Proposal - Description - Southern Illinois University

advertisement

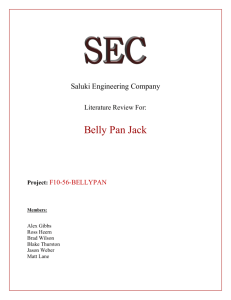

Saluki Engineering Company Proposal For: Belly Pan Jack Project: F10-56-BELLYPAN Members: Alex Gibbs Ross Heern Brad Wilson Blake Thurston Jason Weber Matt Lane November 18, 2010 Saluki Engineering Company Southern Illinois University Carbondale College of Engineering – Mail code 6603 Carbondale, IL 62901-6604 gbg@dishmail.net Greg Gibbs Gibbs Construction Co-owner and Operator P.O. 11 Modesto 62667 (618) 527 - 8671 Dear Mr. Gibbs The following proposal was made in response to your request for a proposal of a lifting device for the safe and efficient removal of belly pans from heavy machinery. The main objective of this design is the safe and efficient removal of belly pans. In order to achieve this, a number of different subsystems have been incorporated into the design. The subsystems include the ratcheting safety mechanism, the main lifting mechanism, the power systems, and the platform. The design also integrates a self-propulsion system which will allow the belly pan to be easily moved into position once service on the machine is finished. Along, with the self-propulsion system, fully integrated controls will increase the ease of operation for the operator. Thank you for taking time to review this proposal and for the opportunity to work on this project. We look forward to working with you in the future. If you have any questions or comments please contact Alex Gibbs, at (618) 527 – 8673, or email gbg@dishmail.net. Sincerely, Alex Gibbs (Project Manager) Team 56-Bellypan Jack 2 Executive Summary The Saluki Engineering Company (SEC) design team 56 proposes to design and construct a belly pan jack for Gibbs Construction. The purpose of this jack is to provide an efficient means of removing and installing belly pans on heavy equipment such as bulldozers. There are five main subsystems to the jack: safety system, lifting mechanism, chassis, platform, and power subsystems. The chassis includes wheels that will allow the operator to easily maneuver the jack under the machine via a hydraulic drive motor. Once the jack is in position under the machine the lifting mechanism will raise via the power system to secure the platform to the belly pan. As the lifting mechanism raises the ratcheting safety system will automatically operate to ensure the lifting mechanism will not collapse if the power system fails. After the operator has secured the platform to the belly pan and the safety system is engaged the hardware securing the pan to the machine is removed. Once the hardware is removed the safety device can be disengaged and the pan lowered to a desired level and maneuvered out from the machine. To re-install the belly pan these steps are performed in reverse order. The construction of the prototype will be conducted by SEC design team 56 in Gibbs Construction’s shop in Benton IL. The preliminary designs use steel as the material for the majority of the jack because of its strength, availability, and ease of machining. The jack will be powered by a pneumatic over hydraulic system that controls all functions of the jack from one convenient location. The initial cost estimate for the construction of the prototype is $1800. If when testing the prototype the design is found to be less than adequate, modifications will be made and the cost would reflect the modifications 3 RESTRICTION ON DISCLOSURE OF INFORMATION The information provided in or for this proposal is the confidential, proprietary property of the Saluki Engineering Company of Carbondale, Illinois, USA. Such information may be used solely by the party to whom this proposal has been submitted by Saluki Engineering Company and solely for the purpose of evaluating this proposal. The submittal of this proposal confers no right in, or license to use, or right to disclose to others for any purpose, the subject matter, or such information and data, nor confers the right to reproduce, or offer such information for sale. All drawings, specifications, and other writings supplied with this proposal are to be returned to Saluki Engineering Company promptly upon request. The use of this information, other than for the purpose of evaluating this proposal, is subject to the terms of an agreement under which services are to be performed pursuant to this proposal. 4 Table of Contents Cover Page (AG)…...……………………………………………………………………………...1 Transmittal Letter (ML)...………………………………………………………………………....2 Executive Summary (AG)...……………………………………………………………………….3 Non-disclosure Statement (ML)...………………………………………………………………...4 Table of Contents (BT)……………………………………………………………………………5 1) Introduction (RH)……………………………………………………………………………...8 2) Literature Review……………………………………………………………………………..9 2.1 Introduction (AG)………...…………………………………………………….…......9 2.2 Codes and Safety Standards (RH)……………………………………………………..9 2.3 Lifting Mechanisms (BT)……………………………………………………………10 Fig. 1: Simple manual hydraulic jack……………………………………………11 Fig. 2: Screw design for a scissor jack ……………………………………….…12 Fig. 3: Floor jack that uses a parallel linkage …………………………………...13 Table 1: Actuating Mechanisms…………………………………………………13 Table 2: Lifting Mechanisms…………………………………………………….14 2.4 Chassis and Drive System (BW)…..…………………..……………………………..14 Fig. 4: Cut-away of a simple hydraulic jack …………………………………….15 Fig. 5: Locking caster wheel …………………………………………………….16 Fig. 6: Hydraulic drive motor ….………………………………………………..17 2.5 Platform Fixture System (JW)……………...………………………………………..17 Fig. 7: Transmission jack…….…………………………………………………..18 Fig. 8: Belly pan hoist with tilting platform……….…………………………….19 5 Fig. 9: Belly pan hoist………….………………………………………………...19 Fig. 10: Rubber inserts…………………………………………………………...20 Fig. 11: T-slot table……………………………………..………………………..21 Fig. 12: Ratchet securing device……………………..…………………………..22 2.6 Current State of Art (ML)…..………………………………………………………..22 Fig. 13: Hedweld belly pan hoist……………………………..………………….22 Fig. 14: Truck transmission jack………………………………..………………..23 Fig. 15: Mechanically operated lift table………………………………………...24 2.7 Relevant Patents (AG)…………..…………………………………………………...25 Table 3: Relevant Patents of Complete Lifts…………………………………….25 2.8 Conclusion (AG)……………...……………………………………………………...26 3) Block Diagram (AG)…………...……………………………………………………………..27 4) Design Basis (BW)……………..……………………………………………………………..27 5) Project Description (BT)……………...