Activity-Based Costing and Activity

advertisement

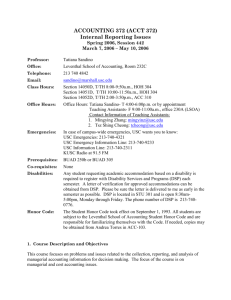

Activity-Based Costing and Activity-Based Management Chapter 5 ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5-1 Learning Objective 1 Explain undercosting and overcosting of products and services. ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5-2 Undercosting and Overcosting Example Jose, Roberta, and Nancy order separate items for lunch. Jose’s order amounts to $14 Roberta consumed 30 Nancy’s order is 16 Total $60 What is the average cost per lunch? ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5-3 Undercosting and Overcosting Example $60 ÷ 3 = $20 Jose and Nancy are overcosted. Roberta is undercosted. ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5-4 Learning Objective 2 Present three guidelines for refining a costing system. ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5-5 Existing Single IndirectCost Pool System Example Kole Corporation manufactures a normal lens (NL) and a complex lens (CL). Kole currently uses a single indirect-cost rate job costing system. Cost objects: 80,000 (NL) and 20,000 (CL). ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5-6 Existing Single IndirectCost Pool System Example Normal Lenses (NL) Direct materials $1,520,000 Direct mfg. labor 800,000 Total direct costs $2,320,000 Direct cost per unit: $2,320,000 ÷ 80,000 = $29 ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5-7 Existing Single IndirectCost Pool System Example Complex Lenses (CL) Direct materials $ 920,000 Direct mfg. labor 260,000 Total direct costs $1,180,000 Direct cost per unit: $1,180,000 ÷ 20,000 = $59 ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5-8 Existing Single IndirectCost Pool System Example INDIRECT-COST POLL INDIRECT COST-ALLOCATION BASE All Indirect Costs $2,900,000 50,000 Direct Manufacturing Labor-Hours $58 per Direct Manufacturing Labor-Hour ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5-9 Existing Single IndirectCost Pool System Example COST OBJECT: NL AND CL LENSES Indirect Costs Direct Costs DIRECT COSTS Direct Materials Direct Manufacturing Labor ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 10 Existing Single IndirectCost Pool System Example Kole uses 36,000 direct manufacturing labor-hours to make NL and 14,000 direct manufacturing labor-hours to make CL. How much indirect costs are allocated to each product? ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 11 Existing Single IndirectCost Pool System Example NL: 36,000 × $58 = $2,088,000 CL: 14,000 × $58 = $812,000 What is the total cost of normal lenses? Direct costs $2,320,000 + Allocated costs $2,088,000 = $4,408,000 What is the cost per unit? $4,408,000 ÷ 80,000 = $55.10 ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 12 Existing Single IndirectCost Pool System Example What is the total cost of complex lenses? Direct costs $1,180,000 + Allocated costs $812,000 = $1,992,000 What is the cost per unit? $1,992,000 ÷ 20,000 = $99.60 ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 13 Existing Single IndirectCost Pool System Example Normal lenses sell for $60 each and complex lenses for $142 each. Normal Complex Revenue $60.00 $142.00 Cost 55.10 99.60 Income $ 4.90 $ 42.40 Margin 8.2% 29.9% ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 14 Refining a Costing System Direct-cost tracing Indirect-cost pools Cost-allocation basis ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 15 Refining a Costing System 1. Design of Products and Process The Design Department designs the molds and defines processes needed (details of the manufacturing operations). ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 16 Refining a Costing System 2. Manufacturing Operations Lenses are molded, finished, cleaned, and inspected. 3. Shipping and Distribution Finished lenses are packed and sent to the various customers. ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 17 Learning Objective 3 Distinguish between the traditional and the activity-based costing approaches to designing a costing system. ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 18 Activity-Based Costing System Fundamental Cost Objects Activities Costs of Activities Assignment to Other Cost Objects Cost of: • Product • Service • Customer ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 19 Activity-Based Costing System A cross-functional team at Kole Corporation identified key activities: Design products and processes. Set up molding machine. Operate machines to manufacture lenses. Maintain and clean the molds. ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 20 Activity-Based Costing System Set up batches of finished lenses for shipment. Distribute lenses to customers. Administer and manage all processes. ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 21 Activity-Based Costing System Activity Indirect Cost Pool Design Setup Shipping Cost Allocation Base PartsSquare feet No. of Setup Hours No. of Shipments Product Cost Objects Lenses NL Lenses CL Lenses Other ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 22 Activity-Based Costing System NL CL Quantity produced 80,000 20,000 No. produced/batch 250 50 Number of batches 320 400 Setup time per batch 2 hours 5 hours Total setup-hours 640 2,000 Total setup costs are $409,200. ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 23 Activity-Based Costing System What is the setup cost per setup-hour? $409,200 ÷ 2,640 hours = $155 What is the setup cost per direct manufacturing labor-hour? $409,200 ÷ 50,000 = $8.184 ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 24 Activity-Based Costing System Allocation using direct labor-hours: NL: $8.184 × 36,000 = $294,624 CL: $8.184 × 14,000 = $114,576 Total $409,200 Allocation using setup-hours: NL: $155 × 640 = $ 99,200 CL: $155 × 2,000 = $310,000 Total $409,200 ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 25 Learning Objective 4 Describe a four-part cost hierarchy. ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 26 Cost Hierarchies A cost hierarchy is a categorization of costs into different cost pools. Cost drivers bases (cost-allocation bases) Degrees of difficulty in determining cause-and-effect relationships ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 27 Cost Hierarchies ABC systems commonly use a four-part cost hierarchy to identify cost-allocation bases: 1. Output unit-level costs 2. Batch-level costs 3. Product-sustaining costs 4. Facility-sustaining costs ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 28 Output Unit-Level Costs These are resources sacrificed on activities performed on each individual unit of product or service. Energy Machine depreciation Repairs ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 29 Batch-Level Costs These are resources sacrificed on activities that are related to a group of units of product(s) or service(s) rather than to each individual unit of product or service. Setup-hours Procurement costs ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 30 Product-Sustaining Costs These are often called service-sustaining costs and are resources sacrificed on activities undertaken to support individual products or services. Design costs Engineering costs ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 31 Facility-Sustaining Costs These are resources sacrificed on activities that cannot be traced to individual products or services but support the organization as a whole. General administration – rent – building security ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 32 Learning Objective 5 Cost products or services using activity-based costing. ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 33 Implementing Activity-Based Costing Step 1 Step 2 Identify cost objects. Identify the direct costs of the products. NL CL Direct material Direct labor Mold cleaning and maintenance ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 34 Implementing Activity-Based Costing Cleaning and maintenance costs of $360,000 are direct batch-level costs. Why? Because these costs consist of workers’ wages for cleaning molds after each batch of lenses is run. ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 35 Implementing Activity-Based Costing Normal Lenses (NL) Cost Hierarchy Description Category Direct materials Unit-level $1,520,000 Direct mfg. labor Unit-level 800,000 Cleaning and maint. Batch-level 160,000 Total direct costs $2,480,000 ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 36 Implementing Activity-Based Costing Complex Lenses (CL) Cost Hierarchy Description Category Direct materials Unit-level $ 920,000 Direct mfg. labor Unit-level 260,000 Cleaning and maint. Batch-level 200,000 Total direct costs $1,380,000 ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 37 Implementing Activity-Based Costing Step 3 Select the cost-allocation bases to use for allocating indirect costs to the products. (1) (2) (3) Activity Cost Hierarchy Total Costs Design Product-sustaining $450,000 Setups Batch-level $409,200 Operations Unit-level $637,500 ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 38 Implementing Activity-Based Costing Step 4 Identify the indirect costs associated with each cost-allocation base. Overhead costs incurred are assigned to activities, to the extent possible, on the basis of a cause-and-effect relationship. ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 39 Implementing Activity-Based Costing Step 5 Compute the rate per unit. (1) (5) NL CL Total Setup-hours: 640 2,000 2,640 $409,200 ÷ 2,640 = $155 ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 40 Implementing Activity-Based Costing Step 6 Compute the indirect costs allocated to the products. NL: $155 × 640 = $ 99,200 CL: $155 × 2,000 = 310,000 Total $409,200 ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 41 Implementing Activity-Based Costing Step 7 Compute the costs of the products. NL and CL would show three direct cost categories. 