June 15, 2008

INCOSE IS08 Utrecht

Model-Based Systems Engineering (MBSE)

Challenge Team Status Update

Mechatronics /

Model Interoperability

Presenter

Russell Peak - Georgia Tech

Team Leaders

Russell Peak, Roger Burkhart, Sandy Friedenthal,

Chris Paredis, Leon McGinnis

v3 - 2008-08-01: Based on IS08 MBSE presentations at Utrecht and ESTEC plus updates for July 23 JPL seminar.

Note: Hidden slides (not presented during the seminar) are included here for context.

Portions are Copyright © 2008 by Georgia Tech Research Corporation, Atlanta, Georgia 30332-0415 USA. All Rights Reserved.

Permission to reproduce and distribute without changes for non-commercial purposes (including internal corporate usage) is hereby granted provided this notice and a proper citation are included.

Integrating Design with Simulation & Analysis

Using SysML—Mechatronics/Interoperability

Team Status Report

Abstract

This presentation overviews work-in-progress experiences and lessons learned from an excavator testbed that interconnects

simulation models with associated diverse system models, design models, and manufacturing models. The goal is to enable

advanced model-based systems engineering (MBSE) in particular and model-based X1 (MBX) in general. Our method employs

SysML as the primary technology to achieve multi-level multi-fidelity interoperability, while at the same time leveraging

conventional modeling & simulation tools including mechanical CAD, factory CAD, spreadsheets, math solvers, finite element

analysis (FEA), discrete event solvers, and optimization tools. This work is currently sponsored by several organizations

(including Deere and Lockheed) and is part of the Mechatronics & Interoperability Team in the INCOSE MBSE Challenge.

Citation

Peak RS, Burkhart RM, Friedenthal SA, Paredis CJJ, McGinnis LF (2008) Integrating Design with Simulation & Analysis Using

SysML—Mechatronics/Interoperability Team Status Report. Presentation to INCOSE MBSE Challenge Team, Utrecht, Holland.

http://eislab.gatech.edu/pubs/seminars-etc/2008-06-incose-is-mbse-mechatronics-msi-peak/

[1] The X in MBX includes engineering (MBE), manufacturing (MBM), and potentially other scopes and contexts such as

model-based enterprises (MBE).

Page 2

Seminar at JPL

July 23, 2008 Pasadena

MBSE/MBX Experiences

in an Excavator Testbed

Enhancing Modeling & Simulation Interoperability

Using SysML

Russell Peak and Chris Paredis

Georgia Tech

Based on IS08 MBSE presentation plus updates (see cover slide).

Note: Hidden slides (not presented during the seminar) are included here for context.

Collaboration Approach

Primary Current Team

• Deere & Co.

– Roger Burkhart

• Georgia Institute of Technology (GIT)

– Russell Peak, Chris Paredis, Leon McGinnis, & co.

– Leveraging collaborations in

PSLM Center SysML Focus Area (see next slide)

• Lockheed Martin

– Sandy Friedenthal

Page 4

GIT Product & Systems Lifecycle Management Center

Leveraging Related Efforts

www.pslm.gatech.edu

• SysML-related projects:

– Deere, Lockheed, Boeing, NASA, NIST, TRW Automotive, ...

• Other efforts based at GIT:

– NSF Center for Compact & Efficient Fluid Power

– SysML course development

• For Professional Masters in SE program, continuing ed. short course, ...

– Other groups & labs

– Vendor collaboration (tool licenses, support, ...)

• Consortia & other GIT involvements:

–

–

–

–

INCOSE Model-Based Systems Engineering (MBSE) effort

NIST SE Tool Interoperability Plug-Fest

OMG (SysML, ...)

PDES Inc. (APs 210, 233, ...)

• Commercialization efforts:

– www.VentureLab.gatech.edu-based spin-off company (InterCAX):

Productionizing tools for executable SysML parametrics

5

Contents

• Problem Description

– Characteristics of Mechatronic Systems

– Challenge Team Objectives

• Technical Approach

– Techniques and Testbeds

• Deliverables & Outcomes

• Collaboration Approach

Page 6

Characterizing Mechatronics

From Rennselaer Mechatronics Web Site

Page 7

Mechatronics Architecture

Software

Interface

• Displays

• User Controls

• Haptics

• Remote Links

• ...

• Functions

• Operating Modes

• State Machines

• Control Systems

• ...

• Modules, Libraries

• Messages

• Protocols

• Code

• ...

Actuators

Electronic

Control Unit

(ECU)

Sensors

Communications Bus

“Mechanical System”

• Kinematics & Dynamics

• Powertrain

• Thermal

• Fluids

• Electric Power

• ...

Electronics

Feedback Control Loop

Page 8

MBSE Challenge Team Objectives

Phase 1: 2007-2008

Overall Objectives

• Define & demonstrate capabilities

to achieve modeling & simulation interoperability (MSI)

• Phase 1 Scope

– Domain: Mechatronics

– Capabilities: Methodologies, tools, requirements,

and practical applications

– MSI subset: Connecting system specification & design models

with multiple engineering analysis & dynamic simulation models

• Test & demonstrate how SysML facilitates effective MSI

Objectives to date primarily based on projects in GIT PSLM Center

sponsored by industry and government—see backup slides.

Page 10

MBSE Challenge Team Objectives

Phase 1: 2007-2008

Specific Objectives

1. Define modeling & simulation interoperability (MSI) method

2. Define SysML and tool requirements to support MSI

1. Provide feedback to vendors and OMG SysML 1.1 revision task force

3. Demonstrate MSI method with 3+ engineering analysis

and dynamic simulation model types

1. Include representative building block library: fluid power

2. Include hybrid discrete/continuous systems

described by differential algebraic equations (DAEs)

4. Develop roadmap beyond Phase 1

Page 11

Primary Impacts

Enabling Capabilities

Increased Knowledge

Capture & Completeness

Increased

Modularity & Reusability

Increased

Traceability

Reduced

Manual Re-Creation

Increased

& Data Entry Errors

Automation

Reduced

Modeling Effort

Increased

Analysis Intensity

Reduced

Time

Reduced

Cost

Reduced

Risk

Increased

Understanding

Increased

Corporate Memory

Increased Artifact

Performance

Method Objectives

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

12

Contents

• Problem Description

– Characteristics of Mechatronic Systems

– Challenge Team Objectives

• Technical Approach

– Techniques and Testbeds

• Deliverables & Outcomes

• Collaboration Approach

Page 13

Overall Technical Approach

• Technique Development

– “Federated system model” framework technology

• A.k.a. collective product model

– Modeling & simulation interoperability (MSI) method

– Graph transformation technology

– etc.

• Testbed Implementations & Execution

• Iteration

Page 14

Technical Approach—Subset

• Standards-based framework technology

– Federated system models

– Utilize SysML where appropriate (esp. parametrics)

• Modeling & simulation interoperability (MSI) method

– Harmonize, generalize, extend new & existing work

– COBs, CPM, KCM, MACM, MRA, OOSEM, ...

• Testbeds

–

–

–

–

Develop and test techniques iteratively

Implement test cases for verification & validation

Produce reference examples

Produce open resources

(e.g., SysML-based fluid power libraries)

Page 15

Technical Approach—Subset

• Standards-based framework technology

– Federated system models

– Utilize SysML where appropriate (esp. parametrics)

• Modeling & simulation interoperability (MSI) method

– Harmonize, generalize, extend new & existing work

– COBs/SysML, CPM, KCM, MACM, MRA, OOSEM, ...

