Final Slides Day 1

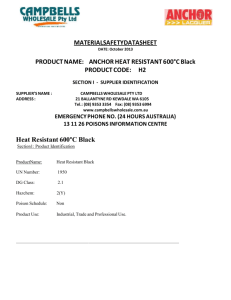

advertisement

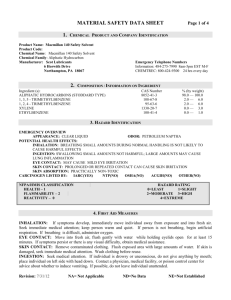

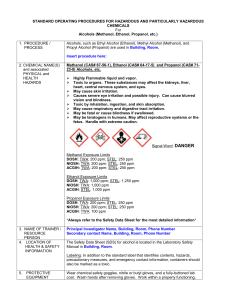

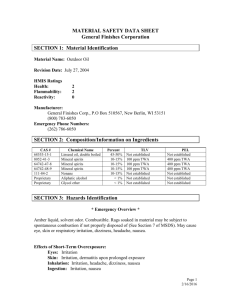

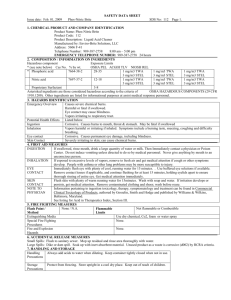

International Module W501 Measurement of Hazardous Substances (including Risk Assessment) Day 1 Insert site Emergency procedures •Insert Lecturer(s) Background Your Background? Two (2) minute overview of your background Course Aims • To provide participants with a sound understanding of the techniques for assessing exposure to hazardous substances in the workplace • To understand how exposure information can be used to assess risk Course Learning Outcomes • Participants will be able to: – Describe the general approach to occupational health risk assessment including role of atmospheric monitoring – Select the appropriate equipment to measure specific airborne contaminants & devise a suitable sampling strategy – Present the results in a useful form What is Required to Complete this Course • Ask questions as we go through the notes • Participate in the case study discussions • Participate in the practical exercises • Attempt the questions each night What is Occupational Hygiene ? 'Occupational Hygiene is the discipline of anticipating, recognising, evaluating and controlling health hazards in the working environment with the objective of protecting worker health and well-being and safeguarding the community at large.' (Source IOHA) Topics to be Discussed • • • • • • • • • Basic physiology & toxicology Risk assessment Hygiene standards Air sampling theory & practice Biological monitoring Sample analysis Dusts, fumes & fibres Vapours & gases Presentation of results Today’s Learning Outcomes • Physiology & toxicology – Understand and be aware of the features of the interacting systems of the human body – Understand the routes of contaminant entry into the human body and their target organs and systems – Understand the concept of dose response Today’s Learning Outcomes (cont) • Risk Assessment – Understand principles & processes of risk assessment – Be able to apply these principles & processes in a workplace situation Today’s Learning Outcomes (cont) • Hygiene standards – Understand the principles of setting hygiene standards – Understand the application and limitations of hygiene standards Work Groups • Each participant will be assigned a work group for the duration of the course • The work groups are expected to work as a team when evaluating cases studies and undertaking practical sessions Introduction to Physiology & Toxicology Discussion Topics The Human Body Routes of Entry Target Organs & Systems Concept of Dose Response The Human Body 12 Interacting systems: Cardiovascular Muscular Digestive Nervous Endocrine Reproductive Immune Respiratory Integumentary Skeletal Lymphatic Urinary Cardiovascular System • Includes the heart, blood & the blood vessels (arteries, capillaries & veins) • Arteries bring oxygenated blood from heart to the tissues • Veins bring deoxygenated blood back to the heart Digestive System • Takes in food, digests it & extracts energy & nutrients & expels the waste • Nutrients can be absorbed into blood & lymph systems • Some used for energy, some for building tissues & cells & some stored for future use Endocrine System • Control system of glands which secrete chemical messengers or hormones • Endocrine glands release hormones directly into bloodstream of the body • Regulate metabolism, growth & sexual development Immune System • Protects body from infection by creating & maintaining barriers to prevent that bacteria & viruses entering the body e.g. hepatitis, influenza, cholera, typhoid & malaria Integumentary System • Comprises skin (cutaneous membrane) & hair, nails & endocrine glands – epidermis – dermis – subcutaneous tissue • Largest organ of body – interface with surroundings – Insulation & temp regulation Lymphatic System • Major component of immune system • Complex system of lymphoid organs, lymph ducts & lymph vessels that produces & transport lymph fluid from tissues to circulatory system – Removal of excess fluids from body tissues – Absorption of fatty acids & transport of fat to circulatory system – Production of immune cells e.g. lymphocytes, monocytes & antibody producing plasma cells Muscular System • Muscle attached to bone by tendons & other tissues • Exerts force