20130401 Quality Control Engineer position with Kawasaki

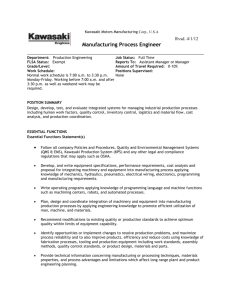

Kawasaki Motors Manufacturing Corp., U.S.A

Engineer, Quality Control

Rvsd. 2.1.12

Department: Quality Control

FLSA Status: Exempt

Grade/Level:

Work Schedule:

Normal work schedule is 7:00 a.m. to 3:30 p.m.

Monday-Friday. Working before 7:00 a.m. and after

3:30 p.m. as well as weekend work may be

Job Status: Full Time

Positions Supervised:

None

Reports To: Asst. Manager, Q.C.

Amount of Travel Required: 0-10% required.

POSITION SUMMARY

Plan, control, and assure product and process quality in accordance with quality principles, which include planning processes, material control, acceptance sampling, and measurement systems.

Investigate and coordinate activities concerned with nonconforming products, product failures, and product improvements.

ESSENTIAL FUNCTIONS

Essential Functions Statement(s)

Follow all company Policies and Procedures, Quality and Environmental Management Systems

(QMS & EMS), Kawasaki Production System (KPS) and any other legal and compliance regulations that may apply such as OSHA.

Analyze and interpret blueprints, data, manuals, and other materials to determine tolerance, inspection and testing procedures, adjustment, formulas, and measuring instruments required, according to standards such as JIS, KES and other Quality specific standards.

Review and update Quality control check sheets, testing procedures, programs and other department documentation as requested or required by customer or special requests.

May create job aide or operator user guides for proper use and care of measuring equipment.

Lead and coordinate teams in failure investigations and improvement projects.

Perform failure analysis and mechanical testing; analyze data to determine root cause and improvement to quality or processes.

Design experiments and conduct tests to reproduce quality problems or failures to ensure the problem is fully understood and that corrective action was effective.

Evaluate analytical methods and procedures to determine how they might be improved.

Establish calibration and Gage R&R standards, studies and improvements.

Create control plans and monitor existing control plans for content, accuracy and efficiency.

Oversee or direct the editing and creation of programs in computerized measuring equipment for specialized or mass production measurement needs.

Analyze measurement data from collection plans and automated equipment to determine potential and existing issues.

Develop, design, and validate inspection gages for sorting nonconforming parts.

Design fixtures for inspection devices to address efficiency, accuracy, and ergonomic concerns.

Create floor plans; prepare set up and implementation of new equipment with consideration for dimensional, environmental, and power requirements.

Troubleshoot and determine usability and functionality of advanced measuring equipment.

Lead or participate in communication with other departments and affected personnel to problem solve or make improvements.

Provide technical support and training for other Team Members.

Research and recommend the purchase of new equipment, technology, or related resources to ensure that section requirements are maintained.

Support Engineering departments and Quality Assurance with complex measurement requests.

Determine process metrics to be monitored, create plans including how they will be sampled, using statistical process control (SPC) tools.

Oversee or direct the editing and creation of programs in computerized measuring equipment for specialized or mass production measurement needs.

Create the main program and structure of CMM to direct new measurement specialized needs.

POSITION QUALIFICATIONS

Competency Statement(s)

KMM Core Behaviors - Responsibility, Integrity, Respect, Adaptability, Communication,

Kawasaki Production System (KPS), Teamwork, Interpersonal skills and Attendance.

KMM Exempt Competencies - Professionalism, Initiative/Self-Motivated, Problem Solving,

Decision Making, Planning, KMM Departmental Functions, Critical Thinking.

Language Skills - Must be able to speak and understand English. Ability to read and interpret documents such as safety rules, operating and maintenance instructions, and procedure manuals. Ability to write routine reports and correspondence. Ability to speak effectively one on one or to groups, as necessary.

Safety Awareness - Ability to identify and correct conditions that affect employee safety.

Trigonometry - .

Gather, Analyze and Report information - Observing, receiving or otherwise obtaining information from all available resources. Identifying the underlying principles, reasons, or facts within the information to provide meaningful results for the given audience.

Production and Processing - Knowledge of raw materials, production processes, quality control, cost and other techniques for maximizing the effective manufacture and distribution of goods.

Engineering and Technology - Knowledge of the practical application of engineering science and technology. This includes applying principles, techniques, procedures, and equipment to the design and production of various goods and services.

Geometric Dimensioning and Tolerancing - Knowledge and awareness of GD&T’s purpose in part design and inspection.

Analytical thinking - Analyzing information and using logic to address work-related issues and problems.

Machine functions - Knowledge of machine and equipment operations and purpose.

Customer Oriented - Customer orientation implies a desire to serve our customers by focusing effort on meeting the customer's needs, understanding their concerns, and seeking to build trust.

Document and Drawing Reading - Ability to interpret and apply symbols and information from prints, work instructions, drawings, schematics and other relevant technical documents.

Departmental procedures and processes - Understands and follows procedures, processes and guidelines of department.

Quality Control Analysis - Conducting tests and inspections of products, services, or processes to evaluate quality or performance.

Technical Writing/communication - Ability to convey technical information to a specific audience by working collaboratively to create deliverables for various distribution such as paper, computer, video, internet etc.

Quality Control Techniques - Knowledge of Quality control techniques and methods to perform capability and process controls (e.g. CPK, SPC, Gage R&R, PPAP. FMEA)

Resourcefulness - Confirms the reliability and accuracy of resources before using them for the specific task. Uses a variety of resources to accurately and efficiently complete the required task/job

Machine Programming - Understand a variety of machine languages to write codes, generally using a PLC, to manipulate machine components to perform a routine set of tasks in order to manufacture or form a product.

