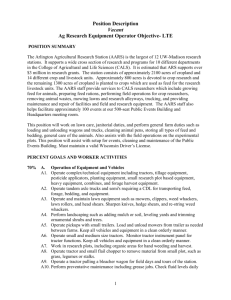

press releases and latest news from VIV Europe exhibitors

advertisement

VIV Europe 2014 Press releases from exhibitors Release date: 20-03-2014 Adifo N.V. Industrielaan 11-B 9990 MALDEGEM Tel: +3250303235 Internet: http://www.adifo.be/en/news/brilliant-alternatives Email: bevd@adifo.be Contact details press officer: bevd@adifo.be Images available: Yes Adifo about to acquire Brilliant Alternatives (US) and Brill Resellers (CN). Belgian Adifo (software for feed and food processes) is about to acquire Brilliant Alternatives (US) and Brill Resellers (CN). The negotiations have entered the final stage. The acquisition will help Adifo significantly strengthen its international position. Brilliant Alternatives has a strong position in its US home market, as well as on the international scene. For instance, it has a significant market share in China via its local distributor Brill Resellers. Peter Tsjoen, Sales Director at Adifo: “This acquisition will make us one of the most important partners for the Chinese food and feed sector, a rapidly expanding market. Food safety is increasingly gaining importance in China. As a European company, Adifo has acquired lots of expertise and experience in this domain over the past forty years. Through Brill Resellers’ extensive network, we will be able to deliver this added value directly to the Chinese market.” The acquisition at hand will enable Brilliant Alternatives to ensure a secure future for its international customer portfolio. Bob Brill, President at Brilliant Alternatives: “Adifo has been active in our sector for forty years and has attained an important position in the international market. Over the past several years, Adifo has brought its software portfolio to a high lever through various innovations. As a result, it is now recognized as the global technological market leader. Moreover, it values long-term business relationships, making it a solid partner for our customers in the long run.” About Adifo Adifo develops and supplies specialized software and services for the food and feed industry. The software tools automate company processes and information flows so that customers can better anticipate and address their market challenges. Since its foundation in 1974, Adifo has grown to become an international player with more than eighty employees. From its headquarters in Maldegem, Belgium and through its global distribution network the company serves customers in more than fifty countries: Nutreco, Agrifirm, Group Depré, Ewos, Cofco, Vitaplus, Lotus Bakeries, Hochland, and more. Available images: http://nieuwsmodule.vnuexhibitions.com/images/image_16895.jpg Attachments: http://nieuwsmodule.vnuexhibitions.com/documents/19752-adifo strengthens market position in china and the us_en.docx Anitox Ltd. 80 Main Road NN6 0HJ EARLS BARTON Tel: 01608 637806 Internet: Email: sam.hiner@whisper.pr Contact details press officer: sam.hiner@whisper.pr Images available: No Anitox to launch new product at VIV Pathogen control specialist Anitox will be officially launching its latest product into the market at VIV this year. For more information please contact Sam.hiner@whisper.pr BioChek B.V. Fokkerstraat 14 2811 ER REEUWIJK Tel: +31182582592 Internet: www.biochek.com Email: rafaelmonleon@biochek.com Contact details press officer: rafaelmonleon@biochek.com Images available: No Innovation at BioChek BioChek, the Smart Veterinary Diagnostics company based in Reeuwijk (The Netherlands) is a global leader in poultry veterinary diagnostics and upcoming in swine veterinary diagnostics. BioChek provides the industry with the largest product portfolio in the market and unparalleled customer support. BioChek products are worldwide recognized for their quality, reliability and efficacy to improve the return of investment of their customers. With main offices in Europe and USA, and a distributor network covering more than 100 countries, BioChek plays a major role in global veterinary diagnostics. BioChek continues to innovate: • New technology featured in BioChek Software: Remotely Managing Serology Data with the smart BioChek cloud solution • Smart automated ELISA: Improve accuracy with the BioChek ELISA Assay Robot with state-of-the-art technology. This robot is a fully automatized ELISA system, fully integrated with the BioChek Software and that allows to run multiples plates at the same time. • Innovative approach to help the industry to fight disease with high quality ELISA kits. BioChek B.V. Dongying Tianrun Biotechnology Co., Ltd. 21 Linqing Road, Shengli Industrial 257081 SHANDONG Tel: 0086-18654636830 Internet: Email: xushan2000@sina.com Contact details press officer: xushan2000@sina.com Images available: No vitamin D3 feed grade welcome to visit our factory Elster Strotheweg 1 D-49504 Lotte Tel: +49 (0) 541 1214 627 Internet: Email: christian.laake@elster.com Contact details press officer: christian.laake@elster.com Images available: Yes Thermorizer TR 75 market launch Thermorizer TR 75 market launch With ermaf, Elster Kromschröder backs a highly efficient heating system for an optimum shed climate Amsterdam, February 2014: Following repeatedly convincing practice trials in the test phase, series production of the ermaf air heater Thermorizer TR 75 was launched at the beginning of this year. Equipped with a ground-breaking heat exchanger system, the highly efficient heater has met in full the demands of the users and developers in terms of innovative technology, efficiency and user-friendliness. A particularly noteworthy feature of the self-contained device is that it can achieve high jet lengths of over 50 metres in practice. This ensures homogenous distribution of the heated air within the shortest possible time, thus eliminating the need for further