by converting chemical energy into force • Nerves link muscle to CNS • Function – Produce movement – Maintain posture – Stabilise joints Nervous System • Electrical impulses carried along nerve cells • CNS – body’s control centre • PNS – all other nerves & neurons – Somatic : • body’s movement & conscious control – Autonomic: • Sympathetic – responds to impending danger or stress • Parasympathetic – evident when resting relaxed Reproductive System Produces offspring by fertilisation or fusion of a sperm and one ovum and the subsequent development of the offspring Respiratory System • Responsible for carrying oxygen from inhaled air to the bloodstream & expelling the waste product of carbon dioxide Skeletal System • 206 bones joined by ligaments & tendons • Protective & supportive framework for attached muscles & soft underlying tissues • Produces red & white blood cells in bone marrow • Bones store minerals eg calcium & can be transported elsewhere Urinary System • The body’s filtering system via the kidneys which reabsorb approx 99% of the fluid into the blood • Waste or urine passed to the bladder for excretion Routes of Entry • Inhalation – By far most common route of entry • Skin absorption – Via direct contact major source of entry of organics eg solvents and pesticides Routes of Entry (cont) • Ingestion – Relatively minor route of accidental ingestion or poor personal hygiene • Eye – Direct entry point for some solvents and also at risk by direct contact Target Organs & Systems Upon entry to the body contaminants can have an adverse effect on one or more organs (target organs) • Respiratory – Irritant & toxic gases eg Carbon monoxide & sulphur dioxide – Dusts & fibres eg silica & asbestos • Blood – Lead and mercury Target Organs & Systems (cont) • Central Nervous System – Solvents eg toluene, xylene, MEK – Polycyclic and polyaromatic hydrocarbons • Liver – Alcohols & solvents • Kidneys – Selenium, alcohol & sodium compounds Target Organs & Systems (cont) • Brain – Mercury - “as mad as a hatter” • Urinary – Biological agents – Some metals • Reproductive – Lead, organic mercury Target Organs & Systems (cont) • Fatty tissues – Solvents • Skin – Acids, alkali – Epoxy resins • Skeletal – Lead – Benzene Target Organs & Systems (cont) • Endocrine – Lead, cadmium – Carbon disulphide Concept of Dose Response “No substance is a poison by itself, it is the dose that makes a substance a poison” Paracelsus 1540 Dose Effect Relationship • For each chemical there is a dose-effect relationship – Acute (immediate) effects (Irritants, CO) – Chronic (long-term) effects (Benzene, Asbestos) – Local effects occur at point of contact – Systemic effects occur at distant target organs Dose Effect relationship (cont) • Factors effecting this relationship include – Physical state of the material – Concentration – Possible routes of entry to the body – Target organs Dose Effect Relationship (cont) – Retention rate in the body – Human pre-disposition (pre-existing medical condition) – Individual sensitivity – Frequency & duration of exposure – Potency of compound – Synergistic effects with other compounds (e.g. asbestos & smoking) Key Factors • Dose • Effect • Critical organ concentration Dose The concentration of a substance at the site of effect (regard being made for the time which substance concentration is maintained) Dose = concentration x duration of exposure Effect Any observable biological change associated with the contaminant concerned: – Should be quantifiable – Does not need to be an adverse observable effect – Certain effects can be beneficial and only become adverse if the dose is excessive or remains for a critical period of time Critical Organ Concentration That concentration beyond which organs exhibit some effect – May not be organ of concentration (eg bone accumulates lead but critical organ is bone marrow) Target Organs • • • • • • • • Respiratory system Skin Eyes Blood Liver Kidneys Bladder Nervous system Dose Effect v Dose Response • Dose effect: Correlation between dose and the magnitude of effect • Dose response: Correlation between response of an organ with estimates of dose Threshold • The dividing line between no-effect and effect levels of exposure • For each substance there is a threshold of intoxication which is usually different for individual substances Dose Response Curve Source: Tranter 1999 –Reproduced with permission Dose Response