost:

- It is represented by the costs encountered in:

- preventing

- finding

- correcting the defective work

- They represent in general a significant amount

- It is affected (reduced) by Total Quality Control.

Prevention costs

The costs encountered in the activities preventing poor quality.

Examples:

Staff training

Early Prototyping/Requirements analysis

Clear Specification/unambiguous documentation

Evaluation of the development tools that will be used

Coding errors

Design errors

Mistakes in the user manuals

Dadly documented or unmaintainably complex code

Appraisal Costs:

• The Costs encountered in the activities aimed at revealing quality problems.

• Examples:

Design review

Testing the raw materials

Quality control

Training testers

Test automation

Usability testing

Pre-release out-of-box testing by customer service staff

Internal Failure

Failure costs are Costs that result from poor quality:

•Bug fixes

•Regression testing

•Wasted in-house user time

•Wasted tester time

•Wasted writer time

•Wasted marketer time

•Wasted advertisements

•Direct cost of late shipment

•Opportunity cost of late shipment

External Failure Costs

Customer service costs

Cost of patching a released product distributing the patch

Examples are:

Lost sales

Lost customer goodwill

Discounts to resellers to encourage them to keep selling the product

Warranty costs

Preparation of support answer books

Investigation of customer complaints

Refunds and recalls

Coding / testing of interim bug fix releases

Shipping of updated product

Risks

• Implementation Risks

– Not being realistic and trying to achieve too much too soon.

– Controversial costs should be left aside, especially the first few times the company is trying to implement the quality-costs analysis

• Other risks:

– Looking only from the point of view of the company, not looking at the customer’s costs

– Might result in other types of risk:

• Customer Dissatisfaction

• Litigation

Benefits

• The goal is to reach minimum quality costs at the desired outgoing quality level.

• It’s a feed-back mechanism: quality costs data is used by the management to make decisions that will impact the quality costs.

• Applications of Quality Costs

– Measurement Tool:

• Quality costs provide comparative measurements for evaluating quality programs

– Process-Quality Analysis Tool

• Quality costs can serve effectively as an analysis tool and point out where the problems are

– Programming Tool

• Quality costs determine how the available resources to be divided

– Predictive Tool

• Quality costs can also be used to evaluate and assure performance in relation to the goals and objectives of the organization.

Operations technology in

Mercedes Benz

Operations technology in

Mercedes Benz

Products Technologically innovators

Technology used to manufacture these products

CAD in Mercedes Benz

Two kinds of software

Mechanical and engineering orientated software

Design in itself software

Production Technology

The cad design has to be integrated in the machine.

Numerical controled Robots

Internet & more corporative

Software

Web page informing aabout their services, new releases and news.

www.mercedes-benz.com

In 1995 they firmed aa contract with IBM to support all the corporative software.

(accounting, net, design)

DESCRIBE A PROCESS IN

OUR FIRM USING ANY OF

THE TOOLS FOR PROCESS

DESIGN.