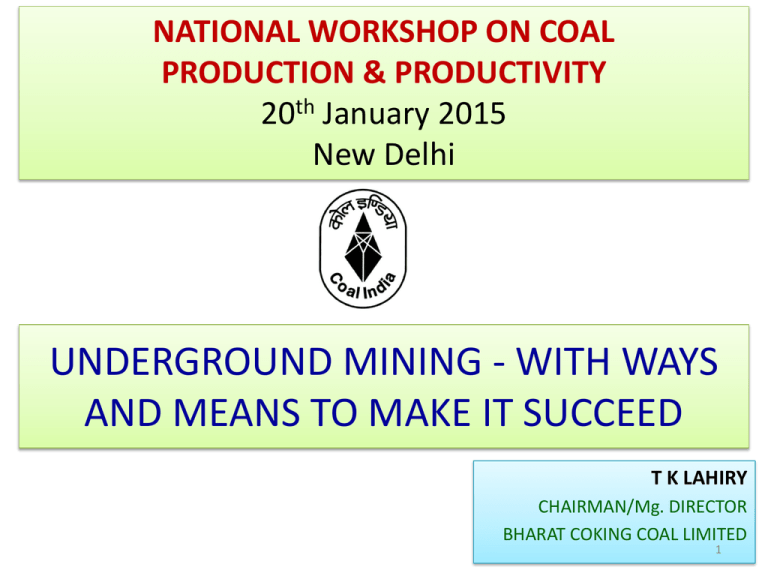

UNDERGROUND MINING

advertisement

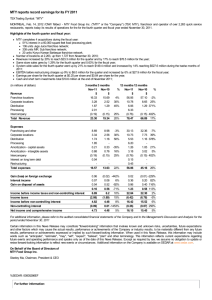

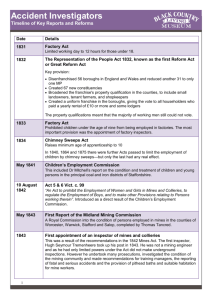

NATIONAL WORKSHOP ON COAL PRODUCTION & PRODUCTIVITY 20th January 2015 New Delhi UNDERGROUND MINING - WITH WAYS AND MEANS TO MAKE IT SUCCEED T K LAHIRY CHAIRMAN/Mg. DIRECTOR BHARAT COKING COAL LIMITED 1 BCCL- Brief Profile A MINI RATNA COMPANY Mines are spread over : Jharia Coalfield located in Jharkhand -273 km² Raniganj Coalfield located in Jharkhand (19 km²)and West Bengal (14 km²) 33km² As per UNFC classification the total Resource and Reserve is 12.976 Bt (1.4.2013) Operating Mines are 53 consisting of Underground- 19 Opencast14 Mixed – 20 MANPOWER : 57010 (AS ON 31.12.2014) The Company also runs 6 coking coal washeries, 2 non- coking/ NLW coal washeries. Construction of 6 new washeries of 18.6 Mty capacity and 2 Nos. Rapid Loading system of 5Mty capacity taken up. 2 Why technology up gradation is needed Need Solution Coal reserves are available in the By introducing global high capacity country up to 1200M. UG technology exploitation of these At present mostly, mining is limited reserve will be successfully done up to 200 to 300M except a few UG with increase in production. mine. Availability of Land & EC capacity is Vast reserve is available for taken care by existing mining exploitation from 300M to 1200M. operation. Most of the land over these reserve This increase in production can full are available or in the process of fill the existing gap between demand acquisition for mining operation. and supply. EMP for the mine is also available. 3 Inherited Legacy • • • • • • • BCCL incorporated in Jan 1972. Inherited large nos. of small loss making UG Mines. Occurrence of multi-seam and adverse geo – mining condition. Occurrence of Fire, gas, subsidence and water logged workings. Zero Environmental clearance of the mines. Prevalence of Manual age old technology prevailing in Mines. Incurring loss to tune of Rs.2000 Cr. from this UG operation. 4 Post 2008 scenario BCCL adopted strategic plan for long term and short term production. It was decided to work up to combined seam by Open cast method within the available Land. The shallow depth UG Mines were converted to Open cast Mines and opencast activities increased thereby increasing production. Introduction of high capacity UG Mines in place of existing small UG Mines and in seams below the existing opencast operation. 16 Nos. of shallow depth UG Mines were converted to Opencast mines because of which financial health of company improved considerably with a profit of Rs. 1714.35 Cr. In 2013-14 compare to a huge loss of Rs 1380.47 Crores loss in 2008-09. 5 Future scenario Conceptually 6 UG mines were identified and tender floated for introduction of mass production technology. Tenders for these six mines have been finalized and they will contribute with high productivity, 8.0 MT of coal to the production of BCCL. Apart from the above, another six underground mines whose tenders are in pipeline are envisaged for capacity addition of about 6 Million Tonne per annum of prime coking coal. The above initiative will not only improve the growth in underground production and contribute profit to the company but also facilitate absorption and adaption of state of the art technologies. 6 UG Production 9.00 7.00 Actual 4.50 2019-20 2018-19 2017-18 3.50 2016-17 2015-16 2014-15 2.70 2.80 2.85 2013-2014 2012-13 2011-12 2010-11 2009-10 2008-09 4.46 4.13 3.90 3.70 3.48 3.15 2007-08 10.00 9.00 8.00 7.00 6.00 5.00 4.00 3.00 2.00 1.00 0.00 Projection 7 UG Production 10.00 9.00 Production growth due to introduction of new technology 7.00 9.00 8.00 7.00 6.00 5.00 4.00 3.00 2.00 1.00 4.46 4.50 4.13 3.90 3.70 3.48 3.15 3.50 2.85 2.70 2.80 Decreasing trend of production if existing mines were continued 2.50 2.30 2.27 2.23 2.20 0.00 8 STEPS TAKEN BY BCCL BCCL took the strategic initiative for exploitation of deeper deposits by underground methods and invited global bids for development and operation of high capacity underground mine by latest global technology. Conditions: Bid evaluation is done on the basis of Long range marginal cost (LRMC) using discounted cash flow technique calculated for each bid but it has to be lower than notified selling price. 