CMD ppt-20.01.15 - Ministry of Coal

advertisement

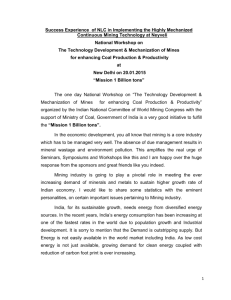

NLC A Navratna Company Neyveli Lignite Corporation Limited Extends Warm Welcome to the Distinguished Delegates & Guests National Workshop on “The Technology Development & Mechanization of Mines for enhancing Coal Production & Productivity” 20.01.2015 Address on “Success Experience of NLC in Implementing the Highly Mechanized Continuous Mining Technology at Neyveli” By Shri B. Surender Mohan, Chairman cum Managing Director, Neyveli Lignite Corporation Ltd. Preamble NLC A Navratna Company The event National Workshop on “The Technology Development & Mechanization of Mines for enhancing Coal Production & Productivity” organized by Indian National Committee of World Mining Congress with the support of Ministry of Coal, Government of India is a very good initiative to fulfill the “Mission 1 Billion tons”. For a sustainable growth , India needs energy from diversified energy sources. India’s energy consumption has been increasing at one of the fastest rates in the world due to population growth and Industrial development. The Demand is outstripping supply. Energy is not easily available in the world market including India. As low cost energy is not just available, growing demand for clean energy coupled with reduction of carbon foot print is ever increasing At this juncture I would like to state that out of 44MT of lignite produced in the country during 2013-14, share of NLC is 26.6MT(60%). In power generation, out of 5211MW lignite based thermal power station installed at the end of XI plan, NLC’s contribution is 2740MW (53%). Preamble NLC A Navratna Company Mining Industry & Economic Development: For an economic development mining is a core industry which has to be managed very well. Absence of due management results in mineral wastage and environment pollution. Mining industry is going to play a key role in meeting the ever increasing demand of minerals and metals to sustain higher growth rate of Indian Economy. This amplifies the real urge of Seminars, Symposiums and Workshops like this and I am happy over the huge response from the sponsors and great friends like you indeed. I would like to share some statistics on lignite mining with the eminent personalities, on certain important issues pertaining to Mining industry. Sources of Energy & Demand NLC A Navratna Company India’s energy supply comes from different sources - Coal, Hydro, Oil & Gas, Nuclear and various forms of non-conventional energy sources. 55% of the country's energy need is met from abundant fossil fuel Coal. Commercial primary energy consumption in India has grown by about 700% in the last four decades. The current per capita commercial primary energy consumption in India is about 350 kgoe/year (Kilo gram oil equivalent / year) which is well below that of developed countries. India has the 5th largest coal reserves in the world (301.56 billion tonnes) & now ranks third amongst the coal producing countries in the world, producing about 565 million tonnes and imports about 168 million tonnes. Being the major fossil fuel in India till date, Coal continues to be one of the most important sources for meeting the domestic energy needs. Considering the limited reserve potentiality of petroleum & natural gas, eco- conservation restriction on hydel project and geo-political perception of nuclear power, coal will continue to occupy centre-stage of India 's energy scenario. Coal & Lignite Reserves in India NLC A Navratna Company Coal reserves: Currently India’s estimated Coal resources stand at 301 billion tonnes of which about 125 billion tonnes or 40% are proved reserves. Lignite reserves: Estimated at 42 billion tonnes of which about 6 billion tonnes or 14% are proved reserves. Efforts are required to bring more reserves to “proved