………………………………………………………28 5.1 Safety Mechanism Subsystem (RH)……………...………………………………….28 Fig. 16: Locking mechanism……………………………………………………..29 5.2 Lifting Mechanism Subsystem (AG)………...………………………………………30 Fig. 17: Lifting mechanism………………………………………………………31 5.3 Chassis Subsystem (BW)…………..………………………………………………...32 Fig. 18: Chassis…………………………………………………………………..32 5.4 Platform and Fixture Subsystem (JW)………...……………………………………..33 Fig. 19: Platform…………………………………………………………………34 5.5 Power Subsystem (ML)…………..………………………………………………….35 6 6) Project Organization Chart (BT)……………...………………………………………………36 7) Action Item List (AG)……...…………………………………………………………………37 8) Timeline (BT)………...……………………………………………………………………….38 9) List of Resources (BW & JW)………………………………………………………………...39 10) Future Testing and Analysis (BW)………………..………..………………………………..40 References (ALL)………………………………………………………………………………..41 Appendix (BT)………...…………………………………………………………………………43 Appendix A: Resumes (ALL)…………………………….……………………………...44 Appendix B: Pictures of Completed Lifts from Relevant Patents (BT & AG)………….54 7 1) Introduction In the heavy machinery industry, equipment needs to be serviced on a regular basis. When purchasing equipment one looks at: the value, cost, dependability, ease of operation, and ease of maintenance of the machine. In many cases the maintenance of the machinery is among the most important. Many areas of maintenance involve the removal of protective plates from beneath the machine; these protective plates are often referred to as the belly pan. Belly pans are large, bulky, and difficult and dangerous to remove and return beneath the machine. Methods of removing belly pans have consisted of using a crane to apply a force to a strap from one side of the machine, anchored to the opposite side of the machine and put tension on the belly pan to support it. Obviously a major problem with this is safety, as well as effectiveness, not to mention the availability of a crane. Other methods involve using several different jacks in conjunction with blocks to lift the belly pan. Safety and effectiveness are concerns with this method as well. There are a number of transmission jacks and lift tables that may work better, but safety and effectiveness are still a major concern because the manufacturer did not design the device for such conditions. Among safety and effectiveness; dependability, ease of operation, ease of maintenance, maneuverability, and cost were considered for the proposed belly pan jack. The proposed belly pan jack will: provide a safe and effective way of removing and replacing the belly pan, be self propelled and easily maneuvered , have fully integrated controls, be easy to work around while in the open shop as well as under the machine, and be cost effective. The subsystems which the belly pan jack consists of are: a ratcheting safety mechanism, main lifting mechanism, power system, chassis, and platform. The belly pan jack will be easily situated beneath the machine, the wheels locked, connected to the shop air supply, raised to the belly pan which will then be secured, the belly pan unbolted, the jack will then be lowered and the belly 8 pan taken to be cleaned and service on the machine can be done easily. The innovative, user friendly design of the belly pan jack makes it an excellent choice for the future service of large machinery. 2) Literature Review 2.1 Introduction The objective of this project is to design and build a jack to assist in removing and installing belly pans on heavy construction equipment. The jack could be used on bulldozers, excavators, and haul trucks as well as many other pieces of equipment. This research document contains a review of the current state of the art designs in this area as well as the subsystems of the designs. The subsystems include: chassis systems, drive systems, lifting mechanisms, and platform fixture systems. Current patents pertaining to these systems are integrated into the body. Despite the fact that development of the proposed project has been designed for one particular function, there have been numerous developments in similar ideas, which will be explored in this document. 2.2 Codes and Safety Standards There is no current standard to the size of belly pans, as is such; the belly pan jack will need to be able to accommodate varying sizes of pan surfaces. The belly pan jack will need to be small enough to be able to work around while under the machine, yet large enough to handle the large belly pans safely. The size of belly pans range from approximately 30 inches to 70 inches in length and approximately 36 inches to 58 inches in width. The belly pan jack will also need to be able to raise high enough to reach the belly pan on high ground clearance machines, as well as low enough to work under the smaller machines. The lowest belly pans are approximately 15 9 inches and the highest belly pans are approximately 24-28 inches. The weights of belly pans are influenced not only by the size of the pan, but also by the amount of debris accumulated in them. Due to this, the actual weight of belly pan that will need to be lifted is yet to be determined. All preliminary calculations will be done using a weight of 2000 lbs. Belly pans will be weighed with different amounts of debris to come to a more accurate number. Again, these numbers are approximations due to the large variations in the sizes of belly pans. This project will not be restricted by any construction codes. The safety regulations that apply to this device include but are not limited to; the maximum operating load must be legibly marked, must have a positive stop to prevent over travel, every air receiver shall be equipped with an indicating pressure gage (so located as to be readily visible) and with one or more spring-loaded safety valves, a drain pipe and valve shall be installed at the lowest point of every air receiver to provide for the removal of accumulated oil and water. Hydraulics exposed to freezing temperatures shall be supplied with an adequate antifreeze liquid, according to [1]. By complying with standards and regulations the belly pan jack will do the requested job easily, effectively, and safely. 2.3 Lifting Mechanisms As mentioned in the Codes and Standards section, the dimensions of belly pans on different equipment can vary considerably. The width, length, weight, height of the belly pan when it is installed on the equipment, and the shape of the pans, are the dimensions that are of most importance. The shape of the engine pans can vary greatly. The pans can be flat, sloping, or made to fit around the sump in the engine oil pan. Transmission belly pans are normally flat with little variations. 