For this project, the tasked was building a catapult out of cardboard

advertisement

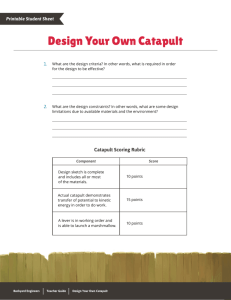

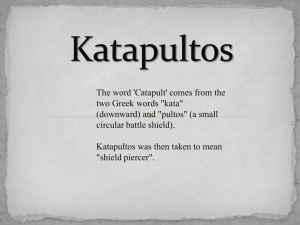

Mini Cardboard Catapults Sam McConnell, Max Dietrich, Patrick Revilla Chen Math Applications in Engineering 20 January 2015 Abstract For this project, the tasked was building a catapult out of cardboard and other household materials, and using it to hit a target at a set but unknown distance away (another catapult). This was a direct test of knowledge of ODEs and the ability to understand and manipulate the math behind creating a catapult such as this one. Though this is a small scale model, the same principles could also be scaled up to a larger catapult, using real materials like wood, metal, and high-strength cables instead of cardboard, popsicle sticks, and weak rubber bands. It was decided to go with a simple yet effective catapult design, using an onager-style catapult. The flexibility and consistency that this design provided served the needs of the situation well, although limitations in its maximum range might make it unsuitable for all situations. After trying to hit a target at range 120in, the projectile came very close, hitting the ground right next to the target twice. However, the catapult was not quite accurate enough to hit the target directly. This most likely had to do with the inaccuracy of determining the launch angle. However, the catapult came very close to its mark and served as a fine example of the principles involved. Introduction Catapults were one of the earliest yet most effective war machines, developed by the Greek and Roman Empires and used in serious combat all the way into WWI, where they were used to hurl grenades from the trenches to the enemy side of the No Man’s Land. However, they reached their most popular use before the development of explosive weapons, which were able to outclass catapults in terms of devastation and accuracy. This occurred in the Middle Ages, when walled cities were used as a primary defense against invaders. Attackers could use the catapults to either throw incendiary or biological weapons (decaying carcasses) over a cities walls to harm the inhabitants, or simply throw heavy objects to bash down the walls. They were used primarily to break sieges or other longer assaults, as shorter battles often could not benefit as much from the power of a catapult. In the past, heavy duty catapults--like the ones previously mentioned--were made out of wooden beams for strength and iron reinforcements for connecting 2 pieces together. In early history, the most common type of catapult was the ballista, which functioned like a giant bow. They also used iron plates and bolts for the structural pieces, and would cut trees near the attacking point and use the local wood to finish the catapult. They also used ropes as the power source, and used animal sinew and other materials in order to generate the necessary torsion. These catapult designs were very prominent in Greek and Roman models, as they could be easily be deployed just about anywhere. As materials became scarce in the Medieval Ages, these were replaced by onagers and trebuchets, the former of which the catapult was modeled after. There are three basic designs of catapults, torsion, ballista, and trebuchet. The simplest is the trebuchet where you have a short arm on one side of the pivot point with a very heavy counterweights and a long arm with a comparatively light projectile on the other side. This type of catapult uses the torque caused by the counterweights to fling the projectile great distances. It is also very important for this type of catapult that the counterweights are on the short side of the arm because they can only be accelerated no faster than 9.8 meters per second2 and to cause the projectile to be accelerated faster than that the projectile side of the arm must be longer. It was decided not to use this one because it was not know how to make the counterweight or the structural integrity to support that counterweight. The most complicated of the threes basic kinds of catapults is the ballistia. it has two torsion springs each attached to a arm which is inturn attached to a rope that propels the projectile toward the intended target. Because it has the two torsion springs it is more powerful, more compact, and much harder to build, also if the two springs are not perfectly calibrated it will shoot at an angle and not at full force. It was decided against this design because the two springs would both be hard to use and overly complicated to build. The chosen catapult was the onager, which relies on torsion power. This catapult uses a single spring (in this case, the coiled bands) and a single lever to throw the projectile. It is arguably the weakest of the catapults but that is a very relive term. It was easy to build and calibrate, it was also strong enough to launch the projectile the distance it needed to. for theses reasons and the reasons against the other designs it was decided to use the torsion catapult. Analysis of the Problem The problem presented is to design, build, and perform calculations for a catapult