Slide Presentation

advertisement

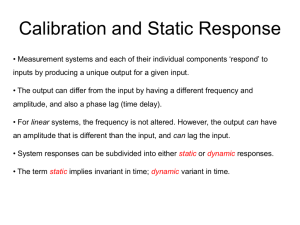

February, 2012 Calibration issues and answers Service Department GfG Instrumentation 1194 Oak Valley Drive, Suite 20 Ann Arbor, MI 48108 Ph: +1 734 769 0573 Internet: www.gfg-inc.com February 2012 Calibration issues and answers Slide 1 Calibration • Verify accuracy on a regular basis to guard against any unexpected loss of sensitivity • Document! February 2012 Calibration issues and answers Slide 2 Mandatory to use a "calibrated" instrument • USA OSHA 1910.146(c)(5)(ii)(C) “Permit required confined spaces” requires: • Before an employee enters the space, the internal atmosphere shall be tested, with a calibrated direct-reading instrument • What does OSHA accept as a "calibrated" direct reading instrument? • A testing instrument maintained and calibrated in accordance with the manufacturer's recommendations • The best way for an employer to verify calibration is through documentation February 2012 Calibration issues and answers Slide 3 Why do instruments need to be tested and / or calibrated? • The response of gas detecting sensors can change over the life of the sensor • The changes may be sudden, or can be gradual • Substances or conditions present in the atmosphere can have an adverse effect on the sensors • Different types of sensors have different constraints and conditions which can lead to loss of sensitivity or failure • Important to know how sensors detect gas to understand conditions that can lead to inaccurate readings February 2012 Calibration issues and answers Slide 4 Make sure the instrument has been calibrated! • Follow manufacturer recommendations • “Zero” instrument in fresh air prior to use • Verify Accuracy Daily! • Functional “bump” test sufficient • Adjust “span” only if necessary February 2012 Calibration issues and answers Slide 5 Loss of sensitivity can be due to: • Aging or desiccation of the sensors, • Mechanical damage due to dropping or immersion • Exposure to sensor poisons present in the atmosphere being monitored • Loss of sensitivity due to other causes February 2012 Calibration issues and answers Slide 6 Regulatory Requirements • OSHA 1910.146 requires use of a “calibrated” instrument • This means (per OSHA CPL 2.100) that the instrument must be maintained and calibrated according to manufacturer guidelines February 2012 Calibration issues and answers Slide 7 Manufacturer Guidelines • OSHA holds instrument users accountable to maintain, calibrate and operate their instruments according to manufacturer guidelines February 2012 Calibration issues and answers Slide 8 Additional Canadian Requirements • Canadian Standard CSA 22.2 requires mandatory “bump test” before each day’s use for all instruments equipped with a sensor for the measurement of combustible gas • Operation manuals of instruments Certified for sale in Canada carry this warning Small “c” indicates the certification includes conformity with Canadian requirements 00000000000 February 2012 Calibration issues and answers Slide 9 Calibration Frequency • The safest course of action is to expose the sensors to known concentration test gas before each day’s use! • This test is very simple and takes only a few seconds to accomplish February 2012 Calibration issues and answers Slide 10 Functional “Bump” Test vs. Calibration • Functional “bump” test only provides verification of sensor performance • Calibration includes adjustment • Only necessary to adjust sensor sensitivity if readings are off • Most manufacturers recommend adjustment if readings are off by more than 10% of expected values February 2012 Calibration issues and answers Slide 11 Industrial Safety Equipment Association (ISEA) Guidelines • Provides procedure for lengthening the interval between calibration checks • During period of initial use of at least 10 days in the intended atmosphere, check the response daily to be sure there is nothing in the atmosphere which is poisoning the sensor(s). • Period of initial use must be of sufficient duration to ensure that the sensors are exposed to all conditions which might have an adverse effect on the sensors. February 2012 Calibration issues and answers Slide 12 Industrial Safety Equipment Association (ISEA) Guidelines • If these tests demonstrate that it is not necessary to make adjustments, the time between checks may be lengthened • This interval should not be lengthened beyond thirty days • History of the instrument should be tracked or logged February 2012 Calibration issues and answers Slide 13 Industrial Safety Equipment Association (ISEA) guidelines • Any conditions, incidents, or exposure to contaminants which might have an adverse effect on the sensors should trigger immediate re-verification before further use • Any changes in the work being done, or environment in which the instrument is being used should trigger re-verification by means of daily checking that it is safe to lengthen the interval between calibration checks February 2012 Calibration issues and answers Slide 14 Conditions which should trigger immediate re-verification of