SLLIMM_PUSH_Program - Future Electronics

advertisement

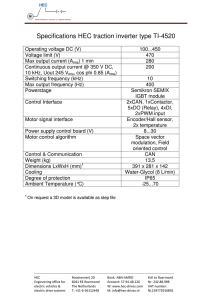

SLLIMM™ Small Low-Loss Intelligent Molded Module Simple, Compact, and Cool solution for motor drive up to 2kW Microelectronics SLLIMM™ Main features and integrated functions ● 600 V, 10 - 20 A ratings ● 3-phase IGBT inverter bridge including: – six low-loss and short-circuit protected IGBTs – six low forward voltage drop and soft recovery freewheeling diodes ● three control ICs for gate driving and protection including: – smart shutdown function – comparator for fault protection against overcurrent and short-circuit – op amps for advanced current sensing – three integrated bootstrap diodes – interlocking function – undervoltage lockout Main Applications • Washing machine • Dish washers • Refrigerators • Air conditioning compressor drives • Sewing machines • Pumps • Fans • Tools • Low power industrial applications • Rehabilitation and fitness applications 2 SLLIMM nomenclature Technical literature available: • Datasheets already published in st.com • Application Note AN3338 • Dedicated technical note TN0107 for mounting instructions published in st.com SLLIMM Line up Tj=from -40ºC to 150ºC Special features and protections • Shutdown pin (/SD) for an efficient connection with micro-controller • Embedded Op amps for advanced current sensing The IPM op-amp is completely uncommitted so a large amount of amplifier configurations can be implemented by the application designer. An example of amplifying network is figure below. Typically low tolerance resistors are used, if high accuracy is required in the conditioning of analog signals. • Embedded Comparator input (CIN) for Smart shut down The comparator non-inverting input (CIN) can be connected to an external shunt resistor in order to implement a simple over-current protection function. JUST IN 200 ns when the comparator triggers, the device is set in shutdown state and both its outputs are set to low level leading the half-bridge in tri-state The time delay between the fault and the outputs turn-off is no more dependent on the RC values of the external network connected to the shutdown pin. This feature is based on an innovative patented circuitry which provides an intelligent fault management operation and greatly reduces the protection intervention delay independently on the protection time duration which can be set as desired by the device user • Interlocking Function To Avoid any fault or mistake that can compromise the inverter leg due to the overlapping of the input signal • Integrated bootstrap diodes Component cost saving Easy layout • Overtemperature protection Negative temperature coefficient (NTC) thermistor for an easy overtemperature protection, in the case of slow case temperature drift or just for the temperature measurements, sending this information to the microcontroller in real-time DBC & Vacuum soldering process Part number PCB layer for gate drivers and SMD DBC technology for power stage for better heat dissipation (direct bonded copper has two layers of copper that are directly bonded onto an aluminum-oxide (Al2O3) ceramic base) RTH (°C/W) STGIPS10K60A 3.8 STGIPS14K60 3 STGIPL14K60 2.4 STGIPS20K60 2.8 ST’s dual in line (DIP) molded packages use A vacuum soldering process is used to avoid any gas inclusion (voids) during the soldering process that could cause potential hot spots. It results in a further increase in the reliability of ST’s IPMs due to the improved thermal and electrical conductivity. DBC + Vacuum soldering process = low thermal resistance values