Why no TFA - Personal Web Pages

advertisement

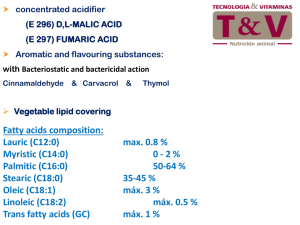

Partial Hydrogenation of Vegetable Oil using Membrane Reactor Technology Devinder Singh, Brent Dringenberg, Dr. Peter Pfromm, Dr. Mary Rezac Department of Chemical Engineering Kansas State University Manhattan, Kansas Trans-Fatty Acids • "..there is a direct, proven relationship between diets high in trans fat content and LDL (“bad”) cholesterol levels and, therefore, an increased risk of coronary heart disease..." from FDA web site 10-3-2005, FDA fact sheet dated July 9, 2003 • By January, 2006 trans fat content will be shown on the Nutrition Facts Panel. Note: <0.5 g trans fat/14 g serving = label "zero" Trans-Fatty Acids USDA/CFSAN http://www.cfsan.fda.gov/ ~dms/transfat.html 10-4-05 • ChE Freshmen class (9-2005): the vast majority knew trans fats were "bad" for you. • Switch to butter? Origin of trans-fatty acids stearic acid MP 70C (C18:0) oleic acid MP 16C elaidic acid MP 52C cis (C18:1 9c) trans (C18:1 9t) • Except for some animal fats (beef, mutton), natural oils/fats are cis. • Trans-fatty acids: by partial hydrogenation (in the rumen: vaccenic acid; or in technical hydrogenation of plant oils: elaidic acid; C18:1 9t ) • Why technical partial hydrogenation: optimize physical parameters (melting point), improve stability, reduce peroxidation Strategies to avoid/minimize trans-fatty acid intake • Use trans fatty acid free fats and oils • Avoid partial hydrogenation by changing the composition (Example: "Crisco® 0 trans fat": sunflower and soybean oil+waxy fully hydrogenated cotton seed oil) • Minimize/avoid formation of trans fatty acids during hydrogenation Standard hydrogenation process • 1809 Sir Humphrey Davy coins the term "hydrogenation" W. Normann, 1902: liquid/solid/gas for fat hardening • Generally batch, 5-20 tons of oil. Parameters: pressure, temperature, agitation, catalyst, catalyst/oil ratio. 15 MM tons/year world wide. catalyst: Ni 0.05-0.1 wt% Ni on oil supported catalyst 120-190C 1-6 atm steam "selective" conditions: hydrogenate most highly unsaturated fatty acids first H2 http://www.thesoydailyclub.com/SFC/MSPproducts501.asp Soyfoods Center, from unpublished manuscript by Shurtleff, W., Aoyagi, A., (160-205C, low H2 pressure, more catalyst, less agitation): ~50% more trans Alleviating mass transfer limitations of hydrogenation Conventional Here: Membrane based H2 starved catalyst boundary layer Defect-free integral-asymmetric polymeric membrane with metal sputtered surface ΔP Oil ΔpH2 Catalyst Membrane H2 H2(dissolved) H2 supplied solubility is by diffusion low in oils H2 flux can be adjusted self-controlled H2 transport boundary layers can be controlled shear can be introduced at the membrane Approach: supply hydrogen where catalysis takes place Pt layer H H H+ H-H H H H+ "skin" (defect-free polymer layer) H-H 100µm metal layer defects Oil Pt Layer (10-20 nm) integral skin 100-500 nm 200-300 µm hydrogen porous substructure (polymeric) Baker, R. W., Louie, J., Pfromm, P. H., Wijmans, J. G., "Ultrathin Metal Composite Membranes for Gas Separation", U.S. Patent 4,857,080, Integral-Asymmetric Polyetherimide membrane: QA/QC [casting after US Patent: 4,673,418, Peinemann et. al., 1987] Gas Flux (GPU), RT Selectivity [10-6 cm3 (STP)cm(H2/N2) 2 s-1 (cm Hg)-1 ] Before Pt Coating Hydrogen 11.7 Nitrogen 0.18 66 After Pt Coating, before hydrogenation Hydrogen 8 Nitrogen 0.18 46 After hydrogenation and washing in hexane Hydrogen 0.5 Nitrogen 0.04 12 Peinemann et. al., 1987 Hydrogen 68 Nitrogen 1.4 49 base membrane OK (flux could be optimized) Integral-asymmetric membranes: bridging the gap from nanomaterials to the macroscopic world • The selective polymer layer: – 100-500 nanometers thick – absolutely defect-free – made on a scale of – square centimeters to square meters • The porous support: – enables