Use of Streamlined Life Cycle Assessment (SLCA)

advertisement

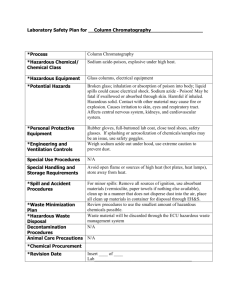

GREEN BY DESIGN Pratt & Whitney’s Green Engine Program Columbia University Industrial Ecology Course February, 2001 Pratt & Whitney - United Technologies Corporation Pratt & Whitney Bob Tierney Today’s topics... • • • • United Technologies Corporation Pratt & Whitney’s Green Engine Program Our conception of Life Cycle Assessment Elimination of hazardous materials from life cycle • Strategic thoughts on implementing green Progress !! Lead air emissions 98% decrease 1970-95 Lead in child’s blood 82% decrease 1976-95 CO emissions 30% decrease 1970-92 Auto hydrocarbons 98% decrease 1970-95 Lakes/ rivers 60% fully meet water stds. Bald eagle off endangered species list Sewage 100% treated in US (EU -72%) U.S. data unless noted Progress ?? Electricity use per capita 21 % increase Aluminum consumption 1200% increase 1970-88 CO2 concentration 7% increase 1975-95 Waste to landfills 34% increase 1970-90 Ozone hole 60% deeper 1970-95 U.S. data unless noted 1977-87 The Master Equation Global Envi. Impact = Population X Resource use Person Unit of Waste X Unit of Resource Drivers for Green • • • • • • • State of the environment Customers Bottom line (Green = $$$$) Top Line Growth Wall St. Politics/ Regulations UTC Policy/ 10X Goals Local Restrictions Increasing at an Accelerating Rate * Noise Abatement Procedures Number of Restrictions Curfews 400 350 300 250 200 150 100 50 0 1970 Charges Levels Quotas Budgets Ch. 2 Phase-out Ch. 2 Restrictions Ch. 3 Restrictions 1980 1990 2000 Year * Based on 594 airports in Boeing database 2/22/00 http://www.boeing.com/assocproducts/noise/list.html 25 Green Engine Program is structured as a matrix organization Design Suppliers Management Green Factory Technology Customer Requirements/ Communications Life Cycle Assessment: The Stages For the sake of simplicity the life cycle is divided into unit processes usually broken down as follows: premanufacture, manufacture, distribution and installation, use and service, and end of life management. Each unit process is then evaluated in three areas: safety, conservation, and pollution. The inputs and outputs of each life stage are the criteria for evaluation. Pre-Manu facture Manufacturing Distribution Use & Service Recovery Management Reuse Remanufacture Revert CO2 Emissions Factory vs. Use MILLION METRIC TONS OF CO2 120 100 80 60 40 20 0 55X UTC P&W FLEET Develop Process Map with the “Goes-Ins” and the “Goes-Outs” Inputs Outputs Process or Activity Product or Service Raw Materials Actions of People, By-products Equipment, Machines Chemicals Reactions of Energy Injuries Chemicals and Materials Fuels Illnesses Electricity Inefficiencies Air Emissions Water Discharges Solid/Liquid Waste Tap Into Existing Data Sources Degreasing 4% Misc.. Sources 32% Machining & Metalworking 8% Painting 14% All Other Injuries 43% Ergonomic Injuries 57% Plating 5% Material Handling 37% Stripping 9% Cleaning & Rinsing 11% Surface Preparation & Treatment 17% Hazardous waste sent off site by process source Maintenance & Service 11% Manufacturing & Assembly 26% Injuries by type and operation Is it Good, Bad or Ugly? EH&S IMPACTS LIFE STAGE PREMANUFACTURE MANUFACTURE DISTRIBUTION & INSTALLATION USE & MAINTENANCE END OF LIFE MAKE PRODUCTS & WORKPLACE SAFE PROTECT ENVIRONMENT CONSERVE RESOURCES Elements of a Green Engine Vision: Pratt & Whitney sets the Standard for Green Has the lowest possible Emission Impact during use Has lowest possible Noise Impact Is manufactured and serviced using Green Processes Is designed with Human Factors in mind Is Material Efficient (Metal Buy-to-fly, Propellant Yield ) Is Energy Efficient during use (Fuel Burn) Contains Green Materials Has least possible Factory Impacts Involves Green Suppliers and Partners Is Designed for Serviceability, Reusability, Recyclability Understanding Impacts is Key to Continuous Improvement Job Ticket/ SRD/ CRD LCA Goals Design Standard Work Design Specifications Procurement Process Operating Procedures End of Life Service Use Distribute P&W Manufacturing Environment, Safety, Natural Resources Impact Supplier Manufacturing Knowing Where to Apply the ‘Green’ Pressure Points Technology Team Customer Req’mt Team Supplier Team Job Ticket/ SRD/ CRD LCA Goals Design Standard Work Design Team End of Life Design Specifications Operating Procedures Green Factory Team Service Use Procurement Process Distribute P&W Manufacturing Environment, Safety, Natural Resources Impact Supplier Manufacturing LCA as Part of Integrated Program Deployment (IPD) PRODUCT LIFE CYCLE ASSESSMENT TECHNICAL SUPPORT PLANNING DEFINITION VALIDATION DELIVERY Product Requirements Objectives & Targets