PowerPoint-Präsentation - Institute of Chemical Process

Increase of the product recovery of

Clostridium acetobutylicum fermentation product by pervaporation

P. Izák 1 , V. Jarmarová 1 , K. Schwarz 2 , W. Ruth 2 ,H. Bahl 2 , U. Kragl 2

1 Institute of Chemical Process Fundamentals, Rozvojová 135, 165 02 Prague 6, Czech Republic

2 Institute of Chemistry, University of Rostock, Albert Einstein Str.3a, 18059 Rostock, Germany http://www.icpf.cas.cz/

Supported ionic liquid membranes offer a range of possible advantages:

Molecular diffusion - higher in liquids than in solids , allowing high fluxes;

The selectivity of the separation can be influenced by variation of the liquid especially ionic liquids offer the advantage of a wide variety of properties ;

Ionic liquids as liquid membranes allow three-phase systems due to their special mixing behavior;

Due to their good thermal stability , reactive processes - at high temperatures (up to around 250 ºC), which leads to faster kinetics in the case of endothermic reactions;

The use of nano-, ultra- and micro-filtration ceramic modules diminish concentration polarization due to rough liquid-membrane surface;

Contrary to the extraction, only small amounts of liquids are necessary to form the liquid membrane, thus allowing the use of more expensive materials.

The “only” problem is long time stability of the liquid in the pores

.

Stability of the hydrophobic ILs inside the pores (in hours) ceramic module pore size (nm)

200

60

5

0.9

IL

C

14

H

24

N

+

BF

4

-

0.1

0.5

-

1.2

C

4 mim

+

PF

6

-

-

1.3

2.4

C

8

H

26

N

2

B(CN)

4

-

-

1.9

3.5

C

27

H

54

F

6

N

2

O

4

S

2

-

-

-

0.15

Experimental

• As a support matrix for the polymer-IL membrane the ceramic ultrafiltration module used. made from TiO

2 with pore size 60 nm was

• The

PDMS was prepared by mixing a solution of RTV 615A and

RTV 615B (General Electric) in 10:1 ratio at 60 ° C for 0.5 hour.

• 15 wt% of tetrapropylammonium tetracyano-borate ionic liquid and 85 wt% polydimethylsiloxane ( IL1 ).

• 50 wt% of

1-ethenyl-3-ethyl-imidazolium hexafluorophosphate ionic liquid was mixed with 50 wt% polydimethylsiloxane -

( IL2 ).

• The ternary system - practical application in biotransformation processes, where the fermentation broth from Clostridium acetobutylicum is normally used

• The compound of interest is biofuel, namely

BIObutanol

• It is the main product of butan-1-ol fermentation and it is also the primary inhibitory product affecting the bioconversion

Sorption apparatus for determination of sorption and diffusion coefficients

Dependence of butan-1-ol sorption isotherm on relative pressure at 37 ° C

800

600

400

200

0

0

PDMS

PDMS+IL1

PDMS+IL2

0.2

0.4

p rel

0.6

0.8

1

Dependence of butan-1-ol diffusion coefficient on relative pressure

5,E-10

4,E-10

3,E-10

2,E-10

1,E-10

1,E-11

0 0,2 0,4 p rel

0,6

PDMS

PDMS+IL1

PDMS+IL2

0,8 1

Thermostat

Pervaporation set-up

Retentate

Reaction vessel

Feed

Permeate

Pervaporation experiment – standard laboratory pervaporation set-up with effective membrane area of

5 cm 2 ; downstream pressure p = 60 Pa

Vacuum pump

Cold trap

Permeate

Dependence of permeate permeation flux on feed concentration at 37 ° C

20

PDMS

PDMS-IL1

PDMS-IL2

15

10

5

0

0 0.5

1 1.5

Feed concentration of butan-1-ol [(%w/w)]

2

Dependence of enrichment factor of permeate on feed concentration at 37 ° C

12

PDMS

PDMS-IL1

PDMS-IL2

8

4

0

0 0.5

1 1.5

Feed concentration of butan-1-ol [(%w/w)]

2

• The enrichment factor of butan-1-ol increased from 2.2 (PDMS) up to 10.9 (IL2-PDMS) ( Izák P,

Ruth W, Dyson P, Kragl U (2007) Selective Removal of Acetone and Butan-1ol from Water with Supported Ionic Liquid - Polydimethylsiloxane Membrane by Pervaporation, Chem. Eng. J., 139/2 (2008) 318-321

)

• Fermentation was carried out at 37 ° C and pH

4.5.

