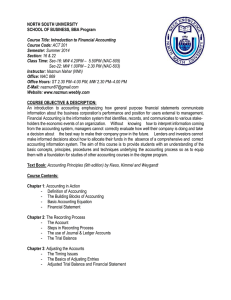

Ch13 Agg Planning

advertisement

Seasonal variation in demand E.g. Ice Cream Factories Agora on employment and departmental space allocation Adeyl Khan, Faculty, BBA, NSU Planning Horizon/Levels Short-range plans (Detailed plans) • Machine loading • Job assignments Intermediate plans (General levels) • Employment • Output Long-range plans • Long term capacity • Location / layout Long range Short range Now Intermediate range 2-3 months Adeyl Khan, Faculty, BBA, NSU Aggregate planning: Intermediate-range capacity planning, usually covering 2 to 12 months. (Also called Macro planning) 18 Months 13-2 Aggregation- what is? Aggregate Plan Month Jan # of Motors Feb 40 Mar 25 Apr 55 May 30 Jun 30 Jul 50 Aug 30 Sep 60 40 Master Schedule Month Jan Feb Mar Apr May Jun Jul Aug Sep 5 hp 15 - 30 - 15 30 - - 10 25 hp 20 25 - 15 - 15 20 30 20 20 hp - - 25 - 15 - 10 10 - 50 hp 5 - - 15 - 5 - 20 10 Adeyl Khan, Faculty, BBA, NSU 3 Why do it? To develop a feasible production plan on an aggregate level that achieves a balance of expected demand and supply usually demand and supply are converted to aggregate units such as labour-hours, working days, general product units, etc. Adeyl Khan, Faculty, BBA, NSU Objective of Aggregate Planning Corporate strategies and policies Economic, competitive, and political conditions Planning Sequence Aggregate demand forecasts Business Plan • Establishes production and capacity strategies Production plan • Establishes production capacity Master schedule • Establishes schedules for specific products Adeyl Khan, Faculty, BBA, NSU Aggregate Planning Approaches Maintain a level workforce Maintain a steady output rate Match demand period by period Use a combination of decision variables Basic approaches Level capacity Maintaining a steady rate of regular-time output while meeting variations in demand by a combination of options. Adeyl Khan, Faculty, BBA, NSU Chase demand Matching capacity to demand; the planned output for a period is the expected demand for that period. Level and Chase Strategies Quantity Output less than demand Demand Normal capacity Demand Output level Output exceeds demand Output above normal Output below normal Adeyl Khan, Faculty, BBA, NSU Level Output Strategy Demand Chase Demand Strategy Normal capacity Cumulative output/demand Cumulative Graph 1 Cumulative production Cumulative demand 2 Adeyl Khan, Faculty, BBA, NSU 3 4 5 6 7 8 9 10 Example - a personal plan An NSU UG student One year expenses tuition 40,000 transportation 1000 x 12 = 12000 food and meal 2000 x 10 = 20000 summer 5000 x 2 = 10000 others 500 x 12 = 6000 Total Adeyl Khan, Faculty, BBA, NSU 88,000 Example - a personal plan A NSU UG student plan income Bank loan, etc 40000 private tutoring part time job summer job family money Total saving 2000 x 12 = 24000 2000 x 10 = 20000 6500 x 2 = 13000 1000 x 10 = 10000 107000 107000 - 88000 = 19000 Objective: income meets expenses; maximize saving; etc. (What do you call this?) Adeyl Khan, Faculty, BBA, NSU General steps in AP 1. Forecast demand in the period 2. Develop plan(s) to meet the demand by setting levels on output, employment, inventory, etc. 3. The plans are refined or reworked until a feasible and satisfactory plan is uncovered. Adeyl Khan, Faculty, BBA, NSU Options to affect demand level Pricing e.g., shift demands from peak periods to off-peak periods. The more the elasticity, the more effective pricing will be on the demand pattern. Promotion Backorders (depend on customers’ willingness) Develop new demand (market) during off-peak period Adeyl Khan, Faculty, BBA, NSU Options to affect capacity Hire and fire workers - depends on the intensity of labour used, the strength of the union, corporate culture, labour laws, etc. Overtime/slack time - to keep a skilled workforce and allows employee to increase earnings Partime workers - depend on nature of work Inventories - smooth production and buffer against demand surge; could be costly Subcontracting - capacity increase in a short time without heavy investment; less