Chapter 7

Chapter 7

Foodservice Equipment. Part II:

Manufactured Equipment

Chapter 7 Overview

This chapter introduces the major kinds of manufactured foodservice equipment, discussed under six functional categories:

Receiving & Storage

Preparation

Cooking/Production

Bakery

Service & Cafeteria

Beverage Equipment

Warewashing

Waste Removal

Chapter 7 Overview

This chapter also describes the characteristics of the equipment & its primary use in a foodservice operation.

When selecting equipment, consideration should be given as to what type of production is to be used. The current methods include:

Cook-serve

Cook-hold-serve

Cook-chill-store-reheat-serve (cook/chill)

Methods of Production

Cook-serve:

Typically used in a restaurant setting, although it can also be used in an institutional setting when display cooking is introduced.

After a meal order has been received, the food is cooked on the appropriate piece of cooking equipment & then immediately served to the customer.

Methods of Production

Cook-hold-serve:

Incorporates an extended period of holding, up to 60 minutes, between the cooking time & service to the customer.

Typically occurs in a cafeteria-type setting.

The food can be held in several different pieces of equipment where customers may or may not be able to see & select their food choice.

Methods of Production

Cook/chill:

Cooking the food then rapidly chilling & storing for later use.

Also known as cook/chill or advanced food production.

Maximizes the advantages of centralized food production through:

Reduced labor costs.

Reduced food costs.

Reduced equipment operating & maintenance costs.

Reduced utility costs.

Consistent quality & production control.

Improved food safety

Receiving & Storage Equipment

Receiving Carts:

Transports foods from receiving to storage areas.

Usually made of relatively light gauge materials, using them to transport heavy cases of food causes the top shelf to bow & buckle.

Receiving Scale:

Upon receiving incoming supplies, it is good practice to verify the shipment against the order for quantity, quality & integrity, product substitutions, & weight.

Receiving & Storage Equipment

Shelving varieties include:

Portable (on casters), freestanding (on posts), or wall-hung (cantilever)

Multiple tiers (shelves), usually four or five for bulk storage

Solid shelves with embossed, louvered, or flat shelf surfaces

Shelves with removable plastic grids that can be cleaned in a dish machine

Solid shelves constructed of stainless steel, galvanized steel, aluminum, high-impact plastic, or other materials

Wire shelves constructed of stainless steel, galvanized steel, or high-impact plastic, chrome-plated or epoxy-coated

Receiving & Storage Equipment

Shelving: Fixed or Attached to Equipment.

Three kinds of attached shelving typically are found in a foodservice facility:

Elevated shelving is attached either to a wall above the equipment or directly to the piece of equipment by stainless-steel tubular uprights.

Under-table shelving.

Cabinet shelving.

Refrigeration

The refrigeration equipment found in the modern foodservice facility may include:

Reach-in refrigerators & freezers

Walk-in refrigerators & freezers

Undercounter refrigerators & freezers

Roll-in refrigerators & freezers

Pass-through refrigerators & freezers

Soft-serve machines & ice cream cabinets

Refrigerated cold pans

Display refrigerators

Walk-In Refrigerators & Freezers

Prefabricated walk-in is usually constructed from a series of 4-inch (10-centimeter)-thick modular panels.

Each panel is made with urethane insulation material that is foamed into place between two sheets of metal.

The kinds of metal that can be specified for prefabricated walk-ins include:

Galvanized steel

Painted galvanized steel

Aluminum (embossed or plain)

Painted aluminum

Stainless steel

Walk-In Refrigerators & Freezers

A built-in refrigerator or freezer, which is more expensive than a prefab, is constructed of insulating foam walls, floors,

& ceiling that are protected with structural glazed tile walls, quarry tile floors, & aluminum or stainless-steel ceilings.

Large built-in refrigerators may also be constructed of fiberglass panels laid over the insulation.

Reach-In Refrigerators/Freezers

Will space & budget permit the installation of 1, 2, or 3 compartments?

