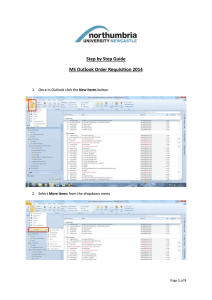

4 The Menu Bar - Ministry of Finance and Treasury

advertisement