• Testbeds

–

–

–

–

Develop and test techniques iteratively

Implement test cases for verification & validation

Produce reference examples

Produce open resources

(e.g., SysML-based fluid power libraries)

Page 19

The Four Pillars of SysML

1. Structure

2. Behavior

interaction

state

machine

activity/

function

definition

use

3. Requirements

4. Parametrics

Page 20

SysML Technology Status

www.omgsysml.org

• Spec

v1.0 - 2007-09 v1.1 - 2008-06

v2.x - RFI expected 2008-12

v1.2 - WIP

• Vendor support

• Learning infrastructure

– Books, vendor courses, academic courses,

INCOSE/OMG tutorial, public examples, etc.

• Emerging production usage

– http://www.pslm.gatech.edu/events/frontiers2008/

Page 21

“Wiring Together” Diverse Models via SysML

Level 1: Intra-Template Diversity

par [cbam] LinkagePlaneStressModel [Definition view]

L

B

s

ts1

ts2

red = idealized parameter

rib1

ds1

shaft

rib2

sleeve1

sleeve2

B

soi: Linkage

ds2

Leff

effectiveLength:

deformationModel:

LinkagePlaneStressAbb

sleeve1:

width:

Mechanical

CAD model

CAE model

(FEA)

l:

wallThickness:

ws1:

outerRadius:

ts1:

rs1:

sleeve2:

ws2:

width:

ts2:

wallThickness:

rs2:

outerRadius:

tf:

wf:

shaft:

tw:

ex:

criticalCrossSection:

uxMax:

nuxy:

basicIsection:

sxMax:

force:

flangeThickness:

flangeWidth:

webThickness:

condition: Condition

material:

reaction:

name:

mechanicalBehaviorModels:

description:

sxMosModel:

MarginOfSafetyModel

linearElastic:

youngsModulus:

determined:

allowable:

marginOfSafety:

poissonsRatio:

yieldStress:

Symbolic

math models

uxMosModel:

MarginOfSafetyModel

determined:

allowableInterAxisLengthChange:

allowable:

marginOfSafety:

[Peak et. al 2007]

22

“Wiring Together” Diverse Models via SysML

Level 2: Inter-Template Diversity (per MIM 0.1)

Naval Systems-of-Systems (SoS) Panorama—An Envisioned Complex Model Interoperability Problem Enabled by SysML/MIM/COBs

c2. Optimization Templates

a0. Descriptive

Resources

d0. Simulation

Building Blocks

ECAD & MCAD Tools

Tribon, CATIA, NX, Cadence, ...

c0. Context-Specific Models

c1. Simulation Templates

(of diverse behavior & fidelity)

2D

General Math

Mathematica,

Maple, Matlab,…

…

CFD

Flotherm, Fluent, …

3D

…

Damaged

Stability

Classification Codes, Materials,

Personnel, Procedures, …

e0. Solver

Resources

Evacuation Codes

Egress, Exodus, …

Operation Mgt. Systems

Libraries & Databases

Parametric associativity

Tool & native model associativity

Composition relationship (re-usage)

Evacuation

Mgt.

Propeller

Hydrodynamics

Systems & Software Tools

DOORS, E+

MagicDraw,

Studio,

Eclipse, …

Legend

Based on HMX 0.1

2008-02-20

b0. Federated

Descriptive Models

Navigation

Accuracy

FEA

Abaqus, Ansys,

Patran, Nastran, …

Discrete Event

Arena, Quest, …

24

Technical Approach—Subset

• Standards-based framework technology

– Federated system models

– Utilize SysML where appropriate (esp. parametrics)

• Modeling & simulation interoperability (MSI) method

– Harmonize, generalize, extend new & existing work

– COBs, CPM, KCM, MACM, MRA, OOSEM, ...

• Testbeds

–

–

–

–

Develop and test techniques iteratively

Implement test cases for verification & validation

Produce reference examples

Produce open resources

(e.g., SysML-based fluid power libraries)

Page 25

Excavator Modeling & Simulation Testbed

Tool Categories View

SysML Tools

RSA/E+ / SysML

Factory

Model

No Magic / SysML

RSA/E+ / SysML

Excavator

Executable

Scenario

Operational

Scenario

Excavator

System Model

Interface & Transformation Tools

(VIATRA, XaiTools, ...)

Traditional

Descriptive Tools

Traditional

Simulation & Analysis Tools

ModelCenter

NX / MCAD Tool

Optimization

Model

Excavator

Boom Model

FactoryCAD

Ansys

Mathematica

FEA Model

Reliability

Model

Factory

Layout Model

Excel

Dymola

Cost Model

Dig Cycle

Model

Excel

Production

Ramps

eM-Plant

Factory

Simulation

2008-02-25a

26

Excavator Modeling & Simulation Testbed

Interoperability Patterns View (MSI Panorama per MIM 0.1)

MCAD Tools

NX

d0. Simulation Building Block

Libraries

Cost

Concepts

Optimization

Concepts

Reliability

Concepts

Solid

Mechanics

Queuing

Concepts

Fluid

Mechanics

Data Mgt. Tools

c0. Context-Specific

Simulation Models

Excavator Sys-Level Models

Optimization Model

Objective

Function

Cost

Model

Excel

b0. Federated

Descriptive Models

Excavator Domain Models

e0. Solver Resources

Optimizers

ModelCenter

Generic Math Solvers

Reliability

Model

Excel

Dig Cycle

Model

Mathematica

Federated Excavator Model

System & Req Tools

RSD/E+

...

MagicDraw

Operations

Req. &

Objectives

Boom Linkage Models

Boom

Extensional

Linkage Model

Linkages

Dump Trucks

Sys Dynamics Solvers

Stress/Deformation Models

Plane Stress

Linkage Model

Dymola

FEA Solvers

Ansys

Factory Domain Models

Federated Factory Model

Factory CAD Tools

FactoryCAD

Req. &

Objectives

Excavator

MBOM

Assembly Lines

AGVs

Buffers

Work Cells

Machines

Boom Mfg. Assembly Models

Assembly Process Models

MM1 Queuing

Assy Model

Discrete Event

Assy Model

Discrete Event Solvers

(Specialized)

eM-Plant /

Factory Flow

Legend

Tool & native model interface (via XaiTools, APIs, ...)

Parametric or algorithmic relationship (XaiTools, VIATRA, ...)

Composition relationship (usage)

Native model relationship (via tool interface, stds., ...)

Dig Site

Hydraulics

Subsystem

Notes

1) The pattern names and identifiers used here conform to HMX 0.1 — a method

under development for generalized system-simulation interoperability (SSI).

2) All models shown are SysML models unless otherwise noted.

3) Infrastructure and middleware tools are also present (but not shown) --e.g.,

PLM, CM, parametric graph managers (XaiTools etc.), repositories, etc.

a0. Descriptive Resources

(Authoring Tools, ...)

2008-02-20

27

Progress to Date: June 2008 (page 1/2)

Phase 1 Report Availability: Sept. 2008

• SysML authoring tools selection and operation

(EmbeddedPlus/Rational, MagicDraw)

• Excavator as testbed problem

– Demo scenario: dig capacity trade study

• Preliminary modeling & simulation interoperability (MSI) method: MIM 1.0

– Harmonizing system design & analysis models integration methods

• Test suites for [topic] development/demonstration/V&V using SysML

– Idealized mass-spring-damper [continuous dynamics]

– Mechanical linkage [MSI method - mechanical benchmark]

• Technique development

– Graph transformation approach

• Masters thesis completed [Johnson, 2008]

– Interoperability via SysML parametrics

• Knowledge patterns, tool wrapping, ...

– Design BOM - mfg BOM interoperability via SysML

28

Progress to Date: June 2008 (page 2/2)

Phase 1 Report Availability: Sept. 2008

• Testbed environment

– Dig cycle simulation (Modelica/Dymola)

– CAD/CAE tools, engineering analysis, solvers

(NX, Ansys, Mathematica)

– Factory design & simulation (Factory CAD, eM-Plant)

– Spreadsheet interface (MS Excel)

– Optimizer (ModelCenter)

• Overall status

–

–

–

–

SysML model developed for core interoperability structure

Most individual models developed, plus 50% interconnected

Most prototype interfaces operational & unit tested

Phase 1 report drafted

• Remaining work

– Completing models & interconnections to support demo scenario

– Completing Phase 1 report & archive of models

29

Demo Scenario

• New market-driven targets:

– 20% increase in dig rate (dirt volume / time)

– 15% increase in mfg. production

• Check if existing design is sufficient by

re-running SysML-enabled simulations

• If not, explore re-design trade space

– Changes in bucket size, hydraulics, ...