category” to increase the confidence level of the Investors. Vast Coal & Lignite resources are at deeper depth (>200m). Commercial Potential for development of deeper depth blocks are not amenable to Conventional methods requires to be analyzed. In this context it requires to look into alternate technologies to address the environmental issues, up gradation of Gross Calorific value, exploration of deep seated deposits etc. NLC A Navratna Company GLIMPSE OF NLC’s OPERATIONS (A ‘Navratna’ Govt. of India Enterprise) Incorporated on 14-11-1956 under Companies act 1956 The biggest lignite mining company in India. ‘Navratna’ Scheduled ‘A’ Government of India Enterprise Core business : Lignite Mining 30.6 MT per annum and Power Generation 2740 MW. Another 500 MW is under implementation. It has highest credit rating and net worth of Rs.14131.50 Crores (Q1 of 2014-15) Highest degree of safety – “AAA” (Stable) for long term barrowings by ICRA, CRISIL etc Over 50 Years of Service to the nation. Poised for many expansion & New Projects in the country. Out looking for venturing into clean Coal technologies viz. UCG & non-conventional energies such as Wind Power & Solar. A front runner in environmental Care. NLC allocates not less than 2% of net profit per year as financial commitment towards CSR activities & 50% of this amount is towards under Swatch Bharat. Corporate Governance:- NLC adheres to highest standards of Corporate Governance in transparency, accountability and integrity 7 68° 70° 72° 74° 76° 78° 80° 82° 84° 86° 88° 90° 92° 94° 96° 36° 36° JAMMU & KASHMIR 34° NICHAHOM SRINAGAR Jammu & Kashmir 34° SHALIGANGA 32° 32° TH A N SIMLA 30° CHANDIGARH Rajasthan PA K IS 30° Gurha BIKANER 28° DELHI BIKANER LIGNITE FIELD Bithnok,Hadla,Palana JAIPUR JAISALMER 26° 28° NEP AL Barsinghsar LUCKNOW 26° NAGAUR LIGNITE FIELD Giral BARMER Panandhro Matasukh-Kasnau KOHIMA RAJASTHAN PATNA BARMER LIGNITE FIELD IMPHAL BANGLADESH 24° 24° KUTCH LIGNITE FUELD Matanomodh GUJARAT Rajpardi GANDHINAGAR 22° BHOPAL BHARUCH & SURAT LIGNITE FIELD 22° KOLKATTA Vastan Gujarat BHAVNAGAR LIGNITE FIELD Tadkeshwar 20° 20° BHUBANESHWAR MUMBAI 18° 18° BAY OF BENGAL Other Lignite Projects HYDERABAD 16° 16° Proposed NLC Project Existing NLC Project PANAJI ARABIAN SEA 14° Tamilnadu & Pondicherry CHENNAI BANGALORE SCALE 12° CANNANORE PONDICHERRY BAHUR KM 100 ALA KER Neyveli TAMILNADU NEYVELI Mine-III JAYAMKONDAM MANNARGUDI Jayamkondam Kerala 10° 14° 0 100 200 12° 300 400 500 10° LEGEND LIGNITE OCCURRENCES VARKALA 8° 70° 72° 74° 76° 8° SRI LANKA TRIVANDRUM 78° 80° 82° 8 84° 86° 88° 90° 92° 94° PROXIMATE ANALYSIS Lignite Coal (In-situ Condition) (In-situ condition) Moisture % 45 – 55 2- 8 Ash % 3 – 12 20- 45 Volatile Matter % 20 – 30 20-30 Fixed Carbon % 18 – 22 25-40 Gross Calorific Value ( Kcal/Kg) 2400-2800 2400-6200 Sulphur % 0.5 – 0.75 <1 9 Four Lignite Mines of total capacity 30.6 MT Lignite Production capacity per annum in MT Over Burden Removal per annum in Mm3 10.5 57.75 Mine-IA 3.0 21.00 Mine-II 15.0 78.00 2.1 9.10 Mine TPS-I Expn. Mine-I TPS-II Expn. Barsingsar Five Thermal Power Stations of capacity 3240 MW No. & Unit size Capacity MW TPS-I 6x50MW + 3x100MW 600 TPS-II 7x210MW 1470 TPS-I Expansion 2x210 MW 420 2x250MW 500 2x125MW 250 TPS TPS-II Expansion Barsingsar * * Project under implementation & under stabilization process 10 The soft strata of sedimentary formation and the existence of powerful system of confined aquifer rules out the possibility of under ground mining method. In NLC mines, Specialized Mining Equipments (SME) are used for mining both overburden and lignite. The SME includes equipments such as Bucket Wheel Excavators (BWE), Mobile Transfer Conveyors (MTC), Conveyor system, Tripper and Spreader etc. 11 OVERALL VIEW OF BENCHES 12 BLASTING IN MINES BRIDGE TYPE 1400 LITRE BWE IN OPERATION 14 700 LITRE BWE