Curve Threshold of Intoxication • For each substance, no matter how toxic, there exists a dose level called the threshold of intoxication, which the human body is capable of accepting and detoxifying without injury to itself Individual Susceptibility Source: AIOH 2007-Reproduced with permission Risk Assessment Definitions – Hazard: potential for a substance to cause harm, injury etc – Exposure: the ability (or potential) for someone to come into contact with a substance by breathing it in (inhalation), getting it onto the skin or into the eyes (absorption) or swallowing it (ingestion) Definitions (cont) – Risk: likelihood that the substance will cause injury or illness in the conditions of its use Note: the terms “risk” & “hazard” are treated solely in relation to chemical (substance) safety and not any broader concept The Risk Assessment Process • Risk management is used in all sectors of the political, business & community environment • Part of our everyday activities (e.g. driving to work) • Central to OH&S legislation in many countries • Extends to occupational hygiene hazards (e.g. conduct of RA for hazardous substances) Key Steps to a Successful Risk Assessment Identify substances in the workplace Establish which are hazardous & obtain information on their properties Assess the exposure of workers Key Steps to a Successful Risk Assessment Evaluate the risks Identify actions Document & communicate outcomes to stakeholders Information • Primary sources of information: – Suppliers MSDS – Label fixed to product What Does an MSDS Tell You? • Product Name • Codes, Listings • Major Uses • Ingredients • Physical Characteristics • Precautions for Use • Safe Handling and Storage Information • First Aid/Emergency To Be Useful, MSDS’s, Must Have… • Issue Date • Company Details (Not O/Seas) • Substance Name • Health Effects/First Aid • Engineering Controls • Flammable/Fire & Explosion Hazards • Storage & Handling • Spills & Disposal What Information Can You Obtain From a MSDS? – Toxic effects – Safe handling procedures – Exposure standards – Control technologies • Engineering • PPE – Reference to other analogous compounds What Information Can You Obtain From a Label • Much less detail than a MSDS but usually – Name of compound – Safety phrases – Risk phrases – Pictograms – Suppliers details & emergency number Examples of Risk Phrases – R26 Very toxic by inhalation – R27 Very toxic in contact with skin – R34 Causes burns – R37 Irritating to respiratory system – R42 May cause sensitisation by inhalation – R45 May cause cancer Examples of Safety Phrases – S3 Keep in a cool place – S8 Keep container dry – S15 Keep away from heat – S22 Do not breathe dust – S23 Do not breathe vapour – S24 Avoid contact with skin United Nations - GHS GHS - Globally harmonised system of classification and labelling chemicals – Single international system – Currently being implemented by many countries as part of national chemical regulations systems – Risk & safety phrases will be replaced by hazard statements Projected GHS Benefits – Enhancement of the protection of human health and the environment by providing an internationally comprehensible system for hazard communication – Will provide a recognised framework for those countries without an existing system Projected GHS Benefits (cont) – Will reduce the need for testing and evaluation of chemicals, and – Will facilitate international trade in chemicals whose hazards have been properly assessed and identified on an international basis GHS Pictograms Source: ASCC information sheet Other Sources of Information Collection Method Interviews of workers, managers and engineers Type of Information Tasks Work practices Health issues Processes Exposure controls Maintenance Environmental agents Other Sources of Information (cont) Collection Method Interviews of medical and safety staff Type of Information Health problems Patterns of problems Work practices Exposure history Environmental agents Other Sources of Information (cont) Records: Process standards Standard operating procedures Production Personnel Medical Engineering Environmental reports Process flow diagrams Historic conditions Chemical inventories Usage amounts Tasks Work histories Performance of engineering controls Past environmental monitoring results Past biological monitoring results Other Sources of Information (cont) Governmental and nongovernmental standards