usefulness of the nanomaterial 100µm If membrane-based hydrogenation shows benefits, can it be done on a technical scale? When? • H2 pressure will be low while maintaining high H2 availability: existing H2 equipment is perhaps OK. • Sputtering of technical membranes is relatively simple (flat sheet, hollow fiber) • Technical scale gas permeation membranes are available (Air Liquide/Medal and others) Iodine value, IV • Measure of the degree of unsaturation of a fat (one I2/DB, "g Iodine reacting with double bonds/100 g of fat") • High IV: less stable to oxidative attack • Soybean Oil IV130, margerine stock soybean oil IV65 (40%TFA), shortening stock IV80 (32%TFA) • If the fat composition is resolved chromatographically, IV can be calculated Analytical: preparation of Fatty Acid Methyl Ester (FAME) AOCS method Ce 2-66 add 2 ml hexane add 0.1 mL methanolic KOH shake centrifuge FAME, hexane (30 sec.) K+ MeO- 0.2 g Oil add 2 drops FAME/hexane to 2 ml hexane FAME, potassium salt of glycerol , water potassium salt of glycerol, water Inject 1µl GC w/FID CP Sill88, 100m x0.25 mm) 170C 50 min Gas Chromatogram of Unhydrogenated Soybean Oil (Iodine Value = 126) (oil supplied by MP Biomedicals, LLC, Irvine, CA; analysis FAME, AOCS method Ce 2-66 MeE C18:2 9c12c Methyl linoleate MeE MeE 6 C18:1 9c 5 FID Response [pA] 4 MeE Methyl Oleate MeE MeE MeE Methyl stearate MeE MeE C18:0 C18:3 9c12c15c Methyl linoleneate 3 C18:3t C18:1 11c 30 C18:2 t 35 Time [min] C20:0 40 C20:1 45 Reactor system Nitrogen P 1/8” SS TC Oil 1/8” SS 60-62 psig P TC Parr reactor (160 ml) Oil, 70 °C Oil 1/8” SS 1/4” SS Data Acquisition ~13 ml/min 50-52 psig P Membrane Reactor (Membrane area 12.6 cm2) 1/8” SS Hydrogen Membrane-facilitated hydrogenation 60 50 220°C, 2.5 atm H2, 0.18 wt % Ni ** 40 Trans Fatty 30 Acid [wt%] 125 hrs 108 hrs 20 Membrane Reactor 70°C, pH2=3.4 atm 64 hrs Pt/polyimide membrane 10 8 hrs 16 hrs 0 hrs 0 80 90 100 110 120 Iodine Value IV [g iodine/100 g oil]] **Karabulut, I. Kayahan, M.Yaprak, S. , Determination of changes in some physical and chemical properties of soybean oil during hydrogenation , Food Chemistry, 81, 453, 2003. 130 140 Non-hydrogenated vs. Partially Hydrogenated Soybean Oil 60 50 40 Trans Fatty 30 Acid, wt. % 20 6 C18:0 C18:1 9c C18:2 9c12c 10 5 0 80 90 100 110 120 Iodine Value, g Iodine/ 100 g Oil 4 FID Response [pA] 3 C18:1 t C18:1 11c C18:2 t C18:3 9c12c15c C18:1 12c C18:3 t C20:0 30 35 40 C20:1 45 Time [min] 130 Compare H2 consumed vs. supply through the membrane 0.05 Max. H2 supplied by membrane (virgin characteristics before hydrog.experiment) 0.045 0.04 H2 consumed (from experiment) 0.035 0.03 mol H2 0.025 process upset (power outage) 0.02 0.015 0.01 Max. H2 supplied by membrane (characteristics after hydrog.experiment) 0.005 0 0 20 40 60 Time [h] 80 100 120 140 Conclusions • Hydrogenation was observed with platinumcoated integral-asymmetric gas permeation membranes • The membranes appeared physically stable over 120 hours • Formation of trans fatty acids was observed, but perhaps can be further reduced Acknowledgements • United States Department of Agriculture Iodine Value (IV) calculation based on gas chromatographic resolution of oil IV = 0.8598*(weight % C18:1)+1.7315*(weight % C18:2)+2.6152*(weight % C18:3) +0.8173*(weight % C20:1) Note: weight% is relative to combined detected analytes Discussion From GC we obtain the relative amount of Fatty Acid in the mixture of their methyl esters. For free fatty acids the factors for IV can be calculated as IVfree= (Mol. Wt. of Iodine/Mol. Wt. of Fatty acid)*n where n=no. unsaturated bonds In oil we have to take into account the extra molecular weight due to glycerol and we find IVoil=(Mol Wt. of Iodine/Mol. Wt. of Fatty Acid+12.68 )*n where 12.68 takes into account the additional molecular weight. So for example for C18:1 = (253.8/(282.47+12.68))= 0.8598 (see above)