circulation fans. In comparison with conventional heating systems, the TR 75 also guarantees considerably lower noise levels. The intelligent control system ensures that only warm air circulates and all control variables can be monitored and documented. It therefore works equally well for different types of husbandry. The optimized temperature distribution in the shed is achieved by a swirl-free (laminar) flow with a stable temperature profile. With the optimized air flow and a lowemission pre-mixing burner, the Thermorizer TR 75 is as quiet as it is environmentally-friendly. Besides the development aim to produce the best possible shed climate, the engineers also took into account the everyday requirements of farmers when developing the technology for the new air heater. A perfect shed climate is at the same time one of the most important requirements for healthy animals. The air must be dry to keep the bedding dry and to counteract the build-up of ammonia. The more evenly the temperature is distributed in the shed and the smaller the carbon dioxide content of the shed air, the better the animals can develop. Elster Kromschröder solutions are based on high safety standards. Combustion thus takes place in a closed combustion chamber with low temperatures at the heat exchanger and Class A gas safety valves. The Thermorizer TR 75 is particularly innovative with its new heat exchanger concept, the intelligent control system and monitoring and the high-quality finish of the stainless steel construction with proprietary core components. The Thermorizer TR 75 is the first model in a series with extremely low energy consumption and viable capital expenditure. Compared to direct heating, self-contained technology can achieve savings of at least 20%. The system is also easy to maintain and service. The desire to keep costs to the minimum goes hand in hand with the ease of cleaning and the simple operation. The air heater can be installed on a wall bracket, is robust, can be cleaned with high-pressure cleaners and is dust-proof. Available images: http://nieuwsmodule.vnuexhibitions.com/images/image_17341.jpg Farmer Automatic GmbH & Co. KG Königstraße 51 48366 LAER Tel: 49 2554 911 0 Internet: www.farmerautomatic.de Email: marketing@farmerautomatic.de Contact details press officer: marketing@farmerautomatic.de Images available: Yes Farmer Automatic Company Profile Farmer Automatic GmbH & Co. KG is one of the world’s leading manufacturers and suppliers of economical poultry farming solutions. The family business has its offices and production facilitiy in Laer, Westphalia, Germany. It is a medium-sized company that is one of the major employers in the region. Before founding the long-established German company in 1962, Josef Kühlmann patented the automatic laying nest in 1961. Today, Farmer Automatic offers systems for rearing, layers, and broilers as well as matching accessories and supplementary equipment. Farmer Automatic places top priority on innovation, quality, service, and reliability. The company has manufactured poultry farming systems for over 50 years – in Germany, from the very beginning, and always in premium quality. All of our systems combine reliability with an advanced, intelligent design – in the interest of the livestock and in the interest of our customers. Rigorous material quality inspections and production monitoring ensure the consistently high quality of our systems. Farmer Automatic continually inovates its products in order to accommodate changing market needs. Apart from our top-quality German products, Farmer Automatic customers appreciate our fast, reliable service. We assist and advise our customers individually and personally throughout the entire process from system planning and installation to servicing. Since we manufacture a large share of our product components in-house, Farmer Automatic can develop systems that are tailored to meet specific customer requirements. Farmer Automatic distributes its systems through a worldwide network of excellently trained, independent sales representatives. This ensures that the company is in close proximity to its customers, which is very important for products as complex as ours. Available images: http://nieuwsmodule.vnuexhibitions.com/images/image_15446.jpg FrieslandCampina Nutrifeed Lage Landstraat 7 5462 GJ VEGHEL Tel: +31 413 372606 Internet: www.nutrifeed.com Email: dianne.herckenrath@frieslandcampina.com Contact details press officer: dianne.herckenrath@frieslandcampina.com Images available: Yes Kalvolac Premium calf milkreplacer Nutrifeed will hightlight its improved range of premium calf milkreplacer: Kalvolac offers a healthy sustainable and profitable start. For the piglet industry Nutrifeed highlights Serolat a homogenized encapsulated fat filled whey: thanks to the very fine fat particles the fat is easily absorbed. Available images: http://nieuwsmodule.vnuexhibitions.com/images/image_16819.jpg Henke-Sass, Wolf GmbH Keltenstrasse 1 78532 TUTTLINGEN Tel: ++49 7462 9466 118 Internet: www.henkesasswolf.de Email: Stefan.Knefel@henkesasswolf.de Contact details press officer: Stefan.Knefel@henkesasswolf.de Images available: Yes Everything for the poultry users Our products range includes all the syringes and needles YOU NEED!!! HSW UNI-MATIC® ̶ The poultry syringe (0,1 ml-1 ml) without o-ring reduces maintenance issues. Failure free valves (fitted with stainless steel balls and springs) ensure continuous injections without interruptions. Feed tube and vial models are available in syringe volumes 1 ml and 2 ml. The metal syringe is designed durably and resistant and enables ergonomically correct handling without hand fatigue also for small dosages. HSW-ECO® needles ̶ Wide range of re-usable metal hub veterinary needles. Available in new poultry sizes e.g. 