Phase 3 Presentation

advertisement

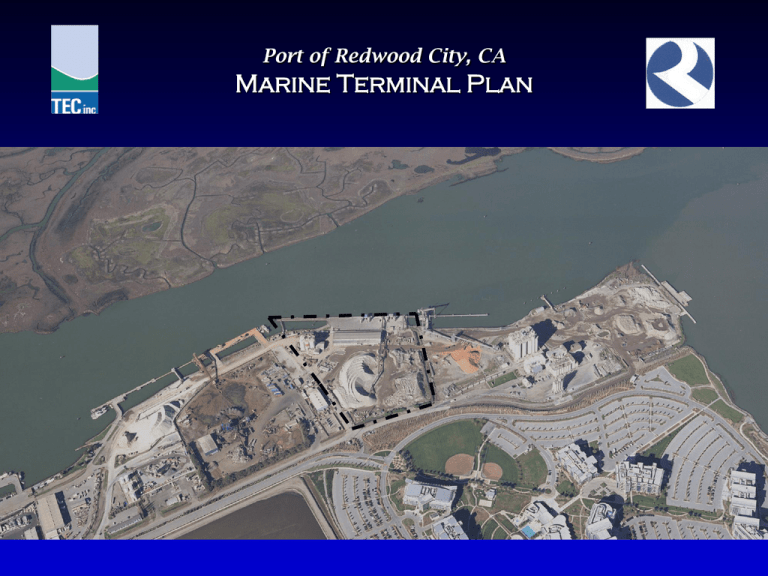

Port of Redwood City, CA Marine Terminal Plan Background and Need BACKGROUND • The Port of Redwood City plays a key role in Bay area Port infrastructure system • Experiencing steady cargo growth, specifically related to dry bulk cargoes • Nearly 2.0 Million tons per year handled in FY2005 • It is anticipated growth and demand will continue into the future • Reliability and stability of Port facilities critical to sustaining operations and attracting new tenants that will foster continued growth Wharves 3 and 4 SIMS Metal HS&G/CEMEX Yard Wharves 1 and 2 Background and Need NEED for MARINE TERMINAL PLAN • Focus for Marine Terminal Plan is the redevelopment of Wharves 1 and 2 • Wharves 1 and 2 are critical to present and future cargo activity at the Port • Berth conflicts between Wharves 1 and 2 and the cement berth demand attention. Need to partially accommodate two ships simultaneously to increase efficiency and berth capacity. • Wharves 1 and 2 present condition: • Timber construction, original wharf constructed in 1937 • Several Wharf and Transit Shed expansion projects since inception • Extensive repairs, upgrades and replacements to pile system completed in 1979 • Wharf system now significantly deteriorated; in need of replacement • Piles support system suspect – no known inspections or upgrades since 1979 project, • Timber deck worn and considered unsafe for vehicle traffic in many areas, • Timber vehicle approach ramp and access walkway are deteriorated and not functional, • Timber fender system collapsing and inadequate for vessel berthing, and • Flooding under landward seawall prevalent at high tides. Marine Terminal Plan Three-Phase Approach • Phase 1 – Completed October 3, 2005 Objective: Review cargo data and Port physical layout to determine the best use for Wharves 1 and 2 within the framework of the overall Port. • Phase 2 – Completed November 16, 2005 Objective: Develop an efficient, cost effective and constructible Marine Terminal Plan that responds to the best current and projected use identified for Wharves 1 and 2. • Phase 3 – Completed February 28, 2006 Objective: Further expand the Phase 2 conceptual plans and cost estimate and provide a plan for moving forward with the redevelopment project. Marine Terminal Plan ELEMENTS OF THE PLAN • Wharf Redevelopment Plan • Demolition plan and recommendations • Interim Conveyor Plan – relocate ship receiving • hopper away from cement berth Site Development Plan – Raze Warehouse #1 and realign HS&G/CEMEX lease area to provide the Port with additional land for future development opportunities • Environmental and Permitting Review • Cost Estimates • Project Schedules Wharf Redevelopment Plan • • • • Concrete pile supported concrete platform, 60’ wide x 490’ long (nominal) 500psf design deck load Two approach trestles/ramps Walkways between existing monopile fender dolphins Wharf Redevelopment Plan • • • • Combination barge/ship fenders spaced along length of proposed wharf Elevation to match existing timber wharf, slope access ramps to existing grade Storm water runoff contained on wharf and directed to land along access ramps Repair/replace landward seawall Demolition Plan • Recommend complete removal of existing timber wharf system – – – – Overall, long term cost savings for demolition Maintenance cost savings related to retaining deteriorating structures Existing wharf stability is suspect, safety issues Environmental benefit of removing old, creosote impregnated piles and deteriorating timber platform Interim Conveyor Plan • • • • Relocate ship-unloading operations away from RMC/CEMEX Demolition of Warehouse #1 NOT required Realignment/modifications to HS&G/CEMEX yard NOT required Low cost solution to help (partially) mitigate berth conflict issues – – May initially utilize portable equipment on existing wharf, prior to reconstruction Viable alternative for permanent system if HS&G/CEMEX does not realign yard Preferred Marine Terminal Plan Environmental & Permitting Review Bay Fill Mitigation Strategy (Demolition & Construction) • BCDC will require mitigation to offset any new construction • Removal off all existing structures are proposed to mitigate proposed construction; • remainder will