• Re-do V&V using simulations on new design

• Explore manufacturing impact

– Factory re-design and simulation

30

Excavator Modeling & Simulation Testbed

Tool Categories View

[WIP models]

RSA/E+ / SysML

Factory

Model

SysML Tools

No Magic / SysML

RSA/E+ / SysML

Excavator

Executable

Scenario

Operational

Scenario

Excavator

System Model

Interface & Transformation Tools

(VIATRA, XaiTools, ...)

Traditional

Descriptive Tools

Traditional

Simulation & Analysis Tools

ModelCenter

NX / MCAD Tool

Optimization

Model

Excavator

Boom Model

FactoryCAD

Ansys

Mathematica

FEA Model

Reliability

Model

Factory

Layout Model

Excel

Dymola

Cost Model

Dig Cycle

Model

Excel

Production

Ramps

eM-Plant

Factory

Simulation

2008-02-25a

31

Excavator Operational Domain

Top-Level Context Diagram

32

Excavator Operational Domain

First Level of Detail—bdd (SysML block definition diagram)

33

Excavator Operational Domain

First Level of Detail—ibd (SysML internal block diagram)

34

Excavator Operational Domain

Top-Level Use Cases

35

Excavator Dig Cycle

Activity Diagram

36

Excavator Requirements & Objectives

req - SysML Requirements Diagram

37

System Objective Function—Excavator

Context: Operational Enterprise

Mathematical Form

n

f k i moei

i 1

n

k

ij

i , j 1;i , j

moei moe j

SysML Parametrics Form

38

Excavator Test Case

Selected System Breakdowns

39

Excavator Modeling & Simulation Testbed

Tool Categories View

SysML Tools

RSA/E+ / SysML

Factory

Model

No Magic / SysML

RSA/E+ / SysML

Excavator

Executable

Scenario

Operational

Scenario

Excavator

System Model

Interface & Transformation Tools

(VIATRA, XaiTools, ...)

Traditional

Descriptive Tools

Traditional

Simulation & Analysis Tools

ModelCenter

NX / MCAD Tool

Optimization

Model

Excavator

Boom Model

FactoryCAD

Ansys

Mathematica

FEA Model

Reliability

Model

Factory

Layout Model

Excel

Dymola

Cost Model

Dig Cycle

Model

Excel

Production

Ramps

eM-Plant

Factory

Simulation

2008-02-25a

40

Hydraulic Circuit Diagram

Pressure-Compensated, Load-Sensing Excavator—ISO 1219 notation

Mechanical

Interface

Mechanical

Interface

Mechanical

Interface

Engineering

Schematic

Mechanical

Interface

LS

43

SysML Schematic (ibd) — Basic View

Pressure-Compensated, Load-Sensing Excavator

Mechanical

Interface

Mechanical

Interface

Mechanical

Interface

Engineering

Schematic

Mechanical

Interface

LS

44

SysML Schematic (ibd) — Detailed View

Pressure-Compensated, Load-Sensing Excavator

ibd [Block] Simple Excavator [Hydraulic System Hxx]

Ref: Doc

Exx

[Electrical

System]

Ref: Doc Mxx

[Mechanical

System]

: Diesel Engine

pn: Cummins242

ElecJunction.a

MechJunction.b

FluidJunction.c

MechJunction.s

A1: Actuator

A2: Actuator

M1: Motor

pn: DBL21

MechJunction.r

FluidJunction.a

FluidJunction.b

pn: DBL21

MechJunction.r

FluidJunction.a

FluidJunction.b

pn: DBL21

MechJunction.r

FluidJunction.a

FluidJunction.b

A1: Servo Valve 5/3

A2: Servo Valve 5/3

M1: Servo Valve 5/3

pn: sv1

pn: sv1

pn: sv1

FluidJunction.5

FluidJunction.4

FluidJunction.2

FluidJunction.1

FluidJunction.3

: Pressure Relief Valve

FluidJunction.1

FluidJunction.2

FluidJunction.5

FluidJunction.4

FluidJunction.2

FluidJunction.1

FluidJunction.3

FluidJunction.5

FluidJunction.4

FluidJunction.2

FluidJunction.1

FluidJunction.3

: Air Separator

pn: AS1

FluidJunction

: FD Pump

A1: Check Valve

A2: Check Valve

M1: Check Valve

pn: CHK1

FluidJunction.2

FluidJunction.1

pn: CHK1

FluidJunction.2

FluidJunction.1

pn: CHK1

FluidJunction.2

FluidJunction.1

pn: AXD

FluidJunction.p

FluidJunction.t

MechJunction.s

pn: TNK-2

: Vented Reservoir

FluidJunction.t

FluidJunction.t

Vendor

or Inhouse

PN

Can use a

specific name for

usage in the

schematic, if like

parts exist

2B: Rubber Hose

Mechanical

Interface

: Heat Exchanger

pn: HXB-3

FluidJunction.h

FluidJunction.c

: Thermostatic Control

Valve

pn: STAT3A

FluidJunction.1

FluidJunction.2

Mechanical

Interface

Engineering

Schematic

FluidJunction.b : Filter

pn: Hose1

FluidJunction

FluidJunction

Mechanical

Interface

pn: Fil1b5

FluidJunction.a

Mechanical

Interface

LS

45

Hydraulics Subsystem Simulation Model

bdd

Mechanical

Interface

Mechanical

Interface

Mechanical

Interface

Engineering

Schematic

Mechanical

Interface

LS

47

Excavator Case Study

ArmCylR... BucketC...

c...

BucketC...

c...

a b1_l b

r={.655,....

Carriage

b

a

r={-0.164,1....

BucketCyl

sw ingComma...

B

B

bra...

B

bC...

m=...

Base

r={...

n={0,...

in...

Sw

ArmCyl

B

BoomCylL

a Arm b

r={3.654,...

aArm2 b

r={2.97,0....

n={...

Bu...

n_a={...

JointR...

Boo...

S...

brake

boomCommand

Mechanical model of complete...

frame_...

BoomCyl...

BoomCylR

Buc...

m=...

BoomCyl...

cyl3f

p10

r={.52...

Sw ingMotor

n={...

Ar...

bArm

n={...

Bo...

m=...

Boom

a

b

r={7.11,0,0}

b2_r

a

b

r={2.85,1....

aArm1b

r={0.49...

a b4y b

r={0,.21...

BoomCyl...

ArmCylB...

cyl1...

ab1_r b

r={.655,....

BoomCyl...

Sw ingFl...

r={-.92...

a b3 b

r={2.85,1.18,... r={4.22,1.3...

a

b

b b2_l a

cyl2f b4x

bB...

Boo...

Arm...

cyl1_l

Hydraulics Model

B...

B...

m=50

c...

c...

bB...

Native Tool Models: Modelica

c...

c...

Multi-Body System Dynamics Model

(linkages, ...)

armCommand

LS B

P

T

LS B

P

LS B

T

P

T

LS B

P

T

LS B

P

accumulator

constantSpeed

max

ma...

max2

ma...

ma...

max3

ma...

circuitTank

pclsPump

bucketCommand

Dig Cycle

hydraulics

B

max1

T

environment

y

world

p_amb = 101325

T_amb = 288.15

x

48

Simulation

in Dymola

Simulation

Results

Modelica

Lexical Representation

(auto-generated from SysML)

[Johnson, 2008 - Masters Thesis]

49

Excavator Modeling & Simulation Testbed

Tool Categories View

SysML Tools

RSA/E+ / SysML

Factory

Model

No Magic / SysML

RSA/E+ / SysML

Excavator

Executable

Scenario

Operational

Scenario

Excavator

System Model

Interface & Transformation Tools

(VIATRA, XaiTools, ...)