10 There are numerous kinds of actuators available for many types of applications. One of the most common types is the hydraulic jack. Like most lifting devices the hydraulic jack utilizes mechanical advantage to apply a force to an object that is greater than the jacking force, in order to move an object. Hydraulic jacks are very reliable and can be operated in several ways. Fig. 1 is a picture of one of the most common ways to operate the hydraulic jack, by manually manipulating a lever up and down in order to pump fluid from the reservoir to the cylinder. Fig. 1: Simple manual hydraulic jack. An alternative way to operate the jack is by an electrical or mechanical pump, or by compressed air, which simply takes the place of the manual lever. Along with the manually operated hydraulic jack, there are also jacks that utilize compressed air as the working fluid. A pneumatic jack fundamentally operates in the same fashion as the hydraulic jack, using compressed air instead of oil as the working fluid. Another type of pneumatic jack is the air bag. The air bag is much simpler than the pneumatic and hydraulic cylinder jacks. An air bag consists of two plates attached to both ends of a strong bag 11 usually made of rubber. Compressed air is forced into the bag through a valve, which inflates the bag and lifts the object. To lower the object, the air is simply released from the air bag. The air bag is very useful in low clearance areas because the bag can be deflated and compressed to only a few inches in height. There are also actuators that incorporate a simple screw design. The screw design uses a course threaded rod that goes through a threaded hole on each end of the lifting mechanism. As the threaded rod is turned, it pulls opposite ends of the lifting mechanism toward each other which pushes the top and bottom of the lifting mechanism apart. Fig. 2 is a car jack that utilizes the mentioned mechanism [2]. Fig. 2: Screw design for a scissor jack [2]. Often times the actuator is placed in a structural mechanism such as the screw design. The purpose of the structural mechanism is usually to increase the lifting height or the lifting capacity of the actuator. Fig. 2 shows a basic structure mechanism called a scissor jack [2]. Usually a scissor jack mechanism has more members or longer members than the four shown in Fig. 2 [2]. Multiple linkages can be added to a scissor lift to reach a desired height while only one lifting device is required. Another type of structural mechanism that is utilized in most floor jacks is the parallel linkage mechanism. A parallel linkage mechanism is used to keep the lifting 12 surface at a desired angle, usually horizontal with respect to the ground, while lifting an object. Fig. 3 shows a parallel linkage mechanism used in a common hydraulic floor jack [3]. Fig. 3: Floor jack that uses a parallel linkage [3]. Table 1 and Table 2 contain some specifications on the lifting and actuating mechanisms discussed in this section. Table 1: Actuating Mechanisms 13 Table 2: Lifting Mechanisms 2.4 Chassis and Drive System Most small lifting devices are portable and therefore they are not anchored to the ground. This means that they must have a base or chassis to support the lifting mechanism. The chassis can be as simple as a base or foot mounted to one end of the lifting device as seen in Fig. 1 and Fig. 2 [2]. This is the most basic chassis which provides a common mounting base for the components as well as providing a larger footprint to make lifting the device more stable and reduce its overall ground pressure. In many lifting devices, the chassis may be a more complex part of the lifting mechanism. This is displayed in Fig.3 where the base is a link in a four bar mechanism that allows the lifting surface to be maintained at a desired angle with respect to the ground [3]. Some hydraulic lifting systems also use the chassis as a fluid reservoir which allows for less overall components and simplifies the product, such as the bottle jack shown in Fig. 4 [3]. 14 Fig. 4: Cut-away of a simple hydraulic jack [3]. Another common component of a portable lifting device chassis is a sub-system that allows the device to be easily maneuvered on the ground plane. These sub-systems vary greatly in type and complexity. To allow for movement simple wheels are commonly attached on the extremities of the chassis. Caster wheels are commonly used in situations where maneuverability and durability are priorities. A caster wheel is a wheel that pivots around an axis that is off set to the wheels contact point with the ground, this allows the wheel to track straight when pushed in a straight line however it can still pivot freely when a lateral force is applied [4]. Fig. 5 is an example of a caster wheel [4]. 15 Fig. 5: Locking caster wheel [4] Caster wheels are the standard solution to making a small lifting device portable while supporting a load. The drawback to this system is that the operator must manually move the device. Therefore if the lifting system is designed to support a mass that is not easily moved by the operator, a drive system may be incorporated into the chassis. Drive systems can be as complex as an internal combustion engine coupled with a multi-speed transmission or as simple as a direct drive electric motor. However, since most lifting devices that require a drive system use hydraulically powered lifting systems, the most common drive system is a direct drive hydraulic motor as seen in Fig.6 [5]. 16 Fig. 6: Hydraulic drive motor [5]. A hydraulic drive motor works by using hydraulic fluid to spin a turbine inside the motor which is attached to the drive shaft which protrudes from one end of the motor [5]. A common way of using a hydraulic drive system on a lifting device is to mount the hydraulic motor to a single wheel and the chassis by some type of a gearing system. As mentioned earlier an electric motor or a pneumatic motor could also be used in the same fashion as the hydraulic motor to propel the lift. By using a single drive wheel along with two caster wheels the chassis can pivot around the drive wheel which allows the lifting device to not only move under its own power but can also be easily steered by the operator. 