safeguarding - National Safety Council

advertisement

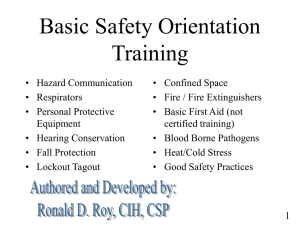

Accident Prevention Manual for Business & Industry: Engineering & Technology 13th edition National Safety Council Compiled by Dr. S.D. Allen Iske, Associate Professor University of Central Missouri CHAPTER 6 SAFEGUARDING 3 Safeguarding • A primary method to reduce worksite hazards • Prevents personnel from contact with moving parts • Key is to identify hazards • Includes barriers, guards, signs, lockout/tagout, safety design, enclosures, fences Definitions • Safeguarding—Any means of preventing personnel from • • • • • coming in contact with moving parts of machinery or equipment, that would potentially cause harm Device—a mechanism or control designed for safeguarding at the point of operation Guard—barriers designed for safeguarding Enclosure—safeguarding by fixed physical barriers that are mounted on or around the machine to prevent accidents Fencing—safeguarding by means of a locked fence or rail Location—safeguarding when a hazard is physically inaccessible under normal operating conditions or use Definitions (Cont.) • Nip points or bites—the hazardous area created by two • • • • or more mechanical parts, rotating in opposite directions within the same plane Pinch point—the point where any body part can be caught between two moving parts or one fixed and one moving Point of operation—the area of a machine where material is positioned or work is performed on material Power transmission—all mechanical parts (gears, cams, shafts, pulleys, belts, clutches) that transmit energy and motion from a source of power to equipment or a machine Shear points—the hazardous area created by the cutting movement of a mechanical part Point-of-Operation Protection Devices • Openings used for safeguarding • should not exceed 3/8” • prevents entry or contact • first 1.5” from danger line should not exceed 1/4” opening Point-of-Operation Safeguards • Guard construction • must be sturdy and secure (substantially constructed) • secured to minimize distortion or movement. • sufficiently strong to withstand stress and exposure • usually made of metal Point-of-Operation Safeguards (Cont.) • Proper guard characteristics: • integration with machine • adequate construction, durability, and strength • handle workpiece in-feed and ejection • protection from the hazards • ease of inspection and maintenance • tamper-proof or foolproof • Proper guard should NOT: • Create additional hazards • Interfere with production • Cause work discomfort Point-of-Operation Safeguards (Cont.) • Types of safeguards • built-in safeguards • barrier guards • interlocking barrier guards • automatic safeguard devices • guarding by location • Substitution • Match machine or equipment to the operator • Study and review Table 6–A Types of Safeguards • Built-in safeguard • factory made, conforms to the machine—appearance, placement, and function • eliminates hazards • withstands normal wear and tear • costs less than improvised/modified safeguard Types of Safeguards (Cont.) • Barrier guard • prevents physical access to dangerous point of operation or work area • usually adjustable for different sets of tools or kinds of work • once adjusted, must not be moved or detached Types of Safeguards (Cont.) • Interlocking barrier guard • can be electrical, mechanical, pneumatic or combination • prevents operation of machine control mechanism until guard moves into predetermined position • when open, machine cannot operate and mechanism is locked. • when machine is in motion or operation, guard cannot be opened until machine comes to rest or fixed position Interlocking Barrier Guards • Effective interlocking barriers must meet three requirements: • guard hazardous area before machine can be operated • stay closed until the rotating equipment is at rest • prevent operation of the machine if the interlocking device fails Types of Safeguards • Automatic safeguarding devices • prevent operator from coming in contact with dangerous parts of a machine while the machine is in motion • stop the machine in the event of a sub-normal operating condition (shuts down operation) • types of devices: • presence-sensing devices • pull-backs • restraints • two-handed controls Guarding by Location • Location of the exposed part will be sufficient for guarding purposes. • OSHA 29 CFR 1910.219 • All exposed parts of horizontal shafting seven (7) feet or less from floor or working platform, excepting runways used exclusively for oiling or running adjustments, shall be protected by a stationary casing enclosing shafting completely or by a trough enclosing sides and top or sides and bottom of shafting as location requires. Types of Safeguards (Cont.) • Substitution • Substitute a less hazardous machine or piece of equipment for a more hazardous one. • Eliminates or reduces machine hazards Types of Safeguards (Cont.) • Match operator to the machine • Workplace—arrange equipment to minimize work • Work height—adjust