OPERATION IN LIGNITE BENCH 15 DUMPING OPERATION OF 20,000 TPH SPREADER 16 SWC PUMPING In Lakh Tons 266 270 262 256 260 246 250 248 240 240 230 220 2011-12 2012-13 Target Actual 2013-14 In Million Units 19989 19902 20000 18576 18789 18600 18929 18000 16000 2011-12 2012-13 Target Actual 2013-14 Sr.No NAME OF PROJECT CAPACITY PROJECT COST Rs.IN CRORES 500 MW (2 X 250 MW) 3,477.22 From 13.5 to 15.0 MTPA 1,458.17 Project Under Implementation: a. Thermal Power Station II Expansion at Neyveli (under stabilization) b. Restructuring of Mine-I & IA c. New Thermal Power Project at Neyveli d. Wind Power e. Solar P.V Project at Neyveli 1000 MW (2 X 500 MW) 5,907.11 51 MW 332.52 (34x1.5 MW) Total 10 MW 77.89 1.5 MTPA/ 1561 MW 11,252.91 20 Sl No NAME OF PROJECT CAPACITY PROJECT COST Rs IN CRORES 1 Bithnok Lignite Mine in Rajasthan 2.25 MT/A 504.21 2 Bithnok Thermal Power Project in Rajasthan 250 MW (1 X 250 MW) 2146.89 3 Hadla Lignite Mine in Rajasthan 1.9 MT/A 519.51 4 Barsingsar TPS Extension 250 MW (1 X 250 MW) 2094.31 5 Lignite Mine III at Neyveli 9.0 MT/A 8333.00 6 Thermal Power Station II – 2nd Expn at Neyveli 1000 MW (2 X 500 MW) 6000.00 7 Coal based Sirkali Thermal Power project (4000 MW – Phase-I:1980 MW) 1980 MW 14482.00 8 Pachwara South coal Mine Jharkhand 10.0 MT/A 750.00 9 Solar Power At Barsingsar, Rajasthan 10 MW 87.76 3490 MW/23.15 MTPA 34917.68 10 Total addition 21 Sr.No PROJECTS I. Projects Under implementation: a. Coal based Tuticorin Thermal PowerStation Sub Total (I) II. Projects under Formulation: a. Coal Based Thermal Power project in Uttar Pradesh b. Jilga-Barpali UG Coal Mine Chattisgarh Sub Total (II) CAPACITY 1000 MW (2 X 500 MW) 1000 MW PROJECT COST Rs. IN CRORES 6602.74 6602.74 1980 MW 14,375.40 6.0 MT/A Yet to be estimated 1980 MW/6.00 MT/A 14,375.40 22 Sr.No PROJECTS CAPACITY PROJECT COST RS. IN CRORES 1 NLC’s Projects under Implementation 1561 MW/ 1.5 MTPA 11,252.91 2 NLC’s Projects under Formulation 3490 MW/ 23.15 MTPA 34,917.68 3 NLC Joint Venture Projects under Implementation 1000 MW 6602.74 NLC Joint Venture Projects under Formulation 1980 MW/6.00 MT/A 14,375.40 8031 MW/ 30.65 MTPA 67,148.73 4 TOTAL 23 Marching towards Brighter Future NLC A Navratna Company Clean Coal Technologies (CCTs like CBM,CMM,UCG,etc) are of paramount important to fulfill the energy demand of the Nation. Few foreign countries proclaim that they have successfully implemented Clean Coal Technologies for exploration of deep seated deposits, up-gradation of Gross Calorific value of low rank Coals/Lignite, minimize CO2 emission etc. However, the above technologies require to be tested for Indian condition. NLC is contemplating to exploit the deep seated Lignite deposits of Ramnad in Tamilnadu by Underground Gasification Technology. NLC has developed a Bio-fertilizer namely ‘Humic acid’ as a by-product from Lignite and obtained Patent rights in the year 2006. NLC is initiating steps to commercialize the product through National Research Development organization (NRD). NLC has executed an R&D project Utilizing Bottom ash of Thermal Power Plants for Construction Activities as substitute of Fine Aggregates (Sand) in collaboration with Vellore Institute of Technology (VIT) at a cost of Rs. 45.46 Lakhs. An experimental building of 920 SFT has been constructed by Utilizing Bottom ash as substitute of Fine Aggregates (sand). NLC Forerunner in Mining with Special Mining Equipments NLC A Navratna Company NLC is the first company having the expertise both in mining of lignite and power generation. It plays a major role in meeting the energy demands of several states of South India. The lignite seam was first exposed in August 1961 in NLC and regular mining of lignite commenced in May 1962. German excavation technology in open cast mining, using Bucket Wheel Excavators, Conveyors and Spreaders (SME