2.5 Platform Fixture System The platform of most equipment lifts consists of two primary subsystems. The subsystems include a method of aligning the platform to the object being lifted, as well as, a method of fixing the object to the platform. The platform can be aligned by using a tilting platform and adjusting it to fit the object. Placing individual fixtures on the platform can also be used to fit a certain object. For an even better and secure fit to a particular object these two methods can be used in conjunction. 17 Several types of tilting platforms are commonly used on lifting mechanisms. Fig. 7 shows a transmission jack [6]. Fig. 7: Transmission jack [6]. This jack uses a two axis pivot. The lift arms support a square frame that has a pivot attached to the center. This pivot is attached to an adjustable link allowing the entire lower platform to pivot with the adjustment, member 50 in Fig. 7 [6]. This platform also has a pivot located in the center. The two pivoting platforms used in conjunction with the caster wheels and lifting mechanism give this transmission jack the ability to adjust to almost any object. However, if the load is off center of the pivot, a great deal of torque is put on the adjusting link making it less than ideal for very heavy objects. Fig. 8 shows another type of tilting platform [7]. 18 Fig 8: Belly pan hoist with tilting platform [7]. This platform has a tilting axis on one end of the platform and the adjustment mechanism on the other. This setup is more stable because most of the elements involved in the adjustment remain only in compression no matter where the load is centered. However, this lift only tilts in one direction reducing the versatility of the lift in unlevel situations. Using fixtures allows another method of adjustment for the lift. Fig. 8 shows a platform that allows a threaded rod, member 26 in Fig. 9, to be inserted into the object being lifted [8]. Fig. 9: Belly pan hoist [8]. 19 This rod can be used to adjust the contact point location between the lift and the object. The screw, however, is limited to only three locations. The platform in Fig. 9 also has sliding arms, member 82, that allow the lift to encompass a wider load [8]. Fig. 10 shows another method of fitting the lift to the object; these are rubber inserts that can be inserted into the platform [9]. Fig. 10: Rubber inserts [9]. The flexibility and variety of these inserts allows for a large range of applications [9]. The inserts, however, are limited in height due to rubber easily buckling. This limits their use for shapes that vary greatly in height. The rubber inserts shown in Fig. 10 could simply be inserted into a hole in the platform [9]. Using a hole means that the fixture is only held in place by gravity and is not completely secure in all situations. The threaded hole used in Fig. 9 however, does give complete security to the object; but, the number of threaded holes limits the fixture’s location [8]. The slots used to hold the sliding arms in Fig. 7 and Fig. 9 offer a durable and adjustable means of attaching fixtures, but they are only adjustable in one direction [6] [8]. Fig. 11 shows a T-slot table, the slots use a t-shaped insert that slides in [10]. 20 Fig. 11: T-slot table [10]. The insert is then attached to the fixture with a bolt which fastens the fixture to the table [10]. This option gives a great deal of flexibility because the fixture can be slid exactly where it is needed. Methods of securing objects to the platform vary by application. Fig.7 shows chains being used which are very strong, but the links do not provide a method of actually tightening the object to the lift [6]. They are used loosely to prevent the object from sliding. Fig. 9 shows arms that extend up and hold the object securely in place [8]. These are fairly secure because the bolts run through the object being held but, this method only works when designed for a unique object. Ratchet straps provide another method of securing an object to a platform. The elasticity of the strap and the ratchet action make it possible to secure almost anything, in addition the straps work well with limited space. Fig. 12 shows the type of ratchet securing device typically shown on semi-trailers for securing cargo [11]. 21 Fig. 12: Ratchet securing device [11]. The disadvantage of using ratchet straps is that all extremities of the object must be exposed in order to be completely secured. 2.6 Current State of the Art Currently there are very few devices made for the sole purpose of aiding in the removal of belly pans. The Belly Pan Hoist made by Hedweld, Fig. 13, is one of the few designed for this purpose [7]. Fig. 13: Hedweld belly pan hoist [7] 22 Hedweld’s design utilizes two hydraulic jacks that are connected to a scissor lift mechanism which provides all of the lifting power for the hoist. The maximum safe lifting load of the hoist is 1543 lbs. Also, the hoist has a very wide range of motion, 9.6 inches fully compressed to 43.3 inches fully extended. The large front wheel is powered by a hydraulic motor. There are two large caster wheels on the back which, along with the motorized front wheel, make it easier to maneuver the lifting mechanism and the belly pan once the belly pan has been completely removed from the machine. The upper platform of the hoist is a solid piece of steel with a 360o turn table for easy placement of the belly pan. There is also an angle attachment that attaches to the upper platform which allows for the removal of angled belly pans. All of the hydraulics on the hoist is controlled by compressed air and all of the controls for the hydraulics are located on the handle of the hoist [7]. Although there are not many specialized tools built specifically for the removal of belly pans there are many that perform similar tasks. Patent Number 5,372,353, Fig. 14, displays a truck transmission jack [12]. Fig. 14: Truck transmission jack [12] 23 The jack employs many of the same devices that the Hedweld belly pan hoist does. It uses a hydraulic bottle jack that is manually operated and a parallelogram lifting style to raise the object. On the top of the jack there are two bars that can be adjusted with screws in order to hold objects that have sloped bottoms. The design of the chassis allows the jack to fully compress; this gives the jack a very low profile and allows it to fit under trucks that have low ground clearance. Also, the design of the chassis allows for large caster wheels which make the jack easier, than ordinary floor jacks, to maneuver on shop floors [12]. Patent number 5,833,198, Fig. 15, displays a lift table which uses a scissor mechanism and a lift spring to provide the lift [13]. Fig.15: Mechanically operated lift table [13] The lift table is very mobile because it does not rely on hydraulics or compressed air to power it. As the table is loaded the spring compresses by an amount that is proportional to the load that is applied which keeps the overall height of the items and the table relatively low. There are four wheels on the lift table so that it can be moved easily once it is fully loaded [13]. 