stability in thermal cycling. SLLIMM™ positionining STGIPS20K60 STGIPL14K60 STGIPS14K60 STGIPS10K60A 1kW 1.5kW 2kW Output Power [kW] 7 New STGIPSxxK60T 600V, 10-14A IPM (Vcc = 21V, NTC, SD) Pin 1 Pin 25 OUT U 3 VCC 4 100nF 5 6 100nF 7 R77 8 Vboot SD/OD HVG HIN OUT VCC NC DT NC OP- LVG OPOUT CP+ GND OP+ U28 L6390 LIN Vboot 16 T1 R75 15 13 12 Driver: L6390 U Pin To Pin compatible vs STGIPS10K60 D31 1 14 P' 3 HIN1 LIN 2 LIN1 2 L6390 R76 11 T2 D34 1 10 3 1 U27 2 VBOOT U 9 E1 OUT V NTC co-packed VBOOT V LIN2 3 4 HIN2 100nF 5 6 100nF 7 R153 8 SD/OD HVG HIN OUT VCC NC DT NC OP- LVG OPOUT CP+ GND OP+ U26 L6390 LIN Vboot 15 13 12 SD PIN 2 D35 1 14 P'' 3 2 T3 R78 V 2 GND 16 R149 11 T4 D36 1 10 3 1 9 E2 44.4 x 22.0 x 5.4 mm OUT W VBOOT W HIN3 3 SD 4 100nF NTC 5 2 6 Pin 16 NTC 100nF 7 R74 HIN OUT VCC NC DT NC OP- LVG OPOUT CP+ GND OP+ 15 13 12 11 R152 2 T6 W D86 1 10 9 D85 1 14 DBC E3 Tj = -40 to 150 °C Pin 17 1 8 SD/OD HVG P''' 3 2 T5 R151 2 LIN3 16 3 1 8 IPM demo-board complementing the MC kit STEVAL-IHM025V1 • 1 x IGBT IPM STGIPL14K60 • 1 x PWM SMPS smart driver VIPer16LD • 1 x IGBT power switch STGP10NC60KD STEVAL-IHM027V1 • 1 x IGBT IPM STGIPS10K60A • 1 x buck converter based on Viper16 • 1 x IGBT power switch STGP10NC60KD Q3’2011 STEVAL-IHM028V1 • 1 x IGBT IPM STGIPS20K60 • 1 x PWM SMPS smart driver VIPer26LD • 1 x IGBT power switch STGW35NB60SD Three-phase power stage with shunt-based current reading Complete source files software libraries for 3-PH Induction and PMSM motors provided Brushless PM Motor with encoder included 1KW Power Inverter complete solution • Single phase connecting - supply voltage from 125VDC to 400VDC • Possibility to use PMAC motors, 3-phase asynchronous motors, • bi-phase AC motors or BLDC motors • Input in-rush limiter with by-passing relay • Brake switch with over-voltage comparator • Hall sensor or encoder input feature, tachometer input feature • Over-temperature and over-current hardware protection • Compact and safety design 1 x IGBT IPM STGIPL14K60 1 x PWM SMPS smart driver VIPer16LD 1 x IGBT power switch STGP10NC60KD Ordering code: STEVAL-IHM025V1 Evaluation boards available at: http://www.st.com/evalboards 3 F Inverter up to 1KW • Single phase connecting - supply voltage from 125VDC to 350VDC • Motor control connector for interface with STM3210B-EVAL board • Possibility to use induction motor or PMSM motors up to 1000 W • Regenerative brake control feature • Input inrush limitation with bypassing relay • Hall\Encoder inputs • Possibility to connect BEMF daughter board for sensor-less six-step control of BLDC motors • Tachometer input • Compact and safety design 1 x IGBT IPM STGIPS10K60A 1 x buck converter based on Viper16 1 x IGBT power switch STGP10NC60KD Ordering code: STEVAL-IHM027V1 Evaluation boards available at: http://www.st.com/evalboards 2KW Power Inverter complete solution HV supply mode -voltage 90VAC to 285VAC or direct DC line 125VDC to 400VDC Input voltage range extended to +400V to be compliant with PFC Input inrush limiter with bypassing relay Brake feature with over-voltage comparator Single or three shunt resistors current sensing method Hall sensor or encoder input feature Tachometer input feature Over-temperature and over-current hardware protection Active fan with automatic over-temperature switching Relative compact and safety design Q3’2011 1 x IGBT IPM STGIPS20K60 1 x PWM SMPS smart driver VIPer26LD 1 x IGBT power switch STGW35NB60SD Ordering code: STEVAL-IHM028V1 Evaluation boards available at: http://www.st.com/evalboards Microelectronics Thanks a lot for the attention! 13