18Gx1/2" (1,20x13 mm), 19Gx1/2" (1,00x13 mm), 20Gx1/4” (0,90x6 mm), 20Gx3/8” (0,90x10 mm), 20Gx1/2" (0,90x13 mm), 21Gx1/4” (0,80x5 mm), 21Gx3/8” (0,80x10 mm), 22Gx1/8 (0,70x4 mm), 22Gx3/8” (0,70x10 mm). They have a very strong and sharp needle bevel for long lasting life and reduced pain for the animal. HSW FINE-JECT® needles ̶ New extra short poultry sizes e.g. 18Gx1/4“ (1.20x6mm), 18Gx1/2” (1,20x13mm), 20Gx1/4“ (0.9x6mm), 22Gx3/8“ (0.7x10mm). The hypodermic needles stand out with their optimized siliconization of the needle tube, the high pull-out forces of canula-hub-connection and the innovative anti-coring treatment of the needle tube. Wing Web Vaccinators ̶ The Wing Web Needles were developed especially for poultry injections and are ideal for pox and other micro-dosage injections. Our Wing Web needles are available in two different versions (Standard Red and Beige). They enable a total dosage per vaccinator of 0.001 ml and 0.01 ml. The small plastic handle has two double nickel plated, carbon steel prongs towards the needle end which allows a micro-dosage vaccination. More information about the products and the company can be found at www.henkesasswolf.de or you can send a request to stefan.knefel@henkesasswolf.de Available images: http://nieuwsmodule.vnuexhibitions.com/images/image_13980.jpg Henke-Sass, Wolf GmbH Keltenstrasse 1 78532 TUTTLINGEN Tel: 0049 7462 9466 118 Internet: 0049 7462 9466 5208 Email: Stefan.Knefel@henkesasswolf.de Contact details press officer: Stefan.Knefel@henkesasswolf.de Images available: Yes Complete system- HSW Injection bar with HSW Disinfection container HSW Injection bar with HSW Disinfection container – for large animals (swine, sheep, goat and cattle) Available images: http://nieuwsmodule.vnuexhibitions.com/images/image_14718.jpg Attachments: http://nieuwsmodule.vnuexhibitions.com/documents/17791-complete system.jpg http://nieuwsmodule.vnuexhibitions.com/documents/17791-complete system.pdf http://nieuwsmodule.vnuexhibitions.com/documents/17791-complete system.jpg http://nieuwsmodule.vnuexhibitions.com/documents/17791-complete system.pdf http://nieuwsmodule.vnuexhibitions.com/documents/17791-complete system.jpg http://nieuwsmodule.vnuexhibitions.com/documents/17791-complete system.pdf http://nieuwsmodule.vnuexhibitions.com/documents/17791-complete system.jpg http://nieuwsmodule.vnuexhibitions.com/documents/17791-complete system.pdf Henke-Sass, Wolf GmbH Keltenstrasse 1 78532 TUTTLINGEN Tel: 0049 7462 9466 118 Internet: 0049 7462 9466 5208 Email: Stefan.Knefel@henkesasswolf.de Contact details press officer: Stefan.Knefel@henkesasswolf.de Images available: No HSW Injection bars for large animals HSW offers a new series of long-distance injection bars which are available in two sizes (total length of 61 cm and 102 cm). The distance to the animal increases user-safety. In addition the stress for the animals will be reduced due to the longer distance, which increases animal welfare. The long injection devices are made of carbon-metal materials and are therefore both flexible and unbreakable. Additionally, they come with safe and stable needle fittings. HSW is also offering rigid and flexible extension with shorter lengths that can be easily adapted to all available syringes. More information about the products and the company can be found at www.henkesasswolf.de or you can send a request to stefan.knefel@henkesasswolf.de. Attachments: http://nieuwsmodule.vnuexhibitions.com/documents/17795-page 14 hsw injection bar.pdf http://nieuwsmodule.vnuexhibitions.com/documents/17795-hsw injection bars.pdf INNOVAD NV/SA Postbaan 69 2910 ESSEN Tel: +32 3 677 01 01 Internet: http://www.innovad-global.be/products/mycotoxins-control/escent/ Email: s.bauwens@innovad-global.com Contact details press officer: s.bauwens@innovad-global.com Images available: No EU authorizations with official anti-mycotoxin claim for components of ESCENT® INNOVAD announces the authorization of components of ESCENT® product line as “Substances for reduction of the contamination of feed by mycotoxins: aflatoxin B1. The brand MAGNET® and components from the fast growing ESCENT@ product line produced by INNOVAD® to mitigate the toxins negative effects in the feed have become part of the first products authorized by the EU as substances with scientifically validated mycotoxin counteracting properties. Based on the most recent developments in the European legislation for feed additives (EC No 1060/2013), European authorities decided to clarify the legal status of components which can be used for the reduction of the contamination of feed with mycotoxins. Due to the presence of many products on the market and the large variability in effectiveness for the claimed purpose, this approach is a step forward to guarantee the mode of action and required effects. Within the text of the legislation, a clear distinction is made on different clay minerals where solid parameters have been defined in order to comply with this new category of feed additives. The compliance with this legislation reflects in the label as well, which mentions clearly the functional group as stated in the legislation: Substances for reduction of the contamination of feed by mycotoxins: aflatoxin B1. INNOVAD, being an important player in the segment of mycotoxin inactivation has always been pioneering in this segment. INNOVAD’s product line ESCENT® has been designed on two important pillars, being direct activity towards mycotoxins and indirect metabolic support (organ support, immunity and oxidative stress reduction). The direct activity of the product towards mycotoxins is partially based on carefully selected clay minerals which now have been officially approved by the EU-legislation to have a reducing effect of the contamination of feed with mycotoxins. Based on