Hazwoper_1 - Mine Rescue Association

advertisement

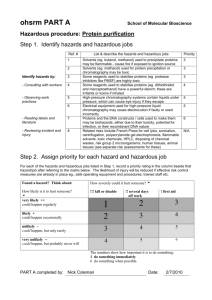

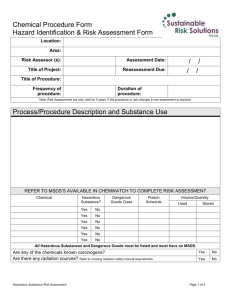

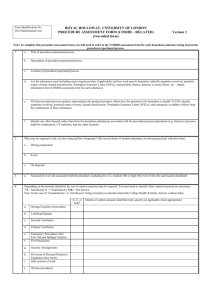

HAZWOPER HAZARDOUS WASTE OPERATIONS AND EMERGENCY RESPONSE 29 CFR 1910.120 INDUSTRIAL SAFETY TRAINING FOR EMERGENCY RESPONSE STAFF 29 CFR Labor 29 PARTS 1900 TO 1910 Revised as of Jan 1, 1995 National Archives Records and Administration 1910.120 Hazardous Waste Operations and Emergency Response COURSE OBJECTIVES Provide Training to the Emergency Response Staff Introduce HAZWOPER & Discuss Its Role in Today’s Industry. Introduce Skills in the Recognition & Control of Occupational Hazards. Introduce Emergency Response Techniques. Define HAZWOPER. APPLICABLE REGULATIONS 29CFR - SAFETY AND HEALTH STANDARDS 1910 - GENERAL INDUSTRY DANGER EYE PROTECTION REQUIRED BEYOND THIS POINT 120 - HAZARDOUS WASTE OPERATIONS AND EMERGENCY RESPONSE (HAZWOPER) TRAINING REQUIREMENTS THE EMPLOYER MUST PROVIDE TRAINING: THE USE OF EQUIPMENT. WHAT PPE IS NECESSARY. WHEN PPE IS NECESSARY. THE LIMITATIONS OF THE PPE. DECONTAMINATION PROCEDURES. PROVIDE RETRAINING AS REQUIRED. CARE AND MAINTENANCE OF EQUIPMENT. CLASSIFICATION OF HAZARDOUS MATERIALS. TRAIN ALL EMPLOYEES PRIOR TO JOB ASSIGNMENT. TRAINING REQUIREMENTS (Continued) EMERGENCY RESPONSE STAFF Level 1 Level 2 Level 3 Level 4 Level 5 First Responder First Responder Operations Level Hazardous Materials Technician Hazardous Materials Specialist On-Scene Incident Commander TRAINING REQUIREMENTS (Continued) EMERGENCY RESPONSE STAFF First Responder Operations Level Hazardous Materials Technician Hazardous Materials Specialist On-Scene Incident Commander Awareness 8 Hours Initial* 24 Hours Initial* 24 Hours Initial* 24 Hours Initial* *Plus Competency at the previous level and annual refresher. TRAINING REQUIREMENTS (Continued) EMERGENCY RESPONSE STAFF Level 1 = Witnesses or discovers a release of hazardous materials and who are trained to notify the proper authorities. Level 2 = Responds to releases of hazardous substances in a defensive manner, without trying to stop the releases. Level 3 = Responds aggressively to stop the release of hazardous substances. Level 4 = Responds with and in support to HAZMAT technicians, but who have specific knowledge of various hazardous substances. Level 5 = Assumes control of the incident scene beyond the first-responder awareness level RETRAINING REQUIREMENTS REQUIRED WHEN THERE IS A: CLOSE-CALL EVENT PROGRAM RELATED INJURY CHANGE IN JOB ASSIGNMENT NEW HAZARD OR EQUIPMENT NEW HAZARD CONTROL METHODS FAILURE IN THE SAFETY PROCEDURES REASON TO DOUBT EMPLOYEE PROFICIENCY PROGRAM IMPLEMENTATION IMPLEMENTATION OF A HAZWOPER PROGRAM REQUIRES: DEDICATION PERSONAL INTEREST MANAGEMENT COMMITMENT NOTE: UNDERSTANDING AND SUPPORT FROM THE WORK FORCE IS ESSENTIAL, WITHOUT IT THE PROGRAM WILL FAIL! DEFINITION HAZARDOUS MATERIALS means a substance or material which has been determined by the Secretary of Transportation to be capable of posing an unreasonable risk to HEALTH PROPERTY ENVIRONMENT when transported in commerce. DEFINITION HAZARDOUS SUBSTANCES means a material and its mixtures or solutions, that is regulated by the U. S. Environmental Protection Agency (EPA). 40 CFR Protection of Environment 40 PARTS 260 TO 299 Revised as of Jan 1, 1995 National Archives Records and Administration DEFINITION HAZARDOUS WASTE means a material that is subject to the Uniform Hazardous Waste Manifest requirements of the EPA. 40 CFR Protection of Environment 40 PARTS 260 TO 299 Revised as of Jan 1, 1995 National Archives Records and Administration THE LIFE CYCLE OF A CHEMICAL AND THE LEGISLATIVE AUTHORITIES CAA DEVELOPMENT OSHA USCG FRA HMTA OSHA CWA MPRSA PWSA MANUFACTURER DISTRIBUTION SDWA FHWA FAA RCRA CPSA FHSA TSCA WASTE FFDCA SDWA OSHA CAA CONSUMER PRODUCTS HMTA CWA MRAS FIFRA WASTE FIFRA OSHA INDUSTRIAL PRODUCTS THE LIFE CYCLE OF A CHEMICAL AND THE LEGISLATIVE AUTHORITIES CAA - CLEAN AIR ACT CPSA - CONSUMER PRODUCT SAFETY ACT CWA - CLEAN WATER ACT FAA - FEDERAL AVIATION ADMINISTRATION FFDCA - FED, FOOD, DRUG, AND COSMETIC ACT FHSA - FED, HAZARDOUS SUBSTANCES ACT FHWA - FEDERAL HIGHWAY ADMINISTRATION FRA - FEDERAL RAILROAD ADMINISTRATION FIFRA - FED, INSECTICIDE, FUNGICIDE, AND RODENTICIDE ACT HMTA - HAZARDOUS MATERIALS TRANSPORTATION ACT THE LIFE CYCLE OF A CHEMICAL AND THE LEGISLATIVE AUTHORITIES MPRSA - MARINE PROTECTION, RESEARCH AND SANCTUARIES ACT OSHA - OCCUPATIONAL SAFETY AND HEALTH ACT PPPA - POISON PREVENTION PACKAGING ACT PWSA - PORTS AND WATERWAYS SAFETY ACT RCRA - RESOURCE CONSERVATION AND RECOVERY ACT SDWA - SAFE DRINKING WATER ACT TSCA - TOXIC SUBSTANCES CONTROL ACT USCG - UNITED STATES COAST GUARD A HAZARDOUS WASTE IS ............... A solid waste is hazardous if it meets any one of the following conditions: IGNITABILITY CORROSIVITY REACTIVITY EP TOXICITY A LISTED WASTE A MIXTURE (10% RULE) NOT EXCLUDED WASTE CHARACTERISTICS IGNITABILITY - D001 CORROSIVITY - D002 REACTIVITY - D003 EP TOXICITY - D004 5 D D D D D F K U P LISTED WASTE General Ignitability Corrosivity Reactivity Toxicity Non-Specific Specific Commercial Chemicals Acutely 261.20 261.21 261.22 261.23 261.24 261.31 (a) 261.32 261.33 (e) 261.33 (f) THE FOLLOWING HAZARDS CODES ARE USED TO INDICATE THE ADMINISTRATORS BASIS FOR LISTING THE CLASSES OR TYPES OF WASTE: Ignitable Waste Corrosive Waste Reactive Waste Reactive Waste Acute Hazardous Waste Toxic Waste (I) (C) (R) (E) (H) (T) O CCUPATIONAL S AFETY H EALTH ACT Enacted in 1970 Amended Continuously Workplace Hazardous Substances H AZARDOUS M ATERIAL T RANSPORTATION ACT Enacted in 1970 Amended 1990 Transportation of Hazardous Materials C LEAN A IR A CT Enacted in 1970 Amended 1977 & 1990 Covers Hazardous air pollutants F EDERAL WATER P OLLUTION CONTROL CT A Enacted in 1972 Amended 1977 & 1990 Toxic pollutants; Hazardous Substances. S AFE D RINKING W ATER ACT Enacted in 1974 Amended 1977 & 1990 Priority pollutants. R ESOURCES C ONSERVATION R ECOVERY ACT Enacted in 1976 Amended 1980 & 1984 Covers Solid and Hazardous Waste and Underground Tanks T OXIC S UBSTANCES C CONTROL ACT Enacted in 1976 Amended as needed Requires premarket evaluation of all new chemical substances other than food additives, drugs, pesticides, alcohol, and tobacco. C OMPENSATION E NVIRONMENTAL R ESPONSE COMPENSATION SUPERFUND L IABILITY ACT Enacted in 1980 Amended 1986 Cleanup of sites where Hazardous substances are improperly disposed. S UPERFUND AMENDMENTS R EAUTHORIZATION ACT RIGHT TO KNOW Enacted in 1986 Cleanup of sites where Hazardous substances are improperly disposed. Adds right to know provision 29 CFR 1910.120 1910.120 Hazardous Waste Operations and Emergency Response covers the following operations, unless the employer can demonstrate that the operations does not involve employee exposure or the reasonable possibility for employee exposure to safety or health hazards: Clean-up operations required by a government body Corrective Actions covered by RCRA Voluntary clean-up operations Operations involving hazardous waste (TSD) Emergency response operations for releases 1910.120 DEFINITIONS BUDDY SYSTEM - means a system of organizing employees into work groups in such a manner that each employee of the work group is designated to be observed by at least one other employee in the work group. The purpose of the buddy system is to provide rapid assistance to employees in the event of an emergency. CLEAN-UP OPERATIONS - means an operation where hazardous substances are removed, contained, incinerated, neutralized, stabilized, cleared-up, or in any other manner processes or handled with the ultimate goal of making the site safer for people or the environment. 