control Adeyl Khan, Faculty, BBA, NSU Mathematical Techniques Linear programming: Methods for obtaining optimal solutions to problems involving allocation of scarce resources in terms of cost minimization. Linear decision rule: Optimizing technique that seeks to minimize combined costs, using a set of cost-approximating functions to obtain a single quadratic equation. Adeyl Khan, Faculty, BBA, NSU Summary of Planning Techniques T e c h n iq u e S o lu tio n C h a r a c te r is tic s G r a p h ic a l/ c h a r tin g T r ia l a n d e rro r L in e a r p r o g r a m m in g L in e a r d e c is io n r u le O p tim iz in g S im u la tio n T r ia l a n d e rro r In tu itiv e ly a p p e a lin g , e a s y to u n d e r s ta n d ; s o lu tio n n o t n e c e s s a r ily o p tim a l. C o m p u te r iz e d ; lin e a r a s s u m p tio n s n o t a lw a y s v a lid . C o m p le x , r e q u ir e s c o n s id e r a b le e f f o r t to o b ta in p e r tin e n t c o s t in f o r m a tio n a n d to c o n s tr u c t m o d e l; c o s t a s s u m p tio n s n o t a lw a y s v a lid . C o m p u te r iz e d m o d e ls c a n b e e x a m in e d u n d e r a v a r ie ty o f c o n d itio n s . Adeyl Khan, Faculty, BBA, NSU O p tim iz in g Example The VP of Operations is about to prepare the aggregate plan that will cover six periods in the horizon. The company has forecasted the following demand: Period 1 Forecast demand 200 2 3 4 5 6 Total 200 300 400 500 200 1800 The output cost is $2 per unit at regular time; $3 per unit at overtime; $6 per unit if subcontracted. Average inventory cost is $1 per unit per period. Back orders are possible, however, the Company estimated the cost to be $5 per unit per period. The initial inventory is zero. There are 15 workers and each worker is able to produce 20 units of the product per period. Can you help the VP to develop an aggregate plan? Adeyl Khan, Faculty, BBA, NSU Example - solution Suppose the VP wants to use a leveling (capacity) approach, I.e., maintaining a steady rate of output. The total output by the workers at the regular time is 20 x 15 x 6 = 1800 which equals to the forecast demand. Average inventory = Beginning Inventory + Ending Inventory 2 Adeyl Khan, Faculty, BBA, NSU Period Forecast demand Output-regular Output-over time Output-subcontract Output-excess Inventory Inven.-beginning Inven.-ending Inven.-average Backlog Cost Regular Overtime Subcontract Hire/Fire Inventory Backorders 1 200 300 2 200 300 3 300 300 4 400 300 5 500 300 6 200 300 Total 1800 1800 100 100 0 -100 -200 100 0 0 100 50 100 200 150 200 200 200 200 100 150 100 0 50 100 0 0 0 600 600 600 600 600 600 3600 50 150 200 150 50 500 0 600 500 Total cost 650 750 800 750 1150 600 4700 Adeyl Khan, Faculty, BBA, NSU Example- Chase demand The VP learned that a regular worker is retiring. Rather than hiring new worker, the VP decides to use overtime. However, the maximum amount of overtime output is 40 units per period. Suggest an aggregate plan for the VP Regular worker produce 14 x 20 units = 280 units per period. The total deficiency is 120 units. These 120 units can be satisfied in 3 periods by overtime and can be produced during the periods of high demand (for cost consideration. Of course, you can put them in other periods too.) Adeyl Khan, Faculty, BBA, NSU Period Forecast demand Output-regular Output-over time Output-subcontract Output-excess Inventory Inven.-beginning Inven.-ending Inven.-average Backlog Cost Regular Overtime Subcontract Hire/Fire Inventory Backorders 1 200 280 2 200 280 3 300 280 40 4 400 280 40 5 500 280 40 6 200 280 Total 1800 1800 80 80 20 -80 -180 80 0 0 80 40 80 160 120 160 180 170 180 100 140 100 0 50 80 0 0 0 560 560 560 120 560 120 560 120 560 3360 40 120 170 140 50 400 0 520 500 Total cost 600 680 850 820 1130 560 4640 Adeyl Khan, Faculty, BBA, NSU Solved Problems: Problem 1 Period 1 2 3 4 5 6 7 8 9 Total 190 230 260 280 210 170 160 260 180 1,940 22 22 22 22 22 22 22 22 22 220 220 220 220 220 220 220 220 220 1,980 30 -10 -40 -60 10 50 60 -40 40 40 0 30 20 0 0 0 0 40 0 Ending 30 20 0 0 0 0 40 