Technology) were used for the first time in the country in Neyveli Mine-I. It is worth to mention here that the Hambach, the largest Lignite opencast Mine in Germany (located in North Rhine-Westphalia) is fore-runner of the state of art of Bucket wheel Excavator technology. The first BWE was commissioned in 1933 in this mine. At present it is claimed that Hambach mine is deploying the world’s biggest Excavator capable of extracting 2.4 LT of lignite/day or 2.4 LCM of OB per day by deploying 5 nos. of BWEs of capacity 2.4 LCM/day, 2 nos. of BWEs of capacity 2.0 LCM/day and 1 no. of BWE of capacity 1.1 LCM/day. The overburden strata in this mine is loose and it does not require any blasting. SMEs deployed in NLC NLC A Navratna Company SMEs deployed in NLC Mines viz. Mine-I, Mine-IA and Mine-II at Neyveli: • 1400 L BWEs : 13 Nos • 700 L BWEs : 16 Nos • 20000 TPH Spreader : 4 Nos • 11000 TPH Spreader : 7 Nos. • 5000 TPH Spreader : 4 Nos • 2400 mm Conveyor : 27.34 Km • 2000 mm Conveyor : 61.80 Km • 2400 mm Conveyor : 27.34 Km • 1500/1600/1800 mm Conveyor : 34.08 Km SMEs deployed in NLC cont… NLC A Navratna Company The configuration of SME equipments deployed in Mine-II of 15.0 MTPA capacity with an Overburden removal capacity of 78.0 Mm3/A is depicted with equivalent CME equipments required for your better understanding. SYSTEM New Surface Bench Capacity # 21.15 Mm3/A Surface Bench Capacity # 21.15 Mm3/A Top Bench Capacity # 19.575 Mm3/A Middle Bench Capacity 9.0 Mm3/A Bottom Bench Capacity # 7.125 Mm3/A Overburden Total capacity Lignite System Capacity 15.0 MTPA Bench Height 25 m 25 m 25 m 25 m 18 m SME EQUIPMENTS 2* 1400L Bridge Type BWEs 2400mm Conveyor (11.58 Km) 1* 20,000 TPH Spreader. 2* 1400 L Bridge Type BWEs, 2400 mm Conveyor (9.64 Km), 1* 20,000 TPH Spreader. 2* 1400 L BWE, 2000 mm Conveyor (7.49 Km), 1* 20,000 TPH Spreader. 1* 1400 L BWE, 2000 mm Conveyor (7.46 Km), 1* 11,000 TPH Spreader. 2* 700 L BWEs, 2000 mm Conveyor (7.64 Km), 1* 11,000 TPH Spreader. Equivalent CME equipments reqd. 26 Numbers shovels of 10 to 12 M3 size with combination of 230 nos. of 100 T Dump Trucks are required for removal of 78.0 Mm3 over burden. 78.0 Mm3/A 18 m 4* 700 L BWEs, 2000 mm conveyor (9.50 Km). 5 Nos. shovels of 10 to 12 M3 with combination of 40 nos. of 100 T Dump Trucks Remarks # Capacity of one 1400 L BWE is 9.0Mm3 for 4000 working hours. By deploying additional BWE during overhaul, working hours of system is increased to 4700 hours and thereby getting increased capacity. Challenges In Lignite Mining NLC A Navratna Company The Twin Challenges are: Handling of OB more than 1:6 Stripping ratio (6 Cu. M per tonne of Lignite) and Pumping to the tune of 8 to 10 Cu. M of water/ tonne of lignite. The lignite is underlined by powerful artisan aquifer. Depressurization of aquifer is being done to control the upward pressure for safe mining of lignite. The above challenges are aptly handled by adopting SME technology and optimizing the Ground water pumping pattern. Challenges In Deploying SME in Neyveli NLC A Navratna Company SME technology is well suited for mining conditions prevailed at Germany. Major teething problems encountered at Neyveli Mines was made possible by adopting suitable modifications in the design of the buckets, teeth and structural parts to tackle the hard and abrasive nature of the Neyveli Overburden strata. Modification in the Teeth & Bucket : Tungsten Carbide tips with hard-faced sides on the teeth are provided Modifications on the structural side reduced the strain on the machine. The sticky nature of soil reduces the bucket volume and the problem was overcome by fixing chain mate on the backside of all the buckets. Blasting: To improve the productivity and to reduce the strain on BWE blasting is inevitable. Presently around 70% Site Mixed Emulsion explosives are used for advantages