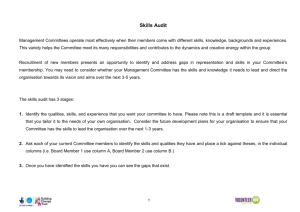

Health & Safety Audit Workbook

advertisement