0 40 Average 15 25 10 0 0 0 20 20 20 110 0 0 20 80 70 20 0 0 0 190 5 1,100 1,100 1,100 1,100 1,100 1,100 1,100 1,100 1,100 9,900 10 150 250 100 0 0 0 200 200 200 500 1,100 100 0 0 2000 8000 7000 2000 0 0 0 19,000 1,750 1,350 3,200 9,100 8,100 3,100 1,300 1,300 1,300 30,500 Forecast # Employees Output Regular Output-Forecast Inventory Beginning Backlog Costs: Output Regular Hire/Fire Inventory Backorders Total Adeyl Khan, Faculty, BBA, NSU 13-21 Quantitative approach Suppose the VP wants to use a more quantitative approach that use overtime only and have in mind that the cost be minimized. Can you help him? Let us define the following notation: Pt = No. of units produced via regular time at period t, t=1, …, 6 Dt = Demand (in No. of units) at period t, t=1, …, 6 Ot = No. of units produced at period t in overtime, t=1, …, 6 It = Inventory level (in No. of units) at the end of period t, t=1, …, 6 Adeyl Khan, Faculty, BBA, NSU For ease of handling, we introduce the concept of back order Bt at period t. The following is a kind of “conservation law” It = It-1 + Pt - Dt , t = 1, …, 6. The Objective function is given by: 6 (2P t 1 t 6 (P t 1 t O t Bt I t ) 3O t 5B t I t ) subject to Pt O t I t -1 B t - I t - B t -1 D t , t 1,...,6 0 Pt 280, t 1,...,6 0 O t 40, t 1,...,6 B t , I t 0, t 1,...,6 Notice that I0 = 0 and B0 = 0, (D1, …, D6) = (200,200,300,400,500,200) Adeyl Khan, Faculty, BBA, NSU Disaggregating the aggregate plan The aggregate plan gives the level of demand and supply in aggregate units at the macro level In order for the company to execute the plan, it needs to disaggregate the plan into appropriate units for implementation and monitoring. The output of this process is a master schedule and a master production schedule. Adeyl Khan, Faculty, BBA, NSU Master Scheduling Process Beginning inventory Forecast Inputs Customer orders A master schedule is a schedule (usually in the form of a table) indicating the quantity and timing (I.e., delivery times) for individual products or a group of individual products. Master scheduling Master production schedule Uncommitted inventory Adeyl Khan, Faculty, BBA, NSU Projected inventory Outputs Example Forecast demand Initial inventory is 64 Forecast demand Committed customer orders Projected onhand inventory MPS ATP inventory Adeyl Khan, Faculty, BBA, NSU 1 30 A Master Schedule June 2 3 4 1 30 30 30 40 July 2 40 June 3 40 4 40 July 1 30 2 30 3 30 4 30 1 40 33 20 10 4 2 2 40 3 40 4 40 Another MPS problem Initial inventory is 64 Forecast demand Committed customer orders Projected on-hand inventory MPS ATP inventory Adeyl Khan, Faculty, BBA, NSU 1 30 June 2 3 30 30 33 20 10 4 30 1 40 4 2 July 2 3 40 40 4 40 Another MPS problem solution Initial inventory is 64 Forecast demand Committed customer orders Projected on-hand inventory MPS ATP inventory Adeyl Khan, Faculty, BBA, NSU 1 30 June 2 3 30 30 33 20 31 1 4 30 1 40 10 4 2 41 70 11 41 70 July 2 3 40 40 1 31 70 4 40 61 70 Another MPS problem solution … Initial inventory is 64 Forecast demand Committed customer orders Projected on-hand inventory MPS ATP inventory Adeyl Khan, Faculty, BBA, NSU 1 30 June 2 3 30 30 33 20 31 1 11 4 30 1 40 10 4 2 41 70 56 11 41 70 68 July 2 3 40 40 1 31 70 70 4 40 61 70 70 Projected On-hand Inventory Beginning Inventory 64 Forecast Customer Orders (committed) Projected on-hand inventory Customer orders are larger than forecast in week 1 1 30 JUNE 2 3 30 30 4 30 5 40 33 20 10 4 2 31 1 -29 JULY 6 7 40 40 8 40 Forecast is larger than Customer orders in week 3 Forecast is larger than Customer orders in week 2 Figure 13.8 Adeyl Khan, Faculty, BBA, NSU 13-30 Relevant important ideas Adeyl Khan, Faculty, BBA, NSU 31 AP and Master scheduling Aggregate planning • planning the quantity and timing of output over the intermediate range by setting/adjusting the • production rate • Employment • Finished goods inventory, and related variables. • planning activities at this “early” stage are concerned with homogeneous categories, e.g. gross volumes Master scheduling • follows aggregate planning and expresses