Traditional

Descriptive Tools

Traditional

Simulation & Analysis Tools

ModelCenter

NX / MCAD Tool

Optimization

Model

Excavator

Boom Model

FactoryCAD

Ansys

Mathematica

FEA Model

Reliability

Model

Factory

Layout Model

Excel

Dymola

Cost Model

Dig Cycle

Model

Excel

Production

Ramps

eM-Plant

Factory

Simulation

2008-02-25a

50

Wrap Dynamic Simulation as

ModelCenter Model in SysML

Fully qualified name points

to ModelCenter model

Stereotypes define

input/output causality

51

DOE Model in SysML

LatinHyperCube

sampler

Reference

Property

Model

52

Automatic Export to

and Execution in ModelCenter

53

Application in Case Study:

Optimization under uncertainty with kriging model

optimizer

Latin Hypercube +

Kriging response surface

• Optimization under

uncertainty

• LatinHyperCube

sampler used to

predict expected

value

• Kriging model used

in conjunction with

sampler to generate

response surface to

reduce

computational cost

Objectives:

• Maximize Efficiency

• Minimize Cost

Design variables:

• bore diameters

54

SysML model

Optimization under uncertainty with kriging model

55

Excavator Modeling & Simulation Testbed

Tool Categories View

SysML Tools

RSA/E+ / SysML

Factory

Model

No Magic / SysML

RSA/E+ / SysML

Excavator

Executable

Scenario

Operational

Scenario

Excavator

System Model

Interface & Transformation Tools

(VIATRA, XaiTools, ...)

Traditional

Descriptive Tools

Traditional

Simulation & Analysis Tools

ModelCenter

NX / MCAD Tool

Optimization

Model

Excavator

Boom Model

FactoryCAD

Ansys

Mathematica

FEA Model

Reliability

Model

Factory

Layout Model

Excel

Dymola

Cost Model

Dig Cycle

Model

Excel

Production

Ramps

eM-Plant

Factory

Simulation

2008-02-25a

56

Excavator Modeling & Simulation Environment

Interoperability Patterns View (MSI Panorama per MIM 0.1)

MCAD Tools

NX

d0. Simulation Building Block

Libraries

Cost

Concepts

Optimization

Concepts

Reliability

Concepts

Solid

Mechanics

Queuing

Concepts

Fluid

Mechanics

Data Mgt. Tools

c0. Context-Specific

Simulation Models

Excavator Sys-Level Models

Optimization Model

Objective

Function

Cost

Model

Excel

b0. Federated

Descriptive Models

Excavator Domain Models

e0. Solver Resources

Optimizers

ModelCenter

Generic Math Solvers

Reliability

Model

Excel

Dig Cycle

Model

Mathematica

Federated Excavator Model

System & Req Tools

RSD/E+

...

MagicDraw

Operations

Req. &

Objectives

Boom Linkage Models

Boom

Extensional

Linkage Model

Linkages

Dump Trucks

Sys Dynamics Solvers

Stress/Deformation Models

Plane Stress

Linkage Model

Dymola

FEA Solvers

Ansys

Factory Domain Models

Federated Factory Model

Factory CAD Tools

FactoryCAD

Req. &

Objectives

Excavator

MBOM

Assembly Lines

AGVs

Buffers

Work Cells

Machines

Boom Mfg. Assembly Models

Assembly Process Models

MM1 Queuing

Assy Model

Discrete Event

Assy Model

Discrete Event Solvers

(Specialized)

eM-Plant /

Factory Flow

Legend

Tool & native model interface (via XaiTools, APIs, ...)

Parametric or algorithmic relationship (XaiTools, VIATRA, ...)

Composition relationship (usage)

Native model relationship (via tool interface, stds., ...)

Dig Site

Hydraulics

Subsystem

Notes

1) The pattern names and identifiers used here conform to HMX 0.1 — a method

under development for generalized system-simulation interoperability (SSI).

2) All models shown are SysML models unless otherwise noted.

3) Infrastructure and middleware tools are also present (but not shown) --e.g.,

PLM, CM, parametric graph managers (XaiTools etc.), repositories, etc.

a0. Descriptive Resources

(Authoring Tools, ...)

2008-02-20

57

Factory & Manufacturing Process

Modeling & Simulation Using SysML

[McGinnis et al. 2007]

SysML State Diagram

SysML Sequence

Diagram

XML Parser

Discrete Event Simulation

58

Excavator Modeling & Simulation Testbed

Tool Categories View

SysML Tools

RSA/E+ / SysML

Factory

Model

No Magic / SysML

RSA/E+ / SysML

Excavator

Executable

Scenario

Operational

Scenario

Excavator

System Model

Interface & Transformation Tools

(VIATRA, XaiTools, ...)

Traditional

Descriptive Tools

Traditional

Simulation & Analysis Tools

ModelCenter

NX / MCAD Tool

Optimization

Model

Excavator

Boom Model

FactoryCAD

Ansys

Mathematica

FEA Model

Reliability

Model

Factory

Layout Model

Excel

Dymola

Cost Model

Dig Cycle

Model

Excel

Production

Ramps

eM-Plant

Factory

Simulation

2008-02-25a

61

MCAD-SysML Interface Scenarios

UGS/Siemens NX

RSD/E+

SysML Model

SysML Model Import

User SysML Model

Manipulation

par [cbam] LinkagePlaneStressModel [Definition view]

L

B

s

ts1

ts2

red = idealized parameter

rib1

ds1

shaft

rib2

sleeve1

sleeve2

B

soi: Linkage

ds2

Leff

effectiveLength:

deformationModel:

LinkagePlaneStressAbb

sleeve1:

width:

l:

wallThickness:

ws1:

outerRadius:

ts1:

rs1:

sleeve2:

par [cbam] LinkageExtensionalModel_800240 [Instance view: state 1.0 - unsolved]

width:

ts2:

soi: FlapLinkage_XYZ-510

wallThickness:

outerRadius:

tf:

totalElongation:

area:

tw:

criticalCrossSection:

length:

ex:

criticalCrossSection:

basic:

uxMax:

nuxy:

basicIsection:

area:

in^2 = 1.125

materialModel:

sxMax:

force:

normalStress:

flangeThickness:

youngsModulus:

totalStrain:

flangeWidth:

material: Steel1020HR

condition:

name:

= “1020 hot-rolled steel”

webThickness:

mechanicalBehaviorModels:

condition: Condition

reaction:

lbs = 10000

description:

= “flaps mid position”

force:

linearElastic:

material:

Model Changes

Propagate to CAD Tool

undeformedLength:

wf:

shaft:

Parametrics

Execution

deformationModel:

rs2:

effectiveLength: in = 5.00

shaft:

Simulation

Execution*

ws2:

name:

youngsModulus:

description:

psi = 30e6

mechanicalBehaviorModels:

linearElastic:

youngsModulus:

reaction:

stressMosModel:

determined:

yieldStress:

psi = 18000

sxMosModel:

MarginOfSafetyModel

allowable:

marginOfSafety:

=?

allowable:

determined:

marginOfSafety:

poissonsRatio:

yieldStress:

uxMosModel:

MarginOfSafetyModel

determined:

allowableInterAxisLengthChange:

allowable:

marginOfSafety:

XaiTools COB Services

Georgia Tech XaiTools™

Engineering

Analysis Models

* = work-in-process

62

MCAD Native Model and Tool UIs

UGS/Siemens NX

63

MCAD Model (Subset) in SysML

RSD/E+

64

Interfacing Spreadsheets

with SysML Parametrics

65

Excavator Modeling & Simulation Testbed

Tool Categories View

SysML Tools

RSA/E+ / SysML

Factory

Model

No Magic / SysML

RSA/E+ / SysML

Excavator

Executable

Scenario

Operational

Scenario

Excavator

System Model

Interface & Transformation Tools

(VIATRA, XaiTools, ...)

