Survey of Rolling Processes

advertisement

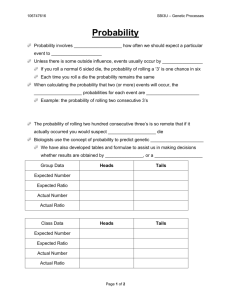

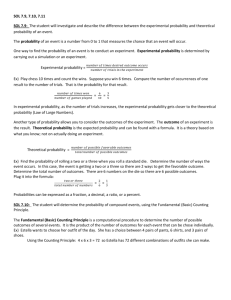

Rolling flat rolling Shape Rolling Note appearance of surfaces Hot rolling is used to reduce forces and promote ductility material savings, ideal grain orientation, strengthening through cold working, fatigue resistance Ring Rolling Thread Rolling Rolled Products Made of Steel Frame, drive, jacks, and rolls comprise a mill or stand which are connected together via conveyors Compressive Stress Rolling Mill Designs 3-high reversing mill. 2-high mill 4-high mill 6-high or cluster mill d t o t f where d = draft; to = starting thickness; and tf = final thickness Reduction = draft expressed as a fraction of starting stock thickness: d r to where r = reduction Tandem Rolling Mill Note how workpiece thickness decreases as the material passes through the roll gap - We need to use average flow stress Note how workpiece velocity must increase while roll velocity will be constant We need to calculate force and power needed to turn the rolls Roll speeds (𝜋𝐷𝑁) must account for increased work velocity Assume no deformation perpendicular to rolling direction (plane strain) Ainlin Aout lout lin l Aout out t t Ain vin Aout vout Ain Ain hin w vout Aout hout w vin Volume in = Volume Out ∴ 𝑣𝑜𝑢𝑡 > 𝑣𝑖𝑛 At point where friction changes direction, this is termed the no-slip point At the no-slip point, the roll pressure distribution is at a maximum We can consider that the average roll pressure is the same as the average flow stress for rolling We can develop an estimate of the force and power for a single stand in cold rolling as follows: K Yf 1 n n For an annealed material: We can also calculate the average flow stress at the i th stand by: i 1 Yf K n d Note average yield stress will increase as the next stand in tandem cold rolling. i i 1 i In cold rolling, the average flow stress will increase due to work hardening . In hot rolling we often assume that flow stress is constant. Mill Load Force = Average Yield Stress * area Change in Width of workpiece = 0 (plane strain) Assume rolling is compression between 2 inclined plates L Roll radius is large compared to arc contact length We can reasonably approximate the length, L, as being a straight line due to roll flattening where 𝐿 = 𝑅(𝑡𝑜 − 𝑡𝑓) Force F, on each roll, will be 𝑌𝑓 𝑤𝐿 F Based on the force equilibrium, we can see that a torque is generated on the roll When no front or back pull is applied, F is midway along the contact length, L L 𝑇=𝐹 F 𝐿 2𝜋 𝑟𝑎𝑑𝑖𝑎𝑛𝑠 𝑃 = 𝐹(𝑙𝑏𝑠) 2(inches) 𝑟𝑒𝑣𝑜𝑙𝑢𝑡𝑖𝑜𝑛 𝑁 Hp = 𝑙𝑏 𝑃 (𝑓𝑡𝑚𝑖𝑛) 𝑙𝑏 33000(𝑓𝑡𝑚𝑖𝑛) 𝑟𝑒𝑣𝑜𝑙𝑢𝑡𝑖𝑜𝑛𝑠 𝑚𝑖𝑛𝑢𝑡𝑒 *hp would need to double hp for 2 rolls 𝐿 2 Power is more useful for the drive motor We would like to roll a workpiece using the minimum number of stands due to the equipment and operations costs i.e. maximize the reduction taken at each stand Clearly, mill load is one factor Rolling requires that we have sufficient friction to pull the workpiece into the roll gap, this represents a second limiting factor as to the maximum reduction that can be taken Consider an element at the entry to the roll gap - Roll force (normal) - Friction force (parallel) Minimum condition for feasible rolling q FN R Fnsinq = Ffcosq m tanq R-d/2 Successive Application of Pythagoreans Theorem Yields dmax=m2R q d/2 Ff Suggests max roughness and roll sizes 10 0.25 ksi Annealed D = 40” diameter W = 24” What is the rolling load at each stand? .050” .041” .045” Second Stand Force F, on each roll, will be 𝑌𝑓 𝑤𝐿 𝐿= i 1 𝑅(𝑡𝑜 − 𝑡𝑓) K Yf 1 n n First Stand Yf K n d i i 1 i Annealed .050” .045” .041” 10 0.2 1.25 .05 10 ln n K .045 Yf 1 n 1.25 First Stand i 1 Second Stand Yf 0.25 4.6 ksi Note work hardening from first stand K nd i i 1 i 10 0.2 10 0.1 K 1 n 2 1 1.25 0.2 0.1 n 1 1.25 1.25 6 ksi Now find contact areas, w is constant in flat rolling Second Stand First Stand 𝐿= 𝑅(𝑡𝑜 − 𝑡𝑓) 𝐿= 𝑅(𝑡𝑜 − 𝑡𝑓) 𝐿 = 20 .05 − .045 = 0.316 Area, A = 0.316*24 = 7.58 𝐿 = 20 .045 − .041 = 0.283 Area, A = 0.288*24 = 6.91in2 Load = 4.6*7.58 = 34.9 kips Load = 6*6.91 = 41.46 kips Uneven thickness across workpiece width (crowning) Minimum thickness achievable due to roll flattening note aluminum foil is 0.2 mm thick No-load Loaded Rolling Thin Sheet Backer Rolls Work Roll 12 High Sendzimir Mill Stand Used for rolling very thin sheet material