Current exposure limits Proposed exposure limits Literature Epidemiological studies Toxicological studies Emerging issues Walkthrough Survey • Can provide information that may not be otherwise evident • Involves commencing at the starting point of a process and following the various components until the end product is reached • To be useful must involve someone familiar with each step of the process Basic Information From a Walkthrough Survey • An understanding of the process • The number of workers involved • The materials (including quantities) used or handled • Evidence of reactions and any material transformations • Engineering controls in place and their effectiveness Basic Information from a Walkthrough Survey (cont) • Housekeeping standards • Visible conditions at the site (any dusts, mists, etc) • Possible routes of entry to the body • Personal protective equipment and its use Generation of Hazardous Substances • May be generated as a result of the process and not by any individual chemical • Process itself may change the form of a substance making it harmful – Fine dusts from solids – Fumes from heating chemicals (ammonia compounds) Assessing the Risk • Factors influencing the level of risk – How much a worker is exposed to a hazardous substance (exposure) – Route of entry to the body (inhalation, skin etc) – Severity of adverse health effects under conditions of exposure (hazard) – Duration and frequency of exposure Level of Risk As a result of using a hazardous substance without controls the level of risk depends upon the combination of the: • hazard of that substance under its condition of use • duration & frequency of exposure i.e. Risk = combination of hazard and exposure Types of Risk Analysis • Qualitative analysis – Uses words to describe magnitude of potential consequences and likelihood that those consequences will occur – Used as a screening activity, where basic analysis is appropriate for decisions or where numerical data or resources are inadequate for a quantitative analysis Types of Risk Analysis • Quantitative analysis – Uses numerical values for both consequences & likelihood – Quality of analysis depends on accuracy & completeness of numerical values and validity of models used – Consequences may be determined by modelling the outcomes of events or extrapolation from past studies or data Process of Risk Analysis • Assessing the risk requires a judgment on the likelihood that a hazardous substance will effect someone’s health • Ask yourself these questions – How much of the substance is used or produced & how could workers be exposed ? – Who could be exposed & how often ? – What are the routes of entry to the body ? – What are the consequences of exposure ? Process of Risk Analysis (cont) • Gathering information to answer previous questions • Monitor workplace (for quantitative analysis) • Determine level of risk Non Monitoring Approaches • HSE (UK) COSHH Essentials • ILO Chemical Control Tool kit HSE (UK) COSHH Essentials • Control banding tool for small to medium size enterprises to do risk assessments for chemicals & mixtures of chemicals • Required information – Type of task – shoveling, drilling – Hazard classification (using risk & safety phrases from MSDS ) – Volatility or dustiness (from guidance material) – Amount used- kg,mg,litres,milliliters HSE (UK) COSHH Essentials (cont) • System identifies – Control band (control approach) – Produces advice on controlling risk from the chemical being used in the task – Provides written guidance & documentation ILO Chemical Control Tool kit • Very similar to COSHH Essentials • Does not apply to process dusts or fumes due to the fact that these are not classified by the supplier of individual chemicals • Has general application to many situations in developing countries but susceptible groups (child workers & pregnant women) need to be considered Stages of the ILO Chemical Control Toolkit Stage 1 – Hazard Classification Stage 1 – Hazard Classification (cont) Stage 2 – How Much is Used Stage 3 - Dustiness Stage 3 – Volatility Source: ILO toolkit Stage 4 – Control Approach Source: ILO toolkit Stage 5 – Task Specific Control Guidance Sheet Source: ILO toolkit Stage 5 – Task Specific Control Guidance Sheet Source: ILO toolkit Stage 5 – Task Specific Control Guidance Sheet Source: ILO toolkit Outcomes of a Risk Assessment • Significant risk – Exposure is high or the substance