Will the refrigerator be used for general storage or for special products that would fit better on interior tray slides?

Should the refrigerator be adapted for roll-in carts?

What capacities of storage are needed in the food production area?

Is this refrigeration the primary cold storage capacity for the food facility?

What special features would the owner like to have specified for this refrigeration?

Courtesy of All True Photos.

Mixers

Versatile

Found in nearly all kitchens.

Sized by bowl capacity, ranges from 5 to 140 qts.

Beaters usually furnished with the mixer include:

Flat beater (general mixing)

Wire whip (light products)

Dough hook (heavy yeast doughs)

Food Processor

The new, smaller highspeed food processors are made by several companies, offering a wide number of choices.

The use of a small model in combination with a buffalo chopper or VCM might be a wise choice for the large food operation.

Courtesy of Robot Coupe, USA, Inc.

Buffalo Chopper

Food is chopped by a semicircular blade that rotates rapidly under a protective cover.

As the food moves around the outside edge of the revolving bowl, it is chopped hundreds of times.

VCM (Vertical Cutter Mixer)

Similar to a blender except that it is much larger & more expensive.

Will cut, mix, & blend foods in seconds, used primarily for chopping meats & vegetables.

Uses a high-speed stainless-steel curved knife that rotates on the inside of the bowl.

Slicer

Motor-driven with a round carbon-steel or stainlesssteel blade that is hollowor bevel-ground.

The blade & carrier are tilted at an angle of approx. 30 degrees from vertical, gravity pulls the food product down the carrier into the path of the blade.

Production/Cooking

The production area should always include this equipment for storing & handling:

Worktables or spreader plates

Utensil racks & storage drawers

Sinks

A pickup station

Hot & cold food holding equipment

A storage place for raw ingredients

Ovens

The most popular ovens are classified as:

Standard (under the range)

Convection

Deck

Rack

Conveyor

Slow-roasting

Combi

Microwave

Standard Ovens

Typically built into a hot-top, open-top, grilltop, or other heavy-duty piece of range equipment.

Popular because they are inexpensive & are conveniently located in the range (hotfood preparation) section of the kitchen.

Standard Ovens Disadvantages

The location under the range makes it difficult for the cook to see or reach into the oven.

The ovens are poorly insulated & thus energyinefficient.

Under conditions of heavy usage, standard ovens require frequent maintenance & repair of door hinges & thermostats.

Cleaning under & behind standard ovens is extremely difficult.

The capacity of the standard oven is relatively small in comparison to other oven designs.

Convection Ovens

The most widely used oven in the foodservice industry.

Fan circulates the heated air through the cooking cavity at a high rate.

Typical convection ovens will hold 5 full sheet pans of product in each of the oven chambers.

Deck Ovens

Often called a pizza oven.

Constructed of 1, 2, or 3 levels of oven space & can be either gas-fired or electric.

Rotary Ovens

Designed to increase airflow over the food.

Moves food itself within cooking cavity.

Popular with bakers because of their large capacity & even baking characteristics.

Revolving Rack Oven

Moves the food while baking or roasting.

Can match capacity of the rotary oven while using substantially less floor space.

Simply roll the entire rack into the oven & back out when baking is complete.

Conveyor Ovens

Permits the food product to flow through the heated cavity at a predetermined speed while ensuring the same cooking time for each product prepared.

Best used in high-volume foodservice operations.

Slow-Roasting Ovens

Low-temperature roasting of meats reduces the shrinkage & decreases the browning effect on the outside of the product.

Primarily used for roasting meats.

Can be very effective as a warming cabinet for holding hot foods & as a proof box for bakery products.

Combi Steamer Oven

Brings together oven & steamer.

Uses both convected heated air & steam.

Permits the cook to steam, braise, roast, bake, defrost, or reheat a wide variety of food products.

Advantages:

Consistent flavor, color, & texture.

Multiple food items can be cooked at the same time without flavor transfer.