1. Direct materials 2. Direct manufacturing labor 3. Cleaning and maintenance ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 42 Implementing Activity-Based Costing NL and CL would show six indirect cost pools. 1. Design 2. Molding machine setups 3. Manufacturing operations 4. Shipment setup 5. Distribution 6. Administration ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 43 Learning Objective 6 Use activity-based costing systems for activity-based management. ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 44 Activity-Based Management ABM describes management decisions that use activity-based costing information to satisfy customers and improve profits. Product pricing and mix decisions Cost reduction and process improvement decisions Design decisions ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 45 Product Pricing and Mix Decisions ABC gives management insight into the cost structures for making and selling diverse products. It provides more accurate product cost information and more detailed information on costs of activities and the drivers of those costs. ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 46 Cost Reduction and Process Improvement Decisions Manufacturing and distribution personnel use ABC systems to focus on cost-reduction efforts. Managers set cost-reduction targets in terms of reducing the cost per unit of the cost-allocation base. ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 47 Design Decisions Management can identify and evaluate new designs to improve performance by evaluating how product and process designs affect activities and costs. Companies can work with their customers to evaluate the costs and prices of alternative designs. ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 48 Learning Objective 7 Compare activity-based costing systems and departmentcosting systems. ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 49 ABC and Department Indirect-Cost Rates Many companies have evolved their costing system from using a single cost pool to using separate indirect-cost rates for each department: Design Manufacturing Distribution ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 50 ABC and Department Indirect-Cost Rates Why? Because the cost drivers of resources in each department or subdepartment differ from the single, company-wide, cost-allocation base. ABC systems are a further refinement of department costing systems. ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 51 Learning Objective 8 Evaluate the costs and benefits of implementing activity-based costing systems. ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 52 Benefits of ABC Systems Significant amounts of indirect costs are allocated using only one or two cost pools. All or most costs are identified as output unit-level costs. Products make diverse demands on resources because of differences in volume, process steps, batch size, or complexity. ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 53 Benefits of ABC Systems Products that a company is well-suited to make and sell show small profits while products for which a company is less suited show large profits. Complex products appear to be very profitable and simple products appear to be losing money. ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 54 Benefits of ABC Systems Operations staff have significant disagreements with the accounting staff about the costs of manufacturing and marketing products and services. ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 55 Limitations of ABC Systems The main limitations of ABC are the measurements necessary to implement the system. ABC systems require management to estimate costs of activity pools and to identify and measure cost drivers for these pools. ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 56 Limitations of ABC Systems Activity-cost rates also need to be updated regularly. Very detailed ABC systems are costly to operate and difficult to understand. ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 57 ABC In Service and Merchandising Companies The general approach to ABC in the service and merchandising areas is very similar to the approach in manufacturing. Costs are divided into homogeneous cost pools and classified as output unit-level, batch-level, product- or service-sustaining, and facility-sustaining costs. ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 58 ABC In Service and Merchandising Companies The cost pools correspond to key activities. Costs are allocated to products or customers using activity drivers or cost-allocation bases that have a cause-and-effect relationship with the cost in the cost pool. ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 59 End of Chapter 5 ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 5 - 60