• Firstly, a continuous fermentation with removal of

ABE by pervaporation was measured without any butan-1-ol addition to test, if the SILM was selective and stable.

Experiment

•

C. Acetobutylicum ATCC 824 was grown under anaerobic phosphate-limited conditions.

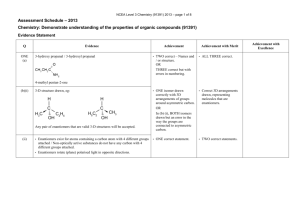

• In the chosen fermentation system, especially the phosphate concentrations as well as the dilution rates were responsible for the amount of produced solvents . dilution rate

(h

-1

)

0.05

0.075

0.075

0.09 phosphate

(mM)

0.75

0.75

0.5

0.75

OD

600 acetone

(g l

-1

)

7.12 3.82

7.1 2.82

8.52 5.00

6.25 3.18 butan-1-ol

(g l

-1

)

7.12

5.44

10.38

7.07 acetate

(g l

-1

)

0.97

0.98

1.62

0.93 butyrate

(g l

-1

)

0.64

0.65

0.44

0.69 ethanol

(g l

-1

)

0.67

0.50

0.94

0.77 solvent productivity

(g l

-1 h

-1

)

0.66

0.78

1.38

1.14

1 2

3

Feed

5

Retentate

4

Permeate

6

Vac

Schema of continuous culture fermentation connected with pervaporation

1.Waste tank; 2. Tank with substrate; 3. Culture vessel; 4.

Pervaporation cell; 5. Cold trap; 6. Vacuum pump

Dependence of permeate concentration on fermentation time at 37 ° C, at dilution rate 0.075 h -1 , 0.5 mM phosphate concentration in supplying vessel and pH 4.5.

Butan-1-ol addition Pervaporation off

20

16

12

8

3

2

4

1

0

0 100 200 300 400

Time of fermentation (hours)

500

0

●

Butan-1-ol (summary of the produced and added butan-1-ol);

∆ Acetone; □

Ethanol; Acetate; x Butyrate

6

5

4

Dependence of optical density and butan-1-ol concentration on time of fermentation

Butan-1-ol addition Pervaporation off

20 20

Butan-1-ol

OD600

15 15

10

5

0

0 100

─ Butan-1-ol concentration;

Optical density

200 300

Time (hours)

400

10

5

500

0

• After successful tests

, the concentration of butan-

1-ol was several times increased to test the SILM under more stringent conditions and to study the effect of pervaporation on the cells.

• After 3 months of the experiment we did not observe any change of mass or selectivity of IL in the pores of the ultrafiltration membrane.

Dependence of butan-1-ol and acetone permeation flux on its culture vessel concentration.

20

15

10

5

Acetone - PDMS+IL

Butanol - PDMS+IL

0

0 3 6 9 12 15

Permeate concentration in the feed [g/L]

18

● Butan-1-ol; ∆ Acetone

Dependence of butan-1-ol and acetone enrichment factor on its culture vessel concentration.

20

16

12

8

4

0

0 3 6 9

Acetone - PDMS+IL

Butanol - PDMS+IL

12 15 18

Permeate concentration in the feed [g/L]

● Butan-1-ol; ∆ Acetone

Conclusions

• To get more effective ABE removal from fermentor we used pervaporation with IL-PDMS nonporous membrane.

• Using this membrane we were able to remove

ABE from the culture supernatant more effectively than it was described by others (Qureshi et al.

(1992), Soni et al. (1987), Liu et al. (2004)).

Conclusions

• The supported ionic liquid membranes were weighted after all experiments and no weight changes were observed – stable SILM.

• Higher diffusion coefficient is most probably responsible for higher permeation flux and enrichment factors of butan-1-ol in IL-PDMS membrane.

• If we would run pervaporation with continuous and complete removal of butan-1-ol from the culture supernatant, it would lead to more stable fermentation process with higher production of

BIObutanol.

Acknowledgement

This research was supported partially by grant

No. 104/08/0600 from Czech Science

Foundation and Marie Curie Reintegration

Fellowships within the 6 th European

Community Framework Programme.