24 2.7 Relevant Patents: An extensive patent search was conducted on relevant patents pertaining to this project. Most of the relevant patents covered designs for aiding in the removal of components from automobiles such as a rear-end or a transmission. However, the systems are very similar to what will be involved in the belly pan jack. Nine out of the ten patents listed utilized a parallelogram style lifting device and the majority of them were hydraulically powered. A safety mechanism will be essential on the belly pan jack to prevent an accident from the lifting device failing. The majority of the researched patent did not have a safety device whatsoever, and the one that did wasn’t very easy to use. An adjustable platform on which the belly pan will rest is another crucial part of this project. 80% of the researched patents have an adjustable platform; many of the designs should aid in the development of the belly pan jack. Table 3: Relevant Patents of Complete Lifts Pictures of the completed lifting systems are in Appendix B. 25 2.8 Conclusion: The research information gained from this document will provide a foundation to start the design process of the development of the belly pan jack. All related areas of the proposed jack have been covered including: chassis systems, drive systems, lifting mechanisms, platform fixture systems, current state of the art devices, and related patents. Undoubtedly this document alone is not enough information to ensure a successful design however, it has efficiently provided factual knowledge on which to develop new ideas. 26 3) Block Diagram 4) Design Basis 27 5) Project Description The proposed belly pan jack will aid in safely and efficiently removing belly pans from large machinery. The belly pan jack will be secured to the belly pan and hold the belly pan up while it is being removed from the machine. The belly pan jack will then lower the pan from the machine and will be able to move out from under the machine so that maintenance can be conducted on the machine. The belly pan jack will have five subsystems: 1) Safety 2) Lifting Mechanism 3) Chassis 4) Platform 5) Power 5.1 Safety Mechanism Subsystem The purpose of the safety mechanism subsystem is to help ensure safe operation of the belly pan jack. The safety mechanism will automatically lock, in intervals of approximately 1 inch, as the jack is being raised. The ratchet teeth of the safety mechanism will be mounted in the middle of the belly pan jack, between the two main lifting members where the lifting cylinder attaches to the bottom sliding portion of the scissor. The disengagement lever will be attached at the same pin as the safety latch and the cylinder. A spring attaches the disengagement lever and safety latch at the middle of each, allowing the disengagement lever to control the safety latch. The spring and disengagement lever will allow the safety latch to be in either the lock or unlock position. This allows the operator to be out from under the jack while lifting and lowering. 28 While lifting, the safety latch will be in the lock position and lock in intervals of approximately 1 inch. While lowering, the safety latch will be in the unlock position to allow the jack to lower smoothly. The safety latch and teeth will be able to hold the weight of the maximum working load of the jack as well as the force of the cylinder, due to the risk of the cylinder accidently being activated. The safety mechanism will protect the operator and other bystanders in the event of hydraulic failure and loss of pressure causing the lifting mechanism to collapse without warning. Fig. 16: Locking mechanism List of Deliverables: CAD drawing showing all parts CAD drawing attached to the jack assembly Cost analysis Parts list 29 List of Activities: Analysis Finalize CAD drawings Purchase parts Machine parts necessary for the safety mechanism Integrate safety mechanism into other subsystems Testing Troubleshooting 5.2 Lifting Mechanism Subsystem The purpose of the lifting mechanism is to provide a mechanism that will raise and lower the platform that holds the belly pan in the vertical direction. The lifting mechanism will be attached to the chassis at a point that maintains the load at the center of the chassis for the length of the travel. The scissor mechanism will achieve a minimum height of approximately 10 inches with a 10o angle with respect to the chassis and a maximum height of approximately 6 inches with an angle of approximately 60o with respect to the chassis. The upper end of the lifting mechanism is attached to the platform which holds the belly pan. Two of the extreme pivots on the scissor are fixed in order that they cannot move in the horizontal direction. The other two extreme pins will pivot as well as slide in the horizontal direction. This arrangement of the pins ensures that the load will travel straight up in the vertical direction without any movement in the horizontal direction. This is crucial when re-installing the belly pan in order that the mechanic can easily line up the bolt holes without having to move the entire chassis. The lifting mechanism will be raised by a hydraulic cylinder at the bottom of the mechanism that has the barrel end attached to the chassis and the rod end attached to the sliding/pivoting pin. The 30 hydraulic cylinder will maintain a 0o angle with respect to the chassis at all times. The travel of the hydraulic cylinder is approximately 12 inches. Fig. 17: Lifting Mechanism List of Deliverables: Assembled CAD drawing CAD drawing of all parts Load and stress analysis Cost analysis