Chapter 13: Types and Applications of Materials

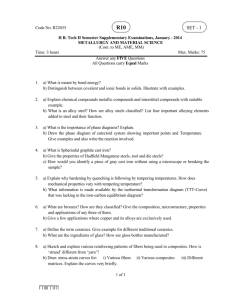

advertisement

Chapter 13: Types and Applications of Materials ISSUES TO ADDRESS... • How are metal alloys classified and what are their common applications? • How do we classify ceramics? • What are some applications of ceramics? • What are the various types/classifications of polymers? Chapter 13 - 1 Classification of Metal Alloys Metal Alloys Ferrous Steels Steels <1.4wt%C <1.4 wt% C Nonferrous Cast Irons Cast Irons 3-4.5 wt%C 3-4.5 wt% C microstructure: ferrite, graphite/cementite T(ºC) 1600 d L 1400 1200 g austenite g+L a800 ferrite 600 0 (Fe) L+Fe3C 1148ºC 4.30 1000 400 Adapted from Fig. 13.1, Callister & Rethwisch 4e. 727ºC Eutectoid: 0.76 1 2 Eutectic: g+Fe3C Fe3C cementite a+Fe3C 3 4 Adapted from Fig. 10.28, Callister & Rethwisch 4e. (Fig. 10.28 adapted from Binary Alloy Phase Diagrams, 2nd ed., Vol. 1, T.B. Massalski (Ed.-inChief), ASM International, Materials Park, OH, 1990.) 5 6 Co , wt% C 6.7 Chapter 13 - 2 Steels High Alloy Low Alloy low carbon Med carbon <0.25 wt% C 0.25-0.6wt% C high carbon 0.6-1.4wt% C heat plain treatable Cr,V Cr, Ni Additions none none none Ni, Mo Mo Example 1010 4310 1040 4340 1095 Hardenability 0 + + ++ ++ TS 0 + ++ + EL + + 0 Name plain Uses auto struc. sheet HSLA bridges towers press. vessels plain crank shafts bolts hammers blades pistons gears wear applic. wear applic. tool Cr, V, Mo, W 4190 +++ ++ -drills saws dies increasing strength, cost, decreasing ductility Based on data provided in Tables 13.1(b), 13.2(b), 13.3, and 13.4, Callister & Rethwisch 4e. stainless Cr, Ni, Mo 304, 409 varies varies ++ high T applic. turbines furnaces Very corros. resistant Chapter 13 - 3 Refinement of Steel from Ore Coke Iron Ore gas refractory vessel layers of coke and iron ore air slag Molten iron Limestone BLAST FURNACE heat generation C+O2 CO2 reduction of iron ore to metal CO2 + C 2CO 3CO + Fe2O3 2Fe+3CO2 purification CaCO3 CaO+CO2 CaO + SiO2 + Al2O3 slag Chapter 13 - 4 Ferrous Alloys Iron-based alloys • Steels • Cast Irons Nomenclature for steels (AISI/SAE) 10xx Plain Carbon Steels 11xx Plain Carbon Steels (resulfurized for machinability) 15xx Mn (1.00 - 1.65%) 40xx Mo (0.20 ~ 0.30%) 43xx Ni (1.65 - 2.00%), Cr (0.40 - 0.90%), Mo (0.20 - 0.30%) 44xx Mo (0.5%) where xx is wt% C x 100 example: 1060 steel – plain carbon steel with 0.60 wt% C Stainless Steel >11% Cr Chapter 13 - 5 Cast Irons • Ferrous alloys with > 2.1 wt% C – more commonly 3 - 4.5 wt% C • Low melting – relatively easy to cast • Generally brittle • Cementite decomposes to ferrite + graphite Fe3C 3 Fe (a) + C (graphite) – generally a slow process Chapter 13 - 6 Fe-C True Equilibrium Diagram T(°C) 1600 Graphite formation promoted by 1400 • Si > 1 wt% 1200 • slow cooling L g Austenite Liquid + Graphite g +L 1153°C 4.2 wt% C 1000 g + Graphite a+g 800 0.65 740°C 600 Adapted from Fig. 13.2, Callister & Rethwisch 4e. [Fig. 13.2 adapted from Binary Alloy Phase Diagrams, 2nd ed., Vol. 1, T.B. Massalski (Ed.in-Chief), ASM International, Materials Park, OH, 1990.] 