the ingredients used, MAGNET® & ESCENT® product line is fully conform with the current European legislation which stands for guarantee on performance and efficiency. The product carries the label conform EUDirectives as “Substance for the reduction of the contamination of feed by aflatoxin B1.” Attachments: http://nieuwsmodule.vnuexhibitions.com/documents/20283-0001rm.jpg Inteqnion B.V. Weverij 2 7122 MS AALTEN Tel: 0543-494466 Internet: www.inteqnion.com Email: m.benes@inteqnion.com Contact details press officer: m.benes@inteqnion.com Images available: Yes Corporate Brochure Inteqnion has released its new corporate brochure. Available images: http://nieuwsmodule.vnuexhibitions.com/images/image_14460.jpg Meyn Food Processing Technology B.V. Westeinde 6 1511 MA Oostzaan Tel: +31(0)202045000 Internet: https://www.meyn.com/en-GB/357/flex-grader-m1.0.html Email: jkoops@meyn.com Contact details press officer: jkoops@meyn.com Images availbale: Yes Meyn introduces new Flex grader The new Meyn Flex grader uses proven high performance weighing technology to provide a high speed operation with excellent accuracy that is able to grade poultry products to a variety of different specifications. Depending on the application, top speeds of 235 weighings per minute can be achieved allowing direct connection to any cut up system. Grading can be carried out to specified weights, minimum weight or number per batch. It can also deliver target batching with tolerances and priorities. The Flex grader features a modular design that is suitable for any application and can easily be integrated into existing processing and packing lines and allows for future expansion. The double or single sided machine, with a minimum of four and a maximum of 24 stations, can be fitted with catch or slap arms, depending on application. The robust construction ensures reliable operation in even the harshest environments, while simple set-up operations via the touch screen and an easy-clean open frame design minimize downtime for cleaning and product changeovers. The Meyn Flex grader provides maximum flexibility and largely reduces give away while allowing you to quickly and effectively respond to ever changing market demands. Randox Food Diagnostics 55 Diamond Road BT29 4QY CO. ANTRIM Tel: +442894422413 Internet: http://www.randoxfooddiagnostics.com/Tissue Email: joanne.mcknight@randoxfooddiagnostics.com Contact details press officer: joanne.mcknight@randoxfooddiagnostics.com Images available: No Randox Food Diagnostics lead the way with first comprehensive test for Coccidiostats The wait is over for egg and poultry processors seeking a workable solution to screening for Coccidiostats with the welcome news of Randox Food Diagnostics bringing the first multi-analyte screening test to the market. As the Northern-Ireland headquartered firm grows its presence in the meat & poultry market the pioneering product is a direct result of customer demand, spending 24 months in development. Coccidiosis is a parasitic disease of animal intestinal tracts caused by coccidian protozoa. Symptoms usually include bloody droppings, weight loss and mortality in young chickens. With no sign of the growth in global appetite for poultry meat waning (up by 50% since 2000), the pressure on producers to farm intensively is ever increasing. That in turn, leads to overcramped conditions perfectly suited to the spread of coccidiosis amongst flocks. To prevent infection, farmers may administer prophylactic antiprotozoal Coccidiostats in feed, which increases the chance that coccidiostat residues are retained in both poultry meat and eggs. To reduce the risk of toxicity to consumers, regulatory authorities have set Maximum Residue Limits (MRLs) recommending an appropriate withdrawal period prior to slaughter. Mariclare McGarrity, Senior Customer Support Scientist explained why Randox Food Diagnostics were first to market with a comprehensive test. “The key issue is the range of coccidiostat drugs utilised in the poultry industry. This leaves traditional single-analyte screening ELISA products unsuitable and inefficient. Producers are more likely to utilise confirmatory testing. However, Randox’s ground-breaking Biochip Array Technology is optimised for multiplex testing, identifying up to 22 different analytes from a single sample. As a result, it is an ideal platform to detect and quantify the whole range of commonly-used Coccidiostats throughout the global market.” “Engaging with current and potential customers, we are keenly aware of the level of anticipation around this product, and we are confident it will meet the needs of a market seeking a cost-effective innovative solution.” ENDS For more info visit www.randoxfooddiagnostics.com Randox Food Diagnostics 55 Diamond Road BT29 4QY CO. ANTRIM Tel: +442894422413 Internet: http://www.randoxfooddiagnostics.com/Tissue Email: joanne.mcknight@randoxfooddiagnostics.com Contact details press officer: joanne.mcknight@randoxfooddiagnostics.com Images available: Yes Specific tests for Sulphonamides give greater confidence to food processors Poultry processors struggling to screen accurately for Sulphonamide antibiotics could improve their quality control by testing for each specific compound. Research undertaken by leading test manufacturer Randox Food Diagnostics has demonstrated that investing in products with specific antibodies, as opposed to generic, can provide confidence with a false positive rate of less than 5%. As an antimicrobial agent, Sulphonamides are used in global food production to treat/prevent infections, however, serious health concerns exist over human consumption and the development of antibiotic resistance. As a result, many countries have banned or limited their use in animal production and set Maximum Residue Limits (MRLs) for