1910.120 DEFINITIONS DECONTAMINATION - means the removal of hazardous substances from employees and their equipment to the extent necessary to preclude the occurrence of foreseeable adverse health affects. EMERGENCY RESPONSE - means a response effort by employees from outside the immediate release area or by other designated responder to an occurrence which results, or is likely to result, in an uncontrolled releases of a hazardous substance. 1910.120 DEFINITIONS FACILITY - means (a) any building, structure, installation, equipment, pipe or pipeline, well, pit, pond, lagoon, impoundment, ditch, storage container, motor vehicle, rolling stock, or aircraft, or (b) any site or area where a hazardous substance has been deposited, stored, disposed of, or placed, or otherwise come to be located. HAZARDOUS MATERIALS RESPONSE (HAZMAT) TEAM - means an organized group of employees, designated by the employer, who are expected to perform work to handle and control actual or potential leaks or spills of hazardous substances requiring possible close approach to the substance. 1910.120 DEFINITIONS HAZARDOUS WASTE OPERATION - means any operations conducted within the scope of 29 CFR 1910.120. HAZARDOUS WASTE SITE - means any facility or location within the scope of 29 CFR 1910.120 at which hazardous waste operations take place. PERMISSIBLE EXPOSURE LIMITS - means the exposure, inhalation or dermal permissible exposure limit specified in 29 CFR part 1910, subparts G and Z. 1910.120 DEFINITIONS HEALTH HAZARDS - means a chemical, mixture of chemicals or a pathogen for which there is statistically significant evidence based on at least one study conducted in accordance with established scientific principles that acute or chronic health effects may occur in exposed employees. IMMEDIATELY DANGEROUS TO LIFE OR HEALTH means an atmospheric concentration of any toxic, corrosive or asphyxiate substance that poses and immediate threat to life or would cause irreversible or delayed adverse health effects or would interfere with an individual’s ability to escape from a dangerous atmosphere. 1910.120 DEFINITIONS OXYGEN DEFICIENCY - means that concentration of oxygen by volume below which atmosphere supplying respiratory protection must be provided. It exists in atmospheres where the percentage of oxygen by volume is less than 19.5 percent oxygen. QUALIFIED PERSON - means a person with specific training, knowledge and experience in the area for which the person has the responsibility and the authority to control. SITE SAFETY AND HEALTH SUPERVISOR - means the individual located on a hazardous waste site who is responsible to the employer and has the authority and knowledge necessary to implement the site safety and health plan and verify compliance with applicable safety and health requirements. MATERIAL SAFETY DATA SHEETS VARIOUS SECTIONS OF THE MSDS (TYPICAL FORMAT) SECTION I II III IV V VI VII VIII IX CONTENTS PRODUCT IDENTITY HAZARDOUS INGREDIENTS PHYSICAL/CHEMICAL CHARACTERISTICS FIRE/EXPLOSION/PHYSICAL HAZARD DATA REACTIVITY DATA HEALTH HAZARDS DATA PRECAUTIONS FOR SAFE HANDLING AND USE CONTROL MEASURES/PROTECTION INFORMATION ADDITIONAL INFORMATION/SPECIAL PRECAUTIONS MATERIAL SAFETY DATA SHEETS TRADE SECRETS INFORMATION WITHHELD FROM A MSDS MUST BE PROVIDED DURING AN EMERGENCY OR AT THE REQUEST OF A PHYSICIAN. THE USER OF THE INFORMATION MUST AGREE TO KEEP THE INFORMATION CONFIDENTIAL. Material Safety Data Sheet I. General Information Chemical Name & Synonyms Trade Name & Synonyms Chemical Family Formula Proper DOT Shipping Name DOT Hazard Classification Manufacturer Manufacturer's Phone Number Manufacturer's Address Chemtrec Phone Number Material Safety Data Sheets (MSDS) provide the user general and specific information regarding the product. II. Ingredients Principal Hazardous Components Percent Threshold Limit Value III. Physical Data Boiling Point (F) Specific Gravity (H20 =1) Vapor Pressure (mm Hg.) Percent Volatile By Volume (%) Vapor Density (Air = 1) Evaporation Rate (_____=1) Solubility in Water Appearance & Odor pH IV. Fire & Explosion Hazard Data Auto Ignition Temperature Flash point (Test Method) Flammable Limits Extinguishing Media Special Fire Fighting Procedures Unusual Fire & Explosion Hazard LEL LEL * Must have a date. * Must have a Manufacturer. * Must not have any blanks. * Must be update within 90 days of any new changes. * Must be available to all employees within their workday. Material Safety Data Sheet During any type of V. Health Hazard Data OSHA Permissible Exposure Limit ACGIH Threshold Limit Value Carcinogen - NTP Program Carcinogen - IARC Program Symptoms of Exposure Primary Route(s) of Entry VI. Reactivity Data Unstable Stable Stability Incompatibility Conditions to Avoid Materials to Avoid Hazardous May Occur Conditions to Avoid polymerization Will Not Hazardous Decomposition Products VII. Environmental Protection Procedures Spill Response Waste Disposal Method VIII. Special Protection Information Eye Protection Skin Protection Respiratory Protection (Type) Ventilation Recommended Other Protection IX. Special Precautions Hygienic Practices in Handling & Storage Precautions For Repair & Maintenance of Contaminated Equipment Other Precautions emergency, a copy of the MSDS should be used in assisting in what type of action will be taken. From Cleanup to using the correct protective clothing. The MSDS is not the only source that you have. Some other sources are: Technical Data Sheet The Manufacturer Scientific Studies Chris Manual Emergency Response Guidebook Others Material Safety Data Sheet Dipping Acid Matting Acid Sulfuric Acid Sulfuric Acid Acids Sulfuric Acid 8, UN1830 I. General Information H2O4S Chemical Name & Synonyms Trade Name & Synonyms Chemical Family Formula Proper DOT Shipping Name DOT Hazard Classification Manufacturer Manufacturer's Phone Number Manufacturer's Address Chemtrec Phone Number ABC Corporations 123 Face St Save, Ohio 33333 Corrosive 1-513-555-1111 1-800-424-9300 Material Safety Data Sheet Sulfuric Acid II. Ingredients Principal Hazardous Components Percent MSHA STD TWA 1 mg/m3 Threshold Limit Value OSHA PEL 8 H TWA 1 mg/m3 Water 93-99% 7-0.5% IDLH 80 mg/m3 Material Safety Data Sheet 1 mm @ 145.80 1.834 N/A III. Physical Data N/A 2900 Vapor Pressure (mm Hg.) Vapor Density (Air = 1) Boiling Point (F) Solubility in Water Appearance & Odor Infinitely soluble Specific Gravity (H20 =1) Percent Volatile By Volume (%) Evaporation Rate (_____=1) pH N/A 2 Odorless Liquid Material Safety Data Sheet N/A N/A IV. Fire & Explosion Hazard Data Dry Chemical or CO2 Flash point (Test Method) Flammable Limits Extinguishing Media Special Fire Fighting Procedures Unusual Fire & Explosion Hazard