the overall plan in terms of the amounts of specific end items to produce and dates to produce them. Adeyl Khan, Faculty, BBA, NSU 32 Aggregate Planning Inputs Resources (Available) Demand forecast Policies • Workforce • Facilities • Subcontracting • Overtime • Inventory levels • Back orders Costs • Inventory carrying • Back orders • Hiring/firing • Overtime • Inventory changes • Subcontracting AP Outputs Projected levels of Total cost of a plan Adeyl Khan, Faculty, BBA, NSU • • • • • Inventory Output Employment Subcontracting Backordering 13-33 Aggregate Planning in Services Services generally have variable processing requirements that make it difficult to establish a suitable measure of capacity. Capacity availability can be difficult to predict Services occur when they are rendered. Services cannot be stockpiled or inventoried so they do not have this option. It is considered "perishable,“ An empty hotel room cannot be held and sold later Demand for service can be difficult to predict Labor flexibility can be an advantage in services Adeyl Khan, Faculty, BBA, NSU 13-34 Time Fences in MPS Time Fences – points in time that separate phases of a master schedule planning horizon. Period 1 2 “frozen” (firm or fixed) Adeyl Khan, Faculty, BBA, NSU 3 4 5 “slushy” somewhat firm 6 7 8 9 “liquid” (open) 13-35 Calculating ATP Calculated only in current week and any week with MPS>0 Current period: on-hand plus any current period MPS, minus all orders in that and subsequent periods until next MPS Later periods: MPS – all orders until next MPS Adeyl Khan, Faculty, BBA, NSU level production plan 1 Forecast Available (End) MPS On hand (start) 2 3 4 5 6 7 8 9 10 11 12 10 10 10 10 10 10 10 10 10 10 10 10 20 20 20 20 20 20 20 20 20 20 20 20 10 10 10 10 10 10 10 10 10 10 10 10 20 Forecast Available (Ending) MPS On hand (starting) 1 5 2 5 3 5 4 5 5 5 6 7 8 9 10 11 12 5 15 15 15 15 15 15 25 30 35 40 45 50 45 40 35 30 25 20 10 10 10 10 10 10 10 10 10 10 10 10 20 Different sales forecast - Same total: 120 units, starts lower, goes higher Adeyl Khan, Faculty, BBA, NSU “Chase” production strategy Forecast Available (Ending) MPS On hand (starting) 1 2 3 4 5 6 7 8 9 10 11 12 5 5 5 5 5 5 15 15 15 15 15 15 20 20 20 20 20 20 20 20 20 20 20 20 5 5 5 5 5 5 15 15 15 15 15 15 20 Production adjusts to meet demand Adeyl Khan, Faculty, BBA, NSU 38 Lot size of 30 units Forecast Available (Ending) MPS On hand (starting) 1 2 3 4 5 6 7 8 9 10 11 12 5 5 5 5 5 5 15 15 15 15 15 15 15 10 5 30 25 20 5 20 5 20 5 20 0 0 0 30 0 0 0 30 0 30 0 30 20 Produce if projected balance falls below 5 units Extra on-hand inventory is “cycle stock” 5 unit “trigger” is safety stock Adeyl Khan, Faculty, BBA, NSU Adeyl Khan, Faculty, BBA, NSU 40 BOM formats Single-level BOM only shows one layer down. Indented BOM Bike Frame Assembly Wheel Assembly Wheel Assembly Wheel Tires Adeyl Khan, Faculty, BBA, NSU Components Frame Wheel Hubs & Rims Spokes Tires Low-Level Code Numbers Lowest level in structure item occurs Top level is 0; next level is 1 etc. Process 0s first, then 1s Know all demand for an item Where should blue be? The low-level code controls the sequence in which the material is planned in an MRP run: First the materials with low-level code 0 are planned, then the materials with low-level code 1, and so on. The lower the low-level code, the higher the number that is assigned to the material. Adeyl Khan, Faculty, BBA, NSU LLC 0 1 2 3 4 LLC Drawing Item only appears in one level of LLC drawing Easier to understand Simplifies calculations LLC 0 1 2 3 4 Adeyl Khan, Faculty, BBA, NSU Final Assembly Schedule Master Production schedule is anticipated build schedule FAS is actual build schedule Exact end-item configurations Adeyl Khan, Faculty, BBA, NSU Schedule Stability Stable schedule means stable component schedules, more efficient No changes means lost sales Frozen zone- no changes at all Time fences >24 wks, all changes allowed (water) 16-23 wks substitutions, if parts there (slush) 8-16 minor changes only (slush) < 8 no changes (ice) Adeyl Khan, Faculty, BBA, NSU