Traditional

Descriptive Tools

Traditional

Simulation & Analysis Tools

ModelCenter

NX / MCAD Tool

Optimization

Model

Excavator

Boom Model

FactoryCAD

Ansys

Mathematica

FEA Model

Reliability

Model

Factory

Layout Model

Excel

Dymola

Cost Model

Dig Cycle

Model

Excel

Production

Ramps

eM-Plant

Factory

Simulation

2008-02-25a

66

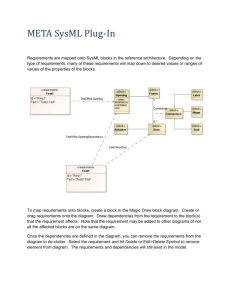

Enabling Executable SysML Parametrics

Commercialization by InterCAX LLC in Georgia Tech VentureLab incubator program

Advanced technology for graph management and solver access via web services.

COB Solving & Browsing

Plugins Prototyped by GIT

(to SysML vendor tools)

1) Artisan Studio [2/06]

2) EmbeddedPlus [3/07]

3) NoMagic [12/07]

NextGeneration

Spreadsheet

Parametrics plugin

COB Services (constraint graph manager, including COTS solver access via web services)

Composable Objects (COBs)

...

Native Tools Models

...

Ansys

(FEA Solver)

...

L

COTS =

commercial-off-the-shelf

(typically readily available)

FL

TL Mathematica

EA

(Math Solver)

XaiTools FrameWork™

2008-05 Status

- Examples working from

IS07 Parts 1 & 2 papers

- Multiple new tutorials:

UAVs, finances, insurance

claims, comm systems, ...

- Commercialization

beta releases soon

COB API

Execution via

API messages

or exchange files

XaiTools SysML Toolkit™

SysML Authoring Tools

Traditional COTS or

in-house solvers

74

Productionizing/Deploying GIT XaiTools™

Technology for Executing SysML Parametrics

www.InterCAX.com

Vendor

SysML

Tool

Prototype by

GIT

Product by

InterCAX LLC

Artisan

Studio

Yes

<tbd>

EmbeddedPlus

E+ SysML / RSA

Yes

<tbd>

No Magic

MagicDraw

Yes

ParaMagic™

(Jul 21, 2008 release)

Telelogic/IBM

Rhapsody/Tau

<tbd>

<tbd>

Sparx Systems

Enterprise Arch.

<tbd>

<tbd>

n/a

XMI import/export

Yes

<tbd>

Others <tbd>

Others <tbd>

<tbd>

<tbd>

[1] Full disclosure: InterCAX LLC is a spin-off company originally created to commercialize technology from RS Peak’s GIT group. GIT has licensed technology to

InterCAX and has an equity stake in the company. RS Peak is one of several business partners in InterCAX. Commercialization of the SysML/composable object

aspects is being fostered by the GIT VentureLab incubator program (www.venturelab.gatech.edu) via an InterCAX VentureLab project initiated October 2007.

75

Various Examples

• Road scanning system using unmanned

aerial vehicle (UAVs)

• ...

• Mechanical part design and analysis (FEA)

• ...

• Insurance claims processing and website

capacity model

• Financial model for small businesses

• Banking service levels model

• ...

76

UAV System Design Problem: LittleEye

Network-Centric Warfare Context — SysML/DoDAF Model

Source: No Magic Inc. and InterCAX LLC

77

Road Scanner System Problem

LittleEye UAV

80

LittleEye SysML Model

Various Diagram Views

81

Solving LittleEye SysML Parametrics

ParaMagic Browser Views

Instance 1 - Before Solving

Instance 1 - After Solving

82

Financial Projections System

Three Year

Corporate

Financial

Projections

• Key questions:

– Given projected sales, expenses and financing, what is the

financial position of the company at the end of 3 years?

– Given the desired financial position at the end of 3 years,

what are the required sales, expenses and financing?

–…

83

Financial Projections SysML Model

Various Diagram Views

84

Solving Financial Projections SysML Parametrics

ParaMagic Browser Views

Instance 1 - Before Solving

Instance 1 - After Solving

85

Using a Spectrum of Modeling Technologies

•

•

•

•

•

•

Mental calculations

Back-of-envelope hand calculations

Spreadsheets

...

SysML (with executable parametrics)

...

• Varying characteristics

– Quickness, flexibility, structure, modularity,

reusability, self-validation/constraints, ...

86

Excavator Modeling & Simulation Testbed

Tool Categories View

SysML Tools

RSA/E+ / SysML

Factory

Model

No Magic / SysML

RSA/E+ / SysML

Excavator

Executable

Scenario

Operational

Scenario

Excavator

System Model

Interface & Transformation Tools

(VIATRA, XaiTools, ...)

Traditional

Descriptive Tools

Traditional

Simulation & Analysis Tools

ModelCenter

NX / MCAD Tool

Optimization

Model

Excavator

Boom Model

FactoryCAD

Ansys

Mathematica

FEA Model

Reliability

Model

Factory

Layout Model

Excel

Dymola

Cost Model

Dig Cycle

Model

Excel

Production

Ramps

eM-Plant

Factory

Simulation

2008-02-25a

87

Recurring Problem:

Maintaining Multiple Views

• Multiple

stakeholders

with different

views and tools

• Models of

different system

aspects

• Different views

are not

independent

System

Design

Model

Aspect

A

Models

Aspect

B

Models

88

Approach: Graph Transformations

• Recent developments in Model-Driven

Engineering

• Tools for Model and Graph Transformations

– Viatra

– GME/GReAT

– Fujaba

– MOFLON

– MoTMoT

– Kermeta

89

Capturing Domain Specific Knowledge

in Graph Transformations

Requirements &

Objectives

system

alternative

SysML

ibd [Block] Hydraulic_Subsystem[ Schematic ]

pump : FDpump

discharge : FlowPort

inputShaft : FlowPort

pump-to-valve : Line

a : FlowPort

b : FlowPort

housing : FlowPort

valve : 4port3wayServoValve

suction : FlowPort

portP : FlowPort

portT : FlowPort

tank-to-pump : Line

Topology Generation using Graph Transf

a : FlowPort

cylB : FlowPort

b : FlowPort

cylA : FlowPort

tank : Tank

System

Alternatives

sump : FlowPort

valve-to-cylP1 : Line

MAsCoMs SysML

return : FlowPort

a : FlowPort

valve-to-filter : Line

filter-to-tank : Line

b : FlowPort

a : FlowPort

b : FlowPort

b : FlowPort

valve-to-cylP2 : Line

a : FlowPort

a : FlowPort

Model Composition using Graph Transf

filter : Filter

b : FlowPort

in : FlowPort

out : FlowPort

actuator : Double-ActingCylinder

System Behavior

SysML

Models

Model Translation using Graph Transf

Executable

Simulations

housing : FlowPort

Dig

Cycle

Traj

rod : FlowPort

Sw ing

Boom

b : FlowPort

a : FlowPort

hydraulics

Arm

Bucket

behavior

model

y

simulation

configuration

world

x

Dymola

Simulation Configuration using Graph Transf

Design

Optimization

ModelCenter

101

Graph Transformations for Systems Design

• Capture complex knowledge

– Language mappings

– Abstractions and idealizations

– Analysis patterns

– Synthesis patterns

– Workflow

• Intuitive graphical formalism

• Powerful tools are maturing

102

Contents

• Problem Description

– Characteristics of Mechatronic Systems

– Challenge Team Objectives

• Technical Approach

– Techniques and Testbeds

• Deliverables & Outcomes

• Collaboration Approach

Page 103

Expected Deliverables & Outcomes

Phase 1 (Sept. 2008)