calibration • If there is any doubt at any time as to the accuracy of the sensors, verify the calibration of the sensors by exposing them to known concentration test gas before further use! February 2012 Calibration issues and answers Slide 15 Don’t be afraid of calibration! • Modern designs make calibration easy and automatic • Keep the Calibration Materials With the Instrument! • All-In-One Calibration Mixtures Make Functional Testing Easy! February 2012 Calibration issues and answers Slide 16 Is the concentration of gas used to calibrate instruments dangerous? Not at all! Consider the concentration if you leaked an entire cylinder of CO cal gas into the interior space of a typical passenger van Approximate interior volume of Honda Odyssey EX-L = 300 cubic feet Typical cal gas cylinder holds 34 liters = 1.2 cubic feet @ 50 ppm CO 1.2 cubic feet = 0.4% of the volume of the entire vehicle 50 ppm X .004 = concentration in vehicle = 0.2 ppm CO February 2012 Calibration issues and answers Slide 17 What about a cylinder that contains 25 ppm H2S? 34 liters = 1.2 cubic feet @ 25 ppm H2S 10 X 10 X 10 room = 1,000 cubic feet 1.2 cubic feet = 0.12% of the volume of the entire room 25 ppm X .0012 = concentration in room = 0.03 ppm H2S February 2012 Calibration issues and answers Slide 18 Record Keeping • Documentation is critical! • Without good records you cannot defend or explain your procedures • If you don’t have the records to prove it was being done right -- it wasn’t! February 2012 Calibration issues and answers Slide 19 Atmospheric hazards are frequently invisible to human senses • You don’t know whether it’s safe until it’s been tested! February 2012 Calibration issues and answers Slide 20 Bump Test (Manual Procedure) • Make sure the instrument is located in fresh air, turn on, and allow to warm up • Note readings, and perform fresh air zero if necessary • Attach calibration adapter; instrument will display "AutoCal menu" • Press "Exit" to show normal gas reading screen • Flow gas to sensors; alarms should activate, and readings should stabilize at expected values (if sensors fail to respond properly, instrument should be calibrated before further use) • Turn off gas, remove cal adapter and allow readings to stabilize at fresh air values February 2012 Calibration issues and answers Slide 21 Bump Test • Response of sensors to Quad Mix (graphs) • Readings recorded while instrument operated in normal gas reading mode • Simultaneous response to all four gases, as well as match between cal gas concentrations and readings February 2012 Calibration issues and answers Slide 22 Bump Test • Response of sensors to Quad Mix (table) • Readings recorded while instrument operated in normal gas reading mode • When a sensor is in alarm readings are recorded in red February 2012 Calibration issues and answers Slide 23 AutoCal • AutoCal allows instrument to be “Fresh air” or “Calibration” (span) adjusted if needed February 2012 Calibration issues and answers Slide 24 Attach Cal Cap to Enter Fresh Air and Span “AutoCal” Attach cal cap to unit; instrument automatically enters “AutoCal “ menu Choose ZERO or CAL and apply gas (if calibrating), e.g. an H2S/CO mix. Adjustment is automatic Display shows when cal adjust has been successfully completed February 2012 Calibration issues and answers Slide 25 Can also enter “AutoCal” mode by pushing “Reset” and “Zoom” buttons at same time Push “Reset” and “Zoom” at same time; instrument automatically enters same “AutoCal “ menu Choose ZERO or CAL and apply gas (if calibrating), e.g. an H2S/CO mix. Adjustment is automatic Push at same time to enter “AutoCal” Mode February 2012 Display shows when cal adjust has been successfully completed Calibration issues and answers Slide 26 Calibration gas concentrations • Best to use the default cal gas concentrations • Default GfG concentrations used to calibrate instrument: • 200 ppm CO • 20 ppm H2S • 50% LEL methane (CH4) • If you use different concentrations you must change instrument settings! February 2012 Calibration issues and answers Slide 27 How does the accuracy of the cal gas affect the accuracy of the readings? • Standard GfG Quad Mix cal gas has 25 ppm H2S, 200 ppm CO, 50% LEL CH4; +/- 10% accuracy, w/ 12-months shelf life dating • GfG Quad Mix also available with +/- 3% accuracy, w/ 6-months shelf life dating • Accuracy of sensors = +/- 5% of reading • Using +/- 3% accuracy gas means the accuracy statement for the combined instrument and cal gas system becomes +/8% of reading, or the minimum resolution of sensor, whichever is greater February 2012 Calibration issues and answers Slide 28 Range and resolution of GfG instruments used to detect H2S • Standard full range is 0 – 100 ppm. (Users can optionally choose a 0 – 500 ppm extended full range version of the product.) • Standard setup displays readings in 0.2 ppm steps over the 0 – 1.0 ppm range. • From 1.0 – 99.9 ppm measurements are always incremented in 0.1 ppm steps. February 2012 Calibration issues and answers Slide 29 Effect of ± 5% sensor accuracy on readings At 1.0 ppm actual, reading between 1.05 