establish a mitigation bank Can not lock in ratio of mitigation credit to new/proposed fill elsewhere in the Port NEPA/CEQA Process • One joint NEPA/CEQA document will be prepared – – NEPA: National Environmental Policy Act CEQA: California Environmental Quality Act – Cultural resources, Air Quality, Biological resources, Traffic – Demolition of Warehouse #1 could potentially effect the level of environmental documentation • NEPA/CEQA review will require studies of impacts including: • Warehouse #1 may be eligible to be listed as a historic resource under CEQA • Potential Project Construction Permits identified and listed in Report • Potential Terminal Operating Permits identified and listed in Report Cost Estimates Environmental Document Preparation: • Historic Evaluation of Warehouse #1: • EA/ND: • EIS/EIR: Wharf Redevelopment Plan: • Wharf with complete demolition: • Wharf with partial demolition: • Costs shown include: – – – – – – – – $10,000 to $12,000 $85,000 $190,000 $15,329,000 $12,782,000 Demolition and removal of existing timber structures Pile supported concrete platform with two approach trestles Fender elements, bollards and other hardware Line handler walkways between existing breasting dolphins Electrical power distribution system upgrades Contractor mob/demob, project administration, overhead & profit Expenses for bonds, engineering, testing, inspection, construction management 15% allowance for contingency Cost Estimates Site Redevelopment Plan: • Landside infrastructure improvements: • Cost includes: $996,000 – – – – – – Demolition and removal Warehouse #1 and foundations Removal of existing rail adjacent to Wharves 1 and 2 Improved access road adjacent to waterfront Rail crossing and intersection improvements at Hinman Road Longshoremen/Stevedore’s building with paved parking area Service improvements including electrical, communications, potable water, sewer and drainage – Contractor overhead & profit – Expenses for bonds, engineering, testing, inspection, construction management – 15% allowance for contingency • Cost excludes: – Purchase and installation of new hopper and conveyor system – Realignment of HS&G/CEMEX storage yard; relocation of existing equipment – Soil improvements, if required to accommodate new stockpile location Project Schedule DESIGN-BID-BUILD vs. DESIGN-BUILD: • The Port may opt to follow either contracting method • Design-Bid-Build: – – – – Port advertises for and selects an A/E Firm to design the project Second advertisement and selection for a contractor to build the project using A/E Firm’s plans and specifications Traditional contracting method A/E Firm works for Port and Port has more input into details of design – – – – Port advertises for and selects an A/E-Contractor team to design and construct the project Generally results in an overall reduction in project cost and shorter schedule to delivery Disputes between A/E Firm and Contractor eliminated Has recently become the contracting method of choice for many owners • Design-Build: RECOMMENDATION: • Overall cost difference between contracting methods not substantial • If project timeline is critical factor, recommend Design-Build contract Project Schedule OVERALL PROJECT SCHEDULE: Time-line from the start of Environmental Documents to completion: • Design-Bid-Build contract: 30 to 33 months (EA/ND or EIS/EIR) • Design-Build contract: 24 to 27 months ENVIRONMENTAL DOCUMENTS and PERMITTING: • Historic Evaluation of Warehouse #1: 2 months • Following Historic Evaluation, level of Environmental Documentation determined – EA/ND: 6 months – EIS/EIR: 9 months • Permitting follows Environmental Document: 5.5 months Project Schedule Project Execution Plan WHERE DO WE GO FROM HERE? • Work with HS&G/CEMEX to install temporary system to • relocate ship unloading operations closer to Wharf 2 and away from RMC/CEMEX cement wharf. Perform Economic Evaluation/Impact Analysis of wharf replacement – Phased construction planning is possible • Initiate Warehouse #1 Historic Review – Results of assessment will determine the level of NEPA/CEQA review • Prepare Environmental Document(s) • Prepare RFP documents to advertise and select a Design/Design-Build Contractor to initiate project design and construction Port of Redwood City, CA Marine Terminal Plan