Reduced shrinkage when roasting.

Efficient use of kitchen space.

Microwaves

Widely used in restaurants to thaw and/or quickly cook small quantities of food.

The oven has not been widely accepted for institutional use because it does not perform well for quantity cooking.

As larger amounts of food are placed in the oven, cooking time increases.

Factors that affect cooking time are:

Temperature of the food placed in the oven

Amount of moisture in the food

Density or thickness of the product

Amount of food placed at one time in the oven

Rated wattage of the oven

Specialty Ovens

Wood-Burning:

Heated by a wood fire in a well insulated brickand-masonry enclosure with a stone or ceramic hearth.

Gives a pleasant smoky flavor to food.

Requires a skilled operator.

Barbecue Ovens:

A variety of ovens are available that will cook pork, beef, or poultry & impart a smoky flavor from either hardwood chips or logs.

Specialty Ovens

Speed Oven:

The turbo oven can have cooking times up to 12 times faster than convectional methods.

Utilizes high-speed forced-air convection heating with microwave energy.

Can cook, bake, brown, broil, & roast a wide variety of fresh, frozen, or reheated products, such as pizza, toasted subs, frozen appetizers,

& fresh-baked chicken.

Typically used at the point of service in a cafeteria setting.

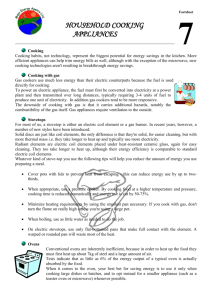

Steamers

Steaming is extremely efficient because of the quick heat transfer between the steam & the food product.

Can be purchased in high, low, & nopressure models.

Tilting Braising Pan (Tilting Skillet)

Very versatile & can be used as a:

Bain-marie for holding foods in a hot-water bath

Grill

Braising pan

Kettle for simmering or stewing

Steamer with the lid in a closed position

Fryer for foods cooked in small amounts of fat

Poacher

Photo Courtesy of Vulcan-Hart.

Steam Jacketed Kettles

Heated from an inner jacket that contains the steam.

Most often used for bringing any liquid product up to a boiling temperature.

Courtesy of Groen, a Dover

The American Society of

Industries Company.

Mechanical Engineers

(ASME) has established safety codes that must be followed by manufacturers of steam equipment that is operated under pressure.

Courtesy of Cleveland Range, Inc,

Bain-Maries

Hotwater bath usually located in the cook’s table or in the range area.

Were usually heated by a coil at the bottom of the bain-marie sink.

In recent years, small bain-maries have become popular again because cooks find a double-boiler effect very convenient for making sauces without fear of scorching or burning.

Primary used for holding sauces, soups, & stock at near-boiling temperatures.

Grills

Flat, heated surface that is used to cook foods quickly in short-order, institutional,

& restaurant food facilities.

Used to prepare a wide variety of food products, including steaks, chops, scrambled eggs, pancakes,

& sautéed vegetables.

Courtesy of Keating of Chicago.

Griddles

The grooved griddle (grill):

Deep grooves are molded into the cooking surface of the grill, which give a dark, striped appearance to the meat as it is cooked.

The clamshell griddle (grill):

Has the addition of a top heating element which allows for cooking both the bottom & top surface at the same time without turning the product over.

Fryers

Cook food by immersing it in hot fat.

Popular pieces of equipment because the public demands foods that are cooked in hot fat to a golden brown appearance.

French fries, breaded meats, batterdipped meats & vegetables, & French toast are foods typically cooked in the deep-fat fryer or pressure fryer.

Pasta Cookers

Adaptation of a fryer, using similar stainless steel enclosures.

Typically, two “fryer” units are placed side by side, & one side serves as the cooker & the second as a means of washing away excess starch.

Ranges

Most heavily used & often the most poorly designed section of the kitchen.