and parts list for this subsystem of prototype List of Activities: Measure all necessary dimensions Finalize design with CAD Perform load and stress analysis Purchase parts Assemble mechanism Test mechanism under actual working conditions 31 5.3 Chassis The chassis will be constructed of both rectangular cross section steel tubing and steel plating. Steel was chosen for its strength and ease of construction which will mainly consist of welding. The chassis will provide a means of connecting the drive system to both the lifting system and the power system. The Chassis will consist of a main frame that will be 42 inches long and 26 inches wide not including the caster wheels that will extend from the rear corners to allow the chassis to remain closer to the ground thus lowering the center of gravity and making the entire system more stable. Connected to the front of the chassis will be a hydraulically driven wheel that will allow for powered fore and aft motion. The caster wheels at the rear of the chassis will allow the chassis to pivot around the drive wheel allowing the entire assembly to be guided by the operator while in motion. Inside the main frame will be floor sections to allow the mounting of the drive ram for the lifting system, the lifting system pivots, and safety mechanism for the lifting system as well as an oil reservoir and the hydraulic power system. Fig. 18: Chassis 32 List of Deliverable: CAD drawings of all pieces CAD drawings with whole jack Stress and Load analysis Cost analysis List of Activities: Analysis Finalize CAD drawings Purchase materials Welding of mainframe Assemble drive system and casters Load testing Integrate other subsystems onto mainframe 5.4 Platform and Fixture Subsystem The platform and fixture system will be used to connect the lifting mechanism to object to be supported. The objects to be supported will have varying shapes and sizes. This brings the need for a platform that is capable of fitting a wide variety of objects. To accomplish this, the platform will employ a t-slot mounting system making it possible to mount fixtures in any location on the platform. This accomplished using a key that slides into the T-slot. This key is connected to fixture with a bolt. When the bolt is tightened, the fixture will be secured to the platform. The fixture to be mounted to the platform will also have to be capable of fitting multiple shapes. There will be a few general fixtures that will easily support flat shapes and simple angles. For more complex shapes, custom fixtures can be employed. The entire platform 33 will be mounted on top of the lifting mechanism. The platform will be mounted using pins on one side and a hydraulic cylinder on the other. This will enable the entire platform to tilt. The ability to tilt will make re-aligning the object with its bolt holes much simpler. An example of the lifting platform can be seen in Fig. 19. Fig. 19: Platform List of Deliverable: CAD drawings of all parts CAD drawings assembled with entire jack Load calculations Support and frame stress analysis Cost analysis List of Activities: Analysis Purchase materials Fabricate pieces Assemble fixtures Load and stress testing Integrate with other subsystems 34 5.5 Power Subsystem The power system on the belly pan jack consists of a hydraulic cylinder, hydraulic motor, and an air over hydraulic pump. A single, double acting, hydraulic cylinder will be used. The hydraulic cylinder will be attached to the bottom of the frame and the sliding end of the scissor lift. The cylinder will remain horizontal at all times. When the scissor lift is at maximum height the sliding end travels 12.3 inches, therefore the cylinder must have a stroke of equal or greater length. The cylinder must also be able to support the maximum load on the jack while maintaining a factor of safety of 3. A high torque, low rpm, hydraulic motor will be used to power the front wheel. The motor will be attached to the front of the frame and will be connected to the front wheel through a gear reduction system. The motor will have a high enough torque to pull the jack when it is fully loaded and will be able to maintain a comfortable speed while moving the belly pan. The air over hydraulic pump will power both the hydraulic cylinder and the hydraulic motor. Controls will be fully integrated to easy operation of the jack. List of Deliverables CAD drawings of individual items CAD drawing integrated into the jack Calculations on amount of oil flow required to power the hydraulic cylinder and motor Cost analysis List of Design Activities Analysis Finalized CAD drawings Purchase the hydraulic cylinder, hydraulic motor, and air over hydraulic pump Fabricate and assemble parts on jack Load test all of the components 35 6) Project Organization Chart Alex Gibbs ME Project Manager Lifting Mechanism Jason Weber Ross Heern Matt Lane ME ME ME Platform Safety Power Bradley Wilson Blake Thurston ME ME Chassis Lifting Mechanism and Editor 36 7) Action Item List Below is an Action Item List for the first two weeks of next semester. 37 8) Timeline 38 9) List of Resources 39 10) Future Testing and Analysis The initial analysis will consist of force analysis of Chassis, Lifting System, Platform and Safety Mechanism. This analysis will assume static conditions and allows for calculation of fastener sizes, reaction forces at the wheels and forces on the hydraulic ram(s). Hydraulic system analysis will enable the calculation of pressures required. FEA will be performed on Chassis, Lifting System, and Platform and Complete Product to assess the stresses in each subsystem and in the final product. After the Complete Product is assembled it will be load tested by loading it with known weights in increasing amounts until the desired load has been met. Once the assembly has passed all load testing the productivity of the product will be tested by comparing the amount of time needed to completely remove a belly pan to previously used methods. 