Chp 11 Key Issue 1 & 2

advertisement

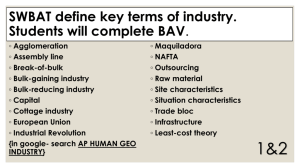

An Introduction to Human Geography The Cultural Landscape, 8e James M. Rubenstein Chapter 11 Industry • Industry: manufacturing of goods in a factory • Utilizes a large number of people, machinery, and money to turn out valuable products. • A generation ago, industry was highly clustered in a handful of MDC’s, but now has diffused to even LDC’s Industry is… • Highly clustered, unlike agriculture • Considers land, labor, and capital ($), and connections to the rest of the world • LOCATION LOCATION LOCATION! markets to sell to and resources needed to make the product Where is Industry Distributed? • ¾’s of world’s industrial production is concentrated in 4 regions – 1. Western Europe & 2. Eastern Europe – 3. Eastern North America – 4. East Asia • Less than 1% of world’s land is devoted to industry Manufacturing Regions Fig. 11-3: The world’s major manufacturing regions are found in North America, Europe, and East Asia. Other manufacturing centers are also found elsewhere. 1. United Kingdom 367 2. Rhine-Ruhr Valley 368 3. Mid-Rhine 369 4. Central Industrial District 370 5. Ural Industrial District 370 3. Northern Italy 369 4. St. Petersburg Industrial District 370 5. Kuznetsk Industrial District 370 6. New England 371 7. Pittsburgh-Lake Eerie 371 8. East Asia 372 5. Eastern Ukraine 370 4. Volga Industrial District 370 5. Silesia 370 6. Mid-Atlantic 371 6. Mohawk Valley 371 7. Western Great Lakes 371 7. Canada’s Industrial Areas Whichever number you are assigned, you are reading about all the topics in that row. Be prepared to explain your topics to the class! Western Europe 1. United Kingdom 367 2. Rhine-Ruhr Valley 368 3. Mid-Rhine 369 3. Northern Italy 369 Eastern Europe 4. Central Industrial District 370 4. St. Petersburg Industrial District 370 4. Volga Industrial District 370 Eastern Europe 5. Ural Industrial District 370 5. Kuznetsk Industrial District 370 5. Eastern Ukraine 370 5. Silesia 370 North America 6. New England 371 6. Mid-Atlantic 371 6. Mohawk Valley 371 North America 7. Pittsburgh-Lake Eerie 371 7. Western Great Lakes 371 7. Canada’s Industrial Areas East Asia 8. East Asia 372 World Industrial Regions • Europe (367 & 370) – European countries competed with each other – Western Europe:1 region, 4 districts (competition) – Eastern Europe: 6…4 in Russia, Ukraine, Poland & Czech Republic • North America (370) – Happened later, but developed faster – Northeast U.S., Southeast Canada – 5% of land but 1/3 of people and 2/3 output • East Asia – Isolated from world markets – abundant cheap labor force – South Korea, Taiwan – Japan: highly skilled jobs at lower cost – China: largest labor force in manufacturing Europe • • • • • Industrial Rev: originated in UK and Scotland High concentration of skilled workers, mechanics, inventors Coal and iron ore: Steel!!!! Diffusion of railway system corresponded with IR (TRADE!) Rhine-Ruhr Valley, Mid-Rhine, Northern Italy Industrial Revolution Hearths Fig. 11-1: The Industrial Revolution originated in areas of northern England. Factories often clustered near coalfields. Diffusion of Railways Fig. 11-2: The year by which the first railway opened shows the diffusion of railways and the Industrial Revolution from Britain. North America • Manufacturing in NE U.S.: iron and other minerals located here, first settlers here, biggest markets are located here • Steel factories around Great Lakes and the St. Lawrence Valley: hydroelectric power • Mini-mills for steel production: smaller, less process, does only a small part of the process; scrap metal for steel instead of ore Industrial Regions of North America Fig. 11-4: The major industrial regions of North America are clustered in the northeast U.S. and southeastern Canada, although there are other important centers. Manufacturing Value Change Fig. 11-5: The value and growth of manufacturing in major metropolitan areas in the U.S. between 1972 and 1997. Manufacturing Centers in Western Europe Fig. 11-6: The major manufacturing centers in Western Europe extend in a north-south band from Britain to Italy. Manufacturing Centers in Eastern Europe and Russia Fig. 11-7: Major manufacturing centers are clustered in European Russia and the Ukraine. Other centers were developed east of the Urals. East Asia • Isolated from other world markets: forced to use own resources, Japan imports natural resources • Japan: high quality, expensive products, low cost because workers are paid less (cultural) • All on the coast or island countries for trade • Few natural resources • Wealth gap between east and west coast (east is urban, west is rural) Manufacturing Centers in East Asia Fig. 11-8: Many industries in China are clustered in three centers near the east coast. In Japan, production is clustered along the southeast coast. Key Issue 2: Why Do Industries Have Different Distributions? Maximize profits by minimizing production costs! Industrial Location • Maximize profit and minimize production costs! • Why is one location profitable for a factory than others? • Situation factors: transport of materials