Advanced Measuring Equipment - Able to understand and use advanced equipment such as data acquisition equipment, engine dynamometer, etc.

Statistical Process Control - Ability to apply statistical methods to monitor and control a process to ensure that it operates to its full potential to produce a conforming product.

Project Management - Follows PDCA process and uses team to see projects through to completion. Defines scope and timelines of projects Plans and tracks effectively using appropriate project management tools Coordinates implementation effectively to include impacted departments or functions. Establishes benchmarks to measure progress Allocates resources to support implementation Adjusts as necessary to overcome obstacles.

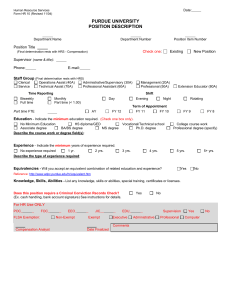

SKILLS & ABILITIES

Education : Education/Experience: Bachelor of Science degree in Engineering or Bachelor of Science degree in Manufacturing/Engineering Technology from a four year college or university and one to two years’ related work experience preferred.

OR Two year Associates’ degree in manufacturing technology or similar technical degree or coursework; with a minimum of three years’ experience as a technician.

Computer Skills

Display appropriate proficiency with computers and computer applications, including: spreadsheets

(e.g., Excel), word processing (e.g. Word), presentation software (e.g., PowerPoint), databases (e. g.,

Access, contact management software), internet/intranet (e.g., browsers, search engines), special applications (e.g., general ledger for accounting/finance; HRIS for human resources, etc.), e-mail; can diagnose and correct minor issues with hardware and software or create instructional materials as needed.

Auto CAD and Solid Modeling Experience.

Other Requirements

Will be required to wear company uniform.

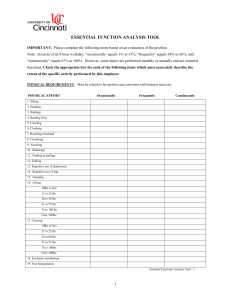

PHYSICAL DEMANDS

Physical Demands

Stand

Walk

Sit

F (Frequently)

F (Frequently)

F (Frequently)

Handling / Fingering C (Constantly)

Reach Outward O (Occasionally)

Reach Above Shoulder O (Occasionally)

Climb

Crawl

Squat or Kneel

Bend

O (Occasionally)

O (Occasionally)

O (Occasionally)

N (Not Applicable)

Lift/Carry

10 lbs or less

11-20 lbs

21-40 lbs

41-100 lbs

Over 100 lbs

Push/Pull

12 lbs or less

13-25 lbs

26-40 lbs

41-100 lbs

O (Occasionally)

O (Occasionally)

O (Occasionally)

N (Not Applicable)

N (Not Applicable)

N (Not Applicable) Activity is not applicable to this occupation.

O (Occasionally) Occupation requires this activity up to 33% of the time (0 - 2.5+ hrs/day)

F (Frequently) Occupation requires this activity from 33% - 66% of the time (2.5 - 5.5+ hrs/day)

C (Constantly) Occupation requires this activity more than 66% of the time (5.5+ hrs/day)

Other Physical Requirements

Vision (Near, Distance, Color, Depth Perception)

O (Occasionally)

O (Occasionally)

N (Not Applicable)

N (Not Applicable)

Sense of Sound (Within OSHA regulatory requirements)

Sense of Touch

Ability to wear Personal Protective Equipment (PPE) (Hearing Protection, Safety Glasses and other PPE as necessary)

WORK ENVIRONMENT

Usually works in an open office environment. Some work may be done on the production floor.

Prepared by:___________________________ Date: ______________

Approval Signature:_____________________ Date: ______________

Approval:______________________________ Date: ______________

The Company has reviewed this job description to ensure that essential functions and basic duties have been included. It is intended to provide guidelines for job expectations and the employee's ability to perform the position described. It is not intended to be construed as an exhaustive list of all functions, responsibilities, skills and abilities. Additional functions and requirements may be assigned by supervisors as deemed appropriate. This document does not represent a contract of employment, and the Company reserves the right to change this job description and/or assign tasks for the employee to perform, as the Company may deem appropriate.

Good afternoon Mr. Yang. I'd like to reintroduce myself. I came to your campus last year with a few of my colleagues from Kawasaki, here in Maryville.

Patsy Reed, Tim Woolery and Galen Cloud and I came to tour your facility and hear more about your programs.

I am now the responsible party here for recruiting and staffing for our Engineer and Technician positions as Patsy has retired.

I am hoping to reconnect with you so we can work together on placing your students in some of our positions.

Just to remind you of some positions that your students could fill, I'll share here a list of relevant jobs at

KMM:

Manufacturing Process Engineer

Product Development Engineer

Engineering Technician

Technician II, R&D

Quality Control Engineer

Please share with your students the types of position we have available. We would appreciate you doing this on on a continuous basis.

We also currently have openings in all the these positions.

I've attached the job descriptions here for you to post on your career services site.

Students and alumni can apply by emailing their resume to hresumes@mvl.kmmfg.com.

Donell R. Anderson

Sr. Supervisor, Human Resources

Kawasaki Motors Manufacturing Corp., U.S.A.

28147 Business Hwy. 71

Maryville, MO 64468

Email: danderson@mvl.kmmfg.com

Phone: (660) 562-7106 www.kawpower.com