• Solution and supporting models

– Excavator test case models, test suites, …

• MBSE practices used

– Modeling & simulation interoperability (MSI) method, …

• Model interchange capabilities

– Tests between SysML tools, CAD/CAE tools, …

• MBSE metrics/value

– See “Benefits” slide with candidate metrics

• MBSE findings, issues, & recommendations

– Issue submissions to OMG and vendors, publications, …

• Training material

– Examples, tutorials, …

• Plan forward (Phase 2 and beyond)

Page 104

Primary Reporting Venues

• Call for Participation @ IS’07

– Jun 26, 2007 in San Diego

• Phase 1 Status Update @ IW’08 MBSE Workshop #2

– Jan 25, 2008 in Albuquerque

• Phase 1 Status Update @ Frontiers Workshop

– May 14, 2008 in Atlanta

• Phase 1 Status Update @ IS’08

– Jun 15-19, 2008 in Utrecht

• Phase 1 Final Report & Archive of Models

– Sep 2008 via website

• Misc. reports/updates/publications @ various venues

– OMG meetings, society & vendor conferences, ...

Page 105

Phase 1 Report

• Draft version: June 2008

– ~100+ pages

– ~75+ figures

• Final version: Sept. 2008

Page 106

MBSE Challenge Team Objectives

Phase 2: 2008-2009

(proposed—pending resources)

Overall Objectives

• Refine & extend beyond Phase 1 capabilities

for modeling & simulation interoperability (MSI)

• Phase 2 Scope

– Domains: Primary: Mechatronics (expanded excavator testbed)

Secondary: Others to demo reusability

– Capabilities: Methodologies, tools, requirements,

and practical applications

– MSI subset: Connecting system specification & design models

with multiple engineering analysis

– Deployment: Productionizing techniques & tools

to enable ubiquitous practice

• Advance & demo how SysML facilitates effective MSI

Page 107

MBSE Challenge Team Objectives

Phase 2: 2008-2009

Specific Objectives

1. Extend modeling & simulation interoperability method: MIM 2.0

1. Generalizations: graph transformations, variable topology, reusability,

parametrics 2.x, trade study support, inconsistency mgt., E/MBOM

extensions, method workflow, ...

2. Specializations: software, electronics, closed-loop control, ...

3. Interfaces to new tools: ECAD, Matlab, Arena, ...

2. Refine SysML and tool requirements to support MIM 2.0

1. Provide feedback to vendors and OMG SysML 1.2/2.x task forces

3. Demonstrate extensions in updated testbed

4. Define deployment plan and initiate execution

5. Refine roadmap beyond Phase 2

Page 108

Potential Excavator Testbed Extension

Building block modularity, reusability, adaptation, ...

Potential Space Systems Test Case #1

Phoenix Digs for Clues on Mars - Credit: Phoenix Mission Team, NASA, JPL-Caltech, U. Arizona, Texas A&M University

What's a good recipe for preparing Martian soil? Start by filling your robot's scoop a bit less than half way. Next, dump your Martian soil into one of your TEGA ovens, being sure

to watch out for clumping. Then, slowly increase the temperature to over 1000 degrees Celsius over several days. Keep checking to see when your soil becomes vaporized.

Finally, your Martian soil is not ready for eating, but rather sniffing The above technique is being used by the Phoenix Lander that arrived on Mars three weeks ago. Data from the

first batch of baked soil should be available in a few days. Pictured above, a circular array of the Phoenix Lander's solar panels are visible on the left, while a scoop partly filled

with Martian soil is visible on the right. The robotic Phoenix Lander will spend much of the next three months digging, scooping, baking, sniffing, zapping, dissolving, and

magnifying bits of Mars to help neighboring Earthlings learn more about the hydrologic and biologic possibilities of the sometimes mysterious red planet.

[http://antwrp.gsfc.nasa.gov/apod/ap080615.html]

109

Potential Space Systems Test Case #2

Transform spreadsheet-based models into SysML ...

(1) Sample 2-Year Titan

Orbital Mission Scenario

http://opfm.jpl.nasa.gov/community/opfminstrumentsworkshoppresentations/ 2008-06

TSSM Orbiter Science Scenario, Rob Lock TSSM Orbiter Science Scenario, Rob Lock

• Four (4) 6-month cycles = eleven campaigns (instrument usage profiles during orbits)

• Three (3) science campaign types; maintain each campaign for 16 days (one Titan revolution)

(2) Atmosphere

& Ionosphere

Campaign

Data & power

timelines for key

~6.5-hour segment

of 16-day campaign

110

Modeling & Simulation Interoperability

Primary Impacts

Enabling Capabilities

Increased Knowledge

Capture & Completeness

Increased

Modularity & Reusability

Increased

Traceability

Reduced

Manual Re-Creation

Increased

& Data Entry Errors

Automation

Reduced

Modeling Effort

Increased

Analysis Intensity

Reduced

Time

Reduced

Cost

Reduced

Risk

Increased

Understanding

Increased

Corporate Memory

Increased Artifact

Performance

Anticipated Benefits of SysML-based Approach

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

Precision Knowledge

for the

Model-Based Enterprise

■

■

111

Contents

• Problem Description

– Characteristics of Mechatronic Systems

– Challenge Team Objectives

• Technical Approach

– Techniques and Testbeds

• Deliverables & Outcomes

• Collaboration Approach

Page 112

MBSE Challenge Team

Mechatronics / Model Interoperability

Open “Call for Participation”

• Systems engineering drivers in commercial settings

– Increased system complexity

– Cross-disciplinary communication/coordination

• Enhancement possibilities based on interest

– Other demonstration examples and testbeds

– Interoperability testing between SysML tools

– Shared models and libraries

• Primary contacts

– Russell Peak [Russell.Peak @ gatech.edu]

– Roger Burkhart [BurkhartRogerM @ JohnDeere.com]

– Sandy Friedenthal [sanford.friedenthal @ lmco.com]

Page 113

Backup Slides

SysML Parametrics—Suggested Starting Points

Introductory Papers/Tutorials

•

Peak RS, Burkhart RM, Friedenthal SA, Wilson MW, Bajaj M, Kim I (2007) Simulation-Based Design Using SysML—Part 1: A Parametrics

Primer. INCOSE Intl. Symposium, San Diego. [Provides tutorial-like introduction to SysML parametrics.]

http://eislab.gatech.edu/pubs/conferences/2007-incose-is-1-peak-primer/

•

Peak RS, Burkhart RM, Friedenthal SA, Wilson MW, Bajaj M, Kim I (2007) Simulation-Based Design Using SysML—Part 2: Celebrating

Diversity by Example. INCOSE Intl. Symposium, San Diego. [Provides tutorial-like introduction on using SysML for modeling & simulation,

including the MRA method for creating parametric simulation templates that are connected to design models.]

http://eislab.gatech.edu/pubs/conferences/2007-incose-is-2-peak-diversity/

Example Applications

•

Peak RS, Burkhart RM, Friedenthal SA, Paredis CJJ, McGinnis LF (2008) Integrating Design with Simulation & Analysis Using SysML—

Mechatronics/Interoperability Team Status Report. Presentation to INCOSE MBSE Challenge Team, Utrecht, Holland.

[Overviews modeling & simulation interoperability (MSI) methodology progress in the context of an excavator testbed.]

http://eislab.gatech.edu/pubs/seminars-etc/2008-06-incose-is-mbse-mechatronics-msi-peak/

•

Peak RS (2007) Leveraging Templates & Processes with SysML. Invited Presentation. Developing a Design/Simulation Framework: A

Workshop with CPDA's Design and Simulation Council, Atlanta. [Includes applications to automotive steering wheel systems and FEA

simulation templates.] http://eislab.gatech.edu/pubs/conferences/2007-cpda-dsfw-peak/

Commercial Tools and Other Examples/Tutorials

•

ParaMagic™ plugin for MagicDraw®. Developed by InterCAX LLC (a Georgia Tech spin-off) [1]. Available at www.MagicDraw.com.