40 References [1] (2010, Nov.) Safety and Health Regulations for Construction, Tools-Hand and Power, 1926.305 Jacks-lever and ratchet, screw, and hydraulic. [online]. Available: http://www.osha.gov/pls/oshaweb/owadisp.show_document?p_table=STANDARDS&p_id =10693 [2] D. L. Engel, “Screw Designs for a Scissors Jacks,” U.S. Patent 5 364 072, Nov., 15, 1994. [3] T. H. Ha, “Hydraulic Jack,” U.S. Patent 7 100 897 B2, Sep., 5, 2006. [4] U. Finkeldey, “Caster Wheel” U.S. Patent 343,787, Feb. 1, 1994 [5] W. Friedrichsen, “Hydraulic Motor”, U.S. Patent 424,516, May 9, 2000 [6] J. Garante, “Transmission Jack,” U.S. Patent 3,958,793, May, 26, 1976 [7] "Belly Pan Hoist." Hedweld Engineering Pty Ltd. Hedweld Engineering. Web. 06 Oct. 2010. <http://www.hedweld.com.au/index.php?Module=Products&Category=4&Product=5>. [8] V. R. C. Durgan, “Crankcase Guard Jack Utilizing Double Parallelogram,” U.S. Patent 3,937,443, Feb., 10, 1976 [9] “Jack Pad Adapter.” ECS Tuning. Web. 05 Oct. 2010. <http://www.ecstuning.com/Volkswagen-Golf_IV-TDI/Search/ES251745%2C_ES251835/?utm_campaign=ecsvagjackpad&utm_source=tdicl ub&utm_medium=forum&utm_content=20th>. [10] “T-Slot Table.” CFM ITBNA LLC Engineering Design Manufacturing. Web 06 Oct. 2010. <http://www.itbona.com/ITBONA/STOLLE/stollehome.htm>. [11] “Winch Construction for Cargo Tie-Down Straps.” U.S. Patent 5,490,749, Feb., 13, 1996 [12] West, “Truck Transmission Jack,” U.S. Patent 5,372,353, Dec. 13, 1994. [13] Graetz, “Mechanically Operated Lift Table,” U.S. Patent 5,833,198, Nov. 10, 1998. [14] Dyers, "Jack Carried Mechanism For Facilitating Removal, Repair, and Replacement of Vehicle Carried Units" U.S. Patent 2938635, May 31, 1960. [15] Wolf, “Hydraulic Jack Mechanism” U.S. Patent 3136526, Jan. 22, 1962. [16] Macpherson, “Double Parallelogram Jack” U.S. Patent 4068825, Jan. 17, 1978. [17] Withcher, “Portable Lift Jacks” U.S. Patent 2814394, March 29, 1954. 41 [18] Etal, “Jack” U.S. Patent 3109626 [19] Nymann, “Jack For Heavy Objects” U.S. Patent 7303181, Dec. 4, 2007 [20] Marsh, “Wheeled Scissors Jack” U.S. Patent 2621891, Sept 26, 1950 42 Appendix Appendix A: Resumes Appendix B: Pictures of Completed Lifts from Relevant Patents 43 Appendix A: Resumes Alex Gibbs, ME – PM Ross Heern, ME Bradley Wilson, ME Matt Lane, ME Jason Weber, ME Blake Thurston, ME 44 Alex James Gibbs gbg@dishmail.net 16097 Toms Road Benton, IL 62812 (618) 527 – 8673 Objective: Entry level mechanical engineering position. Education: Southern Illinois University of Carbondale Expected Graduation Date: May 2011 Bachelor of Science in Mechanical Engineering Relevant Coursework; Thermodynamics Heat Transfer Controls Machine Design HVAC Manufacturing Methods Material Science Numerical Methods Fluids Mechanics of Materials Experience: Skills: Card holding IUOE local 318 heavy equipment operator and mechanic May 2003 to present. Owner of AXLE Transport truck service June 2009 to present. Professional OTR driver for Gibbs Construction April 2007 to present. Proficient in Microsoft word, power point, and excel Experienced in AutoCAD, MatLab, and Simulink Strong leadership skills Seasoned heavy equipment operator and mechanic Seasoned tractor-trailer operator and mechanic Basic machining Basic surveying Activities: Member of the Deacons at Heartland Christian Church Marion IL Sunday school teacher Camping Vintage cars Motorcycles CB-Radio High performance diesel trucks 45 Ross W. Heern Email: ross12heern@hotmail.com Permanent Address: 20846 Stevens Branch Rd. West Frankfort, IL 62896 Primary Contact: (618) 923-2770 Secondary Contact: (618) 923-1154 Professional Objective: Entry level mechanical engineer. Interested in the production of energy, machine design, and production management. Main interest is in heavy machinery and power plants as well as related fields. (May-August) Education: Degree School GPA Expected Completion B.S. Mechanical Engineering SIUC 3.8 Spring 2011 Assoc. in Science Rend Lake College 3.8 Spring 2009 Assoc. in Engineering Science Rend Lake College 3.8 Spring 2009 Honors and Awards: Deans list all semesters at Rend Lake College. Deans list at SIUC. Skills: • Proficient in MS word, excel, and power point • Experience in MATLAB, Simulink, and AutoCAD • Ability to analyze mechanisms and linkages • Work well with people • Ability to lead • Learn and listen very well Experience: • Entrepreneurship in the trucking industry. Purchased my own truck and hauling various aggregates; gravel, lime, rip rap etc. for individuals and local construction companies. (2010 to present) • Working for Gibbs Construction, main task is driving a semi truck. Various other tasks performed such as helping service equipment and surveying. (2008 to present) 46 • Worked for Thompsonville feed mill, Big O Farm and Garden. Responsibilities included loading and unloading trucks with feed, seed, and various other items. Also helped with inventory arrangement and helped with customer needs. (summer 2006) • Working with father operating family farm and cattle operation, main responsibilities are harvesting forage and caring for cattle. (1996 to present) Related Courses: • Engineering Thermodynamics 1 and 2 • Engineering Fluid Dynamics • Mechanism Analysis • Numerical Methods • Mechanics of Materials • Heat Transfer • Material Science • Circuits • University Physics • Calculus 1, 2, and 3 • Differential Equations • Material Selection • Dynamic Modeling and Controls of Engineering Systems • Engineering Economics • Machine Design • Air Pollution Control • HAVC Systems Design References: Available upon request. 47 Bradley M Wilson 609 E Campus Dr Apt 704 Carbondale Il, 62901 Home Phone: 618-428-5495 Cell Phone: 618-292-7806 bmwilson@siu.edu Education Southern Illinois University Carbondale Mechanical Engineering Carbondale, IL Anticipated: Fall 2011 Lake Land Community College Associate in Pre-Engineering Mattoon, IL August 2009 Work Experience Southern Illinois University Carbondale Department of Biochemistry and Molecular Biology- Office worker- Duties are preparing documents for mailing or distribution, answering phones, and maintaining copy machine. College of Physics- Lab Worker-Designed a system to dewater coal, as well as several safety mechanisms for the lab. Rhodes France Scout Reservation Maintenance- Required working alone and with a team as well as problem solving skills. Merit Badge Counselor- Required maintaining a productive learning environment and keeping order over groups of scouts in various setting from beside a lake to in a class room. Grain Systems Incorporated (GSI) Facilities Maintenance- Duties ranged from basic construction such as hanging dry wall and finishing offices to wiring new lights in work areas. Anything that needed done on the property outside of the actual factory work was completed by facilities maintenance. GSI gave me lots of experience in an industrial setting working a variety of jobs. Wilson’s Fish Farm Worker/Operator- Duties involved long hours and direct work with channel catfish, maintaining water systems to keep within water regulations. Working with water monitoring systems to maintain water quality to promote the healthy growth of fish. Operation of heavy equipment and a small crane. 