like: Superior bore hole coupling , Highly safe as it is Non explosive, Eliminates manual loading & unloading and threat of pilferage. Latest systems available in the market like Electronic Detonators and Gas bags are being regularly used in the sensitive areas. Around 7,300 tons of Explosive/annum is consumed in Neyveli. New Initiatives implemented In Lignite Mining at Neyveli NLC A Navratna Company Implementation of Variable Voltage & Variable Frequency (VVVF) Drives: The fully digital VVVF drives are based on pulse encoder feedback technology for individual motors. It increases the power factor - saving substantial energy. Drives facilitate smooth starting - resulting in lesser downtime of the machine. VVVF drives are also introduced in conveyor drive heads. PLC Based Automation System for Lignite Bunker For smooth dispatch of lignite, PLC based automation control including retrofitting of relay logic with PLC networking, centralized control system, operation and monitoring with two way industrial paging system and CCTV system was implemented during 2006. The SMEs with PLC and other advance controls increased the working hours to nearly 6000 hours per year. New Initiatives implemented in Lignite Mining at Neyveli cont… NLC A Navratna Company Wireless Based Centralized Monitoring Operation and Control System : In Mine-IA is very helpful for operation as well as maintenance without much wastage of productive time involving: One 700 L. BWE, one 4420 cubic meter/hour of MTC, Five 1600 mm Conveyor of total length 5000 meters (approximately) and One 4420 cubic meter/hour spreader including networking of existing programmable logical control stations for centralized monitoring, operation and control. Mining equipment maintenance management system (MEMMS) (SAP based): This system reduces the Breakdown, plan preventive maintenance, the stoppage duration and also reduces the inventory. Equipment details, maintenance task details, manpower, spare parts are computerized. For the work either planned or Breakdown, work order will be generated with all the required information and tools to complete the work. New Initiatives implemented in Lignite Mining at Neyveli cont… NLC A Navratna Company Condition Monitoring for SME Equipment: Accepted as an effective method: To assess the requirements of maintenance Increase the operating life of installed plant and machines. Many parameters can be monitored for an effective health condition of the equipment. Using the technique of “Vibration Analysis and Diagnostic Studies” are applied to pinpoint the health condition of the SME equipment. Water Management in Neyveli Mines NLC A Navratna Company Ground water management: As a part of the ground water management Ground water levels and quality are regularly monitored in and around Neyveli. Through continuous study and implementation of new methods, the quantity of water pumped out has been reduced considerably. The water is gainfully utilized in captive Thermal Power stations. Storm Water Management: The clear water from sedimentation sumps of Mine-I is pumped to a modern Water Treatment Plant of 8,000 GPM capacity. The treated water is supplied to township dwellings. Similar treatment plant of 15,000 GPM to treat the storm water from Mine-II, for use in the Thermal Power Station-II & Expansion has been constructed. Utilizing the storm water has resulted in conserving valuable ground water. Further, the clear storm water from Mines is supplied to surrounding villages for agricultural activities helps in raising crops three times in a year. Adaptation of CME Technology in NLC: NLC A Navratna Company CME equipments were mostly used for: Initial development of mines, Ramp formation, road formation, second seam mining etc. In the year 2006, CME outsourcing was introduced to tackle high ratio areas, exploiting