•

Zwemer DA and Bajaj M (2008) SysML Parametrics and Progress Towards Multi-Solvers and Next-Generation Object-Oriented

Spreadsheets. Frontiers in Design & Simulation Workshop, Georgia Tech PSLM Center, Atlanta. [Highlights techniques for executing SysML

parametrics based on the ParaMagic™ plugin for MagicDraw®. Includes UAV and financial systems examples.]

http://www.pslm.gatech.edu/events/frontiers/

See slides below for additional references and resources.

[1] Full disclosure: InterCAX LLC is a spin-off company originally created to commercialize technology from RS Peak’s GIT group. GIT has licensed technology to

InterCAX and has an equity stake in the company. RS Peak is one of several business partners in InterCAX. Commercialization of the SysML/composable object

aspects is being fostered by the GIT VentureLab incubator program (www.venturelab.gatech.edu) via an InterCAX VentureLab project initiated October 2007.

115

MBX/SysML-Related Efforts at Georgia Tech

• SysML Focus Area web page

– http://www.pslm.gatech.edu/topics/sysml/

– Includes links to publications, applications,

projects, examples, courses, commercialization, etc.

– Frontiers 2008 workshop on MBSE/MBX, SysML, ...

• Selected projects

–

–

–

–

–

Deere: System dynamics (fluid power, ...)

Lockheed: System design & analysis integration

NASA: Enabling technology (SysML, ...)

NIST: Design-analysis interoperability (DAI)

TRW Automotive: DAI/FEA (steering wheel systems ... )

116

Selected GIT MBX/SysML-Related Publications

Some references are available online at http://www.pslm.gatech.edu/topics/sysml/. See additional slides for selected abstracts.

• Peak RS, Burkhart RM, Friedenthal SA, Paredis CJJ, McGinnis LF (2008) Integrating Design with Simulation & Analysis Using SysML—Mechatronics/Interoperability

Team Status Report. Presentation to INCOSE MBSE Challenge Team, Utrecht, Holland. [Overviews modeling & simulation interoperability (MSI) methodology

progress in the context of an excavator testbed.] http://eislab.gatech.edu/pubs/seminars-etc/2008-06-incose-is-mbse-mechatronics-msi-peak/

• McGinnis, Leon F., "IC Factory Design: The Next Generation," e-Manufacturing Symposium, Taipei, Taiwan, June 13, 2007. [Presents the concept of model-based

fab design, and how SysML can enable integrated simulation.]

• Kwon, Ky Sang, and Leon F. McGinnis, "SysML-based Simulation Framework for Semiconductor Manufacturing," IEEE CASE Conference, Scottsdale, AZ,

September 22-25, 2007. [Presents some technical details on the use of SysML to create formal generic models (user libraries) of fab structure, and how these formal

models can be combined with currently available data sources to automatically generate simulation models.]

• Huang, Edward, Ramamurthy, Randeep, and Leon F. McGinnis, "System and Simulation Modeling Using SysML," 2007 Winter Simulation Conference, Washington,

DC. [Presents some technical details on the use of SysML to create formal generic models (user libraries) of fab structure, and how these formal models can be

combined with currently available data sources to automatically generate simulation models.]

• McGinnis, Leon F., Edward Huang, Ky Sang Kwon, Randeep Ramamurthy, Kan Wu, "Real CAD for Facilities," 2007 IERC, Nashville, TN. [Presents concept of using

FactoryCAD as a layout authoring tool and integrating it, via SysML with eM-Plant for automated fab simulation model generation.]

• T.A. Johnson, J.M. Jobe, C.J.J. Paredis, and R. Burkhart "Modeling Continuous System Dynamics in SysML," in Proceedings of the 2007 ASME International

Mechanical Engineering Congress and Exposition, paper no. IMECE2007-42754, Seattle, WA, November 11-15, 2007. [Describes how continuous dynamics models

can be represented in SysML. The approach is based on the continuous dynamics language Modelica.]

• T.A. Johnson, C.J.J. Paredis, and R. Burkhart "Integrating Models and Simulations of Continuous Dynamics into SysML," in Proceedings of the 6th International

Modelica Conference, March 3-4, 2008. [Describes how continuous dynamics models and simulations can be used in the context of engineering systems design

within SysML. The design of a car suspension modeled as a mass-spring-damper system is used as an illustration.]

• C.J.J. Paredis "Research in Systems Design: Designing the Design Process," IDETC/CIE 2007, Computers and Information in Engineering Conference -- Workshop

on Model-Based Systems Development, Las Vegas, NV, September 4, 2007. [Presents relationship between SysML and the multi-aspect component model method.]

• Peak RS, Burkhart RM, Friedenthal SA, Wilson MW, Bajaj M, Kim I (2007) Simulation-Based Design Using SysML—Part 1: A Parametrics Primer. INCOSE Intl.

Symposium, San Diego. [Provides tutorial-like introduction to SysML parametrics.]

• Peak RS, Burkhart RM, Friedenthal SA, Wilson MW, Bajaj M, Kim I (2007) Simulation-Based Design Using SysML—Part 2: Celebrating Diversity by Example.

INCOSE Intl. Symposium, San Diego. [Provides tutorial-like introduction on using SysML for modeling & simulation, including the MRA method for creating parametric

simulation templates that are connected to design models.]

• Peak RS (2007) Leveraging Templates & Processes with SysML. Invited Presentation. Developing a Design/Simulation Framework: A Workshop with CPDA's Design

and Simulation Council, Atlanta. [Includes applications to automotive steering wheel systems and FEA simulation templates.]

http://eislab.gatech.edu/pubs/conferences/2007-cpda-dsfw-peak/

• Bajaj M, Peak RS, Paredis CJJ (2007) Knowledge Composition for Efficient Analysis Problem Formulation, Part 1: Motivation and Requirements. DETC2007-35049,

Proc ASME CIE Intl Conf, Las Vegas. [Introduces the knowledge composition method (KCM), which addresses design-simulation integration for variable topology

problems.]

• Bajaj M, Peak RS, Paredis CJJ (2007) Knowledge Composition for Efficient Analysis Problem Formulation, Part 2: Approach and Analysis Meta-Model. DETC200735050, Proc ASME CIE Intl Conf, Las Vegas. [Elaborates on the KCM approach, including work towards next-generation analysis/simulation building blocks

(ABBs/SBBs).]

117

Integrating Design with Simulation & Analysis Using SysML—

Mechatronics/Interoperability Team Status Report

Abstract

This presentation overviews work-in-progress experiences and lessons learned from an excavator testbed that

interconnects simulation models with associated diverse system models, design models, and manufacturing models. The

goal is to enable advanced model-based systems engineering (MBSE) in particular and model-based X1 (MBX) in

general. Our method employs SysML as the primary technology to achieve multi-level multi-fidelity interoperability, while

at the same time leveraging conventional modeling & simulation tools including mechanical CAD, factory CAD,

spreadsheets, math solvers, finite element analysis (FEA), discrete event solvers, and optimization tools. This work is

currently sponsored by several organizations (including Deere and Lockheed) and is part of the Mechatronics &

Interoperability Team in the INCOSE MBSE Challenge.

Citation

Peak RS, Burkhart RM, Friedenthal SA, Paredis CJJ, McGinnis LF (2008) Integrating Design with Simulation & Analysis

Using SysML—Mechatronics/Interoperability Team Status Report. Presentation to INCOSE MBSE Challenge Team,

Utrecht, Holland. http://eislab.gatech.edu/pubs/seminars-etc/2008-06-incose-is-mbse-mechatronics-msi-peak/

[1] The X in MBX includes engineering (MBE), manufacturing (MBM), and potentially other scopes and contexts such as

model-based enterprises (MBE).