Auto Ignition Temperature LEL LEL N/A N/A Violent reaction with water. Material Safety Data Sheet TWA 1 mg/m3 NO V. Health Hazard Data TWA 1 mg/m3 STEL 3 ppm OSHA Permissible Exposure Limit ACGIH Threshold Limit Value Carcinogen - NTP Program Inhalation Ingestion Skin Eyes Carcinogen - IARC Program Primary Route(s) of Entry Symptoms of Exposure Eye, Nose, Throat irritation Pulmonary, Bronchitis Emphysema, Stomatis, dental erosion Burns NO Material Safety Data Sheet Stable Organic materials, VI. Reactivity Data Unstable Stability Conditions to Avoid chlorates, carbides, Incompatibility Stable Materials to Avoid May Occur Neutralization fulminates, water, Hazardous polymerization Will Not powdered metals Hazardous Decomposition Products Will Not N/A Water ph Adjust Caustic Material Safety Data Sheet Do not touch or walk through spilled material; stop leak if you can do it without risk. Fully-encapsulating, vapor protective clothing should be worn for spills and VII. Environmental Protection Procedures leaks with no Spill Response Waste Disposal Method fire. Use water spray to reduce vapor, do not put water directly on leak, spill area or inside container. Disposal must comply with Federal, State, and local Rules and Regulations. Reference: EPA 260-265. Material Safety Data Sheet Chemical Safety Goggles Protective Clothing VIII. Special Protection Information Skin Protection Eye Protection Respiratory Protection (Type) Ventilation Recommended Other Protection Full Face IAW 1910.134 Ventilate below airbonre exposure limits. Material Safety Data Sheet Keep all material on pallets. Do not store next to IX.inSpecial Precautions incompatible Hygienic Practices Handling & Storage Precautions For Repair & Maintenance of Contaminated Equipment material. Other Precautions Wear Safety glasses, rubber gloves and other appropriate safety equipment as needed. NONE NONE SPECIFIC GRAVITY Specific Gravity is an abstract or dimensionless number compared to the mass of an equal volume of water. Density of water is 8.33 lbs (Note: 8.33 lbs represents 1 gallon of water). 1 Gallon of Sulfuric Acid is 15.33 lbs. mass Density = -----------------volume 15.33 lb/gal (Sulfuric) Specific gravity = ------------------------- = 1.84 8.33 lbs/gal (Water) SPECIFIC GRAVITY Many chemicals are soluble in water, but when the liquid does not appreciably dissolve in water, the term immiscible is used. IMMISCIBLE IN WATER Float on top if the SG less than 1.0 Sink to the bottom if the SG greater than 1.0 WATER WATER SOLUBLE IN WATER VAPOR DENSITY Vapor Density is the mass of gases and vapors as it is compared to the mass of an equal volume of air or other reference gas. Air’s density is 1.29 g/L or 0.011 lb/gallons. VD greater than 1.0, the vapors are heavier than air and lay in low areas. VD less than 1.0, the vapors are lighter than air and will rise. pH - pH. THE pH OF A LIQUID IS THE NUMERICAL MEASURE OF ITS RELATIVE ACIDITY OR ALKALINITY. THE RANGE IS FROM 0 - 14 WITH A NEUTRAL LEVEL EXPRESSED AS A pH OF 7.0. ABOVE 7.0 THE LIQUID IS MORE ALKALINE OR BASIC. BELOW 7.0 THE LIQUID IS MORE ACIDIC. COMMON ACIDS (pH 0-6) COMMON BASES (pH 8-14) - HYDROCHLORIC ACID - HYDROFLUORIC ACID - NITRIC ACID - PHOSPHORIC ACID - CHROMIC ACID - SODIUM HYDROXIDE (LYE) - SODIUM HYPOCHLORITE (BLEACH) - AQUEOUS AMMONIA - POTASSIUM HYDROXIDE (POTASH) - AMMONIUM HYDROXIDE pH 12 Limewater Household ammonia 11 Milk of magnesia 10 BASE 9 Blood Pure Water Tap Water Coffee Wine Vinegar Lemon juice Gastric juice 8 7 NEUTRAL 6 5 4 3 2 ACID HAZARD RATING SYSTEMS TWO SYSTEMS NFPA - NATIONAL FIRE PROTECTION ASSOCIATION HMIS - NATIONAL PAINT AND COATINGS ASSOCIATION - HAZARDOUS MATERIAL IDENTIFICATION SYSTEM HAZARD RATING SYSTEMS FOUR HAZARD PARAMETERS HEALTH FLAMMABILITY REACTIVITY SPECIFIC HAZARD (NFPA) HAZARD RATING SYSTEMS FIVE HAZARD LEVELS HMIS 4 SEVERE 3 SERIOUS 2 MODERATE 1 SLIGHT 0 MINIMAL NFPA 4 EXTREME 3 HIGH 2 MODERATE 1 SLIGHT 0 INSIGNIFICANT HOMEMADE LABEL SAMPLE “HOMEMADE” LABEL FOR A SINGLE CHEMICAL (NON-MIXTURE) CHEMICAL NAME (SEE MSDS) DOT HAZARD CLASS USE OF CHEMICAL PPE REQUIRED CHECK ALL THAT APPLY FLAMMABLE TOXIC IRRITANT CORROSIVE WATER REACTIVE OXIDIZER NAME EMERGENCY PHONE ___________ __________________ ADDRESS: __________________________________________________ HMIS LABEL FIVE HMIS HAZARD LEVELS - 4 SEVERE - 3 SERIOUS - 2 MODERATE - 1 SLIGHT - 0 MINIMAL HEALTH FLAMMABILITY REACTIVITY PERSONAL PROTECTION NFPA LABEL FIRE HAZARD FIVE NFPA HAZARD LEVELS - 4 EXTREME - 3 HIGH - 2 MODERATE - 1 SLIGHT - 0 INSIGNIFICANT 2 HEALTH HAZARD REACTIVITY 4 1 W SPECIFIC HAZARD (WATER REACTIVE) HEALTH HAZARDOUS 1 4 3 4 Materials that on very short exposure could cause death or major residual injury even though prompt medical treatment was given. 3 Materials that on short exposure could cause serious temporary or residual injury even though prompt medical treatment was given. 2 Materials that on intense or continued exposure could cause temporary incapacitation or possible residual injury unless prompt medical treatment was given. 1 Materials that on exposure would cause irritation but only minor residual injury even if no treatment was given. 0 Materials that on exposure under fire conditions would offer no hazard beyond that of ordinary combustible material. 4 1 FLAMMABLE HAZARDOUS 3 4 Materials that will rapidly or completely vaporize at atmospheric pressure and normal ambient temperature, or that are readily dispersed in air, and will burn readily. 3 Liquids and solids that can be ignited under almost all ambient temperature conditions. 2 Materials that must be moderately heated or exposed to relatively high ambient temperatures before ignition can occur. 1 Materials that must be preheated before ignition can occur. 0 Materials that will not burn. 3 REACTIVITY HAZARDOUS 4 3 2 1 4 1 0 Materials that in themselves are readily capable of detonation or of explosive decomposition or reaction at normal temperatures and pressures. Materials that in themselves are capable of detonation or explosive reaction but require a strong initiating source or that must be heated under confinement before initiation or that react explosively with water. Materials that in themselves are normally unstable and readily undergo violent chemical change but do not detonate. Materials that in themselves are normally stable, but which can become unstable at elevated temperatures and pressures or which may react with water with some release of energy but not violently. Materials that in themselves are normally stable, even under fire exposure condition, and which are not reactive with water. SPECIAL HANDLING RADIOACTIVE 1 4 3 CORR CORROSIVE OXY OXYGEN W WATER REACTIVE EMERGENCY RESPONSE GUIDEBOOK 1996 NORTH AMERICAN EMERGENCY RESPONSE GUIDEBOOK A GUIDEBOOK FOR FIRST RESONDERS DURING THE INTIAL PHASE OF A HAZARDOUS MATERIALS/DANGEROUS GOODS INCIDENT EMERGENCY RESPONSE GUIDEBOOK YELLOW PAGES ID Guide Name of Material No. No. 1001 17 Acetylene ID Guide Name of Material No. No. 1011 22 Butylene 1001 17 Acetylene, dissolved 1013 21 Carbon Dioxide 1001 12 Air, compressed 1014 14 Carbon Dioxide and Oxygen Mixtures 1003 23 Air, refrigerated liquid 1015 12 Carbon Dioxide and (Cryogenic