9 STEPS TAKEN BY BCCL Contd… Bonus and Penalty Clause Actual Production between 90% -100% : No Penalty. From 70% to 90%: @ 10% of Per tonne rate charged on the difference of actual production from 90% of the annual guaranteed production. Less than 70%: Over & above the deduction made above in (b), further @ 20% of per tonne charged on the difference of production from 70% of annual guaranteed production. 100% TO 110% : No bonus is payable. >110%: @8% of per tonne rate payable for that production year on incremental production above 110% of Annual guaranteed production in that production year provided that the maximum price per tonne inclusive of bonus remains less that the notified price of the coal produced. 10 STEPS TAKEN BY BCCL Contd… The mines whose tenders have been finalized are: • • • • • • Moonidih XVI seamMuraidih Underground Kapuria UndergroundMoonidih XV seamLohapatti Block-II Underground- 0.70 Mty 2.00 Mty 2.00 Mty 2.50 Mty 0.35 Mty 0.45 Mty 11 Moonidih XVI Top project Conceived and tendered : Capacity Sanctioned Capital Expenditure till 31 Mar 14 Anticipated Expenditure in 2014-15 : : : : Tender floated in 07 Mar’ 11. the proposal approve in 287th BCCL board meeting in July 2012 0.70 MTY Rs. 201.53 Crores Rs. 6.44 Crores Rs. 155.60 Crores Year 2015-16 2016-17 2017-18 2018-19 2019-20 Production (MTY) 0.637 0.700 0.700 0.700 0.700 Present Status: Incline drivage & shaft sinking started. 12 Moonidih XVI Top project Contd.. Proposed Technology: Production will be done with powered support long wall system. Face is already installed Production is expected to start from this month. Guaranteed production will come in 2015-16. 13 Moonidih XV Seam UG Turnkey Project Conceived and tendered Capacity Sanctioned Capital Expenditure till 31 Mar 14 Anticipated Expenditure in 2014-15 Profit (In Rs. Per Tonne) : Tender floated in 06 April’ 10. the proposal approve in 279th BCCL board meeting in July 2011 : 2.50 MTY : Rs.1230.274 Crores : 0.0 : Rs. 46.07 Crores : Rs. 585.61 Year 2015-16 2016-17 2017-18 2018-19 2019-20 Production (MTY) 0.00 0.00 0.10 0.543 1.50 Present Status: Incline drivage & shaft sinking started. 14 Moonidih XV Seam UG Turnkey Project Contd.. Proposed Technology: It has been proposed to drive 2 drifts from surface up to XV seam (400ms Depth) by Road Headers associated with conveyor (for coal evacuation) and monorail for man and material transportation. Mechanised technology with self advancing powered support long wall system is proposed. Bolter Miners are proposed to be engaged for all road headings etc. Road headers for drift drivage Face length : 1440 m- 2760 m, and widths of 250 meters. It is proposed to produce 2.5 MTPA from the mine using 800 T capacity two legged shield supports commencing at the end of fifth year. 15 Muraidih U/G turnkey project Conceived and tendered Capacity Sanctioned Capital Expenditure till 31 Mar 14 Anticipated Expenditure in 2014-15 Profit (In Rs. Per Tonne) : Tender floated in 26 Mar’ 10. the proposal approve in 265th CIL board meeting in Feb 2011 : 2.00 MTY : Rs. 339.875 Crores : Rs. 0.0 Crores : Rs. 10.0 Crores : Rs. 259.47 Year 2015-16 2016-17 2017-18 2018-19 2019-20 Production (MTY) 0.250 0.450 0.832 1.832 2.000 Present Status: Incline drivage started & shaft sinking to be done. 16 Muraidih U/G turnkey project Contd… Proposed Technology: • • • • It is proposed to extract of coal by “longwall technology” with powered support in conjunction with gate road development by “Bolter Mine / Low Capacity Continuous Miner”. PSLW Longwall with single lift Face Length :- 200M Averege seam thickness – Seam-iii 4.5m (PSLW set with max. Cutting height of 4.8m and max. Support height of 5.0m will be used) – Seam-i 2.5m (seam-iii PSLW equipment will be modified to make it suitable to work in seam-i by modifying the supports and replacing the shearer. • Average Panel Length – SEAM-III – SEAM-I - • • • 1468M (RANGE 660M TO 2150M) 2037M (RANGE 920M TO 2060M) Gate Road Development Will Be Done With Sandvik Miner Bolter / Low Cost Continuous Miner The production is scheduled to commence in the 3rd year and total guaranteed production is envisaged to be 20.43 million tonne. 