118

Simulation-Based Design Using SysML

Part 1: A Parametrics Primer

Part 2: Celebrating Diversity by Example

OMG SysML™ is a modeling language for specifying, analyzing, designing,

and verifying complex systems. It is a general-purpose graphical modeling

language with computer-sensible semantics. This Part 1 paper and its Part

2 companion show how SysML supports simulation-based design (SBD) via

tutorial-like examples. Our target audience is end users wanting to learn

about SysML parametrics in general and its applications to engineering

design and analysis in particular. We include background on the

development of SysML parametrics that may also be useful for other

stakeholders (e.g, vendors and researchers).

In Part 1 we walk through models of simple objects that progressively

introduce SysML parametrics concepts. To enhance understanding by

comparison and contrast, we present corresponding models based on

composable objects (COBs). The COB knowledge representation has

provided a conceptual foundation for SysML parametrics, including

executability and validation. We end with sample analysis building blocks

(ABBs) from mechanics of materials showing how SysML captures

engineering knowledge in a reusable form. Part 2 employs these ABBs in a

high diversity mechanical example that integrates computer-aided design

and engineering analysis (CAD/CAE).

The object and constraint graph concepts embodied in SysML

parametrics and COBs provide modular analysis capabilities based on

multi-directional constraints. These concepts and capabilities provide a

semantically rich way to organize and reuse the complex relations and

properties that characterize SBD models. Representing relations as noncausal constraints, which generally accept any valid combination of inputs

and outputs, enhances modeling flexibility and expressiveness. We

envision SysML becoming a unifying representation of domain-specific

engineering analysis models that include fine-grain associativity with other

domain- and system-level models, ultimately providing fundamental

capabilities for next-generation systems lifecycle management.

These two companion papers present foundational principles of

parametrics in OMG SysML™ and their application to simulation-based

design. Parametrics capabilities have been included in SysML to support

integrating engineering analysis with system requirements, behavior, and

structure models. This Part 2 paper walks through SysML models for a

benchmark tutorial on analysis templates utilizing an airframe system

component called a flap linkage. This example highlights how engineering

analysis models, such as stress models, are captured in SysML, and then

executed by external tools including math solvers and finite element

analysis solvers.

We summarize the multi-representation architecture (MRA) method and

how its simulation knowledge patterns support computing environments

having a diversity of analysis fidelities, physical behaviors, solution

methods, and CAD/CAE tools. SysML and composable object (COB)

techniques described in Part 1 together provide the MRA with graphical

modeling languages, executable parametrics, and reusable, modular, multidirectional capabilities.

We also demonstrate additional SysML modeling concepts, including

packages, building block libraries, and requirements-verification-simulation

interrelationships. Results indicate that SysML offers significant promise as

a unifying language for a variety of models-from top-level system models to

discipline-specific leaf-level models.

Citation

Peak RS, Burkhart RM, Friedenthal SA, Wilson MW, Bajaj M, Kim I

(2007) Simulation-Based Design Using SysML. INCOSE Intl. Symposium,

San Diego.

Part 1: A Parametrics Primer

http://eislab.gatech.edu/pubs/conferences/2007-incose-is-1-peak-primer/

Part 2: Celebrating Diversity by Example

http://eislab.gatech.edu/pubs/conferences/2007-incose-is-2-peak-diversity/

119

Composable Objects (COB) Requirements & Objectives

Abstract

This document formulates a vision for advanced collaborative engineering environments (CEEs) to aid in the design,

simulation and configuration management of complex engineering systems. Based on inputs from experienced Systems

Engineers and technologists from various industries and government agencies, it identifies the current major challenges

and pain points of Collaborative Engineering. Each of these challenges and pain points are mapped into desired

capabilities of an envisioned CEE System that will address them.

Next, we present a CEE methodology that embodies these capabilities. We overview work done to date by GIT on the

composable object (COB) knowledge representation as a basis for next-generation CEE systems. This methodology

leverages the multi-representation architecture (MRA) for simulation templates, the user-oriented SysML standard for

system modeling, and standards like STEP AP233 (ISO 10303-233) for enhanced interoperability. Finally, we present

COB representation requirements in the context of this CEE methodology. In this current project and subsequent phases

we are striving to fulfill these requirements as we develop next-generation COB capabilities.

Citation

DR Tamburini, RS Peak, CJ Paredis, et al. (2005) Composable Objects (COB) Requirements & Objectives v1.0.

Technical Report, Georgia Tech, Atlanta. http://eislab.gatech.edu/projects/nasa-ngcobs/

Associated Project

The Composable Object (COB) Knowledge Representation: Enabling Advanced Collaborative Engineering Environments

(CEEs). http://eislab.gatech.edu/projects/nasa-ngcobs/

120

Leveraging Simulation Templates & Processes with SysML

Applications to CAD-FEA Interoperability

Abstract

SysML holds the promise of leveraging generic templates and processes across design and simulation. Russell Peak

joins us to give an update on the latest efforts at Georgia Tech to apply this approach in various domains, including

specific examples with a top-tier automotive supplier. Learn how you too may join this project and implement a similar

effort within your own company to enhance modularity and reusability through a unified method that links diverse models.

Russell will also highlight SysML’s parametrics capabilities and usage for physics-based analysis, including integrated

CAD-CAE and simulation-based requirements verification. Go to www.omgsysml.org for background on SysML—a

graphical modeling language based on UML2 for specifying, designing, analyzing, and verifying complex systems.

Speaker Biosketch

Russell S. Peak focuses on knowledge representations that enable complex system interoperability and simulation

automation. He originated composable objects (COBs), the multi-representation architecture (MRA) for CAD-CAE

interoperability, and context-based analysis models (CBAMs)—a simulation template knowledge pattern that explicitly

captures design-analysis associativity. This work has provided the conceptual foundation for SysML parametrics and its

validation.

He teaches this and related material, and is principal investigator on numerous research projects with sponsors

including Boeing, DoD, IBM, NASA, NIST, Rockwell Collins, Shinko Electric, and TRW Automotive. Dr. Peak joined the

GIT research faculty in 1996 to create and lead a design-analysis interoperability thrust area. Prior experience includes

business phone design at Bell Laboratories and design-analysis integration exploration as a Visiting Researcher at

Hitachi in Japan.

Citation

RS Peak (2007) Leveraging Simulation Templates & Processes with SysML: Applications to CAD-FEA Interoperability.

Developing a Design/Simulation Framework, CPDA Workshop, Atlanta.

http://eislab.gatech.edu/pubs/conferences/2007-cpda-dsfw-peak/

121

Mechatronics Definition

“The synergistic combination of mechanical, electronic, and

software engineering” (Wikipedia)

System

Modeling

Mechanics

Electronics

Sensors

Electromechanics

CAD/CAM

Control

Circuits

Mechatronics

Digital Control

Simulation

Software

Control

Micro-controllers

From Tamburini & Deren, PLM World ’06

http://eislab.gatech.edu/pubs/conferences/2006-plm-world-tamburini/

Page 122

Mechatronics—Open Technology

for Modeling & Frameworks

Systems

Mechanics

• SysML

• STEP AP233

• Open Modelica

• Domain-specific models

• MCAD/CAE

• STEP AP203/214/209 ...

• Part & subsystem models

...

Software

• UML 2

• Real-time middleware

• Communication protocols

• Programming languages & libraries

• Code generators

• IDEs (Eclipse, ...)

...

...

Electronics

• ECAD/CAE

• STEP AP210

• Component models

...

Not shown: Cross-cutting infrastructure (PLM, CM, ...)

Page 123

Modelica Multi-Discipline Models

Page 124