liquid) Nitrous oxide mixtures 1005 15 Ammonia 1016 18 Carbon Monoxide 1005 15 Amonia, Anhydrous 1017 20 Chlorine liquefied 1005 15 Ammonia, Solutions with more than 50% ammonia 1018 12 Chlorodifluoromethane 1020 12 ChloropentafluoroEthane 1005 15 Anhydrous Ammonia 1021 12 ChlorotetrafluoroEthane 1006 12 Argon, compressed 1022 12 Chlorotrifluoromethane 1008 15 Boron Trifluoride 1009 12 Bromotrifluoromethane 1022 12 Trifluorochloromethane 1010 17 Butadienes, inhibited 1023 18 Coal Gas 1026 18 Cyanogen 1011 22 Butanes or Butane 1026 18 Cyanogen, liquefied Mixtures EMERGENCY RESPONSE GUIDEBOOK BLUE PAGES Name of Material Guide ID Name of Material No. No. Acetic Acid Solution, more than 80% acid 29 2789 Acridine Acetic Anhydride 39 1715 Guide ID No. No. Acrolein, inhibited 32 2713 30 1092 Acrolein Dimer, Acetone, and solutions 26 1090 stabilized 26 2607 Acetone Cyanohydrin, 55 1541 Acrylamide stabilized Acrylic Acid, Inhibited Acetone Oils 26 1091 Acrylonitrile, inhibited Acetonitrile 28 1648 Activated Carbon Acetyl Acetone 48 2080 Adhesive Peroxide 55 2074 29 2218 30 1093 32 1362 26 1133 Acety Benzoyl Peroxide 48 2081 Adhesives, containing flammable liquid 26 1133 Acetylene 17 1001 Adiponitrile 55 2205 Acetylene, dissolved 17 1001 Aerosols 12 1950 Acetylene Tetrabromide 58 2504 Air, Compressed 12 1002 EMERGENCY RESPONSE GUIDEBOOK ORANGE PAGES GUIDE 11 POTENTIAL HAZARDS FIRE OR EXPLOSION Flammable/combustible material, may be ignited by heat, sparks or flames May ignite other combustible materials (wood, paper, oil, etc..) Container May explode in heat of fire. Reaction with fuels may be violent. Runoff from fire control or dilution water may cause pollution. HEALTH HAZARDS May be fatal if inhaled, swallowed or absorbed through skin. Contact may cause burns to skin and eyes. Fire may produce irritating or poisonous gases. Runoff from fire control or dilution water may cause pollution. EMERGENCY ACTION Keep unnecessary people away; isolate hazard area and deny entry. Stay up wind; keep out of low areas. Positive pressure self-contained breathing apparatus (SCBA) and structural firefighter's protective clothing will provide limited protection. CALL Emergency Response Telephone Number on Shipping Paper first. If Shipping Paper not available or no answer. CALL CHEMTREC AT 1-800-424-9300. FIRE Small Fires: Dry chemical, CO2, water spray or regular foam. Large Fires: Water Spray, fog or regular foam. SPILL OR LEAK Shut off ignition sources, no flares, smoking or flames in hazard area. Keep combustible (wood, paper, oil, etc.) away from spilled material. FIRST AID Move victim to fresh air and call emergency medical are, if not breathing, give artificial respiration, if breathing is difficult, give oxygen. EMERGENCY RESPONSE GUIDEBOOK GREEN PAGES TABLE OF INITIAL ISOLATION AND PROTECTIVE ACTION DISTANCES SMALL SPILLS ID# NAME OF 1005 Ammonia LARGE SPILLS First Then, PROTECT First Then, PROTECT ISOLATE persons ISOLATE persons in all DOWNWIND in all DOWNWIND Direction DAY NIGHT Direction DAY NIGHT MATERIAL (feet) (Miles) (Miles) (feet) (Miles) (Miles) 500 0.1 0.6 500 0.3 2.2 1005 Ammonia, Anhydrous, liquefied 500 0.1 0.6 500 0.3 2.2 1005 Ammonia Solutions, with more than 50% ammonia 500 0.1 0.6 500 0.3 2.2 1005 Anhydrous Ammonia 500 0.1 0.6 500 0.3 2.2 1008 Boron Trifluoride 500 0.3 2.0 500 0.8 2.9 1016 Carbon Monoxide 500 0.3 2.0 500 0.7 2.8 1017 Chlorine 500 0.7 2.8 500 0.7 2.8 1023 Coal Gas 500 0.1 1.2 500 0.7 2.8 1026 Cyanogen 500 0.1 1.1 500 0.7 2.8 1026 Cyanogen, liquefied 500 0.1 1.1 500 0.7 2.8 TOXICOLOGY the study of poisons “ALL THINGS ARE POISONS, FOR THERE IS NOTHING WITHOUT POISONOUS QUALITIES. IT IS ONLY THE DOSE WHICH MAKES A THING POISON.” PARACELSUS (1493 - 1541) TOXICOLOGY TOXIN - Any of a group of poisonous, usually unstable compounds generated by microorganisms, plants or animals. Certain toxins are produced by specific pathogenic microorganisms and are the causative agents in various diseases, as tetanus, diphtheria, etc. TOXICITY - The effect a specific quantity or dosage of a specific toxin (Chemical) has on a living microorganism. This is not an absolute! TOXICITY INGESTION Swallowing of a substance through the mouth and into the stomach. Generally followed by its entrance into the small intestine. ABSORPTION Entering the body through the skin. Substances that absorb through the skin sometime further assimilate into the blood system. INHALATION Breathing causes us to inhale substances which in return travels en route to the lungs. Our lungs are so rich in blood vessels that any substance inhaled into the lungs are readily absorbed into the bloodstream. TOXIC EFFECTS ACUTE - Is generally regarded as a severe injury caused by a one time, relatively short exposure to a chemical substances harmful to the human body. CHRONIC - Is an injury or disease that manifests itself after a relatively long period of time has elapsed since the initial exposure to the substance causing some type of ailment. - Is an injury or disease that remains undeveloped until an incubation period has elapsed. The period of time could be hours, days, months or years. LATENT IRRITANT - Is a chemical substance that injures the tissues of the respiratory system and lungs, thereby causing inflammation of the respiratory passages. AFFECTING FACTORS The Amount Entering the Body. The Length of Time. The Rate of Absorption Into the Blood. The Physical Nature of the Chemical. The Chemical Nature of the Chemical. The Age of the Individual. The Health of the Individual. MEASURING THE TOXICITY PARTS PER MILLION - ppm PARTS PER BILLION - ppb PARTS PER TRILLION - ppt LETHAL DOSE - LD50 LETHAL CONCENTRATION - LC50 THRESHOLD LIMIT VALUE - TLV IMMEDIATELY DANGEROUS TO LIFE AND HEALTH - IDLH APPROXIMATIONS ppb ppm 1 INCH 1 1/4 1/2 3/4 1 INCH 1 INCH = 16 MILES 1 1/4 1/2 3/4 = 1 DROP = 16,000 MILES 1 1/4 1/2 80 FIFTHS 1 DROP 80,000 FIFTHS 1 PENNY = 16,000,000 MILES 1 DROP 80,000,000 FIFTHS = = $10,000.00 3/4 = = = 1 PENNY ppt $10,000,000.00 1 PENNY $10,000,000,000.00 LETHAL DOSE - LD50 The LD50 is the amount of a material that, when administrated to laboratory animals, kill half of them. The expression is made in milligrams of the substance administered per body weight of the animal expressed in kilograms (mg/kg). When extrapolated to humans, the lethal dose of an average person who weighs w kilograms is LD50 x w. LETHAL CONCENTRATION - LC50 The LC50 is the concentration of a material that, normally express as parts per million (ppm) by volume, that when administrated to laboratory animals, kill half of them during the period of exposure. THRESHOLD LIMIT VALUE - TLV The TLV is the upper limit of a toxin concentration to which an average healthy person may be repeatedly exposed on an all-day, everyday basis without suffering adverse health effects. Gaseous substances in air, the TLV is usually express as parts per million (ppm). Fumes or mist in air, it is expressed in milligrams per cubic meter (mg/m3). TLV values are set by the American Conference of Governmental Industrial Hygienist (ACGIH). EXPOSURE MODEL LC50 LD50 T I M E TLV PEL SAFE EXPOSURE 0 DOSE TOXINS IN OUR BODY THE BRAIN TOXIN RESPIRATORY SYSTEMS Toxins inhaled can