used is highly toxic – A dangerous reaction with other substances possible – Reasonably foreseeable that leaks or spills of a hazardous substance may occur • Not significant risk Actions • Process of risk evaluation provides a list of risks requiring control, often with priorities • Need to identify a range of possible control options, evaluating them, selecting appropriate control options and implementing them in the workplace • Control options should be considered as part of overall site or process risk management strategy Actions (cont) • Possible control measures (Hierarchy of Control) – Elimination of the substance – Substitution of the substance – Segregation of the substance from workers – Engineering methods – Administrative controls – Personnel protective equipment Elimination • Difficult to achieve in practice – production – quality – cost • Some examples – preformed components (eliminating dust) – components that can be clipped, screwed or bolted together (eliminating adhesives) Substitution • Use a safer form of the same substance ( e.g. using a substance in pellet rather than powder form) • Use a safer (less hazardous / less volatile) substance / product (e.g. use water based paint rather than oil based paint) • Process modification (e.g. applying a substance with a brush instead of spraying the substance) Segregation (Isolation) Can be achieved by separating people from a harmful agent / process by: • distance • time • barriers Engineering Controls • The use of equipment or processes, to prevent or minimise the release of hazardous chemical agents • Options include: • automation / robots • total enclosure / containment • partial enclosure • partial enclosure plus local exhaust ventilation • local exhaust ventilation • general (dilution) ventilation Total Enclosure / Containment • The operator controls the process from outside the enclosure, and the hazard is contained. It is used when working with; – carcinogens – sensitisers – materials under high temperature or pressure • Examples include: – Pharmaceuticals, chemical plants and refineries – Closed loop sampling systems – Laboratory glove boxes Partial Enclosure Plus LEV • Common examples include: – welding and grinding benches, – spray paint booths and – fume cupboards General Ventilation Compared to LEV General Ventilation LEV • Does not remove contaminant at source • Draws contaminant away from source • Reduces background levels by addition of fresh uncontaminated air • Reduces level of contaminant inhaled by employees • Very effective if designed and used correctly Administrative Controls • Safe systems of work rely heavily on: – good management / supervision – employee engagement / behaviour – written rules and procedures – information, instruction and training • Simple instruction, ‘allow to cool before opening’ Administrative Controls (cont) • Formal standard operating procedure (in wriwhich if adopted ensures a task is undertaken the right way every time – task analysis, – in writing, – training / competence, – supervision • Permit to work – confined space entry Administrative Controls (cont) • Reducing exposure time – Employee rotation – Work rest regimes Personal Protective Equipment (PPE) Head protection Body protection Eye protection Hand protection Ear protection Foot protection Respiratory protection Actions • Induction & training – Extent will depend on level of risk – Use the information on the hazards and controls obtained in the risk assessment to prepare training materials • Ongoing workplace monitoring – Required where serious health effects may occur if controls fail – Statutory requirement for some substances – Useful to check effectiveness of control measures Actions (cont) • Health surveillance – May be required when there is an identifiable work related disease – Likely that disease or condition might occur under conditions of work – Valid techniques for early detection are available • Emergency procedures & first aid – Need to match level risk and address potential consequences of an uncontrolled release etc Records • Documentation of risk assessments is a fundamental step in the process • Needs to be given attention but in some cases is overlooked once the risk level is established • Most organisations use the same format to document risks no matter their origins - brings familiarity to the process ensuring the level of detail required for ongoing