made of cardboard, rubber bands, popsicle sticks and a few other household materials. Then problem is having to use the catapult to hit a target at a previously unknown distance. The objective was to come up with a design for the catapult, as well as model the equations behind it launching a projectile (a small ball). This model relies on the exact same principles of a real catapult launching. It is similar to when medieval engineers had to build catapults to hit a certain city. They have to be accurate, so as not to miss the first shot. The catapult used a cardboard base (as implied by the name “cardboard catapult”), several rubber bands for the torsion within the catapult, a spoon as the catapult arm, and popsicle sticks to hold it together. Other materials like straws were available, but were not used as they were not seen useful. The team received a corner piece of cardboard, so it was much easier to build and reinforce the structure. The rubber bands were stretched across the piece of cardboard, and used popsicle sticks as cross supports to prevent it from bowing inward under the stress. Instead of using the rubber bands as a conventional stretching manner, instead they were used as a form of torsion, and powered the catapult by twisting the rubber bands instead of pulling them. This simplified the build and the calculations, as well as making finding a linear relation in the data easier. These calculations were used to find a value for the number of twists of the rubber bands, and also found a regression in the data to find a value directly from the data. Turns 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5 6 6.5 7 7.5 8 8.5 9 9.5 10 Inches Travelled 24 26 39 48 52 60 72 82 84 94 100 108 120 117 132 137 142 146 132 144 Conclusion Based on the experiments with the Torsion based catapult, the mechanism proved to yield fairly consistent and flexible shot distances, at the cost of durability and maximum range. The main benefits of the catapult were that shots would travel close to the same distance when the rubber bands were given the same number of turns and that a wide range of turns are possible with the design. The fact that the catapult fired fairly consistently was very beneficial to us, as it would have been to armies in the past. Once a ranging shot has been shown to travel the needed distance, the user could feel safe in knowing that the next shot would as well. The angle that the rubber bands on the catapult were twisted could be changed by turning two popsicle sticks on the machine’s exterior (Figure 3, Appendix A), giving the catapult the ability to fire any distance up to twelve feet. These popsicle sticks are held in place by the friction between themselves and the cardboard box. This allows the user to set a certain amount of torsion to fire the catapult with and fire it over and over again, applying only a phase angle to the lever, without having to reset the rubber bands. This allows the catapult to fire much faster and with a much higher precision than many of the other cardboard catapults. These feature in a catapult would be useful to an army that needed to hit a moving target, or one that wanted to have a mobile catapult that could be used in varying circumstances. These benefits did have some tradeoffs however. One of these was the distance that the projectile could be thrown. The torsion constant k of the rubber bands was calculated to be only 1.364x10-3 Newtons/radian, much smaller than their spring force constant. This meant that even when 5 rubber bands were twisted over 3000 degrees each, they could not match the distance of some of the catapults that were not torsion based. Another downside of the catapult that was associated with this was the durability of the rubber bands. As shown in the graph and table above, there were drops in the distance the projectile travelled after 7 turns and 9.5 turns. These decreases were caused by some of the rubber bands being torn apart under the great strain they were subjected to, as the rubber bands were both stretched past their equilibrium lengths and then twisted up to 10 times. This was not a major problem when the strains were applied for short periods of time but if the rubber bands were left in that state for many minutes or hours, then it was not uncommon for them to break enough so that they needed to be replaced. The large amounts of torsion also caused the sides of the catapult to bow inwards until rigid gussets were added in the form of popsicle sticks(figure 3, Appendix A). During the trials where the catapult had to hit another team’s catapult, some of these strengths and weaknesses were exhibited. Once the distance to the target was known, the catapult was able to be quickly set up to fire that distance, 10 feet. Even after the first shot, the popsicle sticks were able to hold the rubber bands in their pre-firing position, allowing for a quick second shot. Both shots however fell a few inches short of the target and the second shot travelled a few inches to the left of the target. These unsuccessful shots might be attributed to improper set up of the catapult, or weakened rubber bands, nevertheless they did