residues in food. Randox Food Diagnostics Meat & Seafood Manager Joanne McKnight said “Standard products on the market are based on generic antibodies designed to detect a range of Sulphonamides. However that compromises the performance of each individual compound. Both our Biochip Array Technology and ELISA products are based on specific antibodies for each individual Sulphonamide so this reduces reliance on crossreactivity and increases accuracy. Feedback from customers to date has been very positive, as investing in quality screening reduces false positives, and dramatically cuts associated costs with superfluous confirmatory testing”. ENDS For more info visit www.randoxfooddiagnostics.com Available images: http://nieuwsmodule.vnuexhibitions.com/images/image_16056.jpg Randox Food Diagnostics 55 Diamond Road BT29 4QY CO. ANTRIM Tel: +442894422413 Internet: http://www.randoxfooddiagnostics.com/Tissue Email: joanne.mcknight@randoxfooddiagnostics.com Contact details press officer: joanne.mcknight@randoxfooddiagnostics.com Images available: Yes Trade disputes create strong demand for Beta-Agonists diagnostics Industry tension surrounding international trade embargoes is creating strong business opportunities for food testing companies according to market leading firm Randox Food Diagnostics. Major meat producers in the US and Brazil have experienced difficulties exporting to Chinese, Russian and European food markets. Recent disputes have been in relation to the level of beta agonist veterinary drugs in meat in particular Ractopamine and Zilpaterol. With no sign of a resolution in sight between the import and export blocs, major exporters are having to ensure their product meets a zero tolerance/maximum residue limit for these drugs to maintain trade links to these key markets. Beta-adrenergic receptors used in veterinary and human medicine to treat cardiovascular and breathing disorders [3]. Commercially Beta agonists are used to increase muscle growth and decrease fat deposition in animals [7]. Zilpaterol is a powerful beta adrenergic agonist that has been developed as a growth promoter for cattle leading to enhanced weight gain and carcass yield. Of particular concern is the use of beta agonist drugs prior to slaughter as this poses a risk to the human health if contaminated meat enters the food chain. David Ferguson, Global Business Manager at Randox Food Diagnostics said, “Within the industry, the potential impact to human health if meat containing beta-agonists enters the food chain is strongly contested. What is clear, is that if meat exporters want to access key markets such as Russia, China and the EU they need to show their products are free from veterinary residues. This creates opportunities for testing companies and with our experience and knowledge we have the ability to react quickly to these changing demands.” Outlining the firm’s response to the trade embargoes he said, “Over the last 3 months we have released Zilpaterol testing products on both ELISA and Biochip Array formats onto the market. Both test for the semi-quantitative determination of Zilpaterol in beef tissue samples with an LOD of 0.08ng/ml and cross reactivity of 100% for both in Zilpaterol. So far the uptake has been very encouraging, both with importers and exporters with a particular demand being seen with major producers like Brazil and the US.” ENDS. Available images: http://nieuwsmodule.vnuexhibitions.com/images/image_16057.jpg SASSO Route De Solferino 40630 SABRES Tel: +33607764925 Internet: Email: edouard@sasso.fr Contact details press officer: edouard@sasso.fr Images available: No SASSO larges choice in colored beeder Sasso is a company fully dedicated to colour breeder genetic. Our genetics are coming from a long and strict selection based on the performance. Established 33 years ago by the leading French "Label Rouge" poultry producers, SASSO's sole objective has always been to breed STRAINS capable of producing high-quality poultry, FULL OF FLAVOR and cost-effective for producers, in the best sanitary conditions. Developments in selection techniques and research in nutrition and breeder management have enabled SASSO to continually improve the economic performance of its stock without compromising their inherent quality. Sasso is constantly listening to the broiler industry to match these expectations. To fit the requirements of the market, SASSO portfolio offers a large range of parent stock: Various dominant phenotypes of males and recessive females able to fit different markets such as free range, organic, but also more rapid differentiated growth. A large range of slow growth: (for label rouge and organic market 81 to 70 days) Medium growth: (for organic, certified markets 56 to 63 days) Rapid growth: (For certified, differentiated broiler and freedom food , and well fare ,standard markets 49days) The characteristics of SASSO’s breed are: An extremely resistant chicken - With Excellent livability, easy to manage with a high rusticity and also a good Carcass uniformity. And of course a premium quality meat!!!! This is why SASSO is today a world-leading breeder of traditional farm poultry, distributing its breeding stock to countries all over the world. Sasso is also the only company who can customise genetic lines, if you have specifics requirements sasso can help you. Sasso with it’s know how is able to offer any made to measure selection at any place in the world. Attachments: http://nieuwsmodule.vnuexhibitions.com/documents/20197-pub sasso ang.png Sichuan Chanhen Chemical Corporation 399 Tongzhan East Road 618400 SHIFANG, SICHUAN Tel: 86-838-8105561 Internet: Email: jeff@chanhen.com Contact details press officer: jeff@chanhen.com Images available: Yes feed phosphate thanks for choosing chanphos Available images: http://nieuwsmodule.vnuexhibitions.com/images/image_13738.jpg Attachments: http://nieuwsmodule.vnuexhibitions.com/documents/16869-mcp22%·.pdf Sime-Tek Srl. Via Del Lavoro 25 33080 ROVEREDO IN PIANO - PN Tel: +39 0434 921972 Internet: Email: info@Sime-tek.com Contact details press officer: info@Sime-tek.com Images available: Yes Sime-Tek www.sime-tek.com Available images: http://nieuwsmodule.vnuexhibitions.com/images/image_15425.jpg SOCOREX ISBA S.A. Champ-Colomb 7 1024 ECUBLENS / LAUSANNE Tel: +41 21 651 6000 Internet: http://www.socorex.com/twin-syringes-tube-feeding-socorex-en-2-1-22-74.html Email: yves.lachavanne@socorex.com Contact details press officer: yves.lachavanne@socorex.com Images available: Yes Save time and money by doubling injection productivity output ! The Socorex® 287 Twin syringes with spring-loaded plunger and three-way valve system are designed for serial precision injections. Simple conception, perfect balance and ergonomic design provide for ease of use, operator comfort and fatigue free fieldwork. Combining reliability with efficiency, they are intended for simultaneous administration of two distinct liquids. Both volumes can be adjusted separately. Quality materials and one by one finish to the smallest details guarantee durability in most difficult conditions of use. Autoclavable fully assembled at 121°C. Optional accessories such as vial holder to convert one or two sides of syringe for vial feeding, or manifold for injection of both liquids through a single needle guarantee a most flexible user comfort. For more information or for product range overview visit the Animal Health section on www.socorex.com Available images: http://nieuwsmodule.vnuexhibitions.com/images/image_17448.jpg Attachments: http://nieuwsmodule.vnuexhibitions.com/documents/20281-b.vet.e.pdf SOCOREX ISBA S.A. Champ-Colomb 7 1024 ECUBLENS / LAUSANNE Tel: +41 21 651 6000 Internet: http://www.socorex.com/pistol-grip-syringes-tube-feeding-socorex-en-2-1-19-72.html Email: yves.lachavanne@socorex.com Contact details press officer: yves.lachavanne@socorex.com Images available: Yes Socorex animal health syringes The Socorex® syringes with spring-loaded plunger and three-way valve system are designed for precision serial animal injections. Feed tube and vial models are available in volumes ranging 0.025 ml to 10 ml covering all needs in poultry, swine, sheep, cattle among other fields. Superior quality materials, simple conception, perfect balance, unsurpassed hand comfort, ease of use and reliable field work are among key characteristics appreciated by professionals for years. Tightness without Oring thanks to optimal match of stainless steel plunger with interchangeable grounded glass barrel. Failure free valve is fitted with stainless steel ball and spring. The syringes are autoclavable fully assembled at 121°C. For more information or for product range overview visit the Animal Health section on www.socorex.com Available images: http://nieuwsmodule.vnuexhibitions.com/images/image_17449.jpg Attachments: http://nieuwsmodule.vnuexhibitions.com/documents/20282-b.vet.e.pdf Trouw Nutrition International BV Nijverheidsweg 2 3881 LA PUTTEN Tel: +31 630 142 708 Internet: Email: elise.van.der.wulp@nutreco.com Contact details press officer: elise.van.der.wulp@nutreco.com Images available: No Nutreco companies to present new breakthrough feed solutions at VIV Europe Trouw Nutrition and Selko Feed Additives, two subsidiary companies of Nutreco – the global leader in animal nutrition and fish feed – will present their latest innovations at the VIV Conferences to be held on 20-22 May 2014 in Utrecht, the Netherlands. Innovation is at the core of Nutreco’s business, as well as that of the companies that it owns. Nutreco has four main Animal Nutrition innovation themes: Life Start, Animal Health and Welfare, Feed Efficiency and Application Solutions. This approach results in nutritional solutions that add real value to customers’ business. The overall goal is to continuously find new ways to enable animal protein producers to increase efficiency and performance – while also making the most of their resources – in order to meet the growing global demand for animal protein and seafood. NutriOpt, optimising nutrition – improving profitability At VIV Europe, Trouw Nutrition – which specialises in innovative feed specialties, premixes, and nutritional models and services – will present the company’s latest breakthrough, NutriOpt. This revolutionary new science-based precision-feeding tool combines Nutreco’s expertise in both feed efficiency and application solutions. NutriOpt increases the accuracy and predictability of animal nutrition and its results by providing real-time access to Nutreco’s latest nutrition knowledge and animal models, enabling customers to quickly and flexibly adapt to changing market conditions, and enables customers to optimize both feed costs and production results. Selko innovations in feed additives - improving intestinal health and feed efficiency Selko Feed Additives, a Nutreco company, develops and produces feed additives for food safety and animal health. During the VIV, Selko will join the 10 minutes pitch at the Crop Tech-FeedTech by detailing its latest developments in feed mill efficiency. On Wednesday 28 May, a conference on Animal Health Summit will be held at which Selko will explain the functionality of feed additives to support animal health. Valli S.p.A. Via Cimatti 2 47010 GALEATA (FC) Tel: +390543975311 Internet: www.valli-italy.com Email: andrea@valli-italy.com Contact details press officer: andrea@valli-italy.com Images available: Yes Our Products We manufacture all models of layer cages from 2 to 12 tiers including all models of the enriched colony systems, all models of rearing cages from 2 to 12 tiers, all model