quickly travel to vital organs and the brain causing either acute or chronic effects. THE HEART THE STOMACH THE LIVER THE INTESTINE THE SKIN DEFENSES (S)URFACE LAYER (K)ERATIN LAYER (P)IGMENT CELLS EPIDERMAL CELLS BASAL CELLS DUCT SWEAT GLANDS WATER SOLUBLE CHEMICALS, CHANGES IN pH, LARGE AMOUNT OF WATER. ACIDS THAT ARE MILD, WATER LOSS, PHYSICAL INJURIES, CHEMICALS, ULTRAVIOLET, MICRO-ORGANISMS. ULTRAVIOLET S SEBACEOUS (OIL) GLAND K P HAIR FOLLICLE SKIN INJURED BY (S)URFACE LAYER (K)ERATIN LAYER (P)IGMENT CELLS EPIDERMAL CELLS BASAL CELLS DUCT SWEAT GLANDS WARM WATER, SOLVENTS, ALKALIS AND SOAP CHEMICALS, TRAUMA, SOLVENTS, ALKALIS, DETERGENTS, AND CERTAIN INTERNAL DISEASES PHYSICAL, MECHANICAL OR CHEMICAL TRAUMA, AND INTERNAL DISEASES S SEBACEOUS (OIL) GLAND K P HAIR FOLLICLE IMMEDIATELY DANGEROUS TO LIFE AND HEALTH - IDLH An IDLH level represents a maximum concentration from which one could escape within 30 minutes without experiencing any escape-impairing symptoms or any irreversible adverse health effects. IDLH levels are published for many substances by OSHA and NIOSH. In practice, when the concentration of a toxic substance in a given area is known, IDLH levels may be used for determining whether self-contained breathing apparatus is needed when entering the area. If the concentration exceeds the IDLH level, positive- demand, self-contained breathing apparatus should be used. SUMMARY OF TLV TLV - Threshold Limit Value: One of three categories of chemical exposure levels - TLV-TWA, TLV-STEL or TLV-C. TLV-TWA - Threshold Limit Value Time-Weighted Average: The time weighted average concentration for a normal 8-hour workday and a 40 hour work week to which nearly all workers may be repeatedly exposed without adverse effect. Should be used as an exposure guide rather than an absolute. TLV-STEL - Threshold Limit Value - Short Term Exposure Limit: A 15 minute time-weighted average exposure that should not be exceeded at any time during the work day. TLV-C - Threshold Limit Value- Ceiling: The concentration that should not be exceeded even instantaneously. FOOD CHAIN EXPOSURE Depending on the chemical, we could potentially eat toxic food. BARLEY SPECIFIC TYPES OF HAZARDS AIR CONTAMINANTS GASES. GENERALLY USED IN A COMPRESSED FORM. CAN EFFECT ALL ROUTES OF ENTRY. VAPORS. FORMED BY EVAPORATION OF LIQUIDS OR SOLIDS. AMOUNT USUALLY DEPENDS UPON EXPOSED SURFACE AREA, TEMPERATURE, AND VAPOR PRESSURE OF SUBSTANCE. CAN BE DEADLY. SPECIFIC TYPES OF HAZARDS AIR CONTAMINANTS FUMES. USUALLY METALLIC AND FORMED BY WELDING, CUTTING, OR BRAZING OPERATIONS. EXTREMELY HAZARDOUS TO INHALE. PARTICULATES. COMPOSED OF SOLID OR LIQUID PARTICLES THAT ARE SUSPENDED OR DISPERSED IN AIR. SUCH AS DUST, MISTS, OR SMOKES. CAN BE EXPLOSIVE AND HAZARDOUS TO BREATH. SPECIFIC TYPES OF HAZARDS ACIDS AND BASES - pH. THE pH OF A LIQUID IS THE NUMERICAL MEASURE OF ITS RELATIVE ACIDITY OR ALKALINITY. THE RANGE IS FROM 0 - 14 WITH A NEUTRAL LEVEL EXPRESSED AS A pH OF 7.0. ABOVE 7.0 THE LIQUID IS MORE ALKALINE OR BASIC. BELOW 7.0 THE LIQUID IS MORE ACIDIC. SPECIFIC TYPES OF HAZARDS ACID ACIDS AND BASES BASE COMMON ACIDS (pH 0-6) COMMON BASES (pH 8-14) HYDROCHLORIC ACID HYDROFLUORIC ACID NITRIC ACID PHOSPHORIC ACID CHROMIC ACID SODIUM HYDROXIDE (LYE) SODIUM HYPOCHLORITE (BLEACH) AQUEOUS AMMONIA POTASSIUM HYDROXIDE (POTASH) AMMONIUM HYDROXIDE SPECIFIC TYPES OF HAZARDS CHECK FOR COMPATIBILITY! LOW pH ACID BASE HIGH pH SPECIFIC TYPES OF HAZARDS ACID BASE SPECIFIC TYPES OF HAZARDS ACIDS and BASES - GENERAL PRECAUTIONS IF YOU’RE NOT FAMILIAR WITH THE CHEMICAL, FIND OUT! READ THE MATERIAL SAFETY DATA SHEET! READ THE LABELS ON CONTAINERS. OBSERVE WRITTEN WARNINGS! DON’T EAT, DRINK, OR SMOKE AROUND CHEMICALS. CHANGE YOUR CLOTHS! DON’T TAKE IT HOME! ENSURE WORK AREA IS VENTILATED. WEAR APPROPRIATE PROTECTIVE EQUIPMENT. SPECIFIC TYPES OF HAZARDS ACIDS and BASES - GENERAL PRECAUTIONS WEAR APPROPRIATE PROTECTIVE EQUIPMENT. CLEAN UP SMALL SPILLS TO PREVENT BEING MISTAKEN FOR WATER. STORE ACIDS FROM BASES TO PREVENT REACTIONS. KNOW THE REACTIONS THAT CAN OCCUR FROM OTHER MATERIALS. ALWAYS ADD ACID TO WATER, NEVER WATER TO ACID! SPECIFIC TYPES OF HAZARDS CLASSES OF SOLVENTS - ORGANIC (CARBON BEARING) SOLVENTS: ORGANIC SOLVENTS CONTAIN CARBON. ORGANIC SOLVENTS INCLUDE: ACETONE, GASOLINE, STODDARD SOLVENT, AND TRICHLOROETHYLENE. EFFECTS ON THE CENTRAL NERVOUS SYSTEM CAN OCCUR IF PROPER VENTILATION IS NOT USED. SPECIFIC TYPES OF HAZARDS CLASSES OF SOLVENTS - AQUEOUS (WATER BEARING) SOLVENTS: AQUEOUS SOLVENTS CONTAIN WATER. SOLUTIONS OF ACIDS, ALKALIS ARE CLASSED AS AQUEOUS SOLVENTS. ENGINEERING CONTROLS ARE USUALLY REQUIRED. RESPIRATORY PROTECTION IS NEEDED WHERE VAPORS CANNOT BE ADEQUATELY CONTROLLED WITH ENGINEERING CONTROLS. SPECIFIC TYPES OF HAZARDS ROUTES OF ENTRY FOR SOLVENTS - INHALATION: MOST COMMON ROUTE OF ENTRY. CAUSES HEADACHE, DIZZINESS, CONFUSION, AND DROWSINESS. ODOR INTENSITY USUALLY NOT GOOD DETERMINATION OF TOXICITY. MORE COULD MEAN LESS, LESS COULD MEAN MORE. DIFFERENT SOLVENTS SEEK DIFFERENT TARGET ORGANS IN THE BODY. SPECIFIC TYPES OF HAZARDS ROUTES OF ENTRY FOR SOLVENTS - INGESTION: EATING, DRINKING, OR SMOKING WITHOUT WASHING HANDS FIRST. EATING, DRINKING, OR SMOKING CONTAMINATED CONSUMABLES. CAN CAUSE SEVERE IRRITATION OF GASTRO-INTESTINAL TRACT. EASILY PENETRATES MUCOUS MEMBRANES TO ENTER THE BLOOD STREAM. SPECIFIC TYPES OF HAZARDS ROUTES OF ENTRY FOR SOLVENTS - ABSORPTION: PREVENT SKIN CONTACT, WEAR GLOVES, APRONS, ETC. CAN OCCUR THROUGH UNBROKEN SKIN OR MUCOUS MEMBRANES. ANY ABSORPTION GENERALLY WILL CAUSE IRRITATION OF SKIN. FLUSH SKIN FOR AT LEAST FIFTEEN MINUTES, SEEK MEDICAL HELP. NEVER WASH EXPOSED SKIN WITH ANY SOLVENT. SPECIFIC TYPES OF HAZARDS ROUTES OF ENTRY FOR SOLVENTS - INJECTION: USUALLY CAUSED BY PUNCTURE WOUNDS. COMPRESSED AIR CAN ALSO CAUSE INJECTION OF SOLVENTS. RAPID INTRODUCTION OF SOLVENTS INTO BLOODSTREAM. MAY BE OTHER DEBRIS IN WOUND OF CONCERN. SPECIFIC TYPES OF HAZARDS SOLVENTS - GENERAL PRECAUTIONS IF YOU’RE NOT FAMILIAR WITH THE SOLVENT, FIND OUT! READ THE MATERIAL SAFETY DATA SHEET! READ THE LABELS ON CONTAINERS. OBSERVE WRITTEN WARNINGS! DON’T EAT, DRINK, OR SMOKE AROUND SOLVENTS. ENSURE WORK AREA IS WELL VENTILATED. SPECIFIC TYPES OF HAZARDS SOLVENTS - GENERAL PRECAUTIONS (CONTINUED) WEAR APPROPRIATE PROTECTIVE EQUIPMENT. USE A BARRIER CREAM, IF YOU’RE SOLVENT SENSITIVE. SPILLS MUST BE CONTAINED, IMMEDIATELY! KNOW THE REACTIONS THAT CAN OCCUR. NEVER DISCOUNT ANY ROUTE-OF-ENTRY! SPECIFIC TYPES OF HAZARDS ROUTES OF ENTRY FOR METALS - INHALATION: MOST COMMON ROUTE OF ENTRY. SMALLER PARTICULATES ARE TRAPPED IN LUNGS AND ABSORBED. SPECIFIC TYPES OF HAZARDS ROUTES OF ENTRY FOR METALS - INGESTION: EATING, DRINKING, OR SMOKING WITHOUT WASHING HANDS FIRST. EATING, DRINKING, OR SMOKING CONTAMINATED CONSUMABLES. SPECIFIC TYPES OF HAZARDS ROUTES OF ENTRY FOR METALS - ABSORPTION. CAN OCCUR THROUGH UNBROKEN SKIN OR MUCOUS MEMBRANES. ABSORPTION GENERALLY LEAST HAZARDOUS ROUTE OF ENTRY. SPECIFIC TYPES OF HAZARDS ROUTES OF ENTRY FOR METALS - INJECTION. USUALLY CAUSED BY PUNCTURE WOUNDS INVOLVING METALS. COMPRESSED AIR CAN ALSO CAUSE INJECTION OF METALS. SPECIFIC TYPES OF HAZARDS SPECIFIC METALS - METAL PARTICULATES: COME FROM SAND BLASTING, DEBURRING, AND LIKE OPERATIONS. METALS CAN TAKE THE FORM OF AIRBORNE DUSTS. ENGINEERING CONTROLS ARE USUALLY REQUIRED. RESPIRATORY PROTECTION IS NEEDED WHERE DUSTS CANNOT BE ADEQUATELY CONTROLLED WITH ENGINEERING CONTROLS. SPECIFIC TYPES OF HAZARDS SPECIFIC METALS - FUMES: FUMES ARE MADE UP OF VERY TINY SOLID METAL PARTICLES. PARTICLES ARE THE CONDENSATES OF VAPORIZED METAL. EFFECTS ON THE HUMAN BODY CAN BE DISASTROUS IF PROPER VENTILATION IS NOT USED. THINK OF THE DIFFERENT TYPES OF METALS AND BONDING MATERIALS USED USED IN A WELDING OPERATION. SPECIFIC TYPES OF HAZARDS SPECIFIC METALS - CADMIUM. HIGHLY TOXIC, INHALATION MOST COMMON ROUTE OF ENTRY. SMALLER PARTICULATES ARE TRAPPED IN LUNGS AND ABSORBED. DANGEROUS DOSES CAN BE ASYMPTOMATIC FOR HOURS. KNOWN HUMAN CARCINOGEN. TARGET ORGANS INCLUDE, KIDNEYS, RESPIRATORY SYSTEM. SPECIFIC TYPES OF HAZARDS SPECIFIC METALS - COPPER AND ZINC. HIGHLY TOXIC, INHALATION MOST COMMON ROUTE OF ENTRY. CAN CAUSE “METAL FUME FEVER” RESULTING IN (SEVERE FLU-LIKE SYMPTOMS). TARGET ORGANS INCLUDE, KIDNEYS, RESPIRATORY SYSTEM. SPECIFIC TYPES OF HAZARDS SPECIFIC METALS - NICKEL. CAN BE ABSORBED THROUGH SKIN, OR LUNGS. ABSORPTION GENERALLY LEAST HAZARDOUS ROUTE OF ENTRY. TARGET ORGANS INCLUDE; CNS, RESPIRATORY SYSTEM. SPECIFIC TYPES OF HAZARDS METALS - GENERAL PRECAUTIONS IF YOU’RE NOT FAMILIAR WITH THE METAL, FIND OUT! READ THE MATERIAL SAFETY DATA SHEET! READ THE LABELS ON CONTAINERS. OBSERVE WRITTEN WARNINGS! DON’T EAT, DRINK, OR SMOKE AROUND METAL DUSTS. SPECIFIC TYPES OF HAZARDS METALS - GENERAL PRECAUTIONS (CONTINUED) ENSURE WORK AREA IS VENTILATED. WEAR APPROPRIATE PROTECTIVE EQUIPMENT. SPILLS OF METALS MUST BE CONTAINED, NOT RAISED! FOR LARGE SPILLS, CONTACT SAFETY OFFICER. STORE ACIDS FROM BASES TO PREVENT REACTIONS. MAGNESIUM IS WATER REACTIVE, USE DRY SAND TO EXTINGUISH MAGNESIUM FIRES. P P E ersonal rotective quipment “YOUR BEST FRIEND” PERMEATION To pass through the protective clothing through a period of time. This passing through may not be noticeable without a microscope. BREAK THROUGH TIME The amount of time it takes to “Break Through” the material. DEGRADATION The changing of the physical properties of the protective equipment due to the chemicals being introduced. PENETRATION The large flow of any chemical through the protective clothing and/or material. KEYS TO SELECTING PROTECTIVE CLOTHING 1. Evaluate the job and then select protective clothing. 2. Know the types of exposures that are likely to occur. 3. Know the effects when contact is made with a chemical. 4. Know the physical resistance. 5. Know the chemical resistance. 6. Consider Human factors 7. Evaluate the cost associated with the equipment. 4 TYPES OF PROTECTION LEVEL - A LEVEL - B LEVEL - C LEVEL - D LEVEL - A PROTECTION Level A is used when the greatest level of skin, respiratory and eye protection is required. Level A protection should be used when: The hazardous substance has been identified and requires the highest level of protection for skin, eyes and the respiratory system based on either the measured (or potential for) high concentration of atmospheric vapors, gases, or particulate; or the site operations and work functions involve a high potential for splash, immersion, or exposure to unexpected vapors, gases, or particulate of materials that are harmful to skin or capable of being absorbed through the skin. Substances with a high degree of hazard to the skin are known or suspected to be present, and skin contact is possible. Operations are being conducted in confined, poorly ventilated areas, and the absence of conditions requiring Level A have not yet been determined. LEVEL - B PROTECTION Level B is used when the highest level of respiratory protection is necessary but a lesser level of skin protection is needed. Level B protection should be used when: The type and atmospheric concentration of substances have been identified and require a high level of respiratory protection but less skin protection. The atmosphere contains less than 19.5 percent oxygen. The presence of incompletely identified vapors or gases is indicated by a direct reading organic vapor detection instrument, but vapors and gases are not suspected of containing high levels of chemicals harmful to skin or capable of being absorbed through the skin. NOTE: This involves atmospheres with IDLH (Immediately Dangerous to Life and Health) concentrations of specific substances that present severe inhalation hazards and that do not represent a severe skin hazard. LEVEL - C PROTECTION Level C is used when the concentration(s) and type(s) of airborne substance(s) is known and the criteria for using air purifying respirators are met. Level C protection should be used when: The atmospheric contaminants, liquid splashes, or other direct contact will not adversely affect or be absorbed through any exposed skin. The types of air contaminants have been identified, concentrations measured, and an air purifying respirator is available that can remove the contaminants. All criteria for the use of air purifying respirators are met. LEVEL - D PROTECTION Level D is used for nuisance contamination only. A work uniform affording minimal protection. Level D protection should be used when: The atmosphere contains no known hazards. Work functions preclude splashes, immersion, or the potential for unexpected inhalation of or contact with hazardous levels of any chemicals. The following constitute LEVEL - A PROTECTION: 1. Positive pressure, full face-piece self-contained breathing apparatus (SCBA), or positive pressure supplied air respirator with escape SCBA, approved by the National Institute for Occupational Safety and Health (NIOSH). 2. Totally-encapsulating chemical protective suit. 3. Coveralls. (Optional, as applicable) 4. Long underwear. (Optional, as applicable) 5. Gloves, outer, chemical resistant. 6. Gloves, inner, chemical resistant. 7. Boots, chemical resistant, steel toe and shank. 8. Hard hat (under suit). (Optional, as applicable) 9. Disposable protective suit, gloves and boots (depending on suit construction, may be worn over totally-encapsulating suit.) The following constitute LEVEL - B PROTECTION: 1. Positive pressure, full face-piece self-contained breathing apparatus (SCBA), or positive pressure supplied air respirator with escape SCBA, approved by the National Institute for Occupational Safety and Health (NIOSH). 2. Hooded chemical resistant clothing (overalls and longsleeved jacket; coveralls; one or two piece chemical splash suit; disposable chemical resistant overalls. 3. Coveralls. (Optional, as applicable) 4. Gloves, outer, chemical resistant. 5. Gloves, inner, chemical resistant. 6. Boots, chemical resistant, steel toe and shank. 7. Boot covers, outer, chemical resistant (disposable) 8. Hard hat. (Optional, as applicable) 9. Face shield. (Optional, as applicable) The following constitute LEVEL - C PROTECTION: 1. Full face or half mask, air purifying respirators, approved by the National Institute for Occupational Safety and Health (NIOSH). 2. Hooded chemical resistant clothing (overalls, two piece chemical splash suit; disposable chemical resistant overalls. 