review is provided in the documentation Reasons for Documentation (cont) • Communication with stakeholders • Evidence of a systematic approach to risk identification & analysis • For later review • Record of risk & develop the organisations knowledge database Reasons for Documentation (cont) • Documentation for managerial approval & implementation • To provide an accountability mechanism & tool • Audit trail • Share & communicate information Management • The use of prescriptive legislation in many countries is diminishing • Most authorities have moved to a risk based approach where the onus is on the employer to establish the level of risk and manage accordingly • Covers a broad range of issues including hazardous substances • Statutory authorities produce guidance material which essentially defines minimum standards Case Study 1 – Risk Assessment Super IH Paints Source: BP International Case Study 1 – Risk Assessment • Paint Manufacturer - vessel cleaning • Case Study video together with background information • Comment on what you see and hear. Ask questions • Determine the information you need to complete a risk assessment on the task of paint vessel cleaning Case Study 1 – Student Exercise • Break up into assigned groups • Critically review the case study video & gathered information • Attempt to document a risk assessment & make conclusions about risk • Determine actions to improve control Case Study 1 – Student Exercise • Use lecture notes for guidance and/or discuss with lecturer if you require clarification • Time allowed is 60 minutes • Be prepared to present your assessment in the group discussion period Hygiene Standards Hygiene Standards Hygiene standard: The level of exposure, via inhalation, that should not cause ill health to a healthy adult when exposed to the contaminant Other (interchangeable) terms include: • Threshold limit values • Exposure standards • Occupational exposure limits • Workplace exposure limits Background • Based on “no observed adverse effect level” • Seems to be “threshold dose” • Epidemiological studies & occupational hygiene measurements assist to identify this threshold • Threshold of intoxication – accepting & detoxification without injury Background (cont) • Also based on physiological response – Irritants – Asphyxiants – Anesthetics – Carcinogens – Unbearable odour – Toxic effect ACGIH “Threshold Limit Values – TLVs® - refer to airborne concentrations under which it is believed that nearly all workers may be repeatedly exposed, day after day, over a working lifetime, without adverse effects. TLVs® are developed to protect normal, healthy adults.” Documentation The source publication that provides the critical evaluation of the pertinent scientific information and data with reference to literature sources upon which the TLV® or BEI® is based “Documentation of Threshold Limit Values for Chemical Substances and Physical Agents and Biological Exposure Indices” Three types of TLVs® • TLV - Time Weighted Average (TLV - TWA) • TLV – Short Term Exposure Limit (TWA - STEL) • TLC – Ceiling (TLC - C) TLV – TWA “TLV-TWA The TWA concentration for a conventional 8-hour workday and a 40-hour work week, to which it is believed that nearly all workers may be repeatedly exposed, day after day, for a working lifetime without adverse effect.” TWA (8-hr) = C1T1 + C2T2 +…..CnTn 8 Calculate 8-hour TWA Working period mg/m3 Duration of sampling (h) 0800 - 1030 0.32 2.5 1045 - 1245 0.07 2 1330 0.2 2 1545 – 1715 0.1 1.5 Assume exposure is zero in rest breaks 1030–1045, 1245–1330 & 1530–1545 8-hr TWA = (0.32 x 2.5) + (0.07 x 2) + (0.2 x 2) + (0.1 x 1.5) + (0 x 1.25) 8 = 0.8 + 0.14 + 0.4 + 0.15 + 0 8 = 0.19 mg/m3 TLV – STEL TLV-STEL is a 15 minute TWA exposure that should not be exceeded at any time during a workday, even if the TWA is within TLV- TWA TLV – STEL (cont) Can be exposed continuously for a short period without suffering from: – Irritation – Chronic or irreversible toxic effects – Dose-rate dependent toxic effects or – Narcosis sufficient to increase likelihood of accident, impaired self rescue, or reduced work efficiency TLV – STEL (cont) • Exposures above TLV-TWA up to TWA-STEL < 15 minutes ≤ 4 times a day 60 minutes between successive exposures TLV - C TLV-C the concentration that should not be exceeded during any part of the working exposure • If instantaneous measurements are not available, sampling should be