to and from a factory – Location near inputs (materials) – Location near markets – Transport choices • Site factors: unique characteristics of a location – Land – Labor – Capital Where should the pencil industry locate their factory? Bulk-gaining/ Bulk-reducing demonstration • Bulk-gaining becomes • Bulk-reducing becomes If cost of transporting finished product is more expensive than the cost of transporting the materials needed to make it, the optimal plant location is near consumer Materials Product factory Consumer If cost of transporting materials is more than the cost of transporting the final product, the optimal plant location is near materials Materials Consumer Product factory Situation Factors • Involves the transporting of materials to and from a factory. • An industrial seeks a location that minimizes the cost of transporting inputs (materials needed) to the factory and finished goods to the consumers • The further something is transported…the higher the cost…time and distance is $$$!!! Proximity to Inputs: Bulk-Reducing Industry • Final product weights less than the inputs – Copper – Steel…mini-mills use scrap metal = easier Main copper production in U.S. Proximity to Market: Bulk-Gaining Industry • Something gains volume or weight during production. – Soft drink bottling: bottle is lightweight, add liquid is gets heavier…liquid is expensive to transport…production is near consumer (market) – Fabricated products: tv’s, refrigerators, AC, and AUTOMOBILES! Proximity to Market: Bulk-Gaining Industry • Perishable Products: – Milkshed: refrigerated trucks – Items that perish, or are irrelevant that are not food??? Transportation: the further it goes, the higher the cost • Water, cheapest • Then, rail • Then, truck • Then, air. Break-of-Bulk Points • Cost rises each time inputs or products are transferred from on more of transportation to another, but…. • Companies that use multiple transport modes locate a break-of-bulk point – Transfer from a ship to a train is possible because it will save money Site Factors • Result from the unique characteristics of a location • Land, labor, and capital are the 3 traditional production factors that may vary among locations Read by Numbers: • Site Factors 1.LABOR pg 379 2.Textile and Apparel spinning pg. 379-380 3.Textile and Apparel weaving pg. 380-381 4.Textile and Apparel Assembly pg. 382 5.LAND pg. 382-384 6.CAPITAL pg. 384 Labor Textile and Apparel Spinning Textile and Apparel Weaving Textile and Apparel Assembly Land Capital Weber’s Law of Industrial Location • Read handout as a class and answer the following questions: – Does this remind you of another model? – What four factors determine location of industry? – What is a footloose industry? Give an example. – What is agglomeration? Give an example. – When is agglomeration a negative? What happens then (vocab word)? If “C” is the market, which diagram shows: • A bulk gaining industry? • A bulk reducing industry? • A possible footloose industry? Copper Industry in North America Fig. 11-9: Copper mining, concentration, smelting, and refining are examples of bulkreducing industries. Many are located near the copper mines in Arizona. Integrated Steel Mills Fig. 11-10: Integrated steel mills in the U.S. are clustered near the southern Great Lakes, which helped minimize transport costs of heavy raw materials. Steel Minimills Fig. 11-11: Minimills produce steel from scrap metal, and they are distributed around the country near local markets. These are the two largest minimill operators. Change in Steel Production, 1973–2002 Steel production has generally declined in MDCs and increased in LDCs, especially in China, India, Brazil, and South Korea. The increase has been especially dramatic in CHINA. Location of Beer Breweries Fig. 11-12: Beer brewing is a bulk-gaining industry that needs to be located near consumers. Breweries of the two largest brewers are located near major population centers. Chevrolet Assembly Plants, 1955 Fig. 11-13a: In 1955, GM assembled identical Chevrolets at ten final assembly plants located near major population centers. Chevrolet Assembly Plants, 2003 Pg. 378 Fig. 11-13b: In 2003, GM was producing a wider variety of vehicles, and production of various models was spread through the middle of the country. Site Selection for Saturn pg. 377 Fig. 11-1.1: GM considered a variety of economic and geographic factors when it searched for a site for producing the new Saturn in 1985. The plant was eventually located in Spring Hill, TN. Motor Vehicle Parts Plants Fig. 11-14: U.S.-owned parts plants are clustered near the main final assembly plants. Foreign-owned plants tend to be located further south, where labor unions are weaker. Car Plant Location activity and reading. Electronic Computer Industry Fig. 11-20: Computer and parts manufacturing requires highly skilled workers and capital. It is clustered in the Northeast and the West Coast. Steel Production, 1973 and 2002 Fig. 11-21b: About 60% of global steel production takes place in MDCs in 2002, compared to 90% in 1973. Growth of steel manufacturing in China has been especially dramatic.