3. Coveralls. (Optional, as applicable) 4. Gloves, outer, chemical resistant. 5. Gloves, inner, chemical resistant. 6. Boots (outer), chemical resistant, steel toe and shank. 7. Boot covers, outer, chemical resistant (disposable) 8. Hard hat. (Optional, as applicable) 9. Face shield. (Optional, as applicable) 10. Escape mask. (Optional, as applicable) The following constitute LEVEL - D PROTECTION: 1. Coveralls. 2. Gloves. (Optional, as applicable) 3. Boots/Shoes, chemical resistant, steel toe and shank. 4. Boot outer, chemical resistant (disposable) 5. Safety glasses or chemical splash goggles. 6. Hard hat. (Optional, as applicable) 7. Face shield. (Optional, as applicable) 8. Escape mask. (Optional, as applicable) PERCENTAGE OF USAGE LEVEL - A 1-2% LEVEL - B 15 - 20 % LEVEL - C 70 - 80 % LEVEL - D 5 - 10% CONSIDER THESE THREE FACTORS WHEN ATTEMPTING TO INFLUENCE THE RATE AND DEGREE OF EXPOSURE: TIME DISTANCE SHIELDING TIME - - As with any type of exposure, such as a sunburn, the longer the exposure the more probable an injury will occur. DISTANCE - - The further away from the source the less the concentration available for exposure. SHIELDING - - Generally considered as a wall or lead shield. With reference to hazardous materials it also refers to PPE worn by the worker. P P E CONSIDERATIONS Age of the Equipment Chemical Resistance Cleanability Comfort Communication Design Durable Flexibility Temperature Resistance Visibility The actual properties of the hazard must be known to make a decision on the specific type of equipment to be used! PROTECTIVE GLOVES Butyl Latex - Vinyl Neoprene PVA PVC PVC/Nitrile The actual properties of the hazard must be known to make a decision on the specific type of equipment to be used! PROTECTIVE GLOVES Natural Rubber - Alcohol's, diluted acids and bases Neoprene - Bases, peroxides, fuels, oils Aliphatic hydrocarbons, glycol, phenols, alcohol Nitrile Rubber - Phenols, PCB, oil and fuels, amines, bases, peroxides Polyvinyl Alcohol - Most organic The actual properties of the hazard must be known to make a decision on the specific type of equipment to be used! PROTECTIVE BOOTS Butyl Natural Rubber Neoprene Nitrile PVC PVC/Nitrile The actual properties of the hazard must be known to make a decision on the specific type of equipment to be used! COVERALL SIZING CHART 6’8” 4x-large 6’6” 3x-large 6’4” 2x-large 6’2” 6’ x-large 5’10” large 5’8” 5’6” 5’4” 5’2” medium small 5’ 110 130 150 170 190 210 230 250 270 290 EQUIPMENT INSPECTION Inspect for tears Inspect for seams Inspect for cracks Inspect for signs of swelling Inspect for signs of stiffness Inspect for signs of deterioration Inspect for signs of discoloration Inspect for non-uniform coatings Inspect for pinholes (hold to light) Inspect for malfunctioning closures Check clothing for compatibility with material. HEAT STRESS - is caused by a number of interacting factors, including environmental conditions, clothing, workload and the individual characteristics of the worker. SIGNS and SYMPTOMS for heat exhaustion and heat stroke. Description Heat Exhaustion Heat Stroke Face Skin Sweating Temperature Pulse Behavior Unconscious Pale Moist Profuse Normal Weak and rapid Subdued Not usually Red and Flushed Hot and Dry None Extremely High Strong and rapid May be erratic at onset Usually Heat Index 90 - 100 Sunstroke, heat cramps & heat exhaustion are possible with prolonged exposure and physical activity. Heat Index 105 - 129 Sunstroke, heat cramps & heat exhaustion likely. Heatstroke possible with prolonged exposure and physical activity. Heat Index 130 or higher Heatstroke or sunstroke imminent. HOW TO USE HEAT INDEX: 1. Across top (Air Temperature) locate today’s predicted high temperature. 2. Down left side (Relative Humidity) locate today’s predicted humidity. 3. Follow across and down to find APPARENT TEMPERATURE” or “WHAT IT FEELS LIKE” Air Temperature 70 75 80 85 90 Relative Humidity Apparent Temperature 0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100% 64 65 66 67 68 69 70 70 71 71 72 69 70 72 73 74 75 76 77 78 79 80 73 78 83 75 80 85 77 82 87 78 84 90 79 86 93 81 88 96 82 90 100 85 93 106 86 97 113 88 102 122 91 108 133 95 100 105 110 87 90 93 96 101 107 114 124 136 150 166 91 95 99 104 110 120 132 144 157 170 95 100 105 113 122 135 149 99 105 112 123 137 150 FIRST AID FIRST AID /HEAT STROKE FIRST AID /HEAT EXHAUSTION * call EMS * remove victim from heat * cool victim fast * immerse victim in cool bath or wet sheets * care for shock * offer cool water..four ounces every 15 minutes * remove victim from heat * place on back with feet up * loosen or remove clothing * cool victim by fanning or with cold packs * care for shock * offer cool water..four ounces every 15 minutes Heat exhaustion can become heat stroke if not treated promptly. DO I NEED A RESPIRATOR? If you work with hazardous chemicals, there could be a danger in the air. You can not always see or smell the hazards, but dust, smoke, fog, mist, fumes, gases, vapors and sprays can be very hazardous to your health and safety. So, you need to ask yourself the following questions? 1. What are the exposure limits allowed for the particular contaminants? 2. Have the hazard levels in your work area been measured? 3. Do you have the correct amount of oxygen in your work area? 4. Are you trained to use and wear a Respirator? Remember - Respirators play a big part in your Safety. The actual properties of the hazard must be known to make a decision on the specific type of equipment to be used! Types of Respirators Air-purifying or Filtering - The APR is used where there is enough oxygen present ( approx. 20%), but the air in the area is contaminated with gases, vapors, and dust. These respirators filter out dangerous materials or diverts air through a chemical filter. WARNING - Some substances can not be safely filtered out requiring you to wear a Air - Supplied Respirator. Types of Respirators Supplied-Air Respirators - The SAR is used whenever there is not enough oxygen in a confined space or area and the concentration of the airborne substances present is immediately dangerous to life and health (IDLH). All respirators must be approved for the contaminant for which the employee is exposed too. Approval is done jointly by the Mine Safety and Health Administration of the Department of Labor and the National Institute for Occupational Safety and Health (NIOSH) of the Department of Health and Human Services. Types of Respirators Self - Contain Breathing Apparatus (SCBA) SCBA uses a source of breathable air carried by the wearer. Although this greatly enhances the mobility of the wearer it limits the duration of protection. At a moderate work rate, using approximately 40 liter minute volume, most SCBA used in hazardous situations have a rated duration of 30 to 60 minutes. SCBA consist of the following: Face piece, Breathing tube, Air supply tube, Regulator, Exhalation valve and Air Cylinder and valve. THE PHYSICAL REQUIREMENTS Respirators places a strain on the wearer’s cardiovascular system. All workers must exert a greater degree of effort to inhale and exhale when wearing a respirator. Some people are claustrophobic and cannot wear respirators. OSHA requires that