EH&S ANNUAL PLANNING& EVALUATION SUPPORT Market Feedback Analysis Aspects & Impacts Baseline LCAs are the Standard by Which Future Products Are Compared Large Gas Turbine Engine General Aviation Engine Liquid Rocket (expendable & serviceable) Solid Rocket (expendable & serviceable) What is a Life Cycle Assessment? •Qualitative process used to assess EH&S impacts of product during its lifecycle What does it provide? •Relative magnitude of EH&S impacts •Areas of information gaps •Priorities for green design •Priorities for green technology development And…. •Raises consciousness of organization Materials/ Processes of Concern MATERIALS OF CONCERN FOR GAS TURBINE AND ROCKET PROPULSION SYSTEMS • Materials Of Concern • Hazardous Materials Index • Product Comparisons • Standard Work • Green Technology Goals • Summary Materials Of Concern Objectives • Identify hazardous material risks across the enterprise • Provide a deliverable for incorporation into standard work • Create a green index to drive green technology plan Rationale • Appearance of targeted materials on one or more industry, customer or regulatory list(s) of hazardous materials • Relevance to Pratt & Whitney product lines or processes • Potential linkage to product and process design callouts Definition Of Categories • Prohibited – high risk materials not permitted in new design and development • Restricted – high risk materials that can only be used with appropriate levels of approval – plan must be established to validate alternate green material • To Be Reduced – materials known to have detrimental environmental, health and safety impacts. Materials of Concern Prohibited Arsenic & compounds Asbestos Benzene Beryllium Cadmium & compounds Chlorinated solvents Ethyl alcohol Ethylene glycol ether compounds Formaldehyde Mercury & compounds Methanol (methyl alcohol) Methylene chloride Class I ozone depleting substances Radioactive materials, including Thoriated (TD) nickel Toluene diisocyanate Restricted Chromium, hexavalent Class II ODS Cyanides Dimethylformamide HCFC-14 lb & HCFC-22 Hydrazine Hydrofluoric acid Hydrogen fluoride gas Lead & compounds Manmade fibers, e.g., cristobalite, fiberfrax MDA (4’, 4’-Methylenedianiline) Methyl alcohol (methanol) Methyl ethyl ketone (MEK, 2butanone) Methyl iso-butyl ketone (MIBK, 4-methyl-2-pentanone) Phenol Styrene Toluene Xylene To Be Reduced Acetone Ammonia Butyl alcohol Ethyl benzene n-Hexane Hydrochloric acid Isocyanates n-methyl-2-pyrrolidone Isopropyl alcohol Nickel plate Nitric acid Petroleum distillates (e.g., naptha, mineral spirits, stoddard solvent, varsol, evaporative lubricants) Phosphoric acid Sec-butyl alcohol Sulfuric acid 1, 2, 4Trimethylbenzene Hazardous Materials Index • Purpose – provide metric to define “greenness” of products – link materials to specifications/design callouts • Assign “toxicity” values to materials & process specifications based on Purdue University rankings • Quantify green indices based on Pratt & Whitney Canada algorithm: Ih = T*nP/N where: Ih = Hazardous Material Index T = toxicity value of specification nP = number of part numbers that call out specification N = total number of part numbers in engine Hazardous Materials Index Implementation • Establish metrics/set goals • Establish signoff/approval protocols • Control via standard work Restricted Materials of Concern - Current Status of Various Engine Programs Hazardous Materials Index 30 25 20 15 10 Technology Opportunity 5 0 JT8D-219 PW2037 PW4168 Goal Standard Work Materials Of Concern • Contains background, contacts and protocols • References material and process specification list • Links to data base containing materials of concern, toxicity rating detail, identified by specifications • Links to menu for selection of alternate materials and processes, cross-referenced by specification Materials of Concern List with Specification Number Specification Number Hazardous Material PWA-316 Lead PWA-333 Xylene, Toluene AMS-3110 Chromium, Toluene QQ-P-416 Cadmium PWA-315 None PWA-1469-3 None AMS-3242 None Green Technology Goals • Goals established based on driving down product hazardous materials index • Goal for legacy products will be based on designing out prohibited materials • Goal for new designs will be based on eliminating the use of restricted materials Summary • Comprehensive effort to identify hazardous material risks across the Pratt & Whitney enterprise • Risks defined by levels of concern • Standard work tool for designers established • Goals in process of being defined • Hazardous Materials Index will drive technology Rod Elkington, Chairman: “Tomorrow’s economy will be about increasing returns where we learn to exploit virtuous cycles rather than manage vicious ones.”