The types of ranges most often used in food-service facilities include:

Open top with burners for sautéing

Grill

Hot top of solid steel, on which pans are placed but not food

Radial fin top, for large stock pots

Courtesy of Vulcan-Hart.

Induction Cooking

Uses electromagnetic energy to heat cookware made of magnetic material (steel, iron, nickel or various alloys).

When the unit is turned on, the coils produce a high-frequency alternating magnetic field, which ultimately flows through the cookware.

Molecules in the cookware move back & forth rapidly, causing the cookware to become hot & cook the food.

Excellent means of producing cooked fresh product in front of the customer.

Broilers

A final preparation piece of equipment that cooks rapidly from radiant or infrared heat.

Four types of broilers are typically used in the foodservice facility:

Freestanding top-burner broilers, often called hotel-style broilers

Charbroilers

Salamanders

Conveyor broilers

Mongolian Barbecue (Grill)

Used in conjunction with a refrigerated buffet counter offering a wide variety of raw, fresh ingredients.

Guests fill bowls & select their sauce's) & pass it to the chef.

The chef then places the ingredients onto the

Mongolian barbecue, essentially a round griddle that allows the cook to rotate the food in a circular fashion, giving guests the enjoyment of watching their food cooked fresh.

Rotisserie

Rotary or Vertical

Popular because it requires no added fat & offers the pleasant taste of chicken or other meats basted in their own juices.

The appearance of rotating meats adds to the merchandising of the product, creating added sales.

Bakery Equipment

Dough Sheeter: a large metal rolling pin, driven by a motor.

Roll Divider/Rounder: compresses a round of dough & divides it.

Proofer: a heated cabinet with moisture in which yeast doughs are placed to rise.

Retarder: special type of refrigerator.

Cold temperatures slow fermentation of the yeast in the bread.

Food Warmers

Heat and/or hold foods to a temperature that is just below the cooking temperature with little loss of moisture.

One common type of food warmer is the steam table.

Cold-Food Holding

Cold-food holding equipment enables the user to safely hold food that needs to be held below 40 degrees.

One common type of cold-food equipment is the cold pan or cold-food well.

Similar in appearance to hot-food wells except that they keep the food cold by mechanical cooling or ice.

Display Cases

Many types of display cases are available including dry (bakery), refrigerated, &heated sections.

Configured for either employee service or self-service.

Majority are floor-mounted.

Primarily a decorative item designed to enhance the appearance of the food & market the food to the customer.

Miscellaneous Equipment

Sneeze guards:

Provides protection between the customer & the food.

Condiment dispensers:

Common in cafeterias & fast-food restaurants.

Soft Serve Machines:

For frozen yogurt, frozen custard, sorbet

(sherbet), & ice milk.

Meal delivery cart:

For meals that are consumed away from the point of production.

Beverage Equipment

Soft-Drink Systems

2 basic soft-drink systems:

Premix: the product is mixed & ready to drink & only needs to be chilled.

Postmix: the product is shipped as a concentrate & water, carbon dioxide gas is added at the dispenser.

Postmix systems are the most popular.

Ice Machines & Dispensers

Commonplace in the United States because of the high demand by

American consumers for ice in almost all beverages.

Used to produce, store, & dispense ice for the various needs of the operation, such as beverage cooling

& food displays.

Ice not only keeps food cold but adds aesthetic appeal to salad bars

& other food displays.

Beverage Systems

Coffee

Urns: used for large quantity batch production.

Portable coffee brewers distribute fresh

Espresso machines selected by market & menu considerations.

batch sizes. Brewer

Urn

Bar Equipment

Typical Selection

Ice chest: an insulated storage area for ice (does not make ice)

Drain board: both a work surface & a place to set glasses & utensils to air-dry

Blender station: a space designed for blenders, including a small sink for sanitizing utensils

Refrigerated storage chest: for holding condiments & cooling bottles

Hand sink: including soap & towel dispensers — required by the health department

Three-compartment sink: required by the health department for washing & sanitizing glassware

Bar Equipment

Typical Selection

Storage bins: a place to stack 20-by-20-inch racks of clean or dirty glasses

Bottle rails, often called “speed rails”: used for storing open bottles of the bar liquor stock

Fruit drawer: a special drawer to store fruit that will be used in mixed

Beer systems

Wine storage & dispensing equipment.