17 Kapuria U/G Turnkey Project Conceived and tendered Capacity Sanctioned Capital Expenditure till 31 Mar 14 Anticipated Expenditure in 2014-15 Profit (In Rs. Per Tonne) :Tender floated in 27 April’ 10. the proposal approve in 279th BCCL board meeting in July 2011 & consequently by CIL Board. : 2.00 MTY : Rs.988.354 Crores : Rs. 0.0 Crores : Rs. 41.90 Crores : Rs. 846.54 Year 2015-16 2016-17 2017-18 2018-19 2019-20 Production (MTY) 0.00 0.00 0.20 0.90 1.50 Present Status: Preparatory work for shaft sinking is started & incline drivage to be done. 18 Kapuria U/G Turnkey Project Contd… Proposed Technology: • It is proposed to drive two reverse drifts to intersect seam XVIIIA & XVIB for coal evacuation and man- riding and for material transportation. One shaft (6.5m dia. upto a depth of 520m.) will be sunk for providing main return air way. • The seam development and coal winning is proposed to be accomplished with the engagement of bolter miner and Powered support Longwall (retreating) technology with power support with capacity of 90-100 T/m² for extraction of coal and Bolter Miner for development of gate roads. 19 Block-II Continuous Miner U/G Turnkey Project Conceived and tendered Capacity Sanctioned Capital Expenditure till 31 Mar 14 Anticipated Expenditure in 2014-15 Profit (In Rs. Per Tonne) :Tender floated in 25 Mar’ 10. the proposal approve in 265th CIL board meeting in Feb 2011 : 0.45 MTY : Rs.113.37 Crores : Rs. 0.0 Crores : Rs. 5.0 Crores : Rs. 107.82 Year 2015-16 2016-17 2017-18 2018-19 2019-20 Production (MTY) 0.00 0.15 0.30 0.45 0.45 Present Status: Agreement is likely to be signed soon after discussion on clarifications sought by M/s. Minop. 20 Block-II Continuous Miner U/G Turnkey Project Contd… Proposed Technology: • The project report for introduction of Continuous Miner for exploitation of I/II seam (0.45 MTY), Block-II Area was approved by CIL Board on cost plus basis. In the proposed area for underground mine, upper seam i.e. V/VI/VII seams is being worked by opencast method and shall be kept sufficiently ahead of proposed underground workings. • It is proposed to drive two Nos. of reverse incline from surface up to seam I/II which shall be utilised as intake and a pit from surface to serve as return. The property is proposed to be worked by Board & Pillar method and followed by depillaring with caving using Continuous Miner. 21 Lohapatti UG Project Conceived and tendered Capacity Sanctioned Capital Expenditure till 31 Mar 14 Anticipated Expenditure in 2014-15 Year Production (MTY) : : : : : Tender floated in 05 April ’ 11. 0.35 MTY Rs.167.243 Crores Rs. 0.0 Crores Rs. 0.0 Crores 2015-16 2016-17 2017-18 2018-19 2019-20 0.00 0.00 0.10 0.35 0.35 Present Status: Approved by BCCL Board. To be implemented soon. 22 Lohapatti UG Project Contd… Proposed Technology: • It is proposed to extract coal by board & pillar method with continuous miner whereas shuttle cars shall be used for face conveying and conveyor belt for final transport. • First set of low height continuous miner will be engage in upper seam with a annual production target of 0.35 Mty up to the 11th Year. • From 12th Year Production district will be shifted to lower seams and normal height continuous miner package will be introduced reproduced @ 0.45 Mty upto 22nd Year. 23 Benefits Infrastructure created for these high capacity UG Mines will be utilized for the exploitation of balance reserve of the mines for next 30 year. Operation of these High capacity UG mines generate confidence among us and train our workforce. During the operation of these high capacity UG mines will develop indigenous capacity for required spares and equipments. These technology development for UG mines will be similar to indigenization of Opencast technology which took place in last two decade. With indigenization the success rate of Long wall technology will improve where delay in supply of spares were major reason for failure as continuity long wall operation is very significant for its success. These global UG technology is being adopted in different mines having different geo mining condition which may help in adopting the technology in large nos. of mines in future with varying geo mining condition. 24 CONCLUSION The above strategy of underground augmentation developed and successfully implemented by BCCL will no doubt bring about landmark success in long term growth. If adopted by all subsidiaries of CIL in their mines and developing high capacity underground mines will make the entire energy sector sustainable. 25 THANK YOU 26