and 0.9 ppm, so accuracy becomes +/minimum resolution = +/0.2 ppm 0 February 2012 5 10 15 25 Calibration issues and answers Slide 30 30 Effect of calibration gas (± 3%) and sensor accuracy (±5) on readings: combined effects = ±8% At 1.0 ppm actual, reading between 1.08 and 0.92 ppm, so accuracy becomes +/- minimum resolution = +/- 0.2 ppm 0 February 2012 5 10 Calibration issues and answers 15 Slide 31 25 30 So how accurate are the readings? • Thus, on a standard basis, from 0 – 4 ppm the accuracy is +/- 0.2 ppm; from 4.0 to 100 ppm the accuracy is +/- 5% of reading. • If you choose the 0.1 ppm resolution over the 0 – 1.0 ppm range, from 0 – 2.0 ppm the accuracy is +/- 0.1 ppm, from 2.0 to 100 ppm the accuracy is +/- 5% of reading February 2012 Calibration issues and answers Slide 32 Use DS400 Docking Station for daily bump check and / or periodic calibration February 2012 Calibration issues and answers Standalone operation: No PC required Automatic bump-test Automatic span calibration Success / failure indication after each test Economic use of test gas Easy collection of unit test and logged data Reduced maintenance cost Slide 33 Use TS-400 Test Station for daily bump check Standalone operation - No PC required! Automatic bump-test only Success / failure indication after each test Economic use of test gas Easy collection of unit test and logged data February 2012 Calibration issues and answers Slide 34 Comprehensive Test Reports Easy to generate custom test reports February 2012 Calibration issues and answers Slide 35 Automatically generate calibration and bump test certificates February 2012 Calibration issues and answers Slide 36 DS-400 Docking Station for daily bump check and / or periodic calibration • Standalone operation: • No computer required! • Docking station controlled by instrument’s control buttons: • Push "Test" for Bump Test • Push "Cal" for Auto Cal • Push "Cancel" to charge only February 2012 Calibration issues and answers Slide 37 DS-404 Multi-inlet Docking Station for bump check and periodic calibration • Inlets for 4 cylinders of gas • Automatic Bump and Cal for 5, 6 and 7 channel instruments • Supports: • Quad mix (O2, LEL, CO, H2S) • 5-mix with SO2 • 5-mix with CO2 • Isobutylene • HCN • NO2 • And other individual gases February 2012 Calibration issues and answers Slide 38 Using DS400 Docking Station for daily bump check and / or periodic calibration February 2012 Calibration issues and answers Slide 39 Standalone operation: DS-400 does not require connection to an external computer Test results and other messages displayed on instrument LCD Using DS-400 Docking Station for daily bump check and / or periodic calibration • Using DS-400 allows instrument to record "Bump Test" as specific event in instrument's memory • It is possible to set a "Bump Test Due" date in the instrument's memory • Only way to reset next "Bump Test Due" date is by means of DS-400 Docking Station February 2012 Calibration issues and answers Slide 40 Using DS-400 Docking Station for daily bump check and / or periodic calibration • Make sure DS-400 attached to test gas and power • Make sure the instrument is located in fresh air, turn on, and allow to warm up • Note instrument readings, and perform fresh air zero if necessary • Place instrument in DS-400 • Docking station controlled by instrument’s control buttons: • Push "Test" for Bump Test • Push "Cal" for Auto Cal • Push "Cancel" to charge only February 2012 Calibration issues and answers Slide 41 How to do bump test • Make sure instrument turned on • Best if instrument allowed to warm-up at least 5 minutes before bump test • Make sure Docking Station plugged in and connected to gas • Higher inlet is for fresh air • Lower inlet is for span gas • Place G460 in Docking Station • Instrument display will indicate status and results of test February 2012 Calibration issues and answers Slide 42 How to do bump test • After 10 second count-down; Docking Station automatically performs bump test • Instrument screen shows a check mark besides each sensor as bump check completed • If G460 is not removed from Docking Station; 5 minutes after test completed G450 turns off and goes into charging mode February 2012 Calibration issues and answers Slide 43 DS400 Docking Station Bump-Test includes: Visual alarm function Audible alarm function Time for activation to alarm 1 Time for activationto alarm 2 Time to t50 Calibration Test Includes: Fresh air zero adjustment Span calibration adjustment All test results: Stored to instrument memory Stored to flash memory card in Docking Station February 2012 Calibration issues and answers Slide 44 What to do if G460 fails bump test • Red color warning screen and message indicates bump test failed • This means G460 needs to be “Autocal” adjusted before further use • Remove instrument from Dock, and press “Reset” (center) G460 control button to clear alarm message • Place G460 back in Dock • Before end of count down press Autocal button February 2012 Calibration issues and answers Slide 45 Questions? February 2012 Calibration issues and answers Slide 46