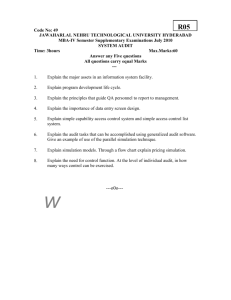

1: Introduction

advertisement