of enriched cages, feeding systems (hoppers, flat chain, spiral), egg collection systems (lifters, de-escalators, elevators or rod conveyors), drinking equipment (nipple, cups, water tanks), manure handling and drying systems, (scrapers, augers, belts, chain conveyors), feed bins and feed augers, automatic broiler cages, and turnkey projects. Available images: http://nieuwsmodule.vnuexhibitions.com/images/image_16903.jpg VDL Agrotech Hoevenweg 1 5652 AW EINDHOVEN Tel: +31402925500 Internet: http://www.youtube.com/watch?v=D94SuzGmMN4 Email: g.camps@vdlagrotech Contact details press officer: g.camps@vdlagrotech Images available: No Pouldry manure drying & processing concepts Pouldry manure drying & processing concepts With a growing livestock business often a growing problem appears: where to go with the manure? Sustainable farming, local legislation but also costs efficiency are key factors for future development of your farming activities. VDL Agrotech offers complete solutions for manure drying and processing. Manure is often seen as a waste product but with VDL technology it can be turned into a valuable fertilizer or energy source. The first stage of the process is drying the manure with the Pouldry system. Fresh manure with 75% humidity will be dried to a level of approx. 15% humidity. By using the ventilation of the poultry house, no additional heat source is required. With a minimum of energy costs the manure will be ready for the next step. VDL Agrotech offers a modular system with 2/4/6 tiers, the length is variable up to 47 mtr. With a maximum drying surface from 511 m2 the capacity is enough for 215.000 layers or even more depending on the local climate. VDL also designed a central drying facility, especially on broiler farms the drying system canbe used in a more efficient way. The required additional input of energy is reduced to the lowest level. This will keep the operational costs for drying manure competitive. Pelletizing the manure gives some important benefits: reduction of logistic costs: storage and transportation. Also it is possible to deliver a certified organic fertilizer which guarantees a minimum of minerals NPK and is also free of diseases. Also no smell and no dust, furthermore it can be spread with automatic devices on fields. VDL offers capacities from 250 kg up to 10 ton’s / hour. With a local energy centre a farm can use it’s own manure to produce hot water for heating up the houses or other buildings like greenhouses/office/factories. Especially on broiler farms or in colder climates this a reliable and sustainable solution for your manure and energy problem. An advanced boiler design and air filtering system guarantees emission values that meet the highest exhaust legislations in Europe. For more information please visit our boot Hall 12, Stand A032 at VIV Europe Attachments: http://nieuwsmodule.vnuexhibitions.com/documents/18701-news @ viv europe pouldry manure drying.docx VDL Agrotech Hoevenweg 1 5652 AW EINDHOVEN Tel: +31402925500 Internet: http://www.youtube.com/watch?v=D94SuzGmMN4 Email: g.camps@vdlagrotech Contact details press officer: g.camps@vdlagrotech Images available: No Pouldry manure drying & processing concepts Pouldry manure drying & processing concepts With a growing livestock business often a growing problem appears: where to go with the manure? Sustainable farming, local legislation but also costs efficiency are key factors for future development of your farming activities. VDL Agrotech offers complete solutions for manure drying and processing. Manure is often seen as a waste product but with VDL technology it can be turned into a valuable fertilizer or energy source. The first stage of the process is drying the manure with the Pouldry system. Fresh manure with 75% humidity will be dried to a level of approx. 15% humidity. By using the ventilation of the poultry house, no additional heat source is required. With a minimum of energy costs the manure will be ready for the next step. VDL Agrotech offers a modular system with 2/4/6 tiers, the length is variable up to 47 mtr. With a maximum drying surface from 511 m2 the capacity is enough for 215.000 layers or even more depending on the local climate. VDL also designed a central drying facility, especially on broiler farms the drying system canbe used in a more efficient way. The required additional input of energy is reduced to the lowest level. This will keep the operational costs for drying manure competitive. Pelletizing the manure gives some important benefits: reduction of logistic costs: storage and transportation. Also it is possible to deliver a certified organic fertilizer which guarantees a minimum of minerals NPK and is also free of diseases. Also no smell and no dust, furthermore it can be spread with automatic devices on fields. VDL offers capacities from 250 kg up to 10 ton’s / hour. With a local energy centre a farm can use it’s own manure to produce hot water for heating up the houses or other buildings like greenhouses/office/factories. Especially on broiler farms or in colder climates this a reliable and sustainable solution for your manure and energy problem. An advanced boiler design and air filtering system guarantees emission values that meet the highest exhaust legislations in Europe. For more information please visit our boot Hall 12, Stand A032 at VIV Europe Attachments: http://nieuwsmodule.vnuexhibitions.com/documents/18702-news @ viv europe pouldry manure drying.docx Vencomatic Group Meerheide 200 5521 DW EERSEL Tel: 0497 517380 Internet: www.vencomaticgroup.com Email: nina.box@vencomaticgroup.com Contact details press officer: nina.box@vencomaticgroup.com Images available: Yes Vencomatic Group proudly presents the Egg way Eersel, 16 January 2013 - From the very first moment an egg is laid until