48 Work Related Skills I am proficient in the entire Microsoft Office Suite, AutoCAD, and the C++ Programming Language. I also have experience in machining through the SIUC Formula SAE racing team. Volunteer Work Herrick Fire Department- Fire Fighter and Engineer/Operator, Fire prevention education with Herrick Grade School and Boy Scouts of America Herrick First Christian Church - Vacation Bible School Leader Herrick Public Library- Summer Reading Program Alpha Chi Sigma-Beta Psi Chapter- Science Demos for Children, Adopt-A-Spot community cleanup ASME- Work out before the pig out 5K event staff, SIUC Engineering Day Vine Community Church (Carbondale)- Event Setup/Preparation Extra Curricular Activities SIUC ASME- American Society of Mechanical Engineers-Officer SIUC Formula SAE- Intercollegiate racing program-Team Captain LLCC Math and Science Club Boy Scouts of America- Eagle Scout 49 MATTHEW LANE MLane89@Gmail.com 618-838-8899 Permanent Address 1202 E. North Ave. Olney, IL 62450 OBJECTIVE College Address 516 S. Poplar St. Apt 4 Carbondale, IL 62901 To further my education and obtain valuable professional experience that is relevant to Mechanical Engineering. EDUCATION Southern Illinois University (2009-Present) Bachelors degree in Mechanical Engineering (graduate Spring 2011) GPA – 3.9/4.0 Dean’s List Fall 2009, Spring 2010 Olney Central College (2007 - 2009) Associates of Science and Arts Degree GPA – 3.4/4.0 Dean's List Spring 2009 EXPERIENCE Under Graduate Assistant: Intelligent Measurement and Evaluation Lab (August 2010 – Present) Perform non-destructive evaluation on many different types of materials using thermography, immersion ultrasonic testing, and air coupled ultrasonic testing Teacher’s Assistant: Math Department (May 2007-August 2009) Graded papers and performed clerical work. Answered students questions pertaining to math SKILLS Microsoft Office Autodesk Inventor MATLAB HONORS/AWARDS Aisin Scholarship, 2010 Member: Tau Beta Pi, 2010 ACTIVITIES Vice President, Moonbuggy Club, Southern Illinois University Carbondale, May 2010 Member, American Society of Mechanical Engineers 50 Jason Weber jasonw.com@gmail.com Permanent Address: 425 N Plum St. Teutopolis, Il 217-857-3876 College Address: 420 W Sycamore St. Carbondale, IL 62901 217-821-8212 Objective: To obtain an internship opportunity. Summary Solid work ethic developed from participating in past activities and occupations. Held several positions dealing with manufacturing and machine repair. Education Bachelor of Science in Mechanical Engineering, Spring 2010 Southern Illinois University, Carbondale, IL 62901 Relevant Coursework Engineering Economics Material Selection Fluid Dynamics Material Science Thermodynamics Heat Transfer Machine Design Mechanical Analysis & Design Numerical Methods Controls Computer-Aided Engr. Drawings Experience All wheeled vehicle mechanic, United States Army (July 2004 to Dec. 2006) Performed regular service and repair of military vehicles Recovered vehicles that had hit I.E.D.’s or broken down outside of the forward operating bases in Iraq Provided transport for battalion Command Sergeant Major and Colonel between different Forward Operating Bases Machine operator, Stevens Industry (June 2008 to Aug. 2008) Responsible for operating laminate press in a timely manner Responsible for finished product quality and troubleshooting causes of defects Machinist, Kremer’s Precision Machine (May 2003 to Aug. 2003 and May 2007 to Aug. 2007) Preparation of stock material to be machined Programming and operation of milling equipment Laborer, J.B. Esker and Sons Concrete Construction (June 2002 to Aug 2002) Assisted in constructing concrete basement foundations 51 Assisted in constructing concrete pads and roads Skills Writing Engineering Lab Reports Machining Experience Experience with AutoCAD, MatLab and Simulink, Basic C++ Programming Honors/Awards Air Assault School graduate Combat Action Badge Activities ASME Member Camping, Wakeboarding, Snowboarding, Hunting 52 Blake Thurston 1398 Vine Street bwt88@siu.edu Pulaski, Illinois 62976 618-342-6573 OBJECTIVE: To obtain a job as a mechanical engineer; staring after graduation in May 2011. EDUCATION: 2009-Present Bachelor of Science in Mechanical Engineering, May 2011 Southern Illinois University Carbondale, Illinois 62901 2005-2009 Associates of Pre-Engineering Shawnee Community College Ullin, Illinois 62992 G.P.A.: 3.96/4.0 2003-2007 High School Diploma Century High School Ullin, Illinois 62992 G.P.A.: 4.0/4.0 EMPLOYMENT: 2000-Present Thurston Brothers Farm Pulaski, Illinois 62976 I work as a laborer, operate large farm equipment, and have started a small farming operation on my own. 2002-Present Blake’s Lawn Care Pulaski, Illinois 62976 I own, operate, and manage a lawn care business. I keep financial records, recruit new clients, handle customer relations, repair equipment, and hire employees. 2008 - 2009 Chris Williamson’s Farm Pulaski, Illinois 62976 I worked as a laborer, made hay, built fence, and operated farm machinery. AWARDS / HONORS Who’s Who Among Students in American Junior Colleges Sons of the American Revolution Outstanding Citizen Award Academics Honor Award – Mathematics ● Illinois State Scholar Math Award Presidents Academic Honors ● Illinois State Scholar Science Award Mid Country Bank Core Value Award ● Academic All State Award National Scholar/Athlete Award ● SAR Outstanding Citizen Award Southern Illinois Society for Achievement Award EXTRA CURRICULAR ACTIVITIES: VOLUNTEER SERVICE: Phi Theta Kappa ● Pulaski Fire department Member of Saluki Racing ● Pulaski County Fair Beta club ● Deacon Pulaski Christian Church Fellowship of Christian Athletes ● Peer math tutor Homecoming King COURSE WORK: Internal Combustion Engines ● C++ Programming 53 ● AutoCAD Appendix B: Pictures of Completed Lifts from Relevant Patents 5,372,353 [12] 2,938,635 [14] 3,136,526 [15] 54 4,068,825 [16] 2,814,394 [17] 3,109,626 [18] 55 7,303,181 [19] 3,958,793 [6] 2,621,819 [20] 56 3,937,443 [8] 5,833,198 [13] 57