conducted for the minimum period of time to detect exposures at or above ceiling value Excursion Limits Excursions limits are applied to TLV-TWAs that do NOT have TLV-STELs • Excursions up to 3 x TLV-TWA - less than 30 min/day and NO excursions above 5 x TLV-TWA, providing TLV-TWA not exceeded (3 x WEL in UK) • A process is not considered to be under reasonable control if these levels occur Mixtures When two or more hazardous substances have a similar toxicological effect on the same target system, their combined effect rather than that of either individually, should be considered Where C1/TLV1 + C2/TLV2 +…+ Cn/TLVn < 1 the TLV for the mixture should be considered as being exceeded Additive Effect Agent Acetone Sec butyl acetate Methyl ethyl ketone Full shift results Short term results (TLV-TWA) (TLV-STEL) 160 ppm 490 ppm (500) (750) 20 ppm (200) 90 ppm (200) 150 ppm (N/A) 220 ppm (320) From the TLV® basics column, the Documentation of the TLVs® and BEIs® all three substances indicate effects on respiratory system and would be considered additive Additive Effect (cont) Full shift calculation C1/TLV1 + C2/TLV2 +…+ Cn/TLVn ≤ 1 therefore 160/500 + 20/200 + 90/200 = 0.32 + 0.10 + 0.45 = 0.87 Hence full shift additive limit not exceeded Additive Effect (cont) Short term calculation = 490/750 + 150/(200 x 5)* + 220/300 = 0.65 + 0.15 + 0.73 = 1.53 This is >1 hence short term additive limit exceeded * where no STEL exists the convention is to multiply TWA exposure standard x 5 (x 3 in UK) Units of Measure • Dusts – mg/m3 • Gases and vapours – parts per million (ppm) or % (v/v) – mg/m3 Conversion of ppm to mg/m3 Conc in mg/m3 = Conc in ppm x molecular weight /24.45 where 24.45 = molar volume of air in litres at NTP conditions (25°C and 1 atm) (NB IUPAC use 0°C and 100 kPa, but ACGIH and other bodies use 25°C and 1 atmosphere) Conversion of ppm to mg/m3 (cont) Where STP conditions are required (i.e. 20°C not 25°C) the equation is: Conc. in mg/m3 = Conc. in ppm x molecular weight 24.06 Definitions & Notations • Carcinogenicity A carcinogen is an agent capable of inducing benign or malignant neoplasms A1 - Confirmed human carcinogen A2 - Suspected human carcinogen A3 - Confirmed animal carcinogen with unknown relevance to humans A4 - Not classifiable as a human carcinogen A5 - Not suspected as a human carcinogen Definition & Notations (cont) • Notice of Intended Change (NIC) – Each year proposed changes are indicated – comments are sought and suggestions for other substances to be added are also sought • Particulate matter / particle size – For solid and liquid matter, TLVs® are expressed as “total” particulate matter except where terms such as inhalable, thoracic or respirable particulate mass are used Definition & Notations (cont) TLV® Basis/Critical Effects – Is discussed in each documentation. – The column comments are intended to provide field reference for symptoms of over exposure and for which compounds may be considered as acting independently or additively • Biological Exposure Indices BEIs® – Listed when a BEI® is recommended – Two sub categories added BEIA = see the BEI® for Acetylcholinesterase inhibiting pesticide BEIM = see the BEI® for Methemoglobin inducers Definitions & Notations (cont) Sen – potential for agent to produce sensitisation. Does not imply that it is the critical effect – Respiratory – Dermal – Conjunctival • Skin – where potential significant contribution to the overall exposure by the cutaneous route by direct contact with the vapour or direct contact with the skin Application of Standards Airborne concentrations are representative of workers exposure: • Collected in the breathing zone • Occupational or personal sampling Note: If para-occupational or static or area sampling carried out results should not be compared directly with exposure standards Extended Work Shifts TLVs® developed for conventional 8-hour workday followed by a 16-hour break from the exposure over a 40-hour week • Number of models used to adjust TWA for unusual & extended shifts • Not necessary to adjust TWA-STEL or TWA-C as these associated with acute rather than chronic exposures Brief & Scala Model Reduces OEL proportionally for increased exposure & reduced recovery time Adjusted OEL = 8 x (24 – h) x TWA 16 x h where h = hours worked each day Brief & Scala Model (cont) Example: Toluene, 12 hour shift, 8 hr TWA is 50 ppm Adjusted OEL = 8 x (24 – 12) x 