for operator • Controls and displays—make them readily accessible • Material handling aids—handles, hoists, belts, conveyors, lifts • Operator fatigue—reduced when job is well designed Guarding Power Transmissions • Rotating, reciprocating, and transverse motions • In-running nip points • Cutting actions • Punching, shearing, and bending actions Guarding Power Transmissions (Cont.) • Methods of guarding actions and motions • Similar to point-of-operation safeguards. • Machine movements can be dangerous. • Guards must cover all moving parts. • Guards must allow for routine maintenance and service, but only when equipment is properly locked out. • Guards must be fixed in place with bolts, hinges, sliding doors, etc. • Guards must be durable. Guarding Power Transmissions (Cont.) • Types of mechanical actions and motions • rotating, reciprocating, and transverse motions • in-running nip points • cutting actions • punching, shearing and bending actions Typical Nip Points Guarding Power Transmissions (Cont.) • Guarding Materials • Material must be sturdy. • Metal is preferred. • If visibility is required, use plastic, polycarbonate, or Lexan. • Use aluminum, another soft metal, or plastic if rust is a concern. • Wood has limited application due to lack of durability and strength, relatively high cost, combustibility, and tendency to splinter. • Provide ample ventilation through the guard. Maintenance and Service • Plan for routine maintenance when designing guards. • Apply engineering techniques that reduce the frequency of, or eliminate, a job/task. • Design guards for easy routine maintenance access. • Equip machines with automatic controls for lubrication, adjustment, or service. Control of Hazardous Energy Source • OSHA Standard 29 CFR 1910.147 • Lockout/tagout procedures • Purpose • Scope • Sequence of Lockout • Restoring equipment to service • Other requirements Lockout/Tagout Procedures • Procedures • must be written • lockout preferred • tagout used when machine can’t be locked • combination of the two is best • strict compliance is required Lockout/Tagout Procedures (Cont.) • Purpose • minimum requirements • isolates energy for routine maintenance and service • guards against accidental restart Lockout/Tagout Procedures (Cont.) • Scope • All employees are required to comply with the restrictions and limitations imposed during use of lockout. • Authorized employees are required to perform the lockout in accordance with procedure. • All employees upon observing a machine or equipment piece that is locked out should not attempt to start, energize, or use that piece of equipment or machine. Lockout/Tagout Procedures (Cont.) • Sequence • Notify employees of servicing or maintenance on a machine or equipment—shut down and lock out. • Authorized employee refers to and follows procedures to identify the type and magnitude of energy source. • Shut down by normal procedure. • Deactivate the energy—isolating device—machine isolated from energy sources (lockout/tagout) • Dissipate stored or residual energy and gas/air/steam • Verify isolation before performing service. • Machine is now LOCKED OUT! Lockout/Tagout Procedures (Cont.) • Restore service • Remove non-essential items from the work area. • Make sure machine is intact. • Remove all employees from the area. • Put controls in neutral. • Remove locks and reenergize the equipment. • Notify employees that maintenance or servicing is completed. Equipment or machine is ready for use. • Group lockout—for a piece of equipment or power source, each employee shall have an individual lock and apply the lock to the device. 35 Lockout/Tagout Procedures (Cont.) • Training • Train all employees in lockout/tagout. • Retrain annually. • Audit training program annually. • Conduct remedial training as needed for individuals for nonconformance actions . • Lockout equipment • Devices shall be durable, marked, color coded, or otherwise identified for each facility and supplied to authorized personnel. Correct tag labels and strength. Robotics Safeguarding • Principal hazards • being struck by the moving parts of a robot while in the operating envelope or movement zone • caught between moving parts of the robot and other machinery or objects within or near the robots movement zone • being struck by objects or tools the robot has dropped or ejected Robotics Safeguarding (Cont.) • Safeguarding methods • Restrict robot movement zone to required range of motion for particular operation • Install an amber light on a robot, which turns on when the robot is “live” or operational. • Install barriers and fixed guards. • Have emergency stop or “deadman” buttons hardwired to robot power source and easy to reach. • Program so operator cannot place into automatic cycle until all interlocked gates are closed and operator is at master control panel outside of robot movement zone. Guards and Noise • If well designed and mounted, guards: • may reduce noise • act as a barrier • absorb, reflect, or confine sound waves