prevent the catapult from achieving its goal. Overall, the design gave the catapult greater flexibility, consistency, and rate of fire than other the catapults of other groups, but caused it to be more prone to breaking, and gave it a shorter maximum distance. This design fit us well for the needs of the problem, hitting a fixed target at an unknown distance, but anyone looking for a catapult design to make should consider whether a large projectile range, or great durability are important for their needs. Appendices Appendix A: Graph/Data Turns 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5 6 6.5 7 7.5 8 8.5 9 9.5 10 Inches Travelled 24 26 39 48 52 60 72 82 84 94 100 108 120 117 132 137 142 146 132 144 Appendix B: Calculations The relationship between the torque of the catapult, the catapult’s moment of inertia and the number of turns given to the rubber bands can be shown by the following differential equation where 𝜏is the catapults torque, I is the catapult-projectile moment of inertia, k is a rubber band’s torsion constant, and 𝜃is the number of angles that each rubber band is turned. 𝛴𝜏 = −𝑘𝑘 = 𝑘𝑘′′ 𝛴𝜏 = 𝑘𝑘′′ + 𝑘𝑘 = 0 This does make several assumptions about the system, however. For one, the term in the net torque that has to do with the torque caused by gravity in in this lab was ignored. As the spoon is more horizontal, Gravity acts more on the spoon, slowing it down and providing a component against the movement of the spoon’s arc. In order to make the equations simple enough to solve, it was assumed that k is the same for all rubber bands, that all rubber bands are twisted the same amount, and that the torque created from the weight of the lever, and projectile are negligible. It was also assumed that the moment of inertia for the spoon and lever can be found by adding the moments of a point mass with the mass of the projectile and of a rod with uniformly distributed weight. 𝑘𝑘2 𝑘= + 𝑘𝑘2 3 Where M is the mass of the lever (spoon), R is the length of the spoon, m is the mass of the projectile, and r is the distance from the projectile to the axis of rotation. For the catapult, M=1.772 g, R=5.75 in, m=7.8 g, and r=4.25 in. This gives us a moment of inertia of 1.035𝑘10−4 𝑘𝑘 𝑘2= 19.670 𝑘 ⋅ 𝑘𝑘2 = 4.99*10. k was calculated by attaching the catapult up to a spring scale, which measured the force that the rotated catapult arm produced on a spring. At 8 rotations, the arm produced .6N of force. Given that this occurred at distance R = 4.25in, k the torque constant can be calculated: FR = k𝜃 (.6N)(4.25in) = k(8π) k = .0812 N in Knowing these values it is possible to,estimate the distance that a projectile will travel given a certain amount number of turns on the rubber bands using the kinematic equations, and the conversions between angular and lateral motion. Given the values for k and I, can be calculated the angle 𝜃 in terms of a time, t. Given the ODE is of the form Iα + kθ = 0, and that α = 𝑘2 𝑘/𝑘𝑘2, the solution to this differential equation is 𝑘 𝑘 θ = a cos(√𝑘t) + b sin(√𝑘t), for unknown constants a, b. The initial angle is 𝑘0 at t = 0, so a = 𝑘0 . By differentiating, a similar equation was calculated for the velocity. However, at t = 0, the angular velocity is 0, so b = 0. Hence the equation is θ = 𝑘 𝑘0 cos(√𝑘t) To find the velocity, it is necessary to differentiate, to obtain 𝑘 𝑘 ɷ = 𝑘0 √𝑘 sin(√𝑘t). However, it is not wanted to have velocity in terms of time, but in terms of theta. Therefore, use the identity cos(𝑘)2+sin(𝑘)2= 1 was used to derive that 𝑘 ɷ = √𝑘 √𝑘0 2 − 𝑘2 Multiplying by the radius gives us v = rɷ to get 𝑘 v = r√𝑘 √𝑘0 2 − 𝑘2 Here it was assumed that the ball is being released when the spoon is at an angle of ψ from vertical. This means that the velocity at launch is given by 𝑘 v = r√𝑘 √𝑘0 2 − 𝑘2 This is now a problem in projectile motion. For an object released at angle 𝑘 from horizontal (is the spoon is offset from vertical, the ball’s trajectory is offset from horizontal), the time it is in the air is 2v sin(𝑘)/g (by solving for t in the equation -v sin(𝑘) = v sin(𝑘) -gt). Based on this, the distance it travels is given by d = v cos(𝑘) t = 2cos(𝑘)sin(𝑘)/g * 𝑘2 . This means that the final equation for the distance is given by d = sin(2𝑘) 𝑘 𝑘2 /𝑘 𝑘 (𝑘0 2 − 𝑘2 ) for angles 𝑘0 and 𝑘, with d in inches. However, this can also be factored as d = sin(2𝑘) 𝑘 𝑘2 /𝑘 𝑘 (𝑘0 − 𝑘 )(𝑘0 + 𝑘 ) = sin(2𝑘) 𝑘 𝑘2 /𝑘 𝑘 (𝑘1 − 𝑘0 )(𝑘1 + 𝑘0 + 4𝑘𝑘) with 𝑘1 being the displacement from 0 vertical of the initial twist (𝑘/2), 𝑘0 being the final release angle from 0 vertical (measured to be around .436 from high frame rate footage), and n being the number of twists of the rubber bands. All of these values are constant except for n, which means that the graph of distance v. twists should have a nice linear regression. When the shots were taken, d = 120 was plugged in, and used the values of k, I, g, 𝑘0 , and 𝑘1 to find the number of twists, n. Finally, an equation was found to relate the number of turns given to the rubber band and projectiles displacement in inches experimentally obtained from the testing (graph as appendix A). The equation is: 𝑘𝑘𝑘𝑘𝑘𝑘𝑘𝑘 𝑘𝑘𝑘𝑘𝑘𝑘𝑘𝑘𝑘𝑘𝑘𝑘 = 0.0379(𝑘𝑘𝑘𝑘𝑘𝑘𝑘 𝑘𝑘𝑘𝑘𝑘𝑘) + 21.305.