50 ppm 16 x 12 = 25 ppm NB Brief & Scala model developed for petroleum industry & has not been validated for dust exposures OSHA Model Previously, OSHA used reduced PELs. Example: If 10 hour shift being worked, TWA (10Hr) = TWA (8 hour) x (8/10) Now, OSHA official must measure the “worst” 8-hour period and compare result with 8-hour TWA Only lead has a exposure reduction Lead PEL = 4000µg/m3 / shift hours OSHA Model - example • Toluene, 12 hour shift, 8 hr TWA is 50 ppm OEL = 50 x 8 12 = 33 ppm Note difference between Brief & Scala v OSHA models with same data Pharmacokinetic Model Model of Hickey & Reist considers metabolism, biotransformation and excretion – Modified TLV = TLV x 1-e-8k 1-e-120k 1-e-t1k 1-e-t2k where t1 = hrs worked per day on usual schedule t2 = 24 x days worked/week on unusual schedule k = ln2/t1/2 This model beyond scope of this course WA Department of Minerals & Energy Source; DOCEP-reproduced with permission Limitations of Hygiene Standards • Values do not exist for all substances • Apply to the workforce – workers healthier than general public • Not meant to apply to general population – Not for environment or boundary emission standards – Not for use with a set safety factor eg divide by 100 • Not a fine line between safe and dangerous concentrations • For use by trained occupational hygienists Standards in Other Countries • Australia – “Exposure Standards” – Based on ACGIH List with reference to standards from Germany, Sweden & UK – www.ascc.gov.au – Data base exists for 696 current national exposure standards – TWA, STEL, peak, carcinogen, Sen, Skin Standards in Other Countries (cont) • United Kingdom – Workplace Exposure Limits – WELs replaced previous Occupational Exposure Limits (OELs) and Maximum Exposure Limits (MELs) – HSE EH40/2005 (Workplace Exposure Limits) – list of assigned substances – 8-hr TWA & STEL – Comments Column containing Safety & Risk Phrases plus the Carcinogenicity, Skin, Sensitivity and Biological Monitoring Guidance Value notations Standards in Other Countries (cont) • European Limits Indicative Occupational Exposure Limit Values IOELVs – – – – Chemical Agents Directive Health based 63 substances 8-hr TWA, STEL, skin Binding Limit Values BLVs – Carcinogen Directive – Also reflect socio-economic & tech feasibility factors – Benzene, hardwood dust, vinyl chloride monomer, lead Standards in Other Countries (cont) • USA – OSHA – Permitted Exposure Levels (PELs) – Based on 1968 TLVs® - approx 400 – Listed updated in 1989 – Number of detailed regulatory requirements eg asbestos, lead, benzene, methylene chloride, vinyl chloride etc – Contained in Title 29 of US Code of Federal Regulations Standards in Other Countries (cont) • USA – NIOSH – Recommended Exposure Limits RELs – NIOSH recommends Standards to OSHA / MSHA (Mine Safety & Health Administration) & some are lower than PELs, TLVs® etc – TWA up to 10-hr day, 40 hour week – Also STEL, C and Ca, skin – Available on CD-ROM or website www.cdc.niosh.gov • Pocket Guide to Chemical Hazards • NIOSH Recommendations • Criteria documents etc Standards in Other Countries (cont) • USA – AIHA – Workplace Environmental Exposure Levels (WEELs) – Intended to provide guidance where NO legal or authoritative limit exists – eg benzyl alcohol, butylene oxide – In current Guide > 100 WEELs – 8-hr TWA, Ceiling, Short Term TWA plus Skin, Dermal & Respiratory sensitiser notations Standards in Other Countries (cont) • Germany – MAK Commission – MAK values for volatile chemicals & dusts – BAT values (biological tolerance values) – Analytical procedures (air & biological materials) – Notations for carcinogens, germ cell mutagenic, sensitizing, percutaneously absorbed & embryonic effects – Published & reviewed annually Review of Today’s Learning Outcomes • Physiology & toxicology – Understand and be aware of the features of the interacting systems of the human body – Understand the routes of contaminant entry into the human body and their target organs and systems – Understand the concept of dose response Review of Today’s Learning Outcomes (cont) • Risk Assessment – Understand principles & processes of risk assessment – Be able to apply these principles & processes in a workplace situation Review of Today’s Learning Outcomes (cont) • Hygiene standards – Understand the principles of setting hygiene standards – Understand the application and limitations of hygiene standards