Water Filtration

Filters on ice machines help inhibit scale buildup & have antimicrobial protection to inhibit any potential bacteria growth.

Water filtration for coffee & other drinking water applications provide clear, fresh, quality drinking water.

It reduces dirt & particles along with reductions in chlorine taste & odor.

Dish Machines

Single Tank Door Type

Manual scraping & loading.

About 50-55 racks per hour maximum capacity.

Requires special racks & high sides for tall items.

Hot or sanitizing rinse.

Generally electric heated.

Straight line or corner machine.

Courtesy of Hobart Corporation.

Dish Machine

Single Tank Conveyor

Conveys racks through the machine.

Single wash tank; fresh water for each rinse cycle.

Capacity upwards of 200 racks/hour.

Electric, gas, or steam tank heat.

Electric, gas, or steam booster heat.

Dish Machine

Two Tank Conveyor

Conveys racks.

Separate wash & rinse water tanks

(saving water compared to single tank model).

Capacity upwards of 250-275 racks per hour.

Electric, gas, or steam tank heat.

Electric, gas, or steam booster heat,

Dish Machine

Flight Type

Dishes & trays loaded on pegs on continuous belt.

High capacity.

Length of loading & air drying sections.

Electric, gas, or steam tank heat.

Electric, gas, or steam booster heat.

Carousel Dish Machine

Like a two-tank conveyor with a continuous circular rack transport.

Racking system options.

Off-loading system options.

Electric, gas, or steam tank heat.

Electric, gas, or steam booster heat.

Courtesy of Adamation, Inc.

Dish Machines

Typical Accessories

Blower dryer for rapid air drying of dishes & utensils.

Chemical sanitizing.

Vent hoods for each end of the machine

Stainless-steel legs & frames (standard on some machines).

Stainless-steel enclosure panels to cover the motors & plumbing.

Automatic fill.

Energy-saving features such as automatic shutoff after dishes (or racks) pass through the machine.

Common water, steam, & electrical connection points.

Power Pot Wash System

Potwashing Machines:

The primary use in a food operation, & the decision to use this type of warewashing machine, may be based on:

Number of persons being fed

Complexity of the menu

Type of equipment used in food preparation (e.g., a steam-jacketed kettle eliminates the need for many pots)

Amount of money and/or space available for equipment

Power Pot Sinks:

Continuous, soil-removing water turbulence in which 115 º F water is circulated at a high rate to loosen & remove soil from pots & pans.

Disposers

Grinds food wastes & mix them with water so that they can be piped from the operation into the sewer system.

Commercial disposals are specified primarily by motor size.

These accessories & features are frequently specified for disposals:

Prerinse sprays

Cones to direct the water & garbage

Electrical control panels for switching the disposal & water on & off

Electrical overload & reversing mechanisms

Silverware saver devices to prevent metal objects from entering the disposal

Stainless-steel covers

Water Recirculation System

Skims off waste & sends it through the disposer & returns most of the water back to the trough.

Built into soiled dish table & connected to scrapping trough.

Courtesy of the Salvajor Company.

Pulper-Extractor System

Water & wastes are mixed together & ground into small particles (slurry).

Reduced waste handling & water consumption.

Labor simplification

Requires high percentage of paper in garbage (e.g. disposable serving plates, cups, etc.)

Trash Compactors & Balers

Trash Compactors: compress waste materials so that the volume is greatly reduced.

Also permit wastes to be more easily transported out of the food production areas in portable carts or containers.

Balers: act much the same as compactors except that they can hold the recycled material together in plastic bags or plastic bandings.

The End

Copyright © 2008 John Wiley & Sons, Inc.