anyone assigned a task requiring the use of respirators be examined and certified as being able to safely wear the respirator. Furthermore, the worker and supervisor must have a basic understanding of respirator selections, operations, fitting, limitations and maintenance. PROPER FITTING The proper fitting of a respirator is determined by a fit tests and seal checks. Fit tests can be “Qualitative” or “Quantitative”. Some OSHA Standards have specific requirements for fit testing. QUALITATIVE QUANTITATIVE Upon issue and semi-annually Irritant smoke or banana oil Recite “Rainbow” passage Subjective response Measure concentration inside mask Port drilled into mask Takes approximately 1 hour Requires expensive equipment and trained personnel Ensures correct fit for model R E S P I R A T O R Y C H E C K L I S T Do a fit test. Receive training. Provide proper care. Measure hazard levels. Receive a Medical test. Review exposure limits. Select correct Respirator. Receive Annual Physical. Receive Annual Training. Check the Oxygen levels. Provide proper maintenance. Look for signs of deterioration. Follow policies and procedures. Wear only approved respirators that you have received instruction. SPILL CONTROL Spill Control The control of any inadvertent release of hazardous materials can be as simple as turning off a valve, turning a drum on its side, to performing a complete day of clean-up in a totally encapsulating suit. CONTAINMENT Any procedures taken to keep the material in its original container, Contaminate activities are generally undertaken by a Hazardous Material Technician or Specialist and require many hours of training and practice. Your imagination is a good place to begin to develop containment methods. Super glue, underwater patching materials for boats and fast setting materials for casts are just some of the simple examples. CONFINEMENT Any procedures taken to keep all the material in a defined area. These activities will vary from plant to plant and will be determined by the company emergency response plan. Spills or releases can be confined by our A, B, C, D materials. Absorption Blocking Collection Diking A B S O R P T I O N Materials like dirt, sand, soda ash, saw dust, vermiculite, or even kitty litter can absorb the spill. The absorption material should be placed in front of the material with consideration of any slope or grade. A key note to remember, the absorption materials MUST be COMPATIBLE with the spilled material. B L O C K I N G Means the protection of drains, ditches, or storm sewers from run-off of any spilled material. These items should be blocked by dams, rubber covers, pillows, booms. C O L L E C T I O N The collection of these materials can be placed in approved DOT containers, or other types of containment for proper disposal. D I K I N G Diking materials like sand, earth, or other similar materials can be used to contain the perimeter of the leak. The material used for diking MUST also be COMPATIBLE with the spilled material. D E C O N T A M IN A T I ON DECONTAMINATION DECONTAMINATION is a very important part of Training. Emergency response workers at the First Responder, Operations Level, Hazardous Materials Technician, Hazardous Materials Specialist, and On-Scene Incident Commander levels are all required to know and understand decontamination procedures. DECONTAMINATION Contamination is derived from the Latin verb meaning “To Touch”, while the prefix De means “Do the opposite of.” So we can not stress this importantly enough, “Do Not Touch” these materials. TOUCH DECONTAMINATION Contamination at hazardous waste sites can occur to people, vehicles, equipment, buildings and to the environment, both plants and animals. By avoiding contamination through proper positioning of people, apparatus and equipment, you eliminate the need to decontaminate. Decontamination is performed whenever any the following conditions are present: When there is obvious contamination by a know substance. When there is suspected contamination by a know substance. When there is likelihood of exposure to a deadly substance. When you don’t want to spread the contamination. When you want to protect the environment. GOAL OF DECONTAMINATION Is to minimize the potential harm to people and the environment by eliminating or reducing the hazards of the chemical contaminant. METHODS OF DECONTAMINATION DILUTION ABSORPTION DEGRADATION ISOLATION NEUTRALIZATION DISPOSAL DILUTION THE THINNING OUT OR WEAKENING OF A SUBSTANCE BY ADDING ANOTHER MATERIAL, CALLED A DILUTENT. DILUTION IS A VALID STEP IN DECONTAMINATION, BUT THE END MATERIAL WILL STILL HAVE TO BE DISPOSED OF. ABSORPTION THE PROCESS WHERE ONE SUBSTANCE COMBINES WITH ANOTHER BY MOVING INTO IT OR ENTERING THE INTERIOR OF THE OTHER SUBSTANCE. WHEN ABSORBENT ARE USED IN THE DECONTAMINATION PROCESS, THE COMBINED MATERIAL MUST BE CONSIDERED AND HANDLED AS CONTAMINATED. DEGRADATION THE MOLECULAR BREAKDOWN OF A MATERIAL. IN THE CASE OF A CONTAMINANT IT CAN RENDER THE MATERIAL LESS HAZARDOUS. THE PROCESS CAN BE USED IN DECONTAMINATION, BUT THE EXTENT OF DEGRADATION MUST BE MONITORED AND VERIFIED. ISOLATION THE ESTABLISHMENT OF A BOUNDARY OR PERIMETER WHERE A MATERIAL IS LOCATED OR PLACED, AND WHERE ENTRY IS RESTRICTED TO UNAUTHORIZED PERSONNEL. ISOLATION IS NOT ALWAYS ACHIEVABLE OVER THE LONG TERM, BUT IT DOES PROVIDE A TEMPORARY METHOD OF DEALING WITH A CONTAMINATED SUBSTANCE. NEUTRALIZATION THE PROCESS THAT OCCURS WHEN ACID AND BASES NEUTRALIZE EACH OTHER; I.E. THE CHARACTERISTIC PROPERTIES OF BOTH ACID AND AND BASES DISAPPEAR OR HAVE A NEUTRAL VALUE. WHERE IT CAN BE ACHIEVED NEUTRALIZATION IS AN EFFECTIVE TECHNIQUE IN DECONTAMINATION. DISPOSAL THE FINAL STEP IN A PROCESS WHEREBY A SUBSTANCE IS TRANSFERRED TO AN AUTHORIZED PARTY, OR TO A FINAL RESTING PLACE. LEVEL 1 DECONTAMINATION 3 LEVELS OF DECON Used when the nature of the incident indicates that there is at least a possibility that an exposure has occurred but no one is certain that it has. An example would be if a reconnaissance team entered a waste site, in appropriate clothing and SCBA, to identify the markings on a leaking 55 gallon drum. LEVEL 2 DECONTAMINATION 3 LEVELS OF DECON Used when you can physically see that contamination of clothing has occurred, but the skin has not been exposed. An example would be a drum is rolled over and you step in the spilled liquid. No one on the team experiences skin contact. LEVEL 3 DECONTAMINATION 3 LEVELS OF DECON Used whenever the chemical has come into contact with the skin. An example would be a member of the team is splashed by the liquid and the liquid has eaten a small hole in the clothing and is burning the skin. DECONTAMINATION CORRIDOR CRITERIA Topography - The decon corridor should be located on a level surface, upwind and upgrade from the site. Distance from spills - A minimum of 100 feet shall be maintained between the decon area and the spill for minor incidents. 500 feet for major incidents. Perimeters - An inner and outer security perimeter will be established. The entrance into the hot zone must be a controlled access point. Markings - Use stakes or cones and brightly colored perimeter tape to clearly identify the decon corridor.