the left out areas Based on the experience gained, CME technology with outsourcing option was adopted for both OB & Lignite production to have better cost effectiveness in Barsingsar mine. For the projects under formulation like Bithnok and Hadla in Rajasthan, it is proposed to adopt the CME technology with outsourcing option to tackle the multi seams apart from having cost effectiveness. NLC Assessment of SME technology: A Navratna Company SME technology is very much suitable for soft strata To improve the productivity after analyzing the experience gained during the operation of SME over 5 decades, the imported technology was indigenously modified periodically to suit the conditions prevailing at Neyveli Mines. This made the SME technology a perfect match for the Geo- mining condition at Neyveli where lignite is associated with unconsolidated sandstones and clays when compared with the sand stone, silt stone and shale in coal deposits. For production of Overburden of about 156 Mm3 per annum at the Mines at Neyveli, within the available range of CME equipments, the capital cost involved and operating cost including carpeting the working benches for CME technology balances with the capital intensive SME technology. SME Technology Vs CME Technology NLC A Navratna Company NLC initially preferred for combination of SME and CME for its Barsingsar Mine. But the annual Overburden removal capacity of 9.0 Mm3 per annum after offsetting OB removal at the bottom most slice over lignite with CME option due to steep gradient and splits in the lignite formation, only lower capacity SMEs was proposed. This resulted in 63% of OB handling by SME and the balance 37% by CME for Barsingsar project. The economics for departmental operation favored for the combined technology for SME & CME against complete operation by CME. When compared with outsourcing, CME technology was mainly preferred on account of reduction of transfer price. As there is no suitable player for Outsourcing of SME technology, a point to point comparison of both the technologies with the outsourcing of CME technology could not be made. However, a theoretical evaluation could always be possible. SME Technology Vs CME Technology Cont… NLC A Navratna Company With the changed Global scenario, a techno commercial evaluation on built own operate transfer (BOOT) basis for various combination of technologies could be evaluated for different geo technical and various capacities of mines. NLC for its proposed Mine-III (9.0 MTPA) at Neyveli, with 60 to 70 Mm3 of OB removal/ annum and for the Jayamkondam project (5.5 MTPA to 13.5 MTPA), actively considers looking for techno economically viable option for either combination of SME & CME or completely SME or CME deployment for attaining the above requirements. Adaptation of NLC’s experience in other Opencast mines NLC A Navratna Company In pursuance of NLC’s high level of success in adopting an imported technology of SME, I would like to suggest consideration of this technology in large opencast mines on the following counts. Superior in environment friendliness as this technology fully use electrical power Higher annual production of OB: For Soft strata associated with trafficability difficulties in deploying CME equipments it is suggested to carry out a techno-commercial evaluation of CME and SME technology prior to freezing the technology. Combination of Technology: Presently coal mines are adopting combination of CME & Dragline, CME & Surface Miners very advantageously. In line with the above, an attempt can be made for combination of SME with any of the above technologies wherever the strata condition is amenable for BWEs. Besides, SCCL is adopting In-pit Crusher, Conveyor and Spreader with CME technology for which NLC has provided consultancy services. NLC A Navratna Company THANK YOU