it reaches its final destination, a commercially produced egg travels a long and tough journey. On this journey it faces numerous impacts and possible contamination sources. Vencomatic Group focuses on perfecting every detail of this journey, calling it the “Egg way”. Their poultry and technical specialists evaluate and optimise every little step to protect the eggs from damage or contamination. Vencomatic Group strongly believes that optimising the Egg way is the only way to maximise profit for poultry producers with today’s tight margins. Extensive research shows that carrying an egg from the nest to the hatchery or the retailer can be managed perfectly if you have the knowledge of every single move the egg experiences along its way. At VIV Europe Vencomatic Group demonstrates their proven solutions that contribute to the Egg way. Furthermore, the Dutch company presents several innovations to successfully ensure the Egg way in a perfect condition, such as: • A perfect egg way starts with a healthy hen laying a maximum number of eggs. A global problem and risk for the hen’s health is red mite, which causes major economic losses resulting from suboptimal productivity. The revolutionary Q-perch (patent pending) is the only true environmental and bird friendly way to eliminate the problem of red mite. Resting on this innovative perch, birds are safe from red mite. As red mites do not get the chance to feed on the hens, the population never develops and the use of pesticides is history. • At the heart of many Vencomatic systems is the laying nest. The Vencomatic nest is based on Vencomatic Group innovations, such as the Vencomat, the tipping floor and the egg belt. Innovations that make the difference along the Egg way ensuring outstanding egg quality. The well-known Vencomatic nest is integrated in the Bolegg Gallery, a new aviary system that combines user friendliness with a clever and economic design. • For Vencomatic Group, the Egg way ends in the broiler house with on-farm hatching (patented). Previously on-farm hatching was only available with the Patio system, with the X-Treck this is now possible in traditional floor houses. The X-Treck enables direct post-hatch feed and water access and eliminates the stressful events of chick handling and transportation, providing an optimal start for chicks on the farm. Vencomatic Group is known for its innovative and sustainable systems for the poultry industry. Combining three well-known brands – Vencomatic, Agro Supply and Prinzen - Vencomatic Group offers a full range of innovative systems for all types’ of poultry farms. Their poultry professionals happily share their knowledge and welcome you at booth 11.C064. Available images: http://nieuwsmodule.vnuexhibitions.com/images/image_15710.jpg Attachments: http://nieuwsmodule.vnuexhibitions.com/documents/18704-2014 01 10 press release viv nibox.docx Winterwarm B.V. Industrieweg 8 7102 DZ WINTERSWIJK Tel: +31 543546306 Internet: http://www.winterwarm.com/agri/dxc_heater__.aspx Email: w.huiskamp@winterwarm.nl Contact details press officer: w.huiskamp@winterwarm.nl Images available: Yes Winterwarm introduces the DXC heater As a totally new heating concept, Winterwarm presents the DXC heater: an indirect gas fired heater with closed combustion system especially designed for poultry houses. High energy prices and government policy force farmers to use efficient heating system with low energy consumption. The DXC fully meets these requirements. Application of the DXC has 2 important effects: 1. a dryer, and therefore healthier stable climate which results in daily liveweight gains. 2. lower energy consumption as ventilation levels can be reduced significantly These two factors result in higher profits and lower costs. Profiting from more than 75 years experience in engineering and manufacturing gas fired heaters, Winterwarm presents a robust and reliable heater for the agricultural market. Extra nice features are the lower sound level of the DXC in comparison with the conventional direct fired heaters, and the possibility to reduce ones insurance premium as there is no open flame in the stable anymore. Look at: http://www.winterwarm.com/landingspage_dxc_heater.aspx Available images: http://nieuwsmodule.vnuexhibitions.com/images/image_17447.jpg Zagro Singapore Pte Ltd. ZAGRO GLOBAL HUB. 5 Woodlands Terrace 738430 SINGAPORE Tel: +65-67591811 Internet: http://www.zagro.com/sg/News_April2013.html Email: cookie.kwong@zagro.com Contact details press officer: cookie.kwong@zagro.com Images available: Yes Thank You for Visiting Us at VIV Asia 2013 Zagro and its Animal Health Sales & Technical team would like to send out their gratitude to all the visitors, customers & exhibitors likewise, who visited Zagro booth in VIV Asia 2013 last March in Bitec, Bangkok. Mr. Poh Beng Swee, CEO and Chairman of Zagro Asia, who believes in the power of networking says, "Thank you for taking the time to meet us in our booth. Should there be opportunities of business collaboration, whether as a solution provider or as our customers, we're looking forward to be in touch with you. We believe Zagro's product range is wide enough to be able to meet most of your requirements. Should it not cater to what you need, we'd appreciate introductions to your contacts who may find our solutions beneficial." Available images: http://nieuwsmodule.vnuexhibitions.com/images/image_15672.jpg Zouping Jujia Choline Industrial Co., LTD Handian Industrial Zone 256209 BINZHOU CITY, SHANDONG PROVINCE Tel: +86-543-4867207 Internet: www.jujiagroup.com Email: lk@jujiagroup.com Contact details press officer: lk@jujiagroup.com Images available: Yes Welcome you to visit our booth in VIV Europe Our booth 08.D091 Available images: http://nieuwsmodule.vnuexhibitions.com/images/image_15261.jpg