400 (Fe) a + Graphite 0 1 2 3 4 90 C, wt% C Chapter 13 - 7 100 Types of Cast Iron Adapted from Fig. 13.3(a) & (b), Callister & Rethwisch 4e. Gray iron • graphite flakes • weak & brittle in tension • stronger in compression • excellent vibrational dampening • wear resistant Ductile iron • add Mg and/or Ce • graphite as nodules not flakes • matrix often pearlite – stronger but less ductile Chapter 13 - 8 Types of Cast Iron (cont.) White iron • < 1 wt% Si • pearlite + cementite • very hard and brittle Adapted from Fig. 13.3(c) & (d), Callister & Rethwisch 4e. Malleable iron • heat treat white iron at 800-900ºC • graphite in rosettes • reasonably strong and ductile Chapter 13 - 9 Types of Cast Iron (cont.) Compacted graphite iron • relatively high thermal conductivity • good resistance to thermal shock • lower oxidation at elevated temperatures Adapted from Fig. 13.3(e), Callister & Rethwisch 4e. Chapter 13 - 10 Production of Cast Irons Adapted from Fig.13.5, Callister & Rethwisch 4e. Chapter 13 - 11 Limitations of Ferrous Alloys 1) Relatively high densities 2) Relatively low electrical conductivities 3) Generally poor corrosion resistance Chapter 13 - 12 Nonferrous Alloys • Cu Alloys • Al Alloys -low r: 2.7 g/cm3 Brass: Zn is subst. impurity (costume jewelry, coins, -Cu, Mg, Si, Mn, Zn additions corrosion resistant) -solid sol. or precip. Bronze : Sn, Al, Si, Ni are strengthened (struct. subst. impurities aircraft parts (bushings, landing & packaging) gear) • Mg Alloys NonFerrous Cu-Be: -very low r: 1.7g/cm3 Alloys precip. hardened -ignites easily for strength -aircraft, missiles • Ti Alloys • Refractory metals -relatively low r: 4.5 g/cm3 -high melting T’s vs 7.9 for steel • Noble metals -Nb, Mo, W, Ta -reactive at high T’s -Ag, Au, Pt -oxid./corr. resistant -space applic. Based on discussion and data provided in Section 13.3, Callister & Rethwisch 4e. Chapter 13 - 13 Classification of Ceramics Ceramic Materials Glasses Clay Refractories products Abrasives Cements Advanced ceramics -optical -whiteware -bricks for -sandpaper -composites -engine -composite -structural high T -cutting -structural rotors (furnaces) -polishing reinforce valves -containers/ bearings Adapted from Fig. 13.7 and discussion in -sensors household Section 13.4-10, Callister & Rethwisch 4e. Chapter 13 - 14 Ceramics Application: Die Blanks • Die blanks: -- Need wear resistant properties! • Die surface: -- 4 mm polycrystalline diamond particles that are sintered onto a cemented tungsten carbide substrate. -- polycrystalline diamond gives uniform hardness in all directions to reduce wear. die Ao die Ad tensile force Adapted from Fig. 14.2(d), Callister & Rethwisch 4e. Courtesy Martin Deakins, GE Superabrasives, Worthington, OH. Used with permission. Chapter 13 - 15 Ceramics Application: Cutting Tools • Tools: -- for grinding glass, tungsten, carbide, ceramics -- for cutting Si wafers -- for oil drilling • Materials: -- manufactured single crystal or polycrystalline diamonds in a metal or resin matrix. -- polycrystalline diamonds resharpen by microfracturing along cleavage planes. oil drill bits blades Single crystal diamonds polycrystalline diamonds in a resin matrix. Photos courtesy Martin Deakins, GE Superabrasives, Worthington, OH. Used with permission. Chapter 13 - 16 Ceramics Application: Sensors • Example: ZrO2 as an oxygen sensor Ca 2+ • Principle: Increase diffusion rate of oxygen to produce rapid response of sensor signal to change in oxygen concentration • Approach: A substituting Ca2+ ion removes a Zr 4+ ion and an O2- ion. Add Ca impurity to ZrO2: -- increases O2- vacancies -- increases O2- diffusion rate • Operation: -- voltage difference produced when sensor gas with an reference O2- ions diffuse from the external unknown, higher gas at fixed O2surface through the sensor to the oxygen content oxygen content diffusion reference gas surface. -- magnitude of voltage difference partial pressure of oxygen at the + voltage difference produced! external surface Chapter 13 - 17 Refractories • Materials to be used at high temperatures (e.g., in high temperature furnaces). • Consider the Silica (SiO2) - Alumina (Al2O3) system. • Silica refractories - silica rich - small additions of alumina depress melting temperature (phase diagram): 2200 T(°C) 3Al2O3-2SiO2 2000 Liquid (L) 1800 mullite alumina + L mullite +L crystobalite +L 1600 1400 mullite + crystobalite 0 20 alumina + mullite 40 60 80 100 Composition (wt% alumina) Fig. 10.26, Callister & Rethwisch 4e. (Fig. 10.26 adapted from F.J. Klug and R.H. Doremus, J. Am. Cer. Soc. 70(10), p. 758, 1987.) Chapter 13 - 18 Advanced Ceramics: Materials for Automobile Engines • Advantages: – Operate at high temperatures – high efficiencies – Low frictional losses – Operate without a cooling system – Lower weights than current engines • Disadvantages: – Ceramic materials are brittle – Difficult to remove internal voids (that weaken structures) – Ceramic parts are difficult to form and machine • Potential candidate materials: Si3N4, SiC, & ZrO2 • Possible engine parts: engine block & piston coatings Chapter 13 - 19 Advanced Ceramics: Materials for Ceramic Armor Components: -- Outer facing plates -- Backing sheet Properties/Materials: -- Facing plates -- hard and brittle — fracture high-velocity projectile — Al2O3, B4C, SiC, TiB2 -- Backing sheets -- soft and ductile — deform and absorb remaining energy — aluminum, synthetic fiber laminates Chapter 13 - 20 Polymer Types – Fibers Fibers - length/diameter >100 • Primary use is in textiles. • Fiber characteristics: – high tensile strengths – high degrees of crystallinity – structures containing polar groups • Formed by spinning – extrude polymer through a spinneret (a die containing many small orifices) – the spun fibers are drawn under tension – leads to highly aligned chains - fibrillar structure Chapter 13 - 21 Polymer Types – Miscellaneous • • Coatings – thin polymer films applied to surfaces – i.e., paints, varnishes – protects from corrosion/degradation – decorative – improves appearance – can provide electrical insulation Adhesives – bonds two solid materials (adherands) – bonding types: 1. Secondary – van der Waals forces 2. Mechanical – penetration into pores/crevices • • Films – produced by blown film extrusion Foams – gas bubbles incorporated into plastic Chapter 13 - 22 Advanced Polymers Ultrahigh Molecular Weight Polyethylene (UHMWPE) • Molecular weight ca. 4 x 106 g/mol • Outstanding properties – – – – high impact strength resistance to wear/abrasion low coefficient of friction self-lubricating surface UHMWPE • Important applications – bullet-proof vests – golf ball covers – hip implants (acetabular cup) Adapted from chapteropening photograph, Chapter 22, Callister 7e. Chapter 13 - 23 Advanced Polymers Thermoplastic Elastomers Styrene-butadiene block copolymer hard component domain styrene butadiene Fig. 13.13(a), Callister & Rethwisch 4e. soft component domain Fig. 13.14, Callister & Rethwisch 4e. (Fig. 13.14 adapted from the Science and Engineering of Materials, 5th Ed., D.R. Askeland and P.P. Phule, Thomson Learning, 2006.) Chapter 13 - 24 Summary • Ferrous alloys: steels and cast irons • Non-ferrous alloys: -- Cu, Al, Ti, and Mg alloys; refractory alloys; and noble metals. • Categories of ceramics: -- glasses -- clay products -- refractories -- cements -- advanced ceramics • Polymer applications -- elastomers -- fibers -- coatings -- adhesives -- films -- foams -- advanced polymeric materials Chapter 13 - 25 ANNOUNCEMENTS Reading